Danfoss Compressors A3 7363 Tropical Conditions M Thermostat Fan 220-240 V • 50 Hz & 60 Hz Legend Danfoss Compressors Gmbh • Mads-Clausen-Str

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Product Bulletin Design of Labels for BD Compressors

Product Bulletin Design of Labels for BD Compressors Marking on Compressor & Electronic Unit Introduction All BD compressors are designed to Date of For the electronic unit, the code for meet specifications according to the manufacture date of manufacture is located on a EC type-approval certificate. label on the backside of the housing. In addition to that we have VDE and For the compressor see Product Bul- UL on most products. See Product Bul- letin (Technical Info) DEHC.EI.000.B . letin (Technical Info) DEHC.EI.100.C for further information. As we achieved Code numbers No BD code numbers will be affected VDE approval we were requested to by the changes. make some changes on the marking of electronic and compressor which Literature Our literature (data sheets) has been will be described in next section. updated with the new labelling. Valid from 2006 - updated 2009 Compressor label Nominal voltage has been removed and moved to the electronic unit. LBP/MBP marking has been removed. Electronic unit label VDE marking will not appear on the Voltage label due to the fact that the com- pressor can be applied with non VDE approved electronic units. BD type label Electronic unit label The label contains the nominal supply voltage. Located between + and – ter- minal. The AC/DC electronic contains in addition the applied nominal AC voltage. UL label Voltage has been re-established on UL label the UL label and can also be found on RoHS marking the electronic unit. Danfoss Compressors GmbH • Mads-Clausen-Str. 7 • D-24939 Flensburg / Germany • Tel: +49 (0461) 4941-0 • Fax: +49 (0461) 44715 • compressors.danfoss.com Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. -

Total Environmental Impact of a Small Hermetic Compressor P

Purdue University Purdue e-Pubs International Refrigeration and Air Conditioning School of Mechanical Engineering Conference 1994 Total Environmental Impact of a Small Hermetic Compressor P. E. Hansen Danfoss Compressors GmbH V. Gustafsson Danfoss Compressors GmbH I. Drabaek de-Teknik A. Schmidt de-Teknik P. B. Pedersen de-Teknik Follow this and additional works at: http://docs.lib.purdue.edu/iracc Hansen, P. E.; Gustafsson, V.; Drabaek, I.; Schmidt, A.; and Pedersen, P. B., "Total Environmental Impact of a Small Hermetic Compressor" (1994). International Refrigeration and Air Conditioning Conference. Paper 245. http://docs.lib.purdue.edu/iracc/245 This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact [email protected] for additional information. Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/ Herrick/Events/orderlit.html Total Environmental Impact of a Small Hermetic Compressor By Poul Erik Hansen, Vibeke Gustafsson Danfoss Compressors GmbH. P.O. Box 1443. D-24939 Flensburg. Germany. Tlf int. + 49464941·109, Fax Int. + 494614941-629 lver Drabek, Anders Schmidt, Preben Buhl Pedersen dk-Teknik, Gladsaxe Moellevej 15, OK 2860 S"borg, Denmark ABSTRACT The relative energy consumption caused by the introduction of the alternative refrigerants has been seen as very important while replacing the CFC's. In the framework of the TEWI concept the influence of alternative refrigerants on the global warming is calculated, taking into account the direct and indirect effect. This paper extends these analyses as it includes the influence of a hermetic compressor in its total lifetime from the production of raw materials to the disposal of the compressor. -

Annual Report 2011 Danfoss Delivers Strong Results

MAKING MODERN LIVING POSSIBLE Annual Report 2011 Danfoss delivers strong results www.danfoss.com Organization On December 31, 2011 The Danfoss Group in brief Danfoss is a global leader in the field of energy-efficient solutions that help save energy and meet the challenge of climate change. Our key competencies are the cooling of food, air conditioning, the control of electric motors and heating systems in buildings – as well as the provision of solutions for renewable energy such as solar power. Danfoss also includes Sauer-Danfoss, which is one of the world’s leading manufacturers of mobile hydraulics. We have built up our competencies within energy-efficient solutions for 78 years. Today Danfoss employs approximately 23,500 employees globally and has 110 sales companies around the world. Read more about Danfoss at www.Danfoss.com and about our energy-efficient solutions at: www.danfoss.com/SolutionsReady/ Date of publication: March 28, 2012 This report is available in Danish and English. In the event of any discrepancy between the two versions, the Danish version shall prevail. 2 Annual Report 2011 I The Danfoss Group Contents Management report – CSR highlights .......................................................................................................................................................................................................................................................................................................................... 4 – Financial highlights of the Group (DKK) ................................................................................................................................................................................................................................................................ -

