United States Patent Office

Total Page:16

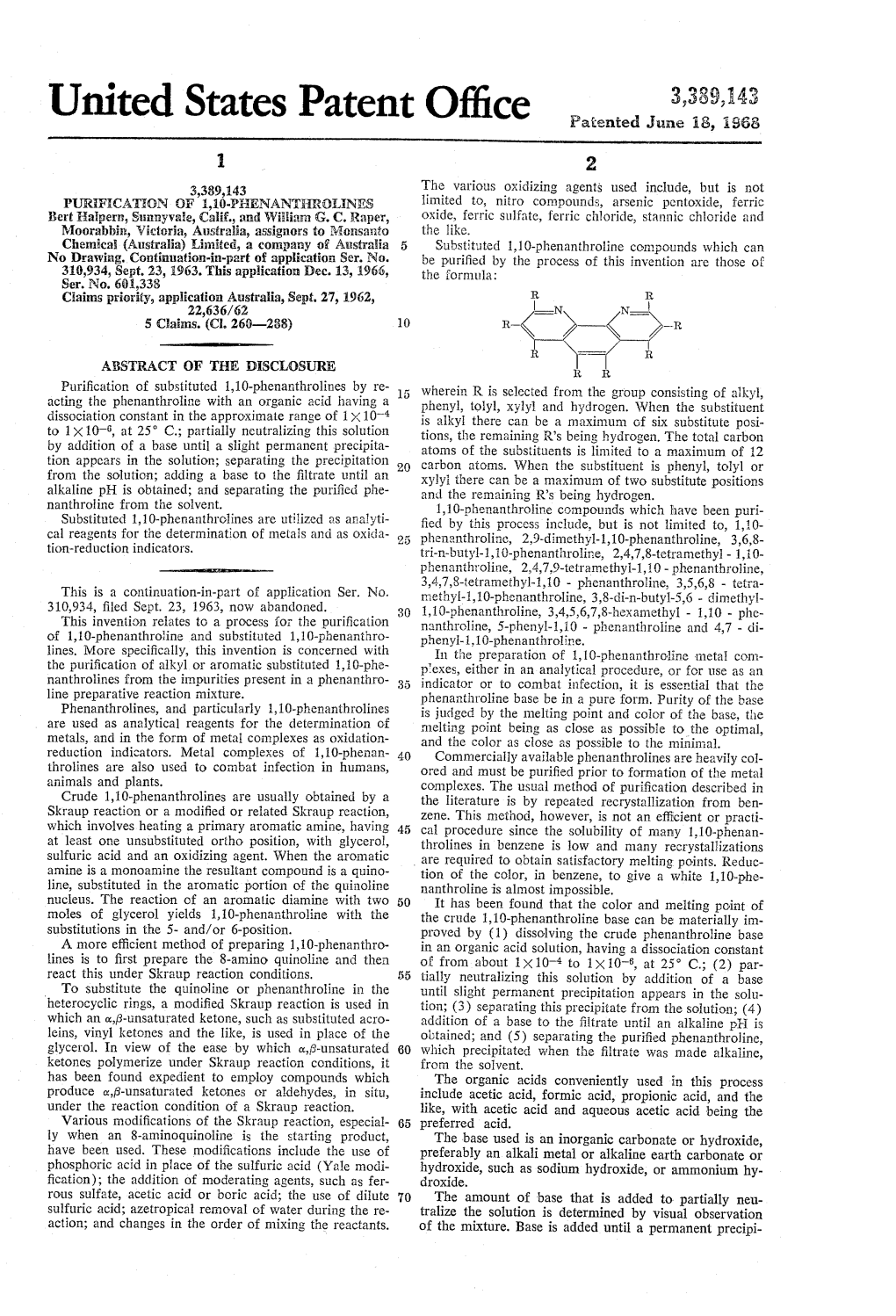

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

APPENDIX G Acid Dissociation Constants

harxxxxx_App-G.qxd 3/8/10 1:34 PM Page AP11 APPENDIX G Acid Dissociation Constants § ϭ 0.1 M 0 ؍ (Ionic strength ( † ‡ † Name Structure* pKa Ka pKa ϫ Ϫ5 Acetic acid CH3CO2H 4.756 1.75 10 4.56 (ethanoic acid) N ϩ H3 ϫ Ϫ3 Alanine CHCH3 2.344 (CO2H) 4.53 10 2.33 ϫ Ϫ10 9.868 (NH3) 1.36 10 9.71 CO2H ϩ Ϫ5 Aminobenzene NH3 4.601 2.51 ϫ 10 4.64 (aniline) ϪO SNϩ Ϫ4 4-Aminobenzenesulfonic acid 3 H3 3.232 5.86 ϫ 10 3.01 (sulfanilic acid) ϩ NH3 ϫ Ϫ3 2-Aminobenzoic acid 2.08 (CO2H) 8.3 10 2.01 ϫ Ϫ5 (anthranilic acid) 4.96 (NH3) 1.10 10 4.78 CO2H ϩ 2-Aminoethanethiol HSCH2CH2NH3 —— 8.21 (SH) (2-mercaptoethylamine) —— 10.73 (NH3) ϩ ϫ Ϫ10 2-Aminoethanol HOCH2CH2NH3 9.498 3.18 10 9.52 (ethanolamine) O H ϫ Ϫ5 4.70 (NH3) (20°) 2.0 10 4.74 2-Aminophenol Ϫ 9.97 (OH) (20°) 1.05 ϫ 10 10 9.87 ϩ NH3 ϩ ϫ Ϫ10 Ammonia NH4 9.245 5.69 10 9.26 N ϩ H3 N ϩ H2 ϫ Ϫ2 1.823 (CO2H) 1.50 10 2.03 CHCH CH CH NHC ϫ Ϫ9 Arginine 2 2 2 8.991 (NH3) 1.02 10 9.00 NH —— (NH2) —— (12.1) CO2H 2 O Ϫ 2.24 5.8 ϫ 10 3 2.15 Ϫ Arsenic acid HO As OH 6.96 1.10 ϫ 10 7 6.65 Ϫ (hydrogen arsenate) (11.50) 3.2 ϫ 10 12 (11.18) OH ϫ Ϫ10 Arsenious acid As(OH)3 9.29 5.1 10 9.14 (hydrogen arsenite) N ϩ O H3 Asparagine CHCH2CNH2 —— —— 2.16 (CO2H) —— —— 8.73 (NH3) CO2H *Each acid is written in its protonated form. -

CHEM 301 Assignment #2 Provide Solutions to the Following Questions in a Neat and Well-Organized Manner

