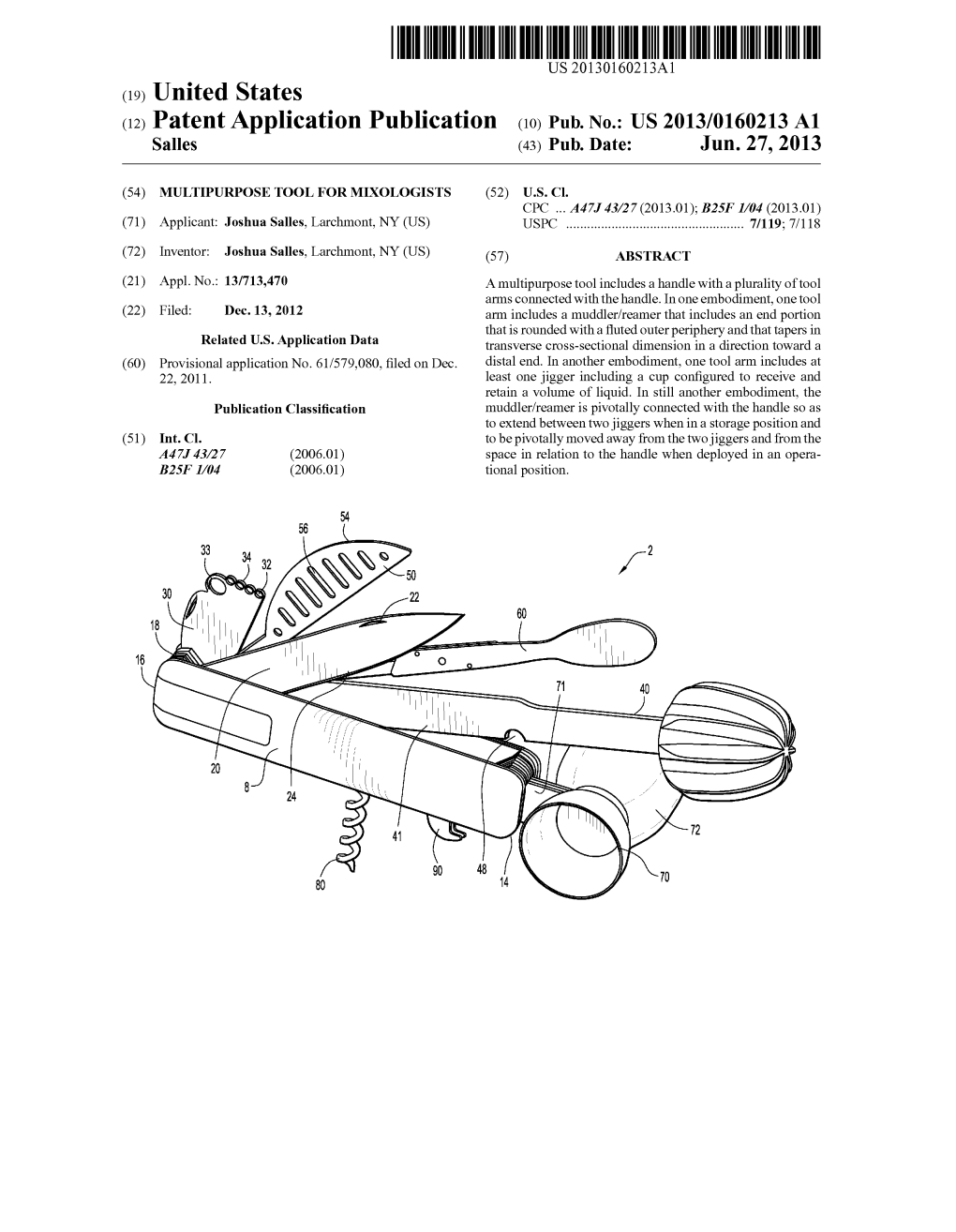

(12) Patent Application Publication (10) Pub. No.: US 2013/0160213 A1 Salles (43) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Masterclass Guide to Cocktails

