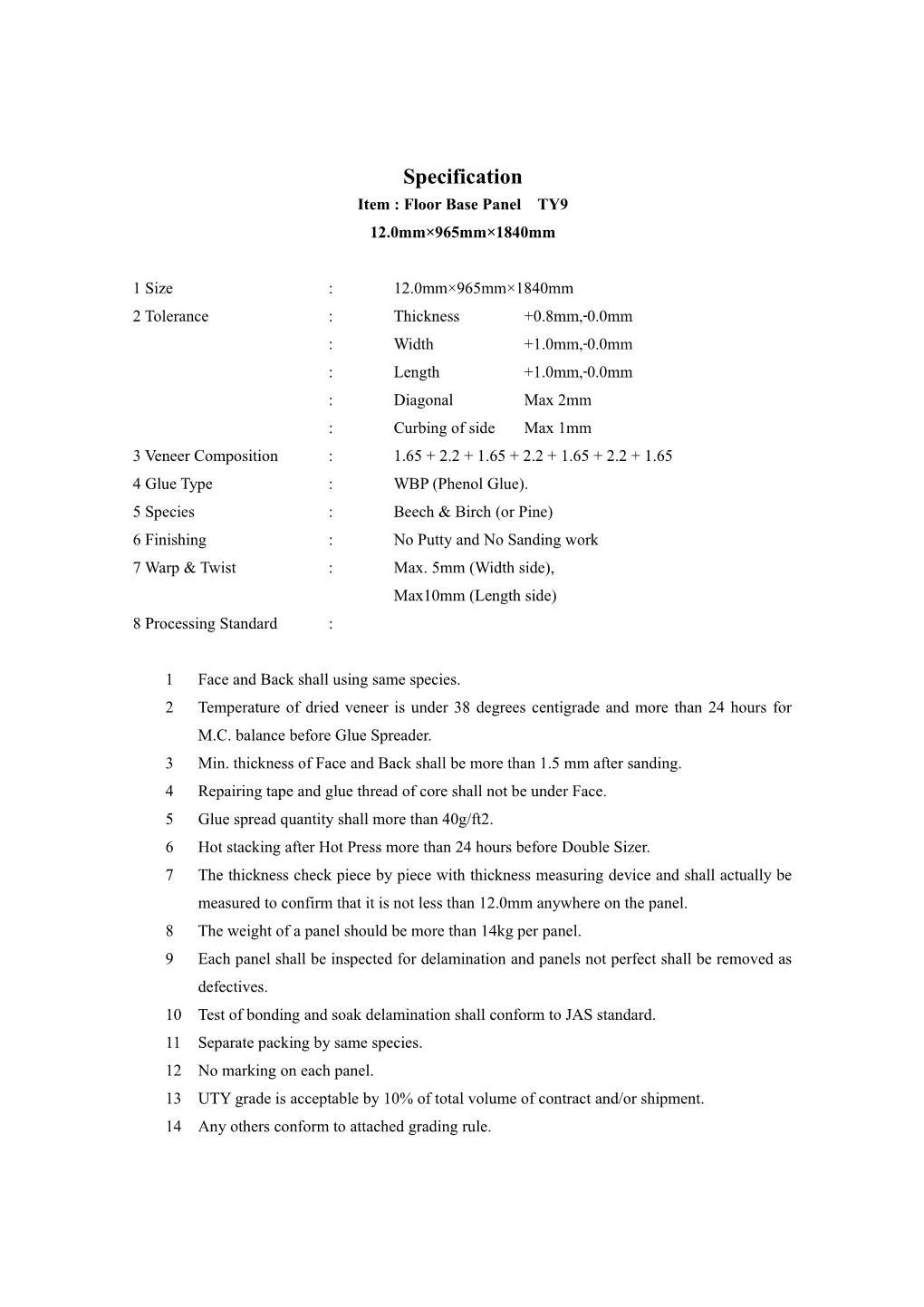

Specification Item : Floor Base Panel TY9 12.0mm×965mm×1840mm

1 Size : 12.0mm×965mm×1840mm 2 Tolerance : Thickness +0.8mm,‐ 0.0mm : Width +1.0mm,‐ 0.0mm : Length +1.0mm,‐ 0.0mm : Diagonal Max 2mm : Curbing of side Max 1mm 3 Veneer Composition : 1.65 + 2.2 + 1.65 + 2.2 + 1.65 + 2.2 + 1.65 4 Glue Type : WBP (Phenol Glue). 5 Species : Beech & Birch (or Pine) 6 Finishing : No Putty and No Sanding work 7 Warp & Twist : Max. 5mm (Width side), Max10mm (Length side) 8 Processing Standard :

1 Face and Back shall using same species. 2 Temperature of dried veneer is under 38 degrees centigrade and more than 24 hours for M.C. balance before Glue Spreader. 3 Min. thickness of Face and Back shall be more than 1.5 mm after sanding. 4 Repairing tape and glue thread of core shall not be under Face. 5 Glue spread quantity shall more than 40g/ft2. 6 Hot stacking after Hot Press more than 24 hours before Double Sizer. 7 The thickness check piece by piece with thickness measuring device and shall actually be measured to confirm that it is not less than 12.0mm anywhere on the panel. 8 The weight of a panel should be more than 14kg per panel. 9 Each panel shall be inspected for delamination and panels not perfect shall be removed as defectives. 10 Test of bonding and soak delamination shall conform to JAS standard. 11 Separate packing by same species. 12 No marking on each panel. 13 UTY grade is acceptable by 10% of total volume of contract and/or shipment. 14 Any others conform to attached grading rule. 9 Grading

Defect items Face Back Total length of widthwise Max.1/15 of width of panel diameter, width or length of live knots, dead knots, loose knots, holes, open splits, cross breaks, linear worm holes Diameter of live knots, dead Max.50mm Max.60mm knots, loose knots or holes (30mm-loose knots) Bark pocket or resin pocket Permitted Decay Slight Permitted Open split Max.6mm x 40% of panel length Max.15mm x 50% of panel length Worm holes Slight Permitted Rough grain Slight Permitted Press mark 15mm x 300mm, 30mm x 100mm Sanding mark Slight Permitted Core overlap Max.10mm x 150mm, one only Core void Max.11mm x 100mm, more than 3mm should be repaired Lack of core & center core Max.4mm x 50% of panel length Uneven core thickness Slight, shall not hinder the panel use Lack of veneer Max.3mm x 200mm Max.4mm x 200mm Others According to JAS-Concrete Panel B grade

10 Packing: 1) 100 pieces/crate. 2) Sorted by Species and packed separately.

11 Crate Marking:

TY TY9

9 R

Size : 12.0x965x1840 Size : 12.0x965x1840 Pcs : 100 Pcs : 100 Species : Species :

12 Test 1) Bonding test 2) Soak delamination test 3) Moisture Contents test

The above test shall conform to JAS standard test, ・Samples shall be taken 1 piece per shift and glue spreader. Toyo Tex Co., Ltd