CHEM 301 Assignment #2 Provide solutions to the following questions in a neat and well-organized manner. Reference data sources for any constants and state assumptions, if any. Due date: Thursday, Oct 20th, 2016 Attempt all questions. Only even numbers will be assessed. 1. A pond in an area affected by acid mine drainage is observed to have freshly precipitated Fe(OH)3(s) at pH 4. What is the minimum value of pe in this water? Use the appropriate pe-pH speciation diagram to predict the dominant chemical speciation of carbon, sulfur and copper under these conditions. 2. The solubility of FeS(s) in marine sediments is expected to be affected by the pH and the [H2S(aq)] in the surrounding pore water? Calculate the equilibrium concentration of Fe2+ (ppb) at pH 5 and pH 8, -3 assuming the H2S is 1.0 x 10 M. pKsp(FeS) = 16.84. + 2+ FeS(s) + 2 H (aq) ==== Fe (aq) + H2S 3. Boric acid is a triprotic acid (H3BO3); pKa1 = 9.24, pKa2 = 12.74 and pKa3 = 13.80. a) Derive an expression for the fractional abundance of H3BO3 as a function of pH b) Construct a fully labeled pH speciation diagram for boric acid over the pH range of 0 to 14 using Excel spreadsheet at a 0.2 pH unit interval. 4. At pCl- = 2.0, Cd2+ and CdCl+ are the only dominant cadmium chloride species with a 50% fractional abundance of each. + a) Calculate the equilibrium constant for the formation of CdCl (1). + - b) Derive an expression for the fractional abundance of CdCl as a function of [Cl ] and 1 – 4 for cadmium chloro species. -

