TECHNICAL BULLETIN: Tremco Topcoat Adhesion to FastPatch

SUMMARY Moisture cure urethane (MCU) topcoats from Tremco were applied over FastPatch MD and XD. Pull-off adhesion results indicate adequate adhesion without primer.

PURPOSE To evaluate the performance of Tremco Vulkem 350 NF and Tremproof 250 GC/SL when applied over FastPatch MD and XD. Tensile properties will also be checked.

MATERIALS & METHODS FastPatch MD and XD were pulled from production stock. Materials were mixed according to instructions from the technical data sheets, and poured into mock-up plinths over 3/8” pea gravel. One MD sample was topped with natural color topping sand. Materials were allowed to cure overnight at ambient conditions.

Tremco provided five gallon containers of their moisture cure urethane topcoats. Vulkem 350 NF is a gray elastomeric coating for pedestrian walkways and general waterproofing. Tremproof 250 GC/SL is a black elastomeric coating for below grade waterproofing. The topcoats were applied with a 2” chip brush, with 25-30 mil wet film thickness targeted for 350 NF, and 60 mil for 250 GC/SL. Topcoats were allowed to cure 3 days at ambient condition, and checked for pull-off adhesion using ASTM D7234 with 20 mm dollies, Duro cyanoacrylate adhesive (cured overnight at ambient), and a Posi-Test AT-A tester at 150 psi/s pull rate.

Free films of Tremco samples were prepared on aluminum sheet pans treated with silicone release agent. Materials were applied to 50 mil wet film thickness using a draw down bar, cured 3 days at ambient, and tested for tensile and elongation using ASTM D412 Die C, and tear strength using ASTM D624 Die C. Shore A and OO hardness were measured using ASTM D2240.

