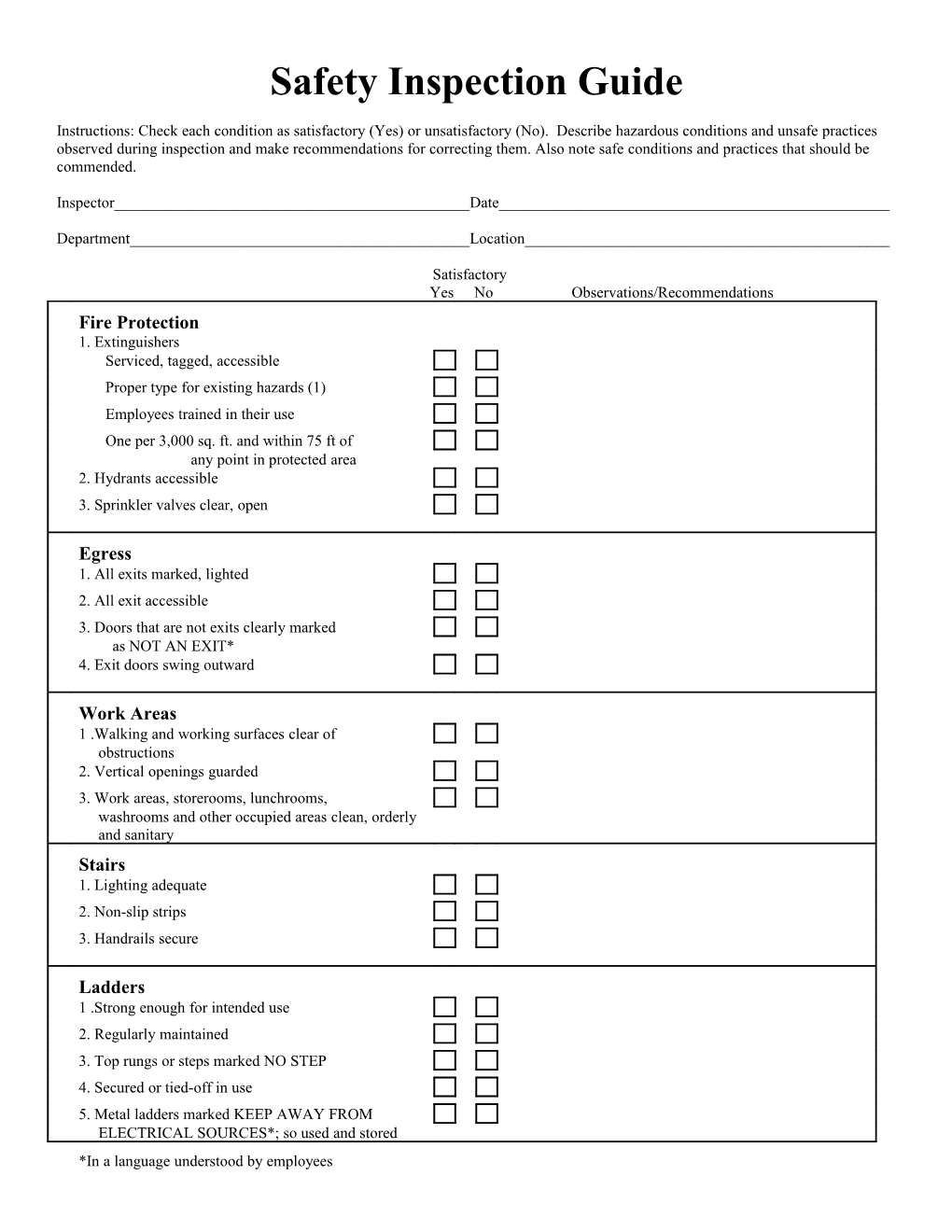

Safety Inspection Guide

Instructions: Check each condition as satisfactory (Yes) or unsatisfactory (No). Describe hazardous conditions and unsafe practices observed during inspection and make recommendations for correcting them. Also note safe conditions and practices that should be commended.