the masterclass guide to cocktails www.bunzlmclaughlin.com www.bunzlmclaughlin.com CONTENTS 03 THE PROFITS IN COCKTAILS 18 RED RUSSIAN 04 PASSIONFRUIT MARTINI 19 PINA COLADA 05 OLD FASHIONED 20 PISCO SOUR 06 GIN & TONIC 21 SAZERAC 07 NEGRONI 22 ESPRESSO MARTINI 08 MOSCOW MULE 23 CAIPRINHA 09 MANHATTAN 24-27 THE KEY KIT 10 MAI TAI 11 TEQUILA SUNRISE 12 MOJITO 13 MARGARITA 14 TOM COLLINS 15 ZOMBIE 16 BLOODY MARY 17 GIN FIZZ 2. Call: (NI) 028 3751 1999 (RoI) 048 3751 1999 OUR 3 MOST the profits in PROFITABLE COCKTAILS MOSCOW MULE page: 08 COCKTAILS Margin: 90.6% Cost: 9.4% The cocktail market is currently worth half a billion pounds in the UK. A third of the bars now have cocktails on their menu and approximately 15,000 more bars offer cocktails that 3 years ago. TEQUILA SUNRISE Cocktails have proven to be a hugely beneficial addition to an outlet’s drinks range. page: 11 They can differentiate you from your competition due to the creatively they can bring Margin: 87.4% and increase your customers spend per head. It is believed that this boom in the Cost: 12.6% cocktail trade is down to a ‘foodie’ culture and a desire for theatre on a night out that can’t be replicated at home. With the portion of alcohol to mixers or fruit juices, this means that the possible profit BLOODY MARY margin for cocktails are extremely high, opening your potential for profit. page: 16 Margin: 87.1% Cost: 12.9% Called ‘The Unforgetables’ by the International Bartenders Association, see below for the average ‘pour costs’ and ‘profit margins’ these cocktails can generate: THE UNFORGETABLES POUR COSTS 0% 4% 8% 12% 16% 20% 24% TOM COLLINS OLD FASHIONED MARTINI NEGRONI SAZERAC MANHATTAN 100% 96% 92% 88% 84% 80% 76% GROSS PROFIT MARGIN *DATA SOURCE: https://www.bevspot.com/2017/01/18/cocktail-profitability-handbook/ www.bunzlmclaughlin.com 3. -

Playing Card Drink Mats • 54 Different Drink Marker Beer Mats (Full Deck of 52 + 2 Jokers)

Playing Card Drink Mats • 54 different drink marker beer mats (Full deck of 52 + 2 Jokers). • Absorbent, durable paper pulp, great for soaking up spills. • Use as drink markers, remember your card, don't lose your drink. Pack Size: 12 Product in pack: W104 x H68 x D97mm • W4.09 x H2.68 x D3.82in Item Code: SK DMATPLAY1 G-Clamp Bottle Opener The right took for a good job. Attach to any surface to conveniently open bottles. Made from cast iron. Pack Size: 12 Product in pack: W61 x H107 x D21.5mm / W2.40 x H4.21 x D0.84in Code: SK BOCLAMP1 UPC/EAN CODE: 5-060043-069940 Dinosaur Bottle Opener For roarsome refreshment! Cast iron dinosaur, designed to open bottles. Pack Size: 6 Product in pack: W225 x H123 x D65mm / W8.85 x H4.84 x D2.55in Code: SK BODINOSAUR1 UPC/EAN CODE: 5-060043-067052 Hippo Bottle Opener Like no other bottle opener, this hungry utensil will be the centre piece of any home bar or the talking point of any party. Made from Cast Iron. Pack Size: 4 Product in pack: W113 x H75 x D55mm / W4.44 x H2.95 x D2.16in Code: SK BOHIPPO1 UPC/EAN CODE: 5-060043-065768 Legless Corkscrew Pirate style classic waiter’s friend bottle opener and corkscrew Pack Size: 12 Product in pack: W78 x H268 x D18mm / W3.07 x H10.55 x D0.71in BOPIRATE1 Code: SK BOPIRATE1 Legless Corkscrew UPC/EAN CODE: 5-060043-063238 Flask in a Book - Good Book A book to hide your flask - comes with 4oz flask Pack Size: 12 Product in pack: W105 x H145 x D22mm / W4.13 x H5.17 x D0.87in Code: SK FLASKBOOK4 UPC/EAN CODE: 5-060576-593073 Flask In A Book A book to hide your flask, comes with 4oz flask Pack Size: 12 Product in pack: W105 x H145 x D22mm / W4.13 x H5.71 x D0.87in SK FLASKBOOK1 Code: SK FLASKBOOK1 Hip-Flask in a Book UPC/EAN CODE: 5-060043-060206 Fridge Magnet Bottle Opener • Sticks to your fridge and opens bottles. -

