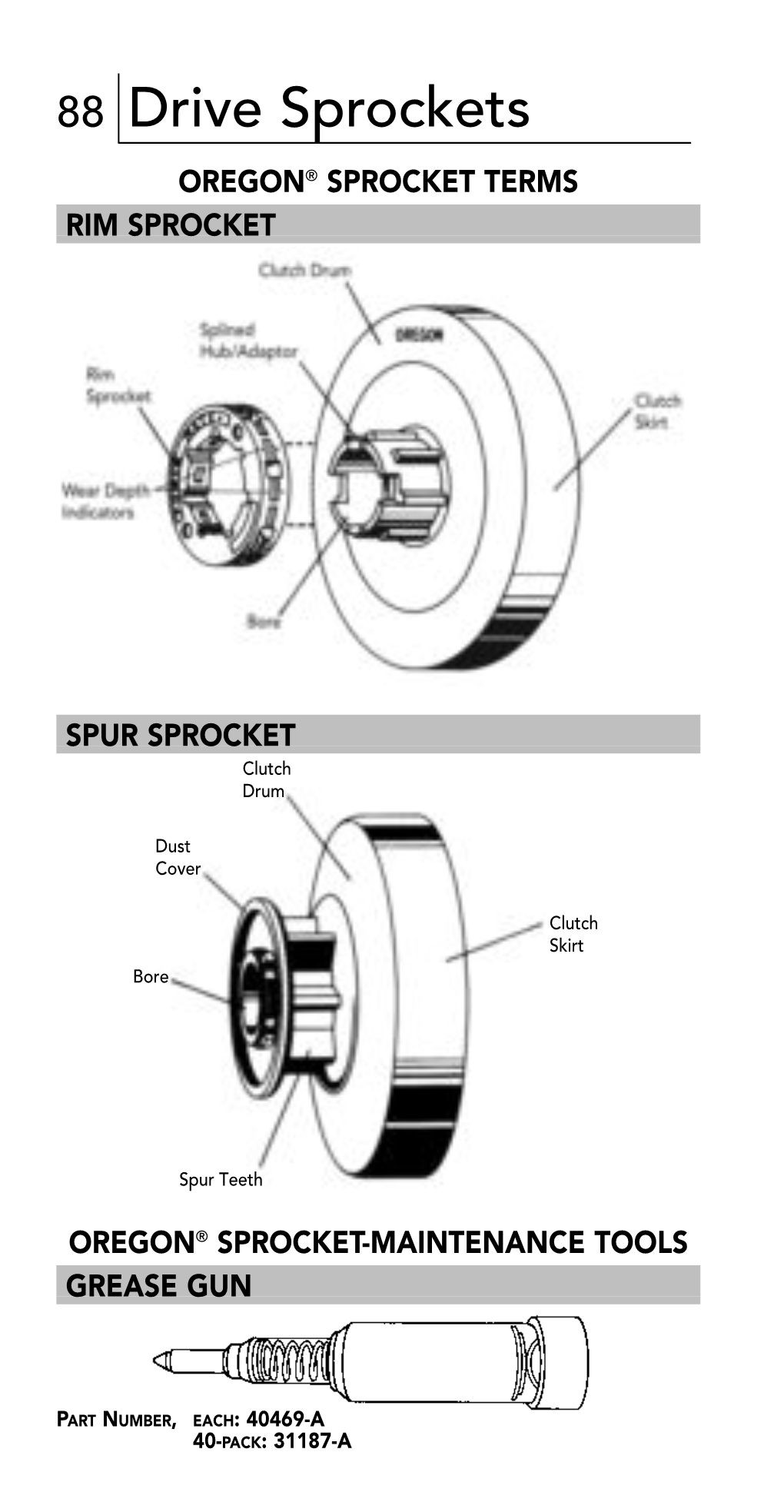

Drive Sprockets OREGON® SPROCKET TERMS RIM SPROCKET

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Forklift Differentials

Forklift Differentials Forklift Differential - A mechanical device which could transmit rotation and torque through three shafts is known as a differential. At times but not at all times the differential would use gears and will operate in two ways: in automobiles, it provides two outputs and receives one input. The other way a differential works is to combine two inputs in order to produce an output that is the sum, average or difference of the inputs. In wheeled vehicles, the differential enables all tires to be able to rotate at various speeds while supplying equal torque to all of them. The differential is intended to drive a pair of wheels with equivalent torque while enabling them to rotate at various speeds. While driving around corners, a car's wheels rotate at different speeds. Several vehicles such as karts operate without using a differential and use an axle instead. If these vehicles are turning corners, both driving wheels are forced to spin at the same speed, normally on a common axle which is driven by a simple chain-drive mechanism. The inner wheel should travel a shorter distance compared to the outer wheel while cornering. Without using a differential, the effect is the outer wheel dragging and or the inner wheel spinning. This puts strain on drive train, causing unpredictable handling, difficult driving and damage to the tires and the roads. The amount of traction necessary to move the car at whichever given moment depends on the load at that moment. How much drag or friction there is, the car's momentum, the gradient of the road and how heavy the automobile is are all contributing factors. -

