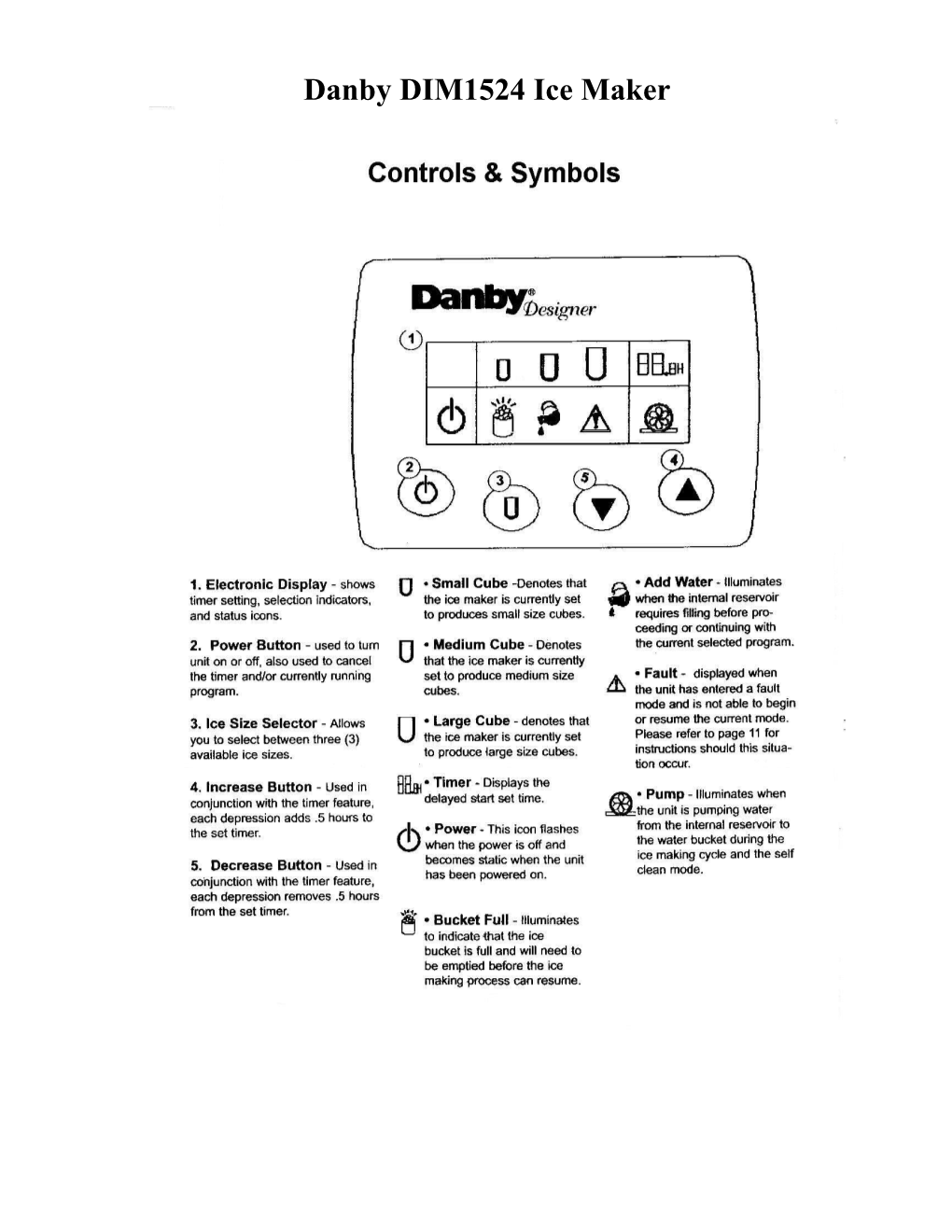

Danby DIM1524 Ice Maker Troubleshooting

Constant Ice full with no ice present:

1. The black eyes, inside on the sides just above the ice bucket dirty 2. Photoelectric Diodes #25 Bad

Fix : first clean the eyes with Q-tip and alcohol. If problem persists, replace the photoelectric diodes.