DUNCAN LIQUOR LAW LETTER July, 2017

Mobile device friendly format. Duncan Liquor Law Letter DUNCAN LIQUOR LAW LETTER July, 2017 A monthly newsletter for the clients of R.E. "Tuck" Duncan, Attorney at Law Please forward as you deem appropriate. ~ ~ ~ ~ ~ This information is not to be considered legal advice. Consult a competent attorney on specific questions. "America was not built on fear. America was built on courage, on imagination and an unbeatable determination to do the job at hand." - Harry S. Truman, 33rd President of the United States IN THIS ISSUE: 2017 session: Kansas lawmakers balk at sin taxes, also decline loosening marijuana laws GRANHOLM REDUX: ILLINOIS JUDGE GIVES VICTORY TO STATE-BASED THREE-TIER SYSTEM Slow and Steady Wins the Direct Shipping Map STAG'S LEAP TRADEMARK CASE FIZZLES OUT UNITED STATES DISTRICT COURT SOUTHERN DISTRICT OF NEW YORK DIAGEO NORTH AMERICA, INC., Plaintiff,v. W.J. DEUTSCH & SONS LTD. d/b/a DEUTSCH FAMILY WINE & SPIRITS, and BARDSTOWN BARREL SELECTIONS LLC, Defendants. (Excerpt) Connecticut: Federal Court Dismisses Anti-Trust Challenge To Connecticut's Liquor Pricing Law BOSTON GLOBE: WAS HUNTERDON FINE PART OF "QUID PRO QUO" ARRANGEMENT? Bill passes United States House with swipe fee protections intact Ninth Circuit Hands Down Rare Victory for Three-Tier En Banc Opinion Could Set Precedent for Tied-House Laws TTB NEWSLETTER FDA Begins Winery Inspections Wine-production facilities must have current registration, comply with Food Safety Modernization Act KANSAS: Appellate Reversal of Conviction for Contempt Thwarted Southeast "Mega" -

Swedish Kitchen Products Since 1932

Swedish Kitchen Products since 1932 DALO LINDÉN MOTTO what we do, we do well. With Swedish simplicity, Swedish ingenuity, and Swedish fortitude, we strive to bring the best products to the market — the classic Jonas™ original vegetable peeler is one of the many examples of products designed for their timeless form and function. 1 Kitchen Tools for Chefs & Cooks | lindensweden.com 1932 2003 2017 Filip Linden began making pastry Linden International AB opened Daloplast AB and Lindén International brushes out of his garage. Word Linden Sweden USA, in Edina AB merged after many years of soon spread about the quality and Minnesota. We feel that “Linden cooperation. Two strong brands and craftsmanship of Linden's brushes. Sweden USA” is Sweden. With companies from the same creative He began making other items and the reputation of an entire country region in southern Sweden, formed the his products were soon known for on the line, we make sure that the household group Dalo Lindén. their simple elegance yet usability. Swedish tradition of design, quality, function and service can be found Dalo Lindén currently owns and Linden’s lessons about the in everything in this catalog. operates 3 separate manufacturing importance of designing useable facilities in Sweden, a US and Russian tools that also looked good became a Linden Sweden USA caters to at distribution facility and maintains cornerstone for the Linden’s business. home and professional chefs, and product representation in 23 countries. One of the company’s early products prides themselves in making sure We are a global company committed to – the Jonas Vegetable Peeler - is a that the focus continues to honor providing our customers with sensible, perfect example of what happens Filip Linden’s original vision – great quality products that are designed to when you blend great design with looking products that work well. -

Mocktails Summer Living

IDEASheet - Mocktails Summer Living We are back in the summer mode! Mocktail recipes are the Summer Living Special We share four versions, each with a berry, a citrus and an herb sweeteners are simple syrup OR agave syrup (simple syrup recipe below, agave can be purchased at most grocery stores) As a tip to adults- you can add a botanical gin to each of these drinks, 1-½ ounces per drink, I recommend my favorite, Hendrick’s Gin. A nice cocktail set up makes these easy. Visit mymostlife.com for details and visual review of tools needed. You can also find us on YouTube and watch our mocktail video series on mymostlifetv on YouTube Follow us on Facebook facebook.com/mymostlife twitter @mofaul1 Living Mocktails | MYMOSTLIFE.COM 1 Berry Ginger Cooler Tools needed Cocktail Shaker Cocktail strainer Citrus handheld juicer Cocktail muddler Ice for shaker Festive glass and decorative straw to serve drink Ingredients 6 blackberries in cocktail shaker, then muddle in the cocktail shaker 56 mint sprigs shake, twist and tear then muddle with berries 2 inches of ginger root, cut and twisted to open the flavor 1 whole lime, cut in half and juice lime into shaker 2 Tblsps. Agave syrup into shaker Add one full cup of ice Close cocktail shaker Shake vigorously and then shake again Open cocktail mixer and place strainer over shaker Add geometric ice cubes to your party glass POUR cocktail shaker contents using strainer over the ice in glass Add all natural ginger ale to glass to fill the glass and stir gently Top glass with mint sprig and place straw serve well!! Enjoy your MOST LIFE Mocktail. -