Technical Engineering Guide

TTEECHCHNINICALCAL EN ENGGINEEINEERRININGG 89 www.diamondchain.com TECHNICAL ENGINEERING General Drive Considerations One of the main advantages of the roller chain drive is its ability to perform well under widely varying conditions. Despite this ability, there are a number of rules of good design practice which, if considered early in the design pro- cess, will enable the user to obtain desirable results. Basic dimensions and minimum ultimate tensile requirements for single-pitch, double-pitch and attachment roller chains are specified by various standards organizations worldwide. ASME/ANSI, The American Society of Mechanical Engineers and The American National Standards Institute, defines dimensions such as: pitch, roller width, roller diameter, link plate height, link plate thickness and pin diameter. The primary purpose of the standard is to ensure that manufacturers will produce chains and sub-assemblies that are similar dimensionally and therefore interchangeable. In addition, the standard does offer the user some assurance of quality by defining a minimum ultimate tensile strength for each model of chain. However, tensile strength is not always a valid method to differentiate one manufacturer’s product from another. It is very important to remember that dimensional standardization does not define quality or performance characteristics. Minimum Ultimate Tensile Strength: Minimum Ultimate Tensile Strength, MUTS, is the static load required to break the chain. Tensile strength values shown in this catalog are not allowable working loads. Load or tension applied 1 to the chain in service should never exceed ⁄6 th of the UTS. If exceeding this value is necessary for a specific applica- tion, contact Diamond Chain. -

Roller Drive Chain Selection and Engineering Information

sec_29.3_29.4_TI 11/19/08 12:45 PM Page 231 Roller Drive Chain Selection 29 Roller Drive Chain Selection and Engineering Information Required information for drive selection: Table 1: Service Factors 1. Type of input power (electric motor, internal combustion Type of Input Power engine, etc.). Internal Internal 2. Type of equipment to be driven. Class of Driven Combustion Combustion Electric Motor 3. Horsepower (HP) to be transmitted. Load Engine with Engine with or Turbine Information Technical Mechanical 4. Full load speed of the fastest running shaft (RPM). Hydraulic Drive Drive 5. Desired speed of the slow-running shaft. NOTE: If the speeds are variable, determine the horsepower to be Uniform 1 1 1.2 transmitted at each speed. Moderate 1.2 1.3 1.4 6. Diameters of the driver and driven shafts. Heavy 1.4 1.5 1.7 7. Center distance of the shafts. NOTE: If this distance is adjustable, determine the Step 3: Calculate the Design Horsepower. amount of adjustment. Design Horsepower = HP x Service Factor 8. Position of drive and space limitations (if any). 9. Conditions of the drive. Drives with more than two The design horsepower equals the horsepower to be sprockets, idlers, or unusual conditions such as severely transmitted times the service factor found in Table 1. abrasive or corrosive environments, severely high or low temperatures, widely fluctuating loads, frequent starts Step 4: Select the Chain Pitch. and stops, etc., require special attention. It is advisable From the Quick Selector Chart on page 234, make a to consult with Renold Jeffrey engineering personnel in tentative chain selection as follows: these situations. -

Mechanical Clutches and Torque Overload Devices Catalog

MECHANICAL CLUTCHES AND TORQUE OVERLOAD DEVICES CATALOG Regal Power Transmission Solutions 7120 New Buffington Road Florence, KY 41042 Customer Service: 800-626-2120 Fax: 800-262-3292 Technical Service: 800-626-2093 www.RegalPTS.com APPLICATION CONSIDERATIONS MECHANICAL CLUTCHES The proper selection and application of power transmission products and components, including the related area of product safety, is the responsibility of the customer. Operating and performance requirements and potential associated issues will vary appreciably depending upon the use and application of such products and components. The scope of the technical and application information included in this publication is necessarily limited. Unusual operating environments and conditions, lubrication requirements, loading supports, and other factors can materially affect the application and operating results of the products and components and the customer should carefully review its requirements. Any technical advice or review furnished by Regal-Beloit America, Inc. and AND TORQUE OVERLOAD its affiliates with respect to the use of products and components is given in good faith and without charge, and Regal assumes no obligation or liability for the advice given, or results obtained, all such advice and review being given and accepted at customer’s risk. For a copy of our Standard Terms and Conditions of Sale, Disclaimers of Warranty, Limitation of Liability and Remedy, please contact Customer Service at 1-800-626-2120. These terms and conditions of sale, disclaimers and limitations of liability apply to any person who may buy, acquire or use a Regal Beloit America Inc. product referred to herein, including any person who buys from a licensed DEVICES CATALOG distributor of these branded products. -