Inorganic Arsenic Compounds Other Than Arsine Health and Safety Guide

OS INTERNATiONAL I'ROGRAMME ON CHEMICAL SAFETY Health and Safety Guide No. 70 INORGANIC ARSENIC COMPOUNDS OTHER THAN ARSINE HEALTH AND SAFETY GUIDE i - I 04 R. Q) UNEP UNITED NATIONS INTERNATIONAL ENVIRONMENT I'R( )GRAMME LABOUR ORGANISATION k\s' I V WORLD HEALTH ORGANIZATION WORLD HEALTH ORGANIZATION, GENEVA 1992 IPcs Other H EA LTH AND SAFETY GUIDES available: Aerytonitrile 41. Clii rdeon 2. Kekvau 42. Vatiadiuni 3 . I Bula not 43 Di meLhyI ftirmatnide 4 2-Buta101 44 1-Dryliniot 5. 2.4- Diehlorpheiioxv- 45 . Ac rylzi mule acetic Acid (2.4-D) 46. Barium 6. NIcihylene Chhride 47. Airaziiie 7 . ie,i-Buia nol 48. Benlm'.ie 8. Ep Ichioroli) Olin 49. Cap a 64 P. ls.ihutaiiol 50. Captaii I o. feiddin oeth N lene Si. Parai.tuat II. Tetradi ion 51 Diquat 12. Te nacelle 53. Alpha- and Betal-lexachloro- 13 Clils,i (lane cyclohexanes 14 1 kpia Idor 54. Liiidaiic IS. Propylene oxide 55. 1 .2-Diciilroetiiane Ethylene Oxide 5t. Hydrazine Eiulosiillaii 57. F-orivaldehydc IS. Die h lorvos 55. MLhyI Isobu I V I kcloiic IV. Pculaehloro1heiiol 59. fl-Flexaric 20. Diiiiethoaie 61), Endrin 2 1 . A iii in and Dick) 0in 6 I . I sh IIZiLI1 22. Cyperniellirin 62. Nicki. Nickel Caution I. and some 23. Quiiiloieiic Nickel Compounds 24. Alkthrins 03. Hexachlorocyclopeuladiene 25. Rsiiiethii ins 64. Aidicaib 26. Pyr rot ii,id inc Alkaloids 65. Fe nitrolhioit 27. Magnetic Fields hib. Triclilorlon 28. Phosphine 67. Acroleiii 29. Diiiiethyl Sull'ite 68. Polychlurinated hiphenyls (PCBs) and 30. Dc lianteth nil polyc h In ruiated letlilienyls (fs) 31. -

Code Chemical P026 1-(O-Chlorophenyl)Thiourea P081 1

Code Chemical P026 1-(o-Chlorophenyl)thiourea P081 1,2,3-Propanetriol, trinitrate (R) P042 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]-, (R)- P067 1,2-Propylenimine P185 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)- carbonyl]oxime 1,4,5,8-Dimethanonaphthalene, 1,2,3,4,10,10-hexa- chloro-1,4,4a,5,8,8a,-hexahydro-, P004 (1alpha,4alpha, 4abeta,5alpha,8alpha,8abeta)- 1,4,5,8-Dimethanonaphthalene, 1,2,3,4,10,10-hexa- chloro-1,4,4a,5,8,8a-hexahydro-, P060 (1alpha,4alpha, 4abeta,5beta,8beta,8abeta)- P002 1-Acetyl-2-thiourea P048 2,4-Dinitrophenol P051 2,7:3,6-Dimethanonaphth [2,3-b]oxirene, 3,4,5,6,9,9 -hexachloro-1a,2,2a,3,6,6a,7,7a- octahydro-, (1aalpha,2beta,2abeta,3alpha,6alpha,6abeta,7 beta, 7aalpha)-, & metabolites 2,7:3,6-Dimethanonaphth[2,3-b]oxirene, 3,4,5,6,9,9- hexachloro-1a,2,2a,3,6,6a,7,7a- P037 octahydro-, (1aalpha,2beta,2aalpha,3beta,6beta,6aalpha,7 beta, 7aalpha)- P045 2-Butanone, 3,3-dimethyl-1-(methylthio)-, O-[methylamino)carbonyl] oxime P034 2-Cyclohexyl-4,6-dinitrophenol 2H-1-Benzopyran-2-one, 4-hydroxy-3-(3-oxo-1- phenylbutyl)-, & salts, when present at P001 concentrations greater than 0.3% P069 2-Methyllactonitrile P017 2-Propanone, 1-bromo- P005 2-Propen-1-ol P003 2-Propenal P102 2-Propyn-1-ol P007 3(2H)-Isoxazolone, 5-(aminomethyl)- P027 3-Chloropropionitrile P047 4,6-Dinitro-o-cresol, & salts P059 4,7-Methano-1H-indene, 1,4,5,6,7,8,8-heptachloro- 3a,4,7,7a-tetrahydro- P008 4-Aminopyridine P008 4-Pyridinamine P007 5-(Aminomethyl)-3-isoxazolol 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- -