Inspector______Date______

Department______Location______

Satisfactory Yes No Observations/Recommendations Fire Protection 1. Extinguishers Serviced, tagged, accessible Proper type for existing hazards (1) Employees trained in their use One per 3,000 sq. ft. and within 75 ft of any point in protected area 2. Hydrants accessible 3. Sprinkler valves clear, open

Egress 1. All exits marked, lighted 2. All exit accessible 3. Doors that are not exits clearly marked as NOT AN EXIT* 4. Exit doors swing outward

Work Areas 1 .Walking and working surfaces clear of obstructions 2. Vertical openings guarded 3. Work areas, storerooms, lunchrooms, washrooms and other occupied areas clean, orderly and sanitary Stairs 1. Lighting adequate 2. Non-slip strips 3. Handrails secure

Ladders 1 .Strong enough for intended use 2. Regularly maintained 3. Top rungs or steps marked NO STEP 4. Secured or tied-off in use 5. Metal ladders marked KEEP AWAY FROM ELECTRICAL SOURCES*; so used and stored *In a language understood by employees Satisfactory Yes No Observations/Recommendations Ramps, Platforms and Catwalks 1. Strong enough for intended use 2. Walking and working surfaces clear of obstructions 3. Handrails and toeboards secure

Pressure Apparatus 1. Inspection certificate posted 2. Gas cylinders secured 3. compressors clear

Electrical 1. Wiring clear of combustibles 2. Adequate clearance around control panels 3. Purpose of each switch or disconnect on panel Identified 4. Circuit breakers and fuses of proper rating 5. "Lock-out" controls 6. Use of extension cords restricted 7. Cord plugs and receptacles not interchangeable among circuits of different voltages 8. Approved systems and fixtures for hazardous locations and atmospheres Hoists, Cranes and Conveyors 1. Guarded 2. Capacities and instructions posted 3. Inspected daily 4. Maintenance record up-to-date

Industrial Powered Lift Trucks 1. Only authorized drivers operate lift trucks 2. Trucks inspected daily 3. Drivers instructed in safe operation 4. NO PASSENGERS rule enforced 5. Precautions taken during refueling or recharging

Machinery and Equipment 1. Moving parts guarded 2. Points-of-operation guards in place 3. Guards interlocked into power source Satisfactory Yes No Observations/Recommendations Power Hand Tools 1 .Equipped only with constant-pressure switches 2. Provided with functioning self-adjusting guards 3. All tools d6uble-insulated or grounded 4. Powder-actuated tools provided with safety shield/guard; operator given special training and certified 5. Given regular inspections

Special Hazards 1. Flammable liquids kept in approved safety containers and cabinets 2. NO SMOKING OR OPEN FLAME signs posted near flammable storage*; rule enforced 3. Dip tanks have exhaust ventilation 4. LP gas, anhydrous ammonia and similar gases stored and handled in approved manner and only by trained personnel 5. Only UL - approved booths used for spraying 6. Material safety data sheets on applicable hazardous materials available 7. Gas cylinders secured when upright 8. Gas cylinders valves capped when not in use; stored separately 9. Welding permit system in force

Safe Practices/Operations 1. Safe lifting procedures observed 2. Separate covered containers for different kinds of waste and scrap 3. Combustible scrap and debris removed regularly from work areas 4. Compressed air nozzles limited to 30 psi 5. Pneumatic hose connections protected against accidental disconnection 6. Warning signs posted*; rules enforced 7. Screening of arc welding to avoid exposure to arc flash Personal Protective Devices 1. Goggles or safety glasses 2. Approved respirators or dust masks 3. Safety footwear 4. Face shields 5. Hard hats 6. Hearing protection 7. Protective clothing 8. Employees trained in proper use Satisfactory Yes No Observations/Recommendations Personal Protective Devices, Cont 9. Devices regularly inspected, maintained, and sanitized 10. Protective gear for welders and assistants such as gloves, aprons, woolen clothing, eye protection Environmental/Health Control 1. Ventilation Exhaust ventilation for blasting, grinding, spraying and similar operations Controls installed for identified air contaminants 2. Lighting Adequate for work conditions Glass and fixtures unbroken Approved fixtures for hazardous areas Cords for portable lights safely placed; guarded against damage, liquids 3. Noise Hearing conservation measures for exposures exceeding standards Surveys made periodically

First Aid 1. Supplies adequate, clear of obstructions, clean and sanitary 2. Emergency phone numbers posted* 3. Emergency procedures posted* 4. Quick eye/body wash facilities near hazardous materials

*In a language understood by employees

This publication is a general guide to safety. Compliance with all federal state or local safety laws and regulations is the policyholder’s responsibility.

Revised 4-00

THE INFORMATION PRESENTED IN THIS “SAMPLE” SAFETY PROGRAM HAS BEEN COMPILED FROM VARIOUS SOURCES BELIEVED TO BE RELIABLE. HOWEVER, IT CANNOT BE ASSUMED THAT ALL ACCEPTABLE MEASURES ARE CONTAINED IN THIS PROGRAM WITH REGARDS TO YOUR INDUSTRY STANDARDS AND REQUIREMENTS UNDER PARTICULAR FEDERAL, STATE, PROVINCIAL AND LOCAL LAW.