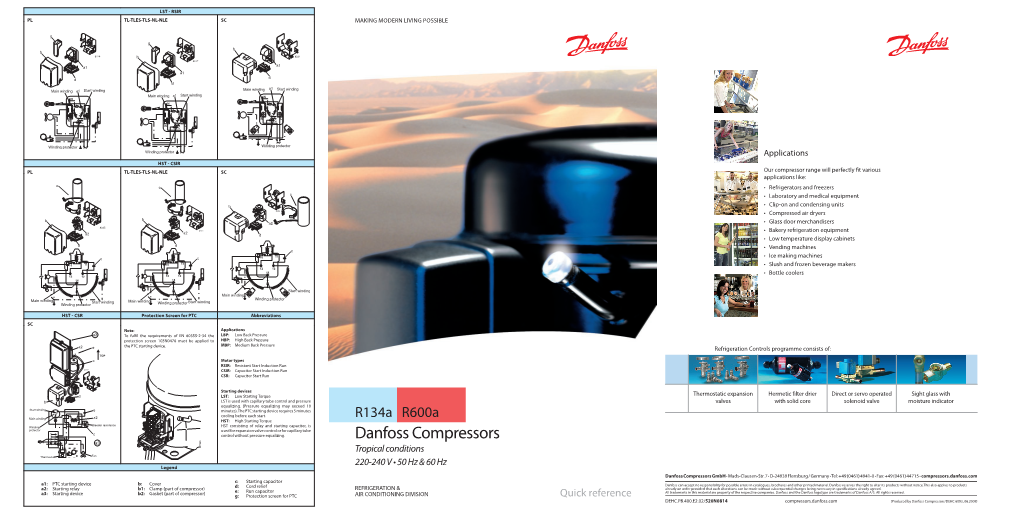

Danfoss Compressors

MAKing modern Living PossiBLE R600a Danfoss Compressors 220-240 V • 50 Hz & 60 Hz REFRIGERATION & AIR CONDITIONING DIVISION Quick reference Compressor Code number EN 12900 (CECOMAF) EN 12900 (CECOMAF) at ASHRAE subcooled at Capacity [W] LBP rating point -25°C / 55°C LBP rating point -23.3°C / 5 Cooling COP COP Cooling COP Capacity without with Capacity without RC Level Evaporating temperature [°C] RC RC Application -35 -30 -20 -15 -10 -5 0 5 [W] [W/W] [W/W] [W] [kcal/h] [W/W] [kcal/Wh] 1. PLE35K 101H0360 38 52 68 87 109 27 0.68 38 33 TLES4KK.3 102H4438 19 29 57 75 96 42 0.90 57 49 1.18 1.02 TLES4.8KK.3 102H4538 28 40 73 94 119 55 1.00 74 65 1.30 1.12 TLES5.7KK.3 102H4638 36 50 89 114 144 68 1.02 91 79 1.32 1.14 3. TLES6.5KK.3 102H4738 45 61 105 134 168 81 1.02 108 94 1.31 1.13 TLES7.5KK.3 102H4838 53 71 122 155 194 94 1.02 1.07 126 108 1.32 1.14 TLES8.7KK.3 102H4938 62 83 143 181 228 110 1.03 1.08 147 126 1.33 1.14 TLES10KK.3 102H4038 73 97 162 205 255 126 0.98 1.06 168 145 1.26 1.08 NLE8.8KK.4 105H6800 63 84 141 179 223 110 1.18 1.22 147 127 1.51 1.30 Energy-optimized NLE10KK.4 105H6867 74 98 164 207 257 128 1.19 1.23 170 151 1.51 1.30 4. -

