02/08/2014

LG

DRAFT

Mechanical dicing and thinning yield for the third (final) batch of wafers of production Ultimate-2 sensors fabricated with DRIE

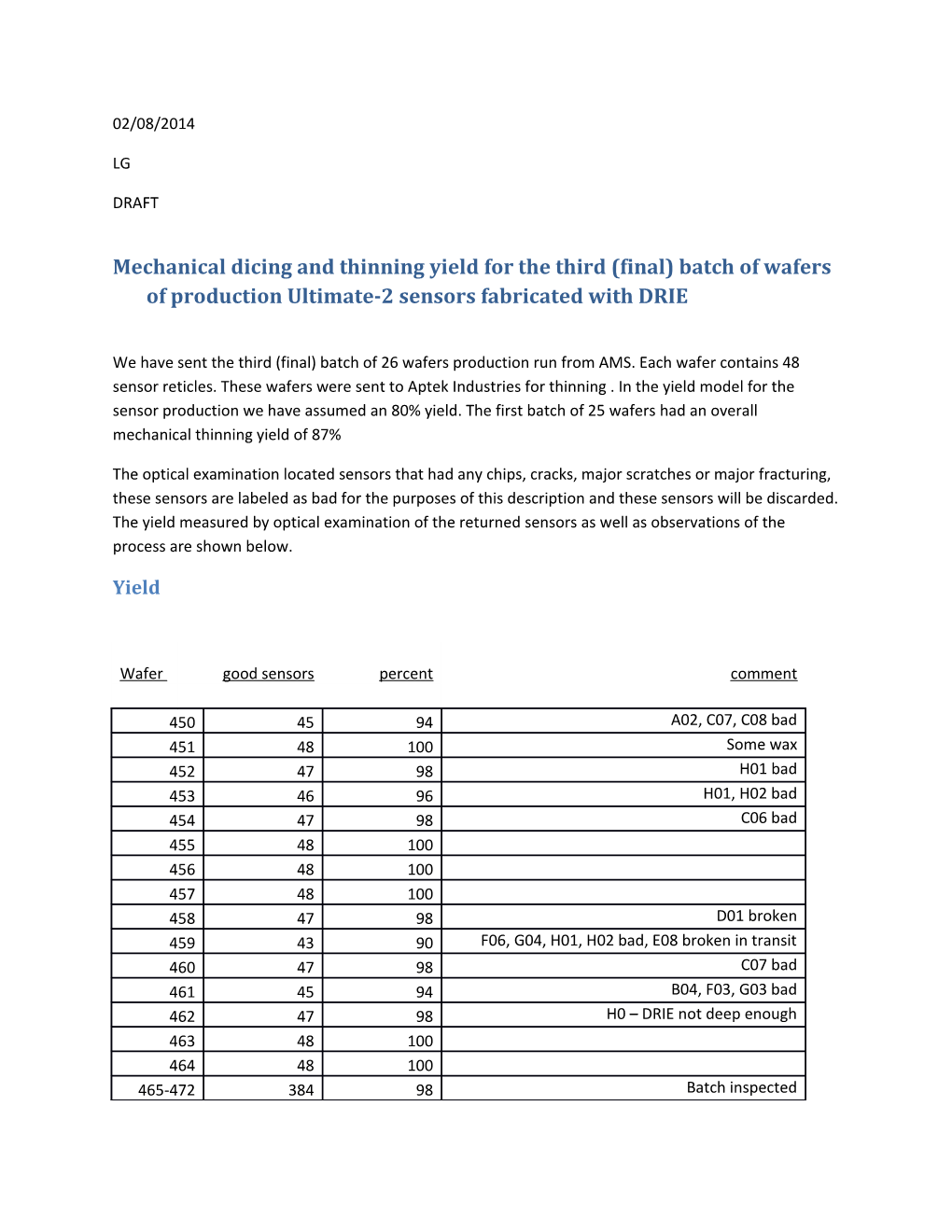

We have sent the third (final) batch of 26 wafers production run from AMS. Each wafer contains 48 sensor reticles. These wafers were sent to Aptek Industries for thinning . In the yield model for the sensor production we have assumed an 80% yield. The first batch of 25 wafers had an overall mechanical thinning yield of 87%

The optical examination located sensors that had any chips, cracks, major scratches or major fracturing, these sensors are labeled as bad for the purposes of this description and these sensors will be discarded. The yield measured by optical examination of the returned sensors as well as observations of the process are shown below.

Yield

Wafer good sensors percent comment

450 45 94 A02, C07, C08 bad 451 48 100 Some wax 452 47 98 H01 bad 453 46 96 H01, H02 bad 454 47 98 C06 bad 455 48 100 456 48 100 457 48 100 458 47 98 D01 broken 459 43 90 F06, G04, H01, H02 bad, E08 broken in transit 460 47 98 C07 bad 461 45 94 B04, F03, G03 bad 462 47 98 H0 – DRIE not deep enough 463 48 100 464 48 100 465-472 384 98 Batch inspected 473 48 100 474 48 100 475 0 0 Delaminated during thinning

Figure 1 Yield of good sensors per wafer for the 26 of the examined wafers.

The total number of bad sensors observed was 74 of 1248 total sensors. The overall mechanical yield measured by optical examination is 94%.

Observations

Some sensors were still quite dirty with residue from the thinning operation. The white residue prevents wire bonding and residue on the wire bonding pads must be removed. We estimate that 10 % of the sensors will need some additional cleaning

Of all sensors, only one appeared to have been damaged in transit (broken fragments of silicon in the die well if the carrier). This increases the mechanical yield.

Occasionally some of the slivers of silicon observed in the die wells of the last batches were observed in this batch (~5 sensors)

A new fault of DRIE trench not deep enough appeared in wafer # 462, sensor H01, a photo of this fault is shown below.

Figure 2 example of DRIE trench not deep enough to allow for clean release from thinning.