Constant Fill when tank is not empty:

The water full sensor is either clogged or bad

Fix: Run through the self-clean mode with 50/50 vinegar water mix. To Engage Self clean turn unit off then press the up and down arrows together twice within 5 seconds. If the problem persists the water sensor* will have to be replaced.

*At this time the water sensor is Not shown on the breakdown and no part number is available. It is located exactly where #57 points to on the exploded view. Information will be provided as soon as it becomes available. Flashing fault symbol:

The Fault Symbol is triggered by any functional interruption of the sequence in the fill, refrigeration, or harvest modes. To test the machine it must be run through a cycle and observed to catch the interruption when it takes place. (turning the unit off with the power button does not cause a fault code) Sequence of events in normal operation When filled with water and started the water tray swings back into a rear vertical position and pauses for approximately 20 seconds. During the pause you hear the defrost solenoid kick on then back off at the end of the pause. Next the water tray swings back up level, stops and the water pump fills the tray for exactly 35 seconds. The tray is generally full within 25 seconds with the excess water flowing back down into the front fill reservoir. After the fill cycle the compressor comes on followed shortly by the condenser fan motor. This refrigeration cycle is timed for the size of cube selected. 9 minutes small, 12minutes medium, and 15 minutes large. Near the end of the cooling cycle the condenser fan stops to allow the unit to build heat for the defrost. At the end of the cooling cycle the water tray swings back vertical again dumping the excess water back into the reservoir. Again you hear the defrost solenoid turn on and with in 10 seconds all cubes fall off the cooling prongs onto the ice tray. The water tray swings back forward to level lifting the ice tray to dump the cubes into the ice bucket. Flashing fault symbol Cont. If the water tray jambs during the initial swing Check the ice tray. If the hinges are trapped under the water tray fig. 1 causing the problem. Fig. 1 Fig. 2

Fix: Push the bottom of the tray back and slide the tray forward to release it then check both sides of the water tray in the fully retracted position fig. 2. The top edge for the tray should not be contacting the cooling tubes or mount. If it is, gently move the mount out of the path of the tray. This will stop the tray from twisting and correct the problem. Water tray stalling but not caught on ice tray.

This is generally caused by a bad drive motor”DIM15.39”, broken tray”DIM15.13” fig.3 or by broken tray hinge “DIM15.15”, or position switches”DIM15.27” fig. 4. Fig. 3 Fig. 4

Fix; Remove right and left side panels and release motor. Inspect for physical damage and continuity of the motor windings and switch contacts. Replace broken or defective components as needed. Flashing fault symbol Cont. The tray completes the cycle but no water comes in.

Remove the right side panel and check for 120V AC on the water pump connection fig.5 during the fill cycle. Fig.5

If voltage is present replace the water pump “DIM15.55”. If no voltage is present then replace the circuit plate “DIM15.43”. ** Note due to changes in production the circuit plate is available in a 7 pin CN6 DIM15.43 or a 9 pin CN6 DIM15.43-1. Check CN6 on the existing board to order proper replacement. The Water comes in but stops before tray is full

First run the self clean mode with a 50/50 vinegar water mix, rinse out and retry. If the problem persists replace the two photoelectric diodes “DIM15.25” on the water flow sensor. Fig.6

Fig.6

Flashing fault symbol Cont. The compressor fails to start.

Check for 120v AC at the compressor during the refrigeration cycle. If no voltage is present then replace the circuit plate “DIM15.43”. If voltage is present check the overload, PTC thermistor, and compressor. Replace bad state component. If the compressor is bad during the warranty period exchange the machine.

Other causes

Ice clumping, sticking to, or refreezing can jamb the tray. Unfortunately when this happens often the unit has been in fault mode for a while and the symptoms have melted away by the time the consumer catches it. At this point it can be reset and in many cases may work fine at least for a few batches. There are several things that can cause this to happen including: 1) Cold room temperature (below 55°F or 12.8 °C.) 2) Damaged or pitted cooling prongs 3) Low refrigerant charge Make sure the unit is in a warm environment. Inspect the cooling prongs for any dents, kinks, or pits fig.7.

If the charge is low some of the prongs may not produce ice nor enough heat in the condenser to break all of the ice loose in defrost. If during the warranty period the cooling prongs are damaged or the charge is low exchange the unit