Survey of Starting Capacitors

Technical Info Survey of Starting Capacitors The following table shows code numbers and technical information about starting capacitors: Code no. Capacity Voltage Stamping IEC Bleeder Mount Comp. Approvals Supplier [µF] [V] Resistor L / D [mm] 220V AB 1.7% ED BHC / NGM 117U5012 125 220 no A SC VDE / UL 300V AB 0.1% ED 121/39 95/39 D A 220V AB 1.7% ED BHC / NGM 117U5014 60 220 no A PL, TL VDE / UL 300V AB 0.1% ED 95/39 L 220V AB 1.7% ED BHC / NGM B 117U5015 80 220 no A FR, NL VDE 300V AB 0.1% ED 95/39 220V AB 1.7% ED BHC / NGM 117U5017 80 220 no A SC VDE / UL 300V AB 0.1% ED 95/39 8621 220V AB 1.7% ED BHC / NGM 117U5018 125 220 no A NF, NL VDE / UL 300V AB 0.1% ED 121/39 95/39 220V AB 1.7% ED BHC 117U5019 80 220 no A SC VDE / UL 300V AB 0.1% ED 95/39 A clamp (snap-on) 125V AB 1.7% ED BHC / NGM B holder (bracket) 117U5022 320 115 no A NF, TFS UL 165V AB 0.1% ED 80/39 D diameter 125V AB 1.7% ED TL, TLS, BHC / NGM 117U5023 240 115 no A UL L lenght 165V AB 0.1% ED SC 80/39 125V AB 1.7% ED FR, NF, BHC / NGM 117U5025 280 115 no A UL 165V AB 0.1% ED TF, TFS 80/39 125V AB 1.7% ED BHC / NGM 117U5028 410 115 no A NF UL 165V AB 0.1% ED 95/39 Please get in touch with your Danfoss 125V AB 1.7% ED BHC contact if any further information is 117U5040 320 115 no B FF UL 165V AB 0.1% ED 95/39 needed. -

Hermetic Compressors R134a • 220V - 240V PL G TL-TLES-TLS-NL-NLE SC MAKING MODERN LIVING POSSIBLE G LBP/MBP Programme B B B 8224 8217 8221 Application Range

LST - RSIR Hermetic Compressors R134a • 220V - 240V PL g TL-TLES-TLS-NL-NLE SC MAKING MODERN LIVING POSSIBLE g LBP/MBP Programme b b b 8224 8217 8221 Application Range a1 a1 a1 • Compressors with denominations ending with F are primarily designed for low evaporating temperatures (LBP Low Back Pressure) for use in refrigerators, freezers and similar applications in regions with stable supply voltage. d d d • Compressors with denominations ending with FT are designed for low evaporation temperatures (LBP Low Back Pressure) for use in refrigerators, freezers and similar applications operating in regions with unstable supply voltage. a1 Main winding a1 Start winding Main winding a1 Start winding Main winding Start winding • Compressors with denominations ending with FK are F-types designed for low evaporation temperatures N N N with LST starting characteristics (capillary tube). • Compressors with denominations ending with FX are F-types designed for low evaporation temperatures with HST starting characteristics (expansion valve). N L • Compressors with denominations ending with MF are primarily designed for medium evaporation temperatures N L N L C C C (MBP Medium Back Pressure) for use in commercial refrigerators, bottle coolers, ice machines and similar applications. Run Capacitor Holder Protection Screen for PTC Winding protector Winding protector Winding protector A run capacitor holder is available for the „Energy- Note: To fulfil the requirements optimized“ and „High Energy-optimized“ compressor of EN 60355-2-34 the protection HST - CSIR range. This optional part enables to fix the run screen 103N0476 must be applied PL TL-TLS-NL SC capacitor for 220V directly and earth-connected on to the PTC starting device. -

Analysis of R134a Cabinets from the First Series Production in 1990 A

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Purdue E-Pubs Purdue University Purdue e-Pubs International Refrigeration and Air Conditioning School of Mechanical Engineering Conference 1996 Analysis of R134a Cabinets from the First Series Production in 1990 A. Riemer Danfoss Compressors GmbH P. E. Hansen Danfoss Compressors GmbH Follow this and additional works at: http://docs.lib.purdue.edu/iracc Riemer, A. and Hansen, P. E., "Analysis of R134a Cabinets from the First Series Production in 1990" (1996). International Refrigeration and Air Conditioning Conference. Paper 372. http://docs.lib.purdue.edu/iracc/372 This document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact [email protected] for additional information. Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at https://engineering.purdue.edu/ Herrick/Events/orderlit.html ANALYSIS OF R134a CABINETS FROM THE FIRST SERIES PRODUCTION IN 1990. Alice Riemer, Paul Erik Hansen, Danfoss Compressors GmbH. Mads Clausen Strasse 7, D-24939 Flensburg, Germany. ABSTRACT Series production of R134a compressors started in 1990. 200 compressors, from the very first series, were built into cabinets placed in an apartment house in Denmark. Cabinets with R12 compressors were placed in the same apartment house as well. The cabinets have two separate cooling systems; one for a cold cabinet and one for a freezer. 10 running cabinets were called back for analysis; 7 cabinets with R134a compressors and 3 cabinets with R12 compressors. Analysis of the cabinets comprises both the refrigeration systems and the compressor from each system. -