RESULTS

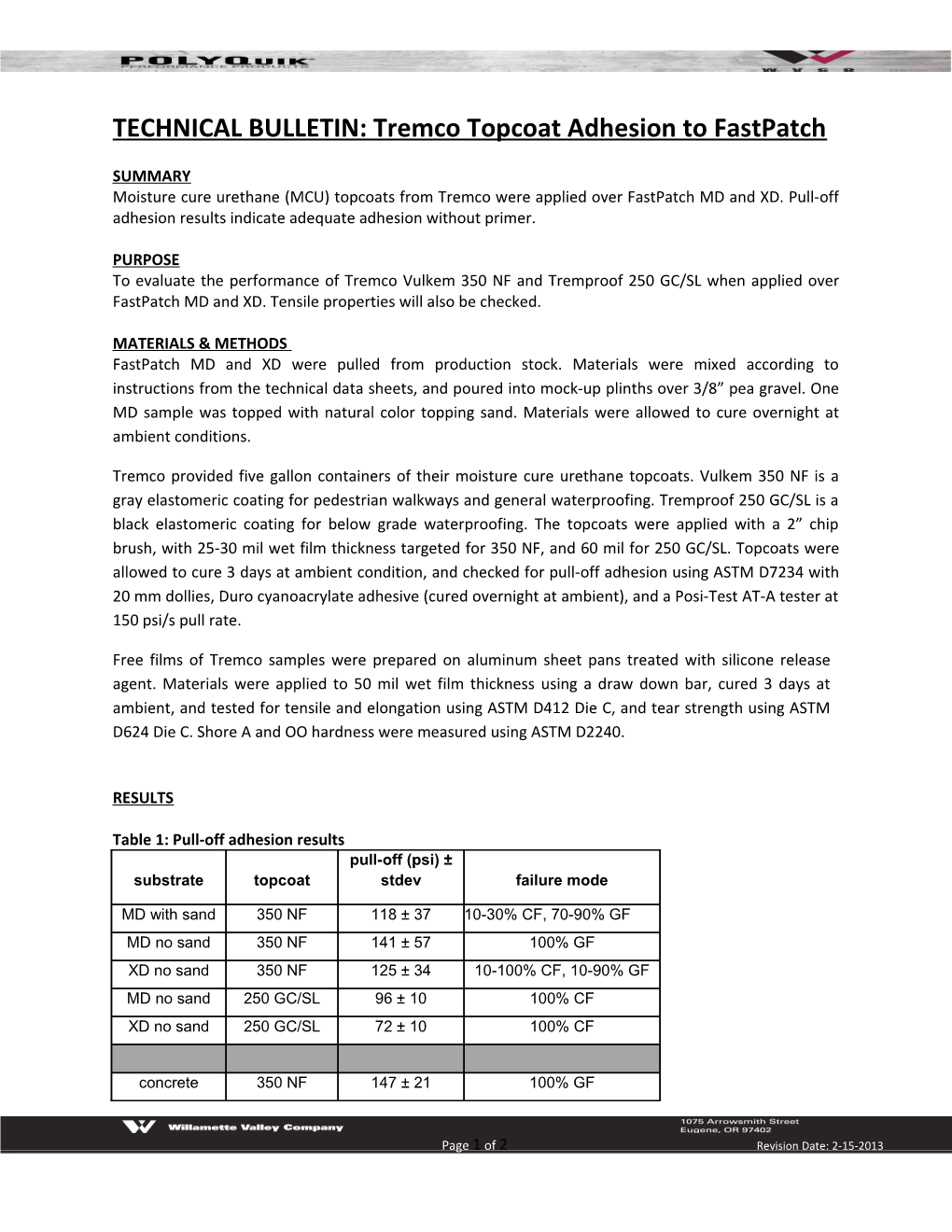

Table 1: Pull-off adhesion results pull-off (psi) ± substrate topcoat stdev failure mode

MD with sand 350 NF 118 ± 37 10-30% CF, 70-90% GF MD no sand 350 NF 141 ± 57 100% GF XD no sand 350 NF 125 ± 34 10-100% CF, 10-90% GF MD no sand 250 GC/SL 96 ± 10 100% CF XD no sand 250 GC/SL 72 ± 10 100% CF

concrete 350 NF 147 ± 21 100% GF

Page 1 of 2 Revision Date: 2-15-2013 concrete 250 GC/SL 77 ± 20 100% CF CF = cohesive failure (within topcoat) GF = glue failure (between topcoat and adhesive)

Table 2: Tensile results Sample Shore hardness Tensile str (psi) Elongation (%) Tear str (pli) 350 NF 38 A 291 ± 51 543 ± 83 68 ± 3 250 GC/SL 50 OO 140 ± 18 627 ± 46 20 ± 2

DISCUSSION

Tremco requested a demonstration of compatibility of its MCU topcoats to typical FastPatch products. If the two technologies can be used in conjunction, there may be synergies between the two companies’ offerings that can be leveraged in the marketplace. Materials were applied over day-old FastPatch MD and XD, as well as dry concrete for comparison. A representative from Tremco was present for the application of MCU. Since the Tremco topcoats are usually used on concrete without primer, the priming step between FastPatch and topcoat was omitted.

Pull-off results were comparable to bare concrete for both FastPatch MD and XD. Vulkem 350 NF gave notably higher results than Tremproof 250 GC/SL, which was to be expected considering the higher hardness and cohesive strength of 350 NF. Slightly higher pull-off numbers were recorded for MD than XD, but considering the rather large standard deviations, this may not be statistically significant. Failure mode was a mix of cohesive and glue failure for 350 NF. Soft materials with high elongation tend to stretch and distort during pull-off, which can cause premature glue failure since the glue is rigid. Cohesive failure was seen in all of the 250 GC/SL samples, even though it was even softer than 350 NF. The low tensile strength of 250 GC/SL allowed it to fail before the glue was distorted. Topping sand is an optional step in FastPatch application. One sample of 350 NF was checked with sand in place to see what the effect would be on pull-off adhesion. The effect was slightly negative.

CONCLUSION

FastPatch MS and XD can be topcoated with Tremco MCU products without primer, and achieve pull-off strengths for the MCU comparable to unprimed concrete. Topping sand is not recommended for FastPatch prior to topcoat.

Page 2 of 2 Revision Date: 4-4-2013