1700 Animated Linkages

Nguyen Duc Thang 1700 ANIMATED MECHANICAL MECHANISMS With Images, Brief explanations and Youtube links. Part 1 Transmission of continuous rotation Renewed on 31 December 2014 1 This document is divided into 3 parts. Part 1: Transmission of continuous rotation Part 2: Other kinds of motion transmission Part 3: Mechanisms of specific purposes Autodesk Inventor is used to create all videos in this document. They are available on Youtube channel “thang010146”. To bring as many as possible existing mechanical mechanisms into this document is author’s desire. However it is obstructed by author’s ability and Inventor’s capacity. Therefore from this document may be absent such mechanisms that are of complicated structure or include flexible and fluid links. This document is periodically renewed because the video building is continuous as long as possible. The renewed time is shown on the first page. This document may be helpful for people, who - have to deal with mechanical mechanisms everyday - see mechanical mechanisms as a hobby Any criticism or suggestion is highly appreciated with the author’s hope to make this document more useful. Author’s information: Name: Nguyen Duc Thang Birth year: 1946 Birth place: Hue city, Vietnam Residence place: Hanoi, Vietnam Education: - Mechanical engineer, 1969, Hanoi University of Technology, Vietnam - Doctor of Engineering, 1984, Kosice University of Technology, Slovakia Job history: - Designer of small mechanical engineering enterprises in Hanoi. - Retirement in 2002. Contact Email: [email protected] 2 Table of Contents 1. Continuous rotation transmission .................................................................................4 1.1. Couplings ....................................................................................................................4 1.2. Clutches ....................................................................................................................13 1.2.1. Two way clutches...............................................................................................13 1.2.1. -

Chain Drive Installation 1

CHAIN DRIVE INSTALLATION THIS DRIVE IS TO BE INSTALLED BY A QUALIFIED HD MECHANIC. FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID OUR WARRANTY AND LIABILITY FOR THIS PRODUCT. 1. BDL’s drives are to be used with stock OEM parts. Use of aftermarket parts may require other modifications or may cause starter and alignment problems. (Aftermarket starters may cause premature wear on our starter gear) 2. Fill out our BDL’s registration card. 3. A starter pinion gear is enclosed and is for use on all 1994-up models only. You must replace the stock pinion gear with BDL’s pinion gear on all 1994 up models. 4. You must inspect the drive after the first 100 miles and every 2500 miles after for proper chain tension. 5. Disconnect battery, remove spark plugs and support bike so it will not fall. 6. Remove primary drive if you are replacing an existing drive. (Refer to HD manual) 7. Inspect new drive and check for fit. Install both sprockets and make sure motor and transmission shafts are square with each other. Align sprockets using a 5/16” drill rod or other sturdy straight edge to check for proper alignment. Remove sprockets at this time. 1 8. Install chain adjuster assembly if this is a new installation. 9. Re-install front sprocket and rear clutch basket assembly with chain. 10. Tighten engine nut and transmission mainshaft nut to HD specifications using red loctite. 11. Adjust chain to proper tension. (Refer to HD manual) 12. Soak clutch plates for 15 minutes. We recommend ATF type F or check the HD manual for whichever is recommended for a clutch lubricant. -