Cheeky Cocktail Book

The Cheeky Cocktail Book Of Drinks To Make At Home Table of Contents Intro ...1 Tools ...3-4 Building vs. Batching ...6-8 How to Read Recipes ...9 Cocktails By Spirit Vodka ... 11 Gin ...17 Rum ...23 Tequila ...29 Whiskey ...34 If you’re already a professional bartender or a beginner home enthusiast, the world of mixology has endless possibility for creativity and playfulness. To support your adventures using Cheeky Cocktail Syrups and Juices we offer you these suggestions for recipes and service. However you decide to shake, stir, batch, or mix your magic...this practice of making drinks is about finding your own flavor and balance. 1 To Make the Cocktails in this Book You Will Need... 1 ounce 2 ounce Jigger 32 oz Widemouth Strainer Cocktail Shaker Bar Spoon Ball Jar 3 No bar tools? Try substituting with some of these household items A shot glass A Pint glass is A Jar or a Measuring Cup for a jigger. easy to batch Only batching? All you need is Usually holds in, or mix a ball jar or something with 1.5-2oz in drinks. measuring lines on the side. volume 4 Build Like The Pros Most people start making cocktails one at a time. This is called “building” a cocktail. Each ingredient is added one at a time to a shaker tin/mixing glass or directly into the serving glass. Ice is added, and you might have to shake, stir or simply add a mixer like seltzer or juice. Then the drink is strained from the mixing glass ( if you are using one) . -

The Bartender's Best Friend

The Bartender’s Best Friend a complete guide to cocktails, martinis, and mixed drinks Mardee Haidin Regan 00 bartenders FM_FINAL 8/26/02 3:10 PM Page ii 00 bartenders FM_FINAL 8/26/02 3:10 PM Page i The Bartender’s Best Friend 00 bartenders FM_FINAL 8/26/02 3:10 PM Page ii 00 bartenders FM_FINAL 8/26/02 3:10 PM Page iii The Bartender’s Best Friend a complete guide to cocktails, martinis, and mixed drinks Mardee Haidin Regan 00 bartenders FM_FINAL 8/26/02 3:10 PM Page iv This book is printed on acid-free paper. Copyright © 2003 by Mardee Haidin Regan. All rights reserved Published by John Wiley & Sons, Inc., Hoboken, New Jersey Published simultaneously in Canada No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permis- sion of the Publisher, or authorization through payment of the appropriate per- copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 750-4470, or on the web at www.copy- right.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, e-mail: [email protected]. Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. -

Bar Basics 1 Bar Basics

BAR BASICS 1 BAR BASICS Equipment THE RIGHT TOOLS make mixing drinks easier, but some tasks sim- ply can’t be done without the right gizmo. BOSTON SHAKER: Two-piece set comprised of a mixing glass and a slightly larger metal container that acts as a cover for the mix- ing glass for shaking cocktails. The mixing glass can be used alone for stirring drinks that aren’t shaken. BARSPOON: Long-handled, shallow spoon with a twisted handle, used for stirring drinks. HAWTHORNE STRAINER: Perforated metal top for the metal half of a Boston shaker, held in place by a wire coil. Serves as a strainer. JULEP STRAINER: Perforated, spoon-shaped strainer used in con- junction with a mixing glass. COCKTAIL SHAKER: Metal pitcher with a tight-fi tting lid, under which sits a strainer. While styles vary widely, the popular retro- style pitcher has a handle as well as a spout that’s sealed with a twist-off cap. ELECTRIC BLENDER: Absolutely necessary to make frozen drinks, puree fruit, and even crush ice for certain recipes. CUTTING BOARD: Either wood or plastic, it is used to cut fruit upon for garnishes. PARING KNIFE: Small, sharp knife to prepare fruit for garnishes. MUDDLER:COPYRIGHTED Looks like a wooden pestle, theMATERIAL fl at end of which is used to crush and combine ingredients in a serving glass or mixing glass. GRATER: Useful for zesting fruit or grating nutmeg. cc01_3p.p.indd01_3p.p.indd 1 88/29/08/29/08 22:36:27:36:27 PPMM 2 MR. BOSTON: OFFICIAL BARTENDER’S GUIDE BOTTLE OPENER: Essential for opening bottles that aren’t twist-off. -

Private Party & Catering Menu

Private Party & Catering Menu On average, we recommend selecting four to eight trays depending on whether you want light snacks, heavy hors d’oeuvres / meal or somewhere in the middle. (Typically, trays serve 20 - 25 people) We can assist with selecting specifics to ensure a good spread! Cheese Tray * $80 Deviled Eggs $50 Assorted artisan cheeses, honey, marcona almonds House-made sous vide deviled Charcuterie Tray * $80 4 Flatbreads $48 (Blackstone only) Chicken Pesto, Bacon Cheddar, Pulled Pork, Mushroom Cured meats, grain mustard, pickled onions Fruit Tