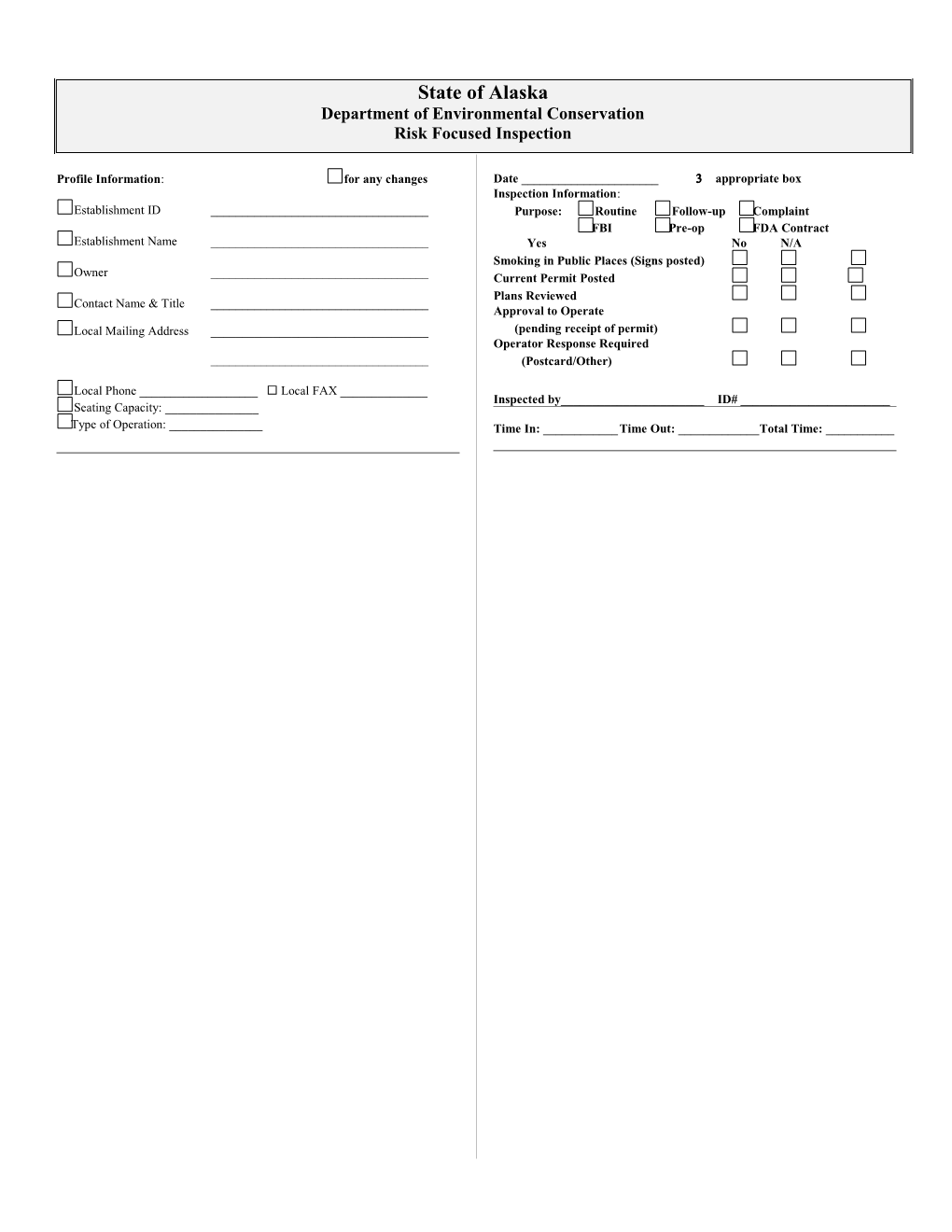

State of Alaska Department of Environmental Conservation Risk Focused Inspection

Profile Information: for any changes Date ______ appropriate box Inspection Information: Establishment ID ______Purpose: Routine Follow-up Complaint FBI Pre-op FDA Contract Establishment Name ______Yes No N/A Smoking in Public Places (Signs posted) Owner ______Current Permit Posted Plans Reviewed Contact Name & Title ______Approval to Operate Local Mailing Address ______(pending receipt of permit) Operator Response Required ______(Postcard/Other)

Local Phone ______ Local FAX ______Inspected by______ID# ______Seating Capacity: ______

Type of Operation: ______Time In: ______Time Out: ______Total Time: ______Establishment Number ______Received by ______Date: ______Presence of insects/ rodents/ other pests; outer openings protected; no RISK FACTOR DEFICIENCIES birds, turtles or other animals; light traps/flypaper.