Adams Model CD3 & WG Rope Winder

Adams Model CD3 & WG Rope Winder INSTALLATION, OPERATION & MAINTENANCE Copyright 2018 by General Machine Products (KT), LLC All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form whatsoever without the written permission of General Machine Products (KT), LLC GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: www.gmptools.com July 17 2018 USA Ver 2a 1 SECTION TABLE OF CONTENTS PAGE 1.0 GENERAL INFORMATION 3 2.0 DESCRIPTION 3 3.0 OPERATION 3 4.0 PLACING WIRE ROPE ONTO THE WINCH DRUM 4 5.0 ADJUSTMENT 5 6.0 LUBRICATION 6 7.0 SPROCKET AND CHAIN SELECTION 6 8.0 WIRE ROPE 7 9.0 WIRE ROPE LUBRICATION 8 10.0 REPAIR PARTS 8 PARTS IDENTIFICATION DRAWING 9 PARTS LIST 10, 11 REDUCER ASSEMBLY INDENTIFICATION 12 Speed Reducer Cross Chain Drive Pin End Sprocket Guide Bars (Underwind Assembly Shown) Carriage/Roller Cage Figure 1 General Machine Products Co. Inc. 2 3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500 1. General Information The Level Wind is a chain driven device specifically designed to distribute wire rope coils or wraps evenly across the winch drum. Level winding the wire rope onto the drum has several advantages: ● Increases drum storage capacity. ● Prevents wire rope pileup. ● Permits smooth, steady pulls. ● Establishes tight, even wraps preventing the wire rope from cutting down through the lower lays resulting in damage to the rope and difficulty in unwinding. 2. Description The level wind assembly includes a carriage/roller cage, guide bars, speed reducer, two single width and one triple width roller chain drive. -

Goodbye Chains. Goodbye Derailleurs. Hello Innovation

GOODBYE CHAINS. GOODBYE DERAILLEURS. HELLO INNOVATION. The world’s most efficient drivetrain Ambitioned to find the most efficient drivetrain that could ROLLING FRICTION VS. SLIDING FRICTION The pinion ever be developed, CeramicSpeed, in partnership with the drive shaft system eliminates eight points of chain sliding Mechanical Engineering Department of the University of friction and replaces it with just two points of higher- Colorado, set out to achieve a drivetrain that is only 1% efficiency bearing rolling friction. away from the 100% efficient drivetrain. COG DESIGN The initial tooth profile was adapted from GOAL The objective was to increase the optimal a linear simulation of rolling pinion bearings. The tooth drivetrain efficiency to 99%. The optimal drivetrain profile development focused on the pitch, the profile and efficiency is currently benchmarked by a conventional tooth thickness. Through numerous iterations of the cog Shimano Dura-Ace drivetrain at 97.8% at 380w loading design energy loss has been improved by more than 50% and 97.21% efficient at a 250w loading. Currently the between designs. most efficient drivetrain available within cycling is a TESTING For conventional drivetrains, the testing has conventional Shimano Dura-Ace drivetrain upgraded with been performed on a High-Precision Chain Efficiency a CeramicSpeed bottom bracket, Oversized Pulley Wheel Tester and loaded accordingly to simulate a rider output System and UFO Racing Chain, this upgraded drivetrain (below left). The testing machine for Driven has been measures at 98.37% at 380w loading and 98.08% at 250w created to answer the same test parameters as the High- loading. Precision Chain Efficiency Tester used for the conventional DEVELOPMENT Current leading drivetrains are using a drivetrain testing (below right). -

Chain Drive Systems

105 Webster St. Hanover Massachusetts 02339 Tel. 781 878 1512 Fax 781 878 6708 Chain Drive Systems Description In order to design, build and discuss chain drive systems it is necessary to understand the terminology and concepts associated with chain drive systems. Good designers and engineers have experience and knowledge and the ability to communicate their thoughts and ideas clearly with others. The students and teachers who participate in this unit will learn the terms and concepts necessary to design, draw and build chain drive systems, and improve their “Chain Drive literacy”. Standards Addressed National Council of Teachers of English Standards (http://www.readwritethink.org/standards/index.html ) • Students adjust their use of spoken, written, and visual language (e.g., conventions, style, vocabulary) to communicate effectively with a variety of audiences and for different purposes. • Students conduct research on issues and interests by generating ideas and questions, and by posing problems. They gather, evaluate, and synthesize data from a variety of sources (e.g., print and non-print texts, artifacts, people) to communicate their discoveries in ways that suit their purpose and audience. • Students participate as knowledgeable, reflective, creative, and critical members of a variety of literacy communities. • Students use spoken, written, and visual language to accomplish their own purposes (e.g., for learning, enjoyment, persuasion, and the exchange of information). National Council of Mathematics Teachers ( 9-12 Geometry Standards) -