Chemical Equilibrium and Reaction Modeling of Arsenic and Selenium in Soils

3 Chemical Equilibrium and Reaction Modeling of Arsenic and Selenium in Soils Sabine Goldberg CONTENTS Inorganic Chemistry of As and Se in Soil Solution .......................................... 66 Methylation and Volatilization Reactions ......................................................... 66 Precipitation-Dissolution Reactions .................................................................. 68 Oxidation-Reduction Reactions .......................................................................... 68 Adsorption-Desorption Reactions ..................................................................... 69 Modeling of Adsorption by Soils: Empirical Models ...................................... 70 Modeling of Adsorption by Soils: Constant Capacitance ModeL................ 72 Summary................................................................................................................ 86 References ............................................................................................................... 87 High concentrations of the trace elements arsenic (As) and selenium (Se) in soils pose a threat to agricultural production and the health of humans and animals. As is toxic to both plants and animals. Se, despite being an essential micronutrient for animal nutrition, is potentially toxic because the concentra tion range between deficiency and toxicity in animals is narrow. Seleniferous soils release enough Se to produce vegetation toxic to grazing animals. Such soils occur in the semiarid states of the western United -

SDS US 1AB Version #: 07 Revision Date: 07-17-2019 Issue Date: 08-26-2013 1 / 9 Precautionary Statement Prevention Obtain Special Instructions Before Use

SAFETY DATA SHEET 1. Identification Product identifier Arsenic acid Other means of identification SDS number 1AB Materion Code 1AB CAS number 7778-39-4 Synonyms ARSENIC ACID Manufacturer/Importer/Supplier/Distributor information Manufacturer Company name Materion Advanced Chemicals Inc. Address 407 N 13th Street 1316 W. St. Paul Avenue Milwaukee, WI 53233 United States Telephone 414.212.0257 E-mail [email protected] Contact person Laura Hamilton Emergency phone number Chemtrec 800.424.9300 2. Hazard(s) identification Physical hazards Not classified. Health hazards Acute toxicity, oral Category 2 Skin corrosion/irritation Category 1 Serious eye damage/eye irritation Category 1 Germ cell mutagenicity Category 2 Carcinogenicity Category 1A Reproductive toxicity Category 2 Specific target organ toxicity, repeated Classification not possible exposure Environmental hazards Hazardous to the aquatic environment, acute Category 1 hazard Hazardous to the aquatic environment, Category 1 long-term hazard OSHA defined hazards Not classified. Label elements Signal word Danger Hazard statement Fatal if swallowed. May cause cancer. Causes severe skin burns and eye damage. Causes serious eye damage. Toxic if inhaled. Suspected of causing genetic defects. May cause cancer. Suspected of damaging fertility or the unborn child. Very toxic to aquatic life. Very toxic to aquatic life with long lasting effects. Material name: Arsenic acid SDS US 1AB Version #: 07 Revision date: 07-17-2019 Issue date: 08-26-2013 1 / 9 Precautionary statement Prevention Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. Do not breathe mist/vapors. Do not breathe dust/fume/gas/mist/vapors. Wash thoroughly after handling. -

Arsenic (As33)

NANO3D SYSTEMS LLC 1110 NE Circle Blvd., ATAMI/Bldg. 11, Corvallis, Oregon 97330-4254 T 503-927-4766| F 541-758-9320| http://www.nano3dsystems.com Arsenic (As33) Properties Arsenic is a silvery-white metalloid with an atomic mass of 74.92 u. As has a density of 5.73 g/cm3, a melting point of 814 oC, and a Brinell hardness of 1440 MPa. The most common compounds have As in the +3 and +5 states, while it also exists in other oxidation states such as -3, -2, -1, +1, +2, +4. Its standard electrode potential in respect to As+3 is +0.3V. Though stable in dry air, arsenic forms a golden-bronze tarnish upon exposure to humidity which eventually becomes a black surface layer. Arsenic makes arsenic acid with concentrated nitric acid, arsenous acid with dilute nitric acid, and arsenic trioxide with concentrated sulfuric acid. It does not react with water, alkalis, or non-oxidizing acids. As is estimated to be at average concentration of 1.5 parts per million (ppm) in the Earth's crust. Plating Solutions Arsenic can be electrochemically deposited from aqueous electrolytes, containing in g/l: a) Example #1. Arsenic trioxide – 90, sodium hydroxide – 110 ml/l, potassium sodium tartrate tetrahydrate (Rochelle salt) - 80 with pH ~8 at temperature of 15-25 oC, current density of 10 – 20 mA/cm2 and current efficiency of ~100%. b) Example #2. Arsenic trioxide – 120, sodium cyanide – 3.7, sodium hydroxide – 120 at temperature of 15-25 oC and current density of 3 – 22 mA/cm2. Arsenic clectrodeposition can be also performed from choline chloride/ethylene glycol deep eutectic solvent [1]. -