1. FOOD SOURCE 13. CHEMICALS Approved Source, wholesome, no home prepared or canned food. No unapproved food or color additives. Receiving/temperature/condition/unadulterated. Poisonous or toxic materials, chemicals, lubricants, pesticides, Records, shell stock tags 90 day retention, HACCP plan. medicines, first aid supplied, personal car items are properly stored and used. 2. FOOD COOKING Poisonous or toxic materials held for retail sale properly stored. Raw eggs for immediate service cooked to 145°F for 15 seconds. Comminuted fish, meats, ratites, injected meats and game cooked to 155°F for 15 seconds. FOOD TEMPERATURES Beef roasts cooked to 130°F for 121 minutes, or as specified. Poultry, stuffed fish, meat, pasta, poultry, stuffed ratites, or stuffing containing these items cooked to 165°F for 15 seconds. Item/Location Temp Wild game cooked to 165°F for 15 seconds. All other PHF cooked to 145°F for 15 seconds. PHF properly reheated to 165°F for 15 seconds.

3. FOOD HOLDING PHF maintained at 140°F or above during hot holding. PHF maintained at 41/45°F or below during cold holding. PHF from ambient ingredients are cooled to 41/45°F or below within 4 hours. PHF is cooled from 140°F to 70°F within 2 hours and from 70°F to 41/45°F or below within 4 hours. 4. PERSONAL HYGIENE PRACTICES Hands are clean and properly washed when and as required. Good employee hygienic practices. Bare hand contact minimized. Hand wash facilities conveniently located, accessible, supplied.

5. PROTECTION FROM CONTAMINATION Food is protected from cross-contamination. Raw animal foods are separated from each other. Raw animal foods are separated from ready to eat foods. After being served or sold to a customer, food is not re-served. Sanitizing rinse clean, temperature, concentration, exposure time: equipment, utensils sanitized.

CRITICAL DEFICIENCIES

6. EMPLOYEE HEALTH Employee not working with infected wound or communicable disease. Employee not working with persistent sneezing, coughing or runny nose.

7. CONSUMER ADVISORY Wild mushrooms conspicuously identified. Consumer advisory for raw undercooked food. Warning statement required.

CRITICAL DEFICIENCIES continued

8. FOOD EQUIPMENT Equipment to maintain product temperature.

9. WATER Water/steam approved source; adequate, hot and cold under pressure; BWN; water/ice samples.

10. SEWAGE Sewage/wastewater disposal approved, adequate.

11. CROSS CONNECTION Cross-connection, back siphonage, backflow.

12. INSECT, RODENT, AND ANIMAL CONTROL Page 1 GOOD RETAIL PRACTICES COMMENTS:

14. OPERATIONS ______Original food container, label/placard, codes, dates, records.

15. FOOD PROTECTION ______Thermometers provided, conspicuous, used. PHF properly thawed. ______Food protection during receiving, storage, preparation, processing, display, bulk display, service, transportation. Handling of food or ice minimized. ______16. PERSONNEL Clean clothes, hair restraints, jewelry, nails. ______

17. FOOD EQUIPMENT AND UTENSILS Food contact surfaces designed, constructed, maintained, installed, located. ______Non-food contact surfaces designed, constructed, maintained, installed, located Dishwashing facilities designed, constructed, maintained, installed, ______located, operated. Accurate dishwashing thermometers and test kits provided, ______used; gauge cock. Preflushed, scraped, soaked. Wash, rinse water clean, proper temperature. ______Wiping cloths clean, use restricted Food contact surfaces of equipment and utensils clean, free of detergents and abrasives ______Non-food contact surfaces of equipment and utensils clean Storage, handling of clean equipment and utensils ______Single service articles storage, dispensing, used No reuse of single service articles ______18. PLUMBING AND FIXTURES Plumbing installed, maintained; janitorial sink; prep sink. Toilet rooms enclosed, self-closing door, fixtures good repair, clean, proper ______waste, receptacles.

19. GARBAGE AND REFUSE ______Containers or receptacles covered, adequate number/size, insect/rodent proof, clean, frequency. ______Outside storage area/enclosures properly constructed, clean, controlled incineration. ______20. FLOORS, WALLS & CEILINGS Floors constructed, drained, clean, good repair, covering installation, dustless cleaning methods. ______Walls, ceilings, attached equipment constructed, good repair, clean surfaces, dustless cleaning methods. ______21. LIGHTING & VENTILATION Lighting provided as required, fixtures shielded. Rooms and equipment vented as required ______

22. DRESSING ROOMS Rooms or lockers provided, facilities clean, located, used.

23. OTHER OPERATIONS Refer to Continuation Sheet for additional comments. Premises maintained free of litter, unnecessary articles; cleaning/ maintenance equipment properly stored; authorized personnel. (g:/eh/act/forms/RiskFocused Protocal/RF Inspection Hardcopy.doc) Revised 8/22/02 Complete separation from living quarters, laundry. Clean, soiled linen/clothing properly stored.

Total Risk Factors/Interventions _____ Total Critical _____