Time Delay Relay for SC-Twin SD 117N0001, 220-240V, 50 & 60Hz

Technical Info Time Delay Relay for SC-Twin SD 117N0001, 220-240V, 50 & 60Hz Introduction Technical data Code number 117N0001 Voltage 220 - 240 V Min. supply voltage 187 V Max. supply voltage 255 V Mains frequency 50 to 60 Hz Max. operating current 7 (7) A Max. starting current 25 A for 4 seconds Temperature range, operation -10 to 55°C Temperature range, storage -40 to 70°C The time delay relay type SD is Time delay at 25°C, 220 V 10 to 25 seconds designed for staggered start of Mounting orientation to suit installation two compressors in the Twin- Life time 500.000 cycles, 50.000 hours version as the one-phase mains Enclosure IP 20 2 cannot normally be loaded with Connection cable / spade connectors 3 x 0,75 mm / 6.3 mm the total starting current of both compressors. When the time delay relay is used, ø 3.8 first one compressor is started, and about 10 seconds later the second compressor is started. This ensures the best possible characteristics SD 117N0001 35 73 and the least load on the mains. 220 / 240 V 50 / 60 Hz 7(7) A The time delay relay has the t 10 - 25 sec. 550 Black Brown 14 following specification: L t Blue N 12 60 108 28 1903 REFRIGERATION AND AIR CONDITIONING Wiring diagrams CSIR Starting relay Starting capacitor N Start winding 10 11 10 11 Main winding 12 13 12 13 Blue 14 Winding protector 14 L Black Brown Thermostat Time delay relay 1969 Winding protector Starting capacitor CSR Main winding Start winding Run capacitor Starting relay Bleeder resistance N 5 2 5 2 4 1 4 1 Black L Brown Blue Time delay relay 1970 Thermostat Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. -

Modified Cover Material 220-240V/50Hz Compressors

Technical Info Modified Cover Material 220 - 240V / 50Hz Compressors In the latest standard “Safety of Therefore, Danfoss will change In case of the standard Ultramid household and similar electrical the material of the cover in con- cover (code no. 103N2010) for TL, appliances, IEC60335-1, Edition 4” nection with our TL, NL, and FR NL, and FR it is permissible that an the flammability safety demands compressors for 220-240V/50Hz inside electrical connection touch- have been changed. operation from Capron 8202 to es the cover. However, there has This new standard becomes Ultramid B3S and in connection to be a certain free space outside effective in EU (EN 60335-1) from with our PL, TF, NF, FF, and SC the cover (ø 20x50 mm to electrical October 2005 for light commercial compressors for 220-240V/50Hz connections). If this is not the case, appliances and from October operation to Noryl SE1. the “disturbing” external part has 2006 for household appliances. The change of material will take to be of non-flammable material or Other countries can have different place by the end of September it has to be able to pass the needle schedules. 2005 at the latest. flame test. Danfoss will change the cover material according to the table to 220 - 240V / 50Hz Material comply with this new standard. Compressor type Cover code no. Today New The cover code nos. will not be PL 103N0491 Capron 8202 Noryl SE1*** changed. Standard = 103N2010 Capron 8202 Ultramid B3S** TL, NL, FR Our existing Capron 8202 covers Special = 103N2011 Noryl SE1*** would normally (e .g. -

Final Webpage Conference1

2004 CONFERENCES About the Conferences The conferences are organized by faculty from the Ray W. Herrick Laboratories, Purdue University, in cooperation with many sponsoring and cooperating organizations from around the world. They have taken place every two years for over 30 years. Their focus is on the results of recent research into compressors and other technologies associated with air conditioning and refrigeration. Over 500 people from 32 different countries attended the conferences held in July, 2002 with a total of 220 papers published in the CD-ROM and hard copy proceedings. The conferences’ technical sessions run simultaneously enabling attendees to attend sessions of interest from either conference. The Purdue conferences provide an opportunity for practitioners and researchers in industry, government, consulting offices, laboratories, and universities to reach a large audience, to exchange current engineering information, problems, and solutions on the important issues of compressor technology, new refrigerants, and refrigeration technology and efficiency. In addition to paper presentations, invited speakers will make presentations at plenary sessions on selected topics of interest. Cost for full registration is $650. This price includes attendance at any session for either conference, a CD-ROM containing the proceedings for both conferences, 20 copies of papers as well as the Monday evening reception, Tuesday night steak barbeque and Wednesday evening’s banquet. All conference hotels are located near the campus or just across the river in Lafayette. There are many new and various restaurants, bars and shops available for attendee’s entertainment in both the Purdue Village, Wabash Landing and downtown Lafayette. Most establishments are within walking distance of all hotels and/or shuttle and trolley service will be available. -