Material Safety Data Sheet (MSDS)

Date of Issue: 19 February 2019 SAFETY DATA SHEET 1. SUBSTANCE AND SOURCE IDENTIFICATION Product Identifier SRM Number: 3103a SRM Name: Arsenic (As) Standard Solution Other Means of Identification: Not applicable. Recommended Use of This Material and Restrictions of Use This Standard Reference Material (SRM) is intended for use as a primary calibration standard for the quantitative determination of arsenic. A unit of SRM 3103a consists of five 10 mL sealed borosilicate glass ampoules of an acidified aqueous solution prepared gravimetrically to contain a known mass fraction of arsenic. The solution contains nitric acid at a volume fraction of approximately 10 %, which is equivalent to a concentration (molarity) of approximately 1.6 mol/L. Company Information National Institute of Standards and Technology Standard Reference Materials Program 100 Bureau Drive, Stop 2300 Gaithersburg, Maryland 20899-2300 Telephone: 301-975-2200 Emergency Telephone ChemTrec: FAX: 301-948-3730 1-800-424-9300 (North America) E-mail: [email protected] +1-703-527-3887 (International) Website: https://www.nist.gov/srm 2. HAZARDS IDENTIFICATION Classification Physical Hazard: Not classified. Health Hazard: Skin Corrosion/Irritation Category 1B Serious Eye Damage/Irritation Category 1 Carcinogenicity Category 1A Label Elements Symbol Signal Word DANGER Hazard Statement(s) H314 Causes severe skin burns and eye damage. H350 May cause cancer through inhalation. Precautionary Statement(s) P201 Obtain special instructions before use. P202 Do not handle until all safety precautions have been read and understood. P260 Do not breathe fumes, mists, vapors, spray. P264 Wash hands thoroughly after handling. P270 Do not eat, drink or smoke when using this product. -

U.S. EPA, Pesticide Product Label, CSI ARSENIC ACID 75%, 07/11/2003

UNITED STATES ENVIRONMENTAL PROTECTION AGENCY WASIUNGTON, DC 20460 OFFICE OF PREVENTION, PESTICIDES AND TOXIC SUBSTANCES Julv 11.2003 Mr. Kevin J. Archer Product Development and Regulatory Affairs Manager Chemical Specialties, Inc. 200 E. Woodlawn Road Charlotte, NC 28217 Subject: CSI Arsenic Acid 75% EPA Registration No. 10465-32 Letter dated May 15, 2003 Dear Mr. Archer: The following amendment, submitted in connection with registration under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), as amended, is acceptable with comments: Proposed Amendment • Revised labeling General Comment 1. Add the statement" This product is toxic to fish" at the beginning of the environmental hazards statement. 2. The first aid statement must be revised in accordance with PR Notice 2001-1 by October 1, 2003. A stamped copy of the accepted labeling is enclosed. Submit three (3) copies of your final printed labeling before distributing or selling the product. 2 Should you have any questions or comments concerning this letter, please contact me at (703) 308-6422, or Lisa McKelvin at (703) 308-7496. Sinc ely, ~1~I/J am Heyward roduct Manager (34) 1Regulatory Management Branch II Antimicrobials Division (7510C) Enclosure PRECAUTIONARY STATEMENTS RESTRICTED USE PESTICIDE POST A COPY OF HAZARDS TO HUMANS & DOMESTIC ANIMALS SPECIFIC! DANGER DUE TO ACUTE TOXICITY AND BECAUSE THIS PRODUCT CONTAINS ARSENIC, CSt Arsemc Acid IS an end-use product used SOME TYPES OF WHICH HAVE BEEN ASSOCIATED WITH TUMOR when tank mixed with CSt Copper Sulfate Soil Corrosl"/e Causes irreversible eye damage and sKin burns Fatal ,f swallowed Reg. No, 10465-25) atlhe use site by commerci inhaled. -