Chain Drive Components. Perfectly Linked for Your Success

Chain drive components. Perfectly linked for your success. The content of this brochure is not legally binding and Copyright © is solely intended for information purposes. Schaeffler Automotive Aftermarket GmbH & Co. KG Where legally permissible, all liability on the part of October 2015 Schaeffler Automotive Aftermarket GmbH & Co. KG devolving in connection with this brochure is excluded. All rights reserved. Any reproduction, distribution, communication, public reproduction, or other publi- cation of this brochure in its entirety or in part is not permitted without prior written consent from Schaeffler Automotive Aftermarket GmbH & Co. KG. Schaeffler Automotive Aftermarket – more innovation, more quality, more passion. Schaeffler Automotive Aftermarket – four strong brands. Schaeffler REPXPERT – the all-in-one portal for garages. Whenever a vehicle needs to go to the garage, the Schaeffler Automotive Aftermarket is entering a new products and repair solutions from Schaeffler Automotive service dimension with REPXPERT. Whether you need the Aftermarket are usually the first choice for the repair online portal, live technical demonstrations, or training – work. all technical services are provided in just one place. Interested in the latest product news, service information, Backed by the four brands LuK, INA, FAG, and Ruville, installation instructions, or training? Looking for specific this business division is responsible for Schaeffler‘s information or damage diagnosis? Are you in need of par- global automotive aftermarket business. Be it a car, light ticular tools to make your everyday garage routine easier? or heavy commercial vehicle, bus, or tractor – Schaeffler Then simply register for free in just a few clicks at: Automotive Aftermarket is able to draw on decades of ex- www.repxpert.com. -

Chain Drive) Honda Shadow Spirit 750 (Chain Drive) Rear Axle Brackets Installed

HONDA SHADOW 750 & HONDA SHADOW ACE 750 (CHAIN DRIVE) HONDA SHADOW SPIRIT 750 (CHAIN DRIVE) REAR AXLE BRACKETS INSTALLED HONDA SHADOW 750 & HONDA SHADOW ACE 750 (CHAIN DRIVE) HONDA SHADOW SPIRIT 750 (CHAIN DRIVE) BELLY BRACKET INSTALLED HONDA SHADOW 750 & HONDA SHADOW ACE 750 (CHAIN DRIVE) HONDA SHADOW SPIRIT 750 (CHAIN DRIVE) DESCRIPTION OF PARTS After installing the mounting hardware and attaching the Voyager frame to the belly bracket you may need a shim to make the motorcycle stand straight up and down. The shim may be used on either the left or the right side depending on which way the motorcycle is leaning. If the motorcycle is leaning to the left put the shim on the left side. If the motorcycle is leaning to the right put the shim on the right side. The shim will go on one side of the belly bracket. Install the shim in-between belly bracket and motorcycle frame. Revised 8-11-10 SECTION 1 INSTALLATION OF HONDA SHADOW 750 & HONDA SHADOW 750 ACE (CHAIN DRIVE) HONDA SHADOW SPIRIT 750 (CHAIN DRIVE) MOUNTING HARDWARE Place motorcycle on a clean flat surface. Be sure to tie down motorcycle so it does not tip over during installation of Voyager hardware. Installation is easier if motorcycle is in an upright position. Disconnect negative cable from battery before beginning installation. NOTE: The Voyager Convertible Kit was designed for a stock motorcycle from the manufacturer. Any after market products that are on a stock motorcycle may cause the installation process to not be done properly and may or may not need to be removed to be able to install the Voyager Convertible Kit completely. -

OPERATOR's MANUAL MILLCREEK MODELS: 27+ and 37+ SPREADERS

OPERATOR'S MANUAL MILLCREEK MODELS: 27+ and 37+ SPREADERS I-86252 PUBLICATION DATE: 4/15/14, Rev. 7 MILLCREEK PART # 43831 Millcreek Manufacturing Company 525 Reservoir Road Honey Brook, PA 17540 Phone: 1-800-311-1323 / Fax: 877-640-9009 www.millcreekspreaders.com WARNING: DO NOT assemble, operate, or maintain this equipment without first reading and understanding the information provided in this manual. Failure to follow all safety precautions as stated in the manual may result in serious personal injury or death. WARRANTY INFORMATION Millcreek Manufacturing Company (hereinafter called the Company) warrants to the original Purchaser, the Equipment, manufactured by the Company, to be free from defects in material and workmanship under normal use and service. The Company obligation under this Warranty shall be limited to replacement or repair of any parts thereof, free of charge, to the original Purchaser, at their place of business, provided, however, that the part(s) to be replaced or repaired, shall, within two years after delivery to the original Purchaser, be demonstrated to be defective; which determination shall be made by the Company. The said components or parts must be returned through the Selling Dealer or Distributor directly to the Company with all transportation charges prepaid. Notice of defect shall be furnished in writing to the Seller and to the agent through whom the machinery was purchased, disclosing in full all known defects and failure in operation and use. Reasonable time shall be given to the Seller to remedy any such defects and failures. Likewise, a ten (10) year, pro-rated warranty is provided on the spray-on polyurethane lining (applied to internal sides of unit, excluding exterior non-lined surfaces).