Annual Report Danfoss Ready for the Future

Annual Report Danfoss ready for the future www.danfoss.com 2013www.danfoss.com Danfoss at a glance Danfoss is a world-leading supplier of technologies that meet the growing need for food supply, modern infrastructure, efficient energy utilization and climate- friendly solutions. The Group is divided into two business segments: Danfoss Climate & Energy and Danfoss Power Solutions. Danfoss Climate & Energy's key expertise lies in food refrigeration, air conditioning systems, controls for electric motors, heating systems for buildings, and components for renewable energy, including solar and wind energy. Danfoss Power Solutions' key expertise is in hydraulic systems and compo- nents for powering mobile machinery used in agriculture, construction, materials handling, and specialty equipment. Danfoss is a privately-owned company that has grown and improved its skills and expertise in energy-efficient solutions over the past 80 years. Danfoss sells its products in more than 100 countries and employs some 22,500 people worldwide. Danfoss… Approximate headcount: 22,500 Products sold in over 100 countries worldwide Top five markets: USA, Germany, China, Russia and Italy Has 59 factories in 18 countries and 58 sales companies in 46 countries Headquartered in Nordborg, Denmark Find us here: Facebook: www.facebook.com/Danfoss Twitter: www.twitter.com/Danfoss Google+: http://plus.google.com/+danfoss YouTube: www.youtube.com/DanfossGroup LinkedIn (Company Page): www.linkedin.com/company/Danfoss 2 Annual Report 2013 I The Danfoss Group CONTENT 4 2013 HIGHLIGHTS 6 LETTER FROM THE EXECUTIVE COMMITTEE 9 FINANCIAL HIGHLIGHTS 10 CORE & CLEAR STATUS 14 INNOVATION 2013 18 FINANCIAL REVIEW 30 FINANCIAL REVIEW, SEGMENT 34 OUTLOOK FOR 2014 42 CORPORATE GOVERNANCE 50 SUSTAINABILITY 52 RISK MANAGEMENT & COMPLIANCE 56 GROUP COMPANIES 60 MANAGEMENT REPORT FOR DANFOSS A/S 61 MANAGEMENT STATEMENT 62 INDEPENDENT AUDITOR'S REPORT 63 ACCOUNTS AND NOTES Annual Report 2013 I The Danfoss Group 3 2013 highlights FINANCIAL PERFORMANCE Danfoss maintained a high level of sales in 2013. -

Danfoss Compressors

LST - RSCR LST - RSIR Hermetic Compressors R600a • 220V - 240V PL g TL-NL e TL-NL g g for Refrigerators and Freezers b b 8224 8217 Application Range Yellow Warning Label b 8223 All compressors for R600a have denominations ending with K after the number for displace- a1 a1 ment or capacity. a1 d d They are designed for low operating temperatures - LBP (Low Back Pressure) for use in refri- d gerators, freezers and similar applications. Main winding a1 Start winding e Main winding a1 Start winding Compressors with endings K and KK are designed for regions with stable supply voltage. N a1 Main winding N S N Endings KTK are designed for less stable supply voltage and tropical conditions. Start winding Some of the smaller compressors and the variable speed compressors are also released for medium operating temperatures - MBP (Medium Back Pressure). N L L N L N 2 C C C Danfoss Compressors R600a 8122- Starting device LST and HST Winding protector Winding protector Winding protector • R600a is flammable in concentrations of air between approximatey 1.5% and 8.5% by volume Variable Speed Drive Protection Screen for PTC (LEL lower explosion limit and UEL upper explosion limit). • An ignition source at a temperature higher than 460°C is needed for a combustion to occur. TLV NLV Note: To fulfil the requirements of • Isobutane is significantly different from R12 and R134a. This means that compressors for R600a cannot be used with R12 or R134a. Screw 3.5x12 mm Screw 3.5x12 mm EN 60355-2-34 the protection screen Mounting Compressor Mounting Compressor recesses recesses 103N0476 must be applied to the PTC • No high potential test nor start tests must be carried out while the compressor is under vacuum.