Chapter 6.1 Arsenic

Chapter 6.1 Arsenic General description Arsenic (As) and its compounds are ubiquitous in nature and exhibit both metallic and nonmetallic properties. The trivalent and pentavalent forms are the most common oxidation states. From both the biological and the toxicological points of view, arsenic compounds can be classified into three major groups: inorganic arsenic compounds; organic arsenic compounds; and arsine gas. The most common trivalent inorganic arsenic compounds are arsenic trioxide, sodium arsenite and arsenic trichloride. Pentavalent inorganic compounds include arsenic pentoxide, arsenic acid and arsenates, e.g. lead arsenate and calcium arsenate. Common organic arsenic compounds are arsanilic acid, methylarsonic acid, dimethylarsinic acid (cacodylic acid) and arsenobetaine. Arsenic trioxide is only slightly soluble in water; in sodium hydroxide it forms arsenite and with concentrated hydrochloric acid it forms arsenic trichloride. Sodium arsenite and sodium arsenate are highly soluble in water. Interchanges of valence state may occur in aqueous solutions, depending on the pH and on the presence of other substances which can be reduced or oxidized (1). Sources Arsenic appears in nature primarily in the form of sulfides in association with the sulfides of ores of silver, lead, copper, nickel, antimony, cobalt and iron. Trace amounts of arsenic are found in soils and other environmental media. Arsenic is mainly transported in the environment by water. In oxygenated water, arsenic usually occurs as arsenate, but under reducing conditions, for instance, in deep well-waters, arsenites predominate. In water, the methylation of inorganic arsenic to methyl- and dimethylarsenic acids is associated with biological activity. Some marine organisms have been shown to transform inorganic arsenic into more complex organic compounds, such as arsenobetaine, arsenocholine and arsoniumphospholipids. -

Arsanilic Acid

A Publication of Reliable Methods for the Preparation of Organic Compounds Working with Hazardous Chemicals The procedures in Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices. In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red “Caution Notes” within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices. The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein. -

United States Patent (19) 11 Patent Number: 4,769,230 Greco Et Al

United States Patent (19) 11 Patent Number: 4,769,230 Greco et al. 45 Date of Patent: Sep. 6, 1988 54 PROCESS FOR PREPARATION OF ARSENIC 56) References Cited ACID U.S. PATENT DOCUMENTS 75 Inventors: Nicholas P. Greco; Byung K. Ahn, 1,650,860 1 1/1927 Askenasy et al. ................... 423/617 both of Pittsburgh, John J. Kozak, 1,974,747 3/1932 Latimer ............................... 423/617 Wexford, all of Pa. Primary Examiner-John Doll Assistant Examiner-Jackson Leeds 73) Assignee: Koppers Company, Inc., Pittsburgh, Attorney, Agent, or Firm-Donald M. MacKay; Herbert Pa. J. Zeh, Jr. 57 ABSTRACT 21 Appl. No.: 404,614 Arsenic acid is formed from arsenous acid and water 22 Filed: Aug. 2, 1982 under oxygen pressure with catalytic amounts of nitric acid and a halide whereby the nitric oxide by-product is regenerated to nitric acid for contact with fresh arse 51) Int. Cl. .............................................. C01G 28/00 nous acid. 52 U.S. Cl. .................................................... 423/617 58) Field of Search ......................................... 423/617 15 Claims, No Drawings 4,769,230 1 2 preferably from about 1 to about 5%. Dilute nitric acid PROCESS FOR PREPARATION OF ARSENIC of about 1 to about 5% is most preferred becaused there ACD is little nitric acid in the product. The use of more con centrated nitric acid requires separation steps such as BACKGROUND OF THE INVENTION 5 distillation to remove it or it can be recycled back to Arsenic Acid is useful in preparing wood preserva feed arsenic trioxide. Less than a stoichiometric amount tives. It is prepared commercially by the nitric acid or of nitric acid is required such as between about 2 and hydrogen peroxide oxidation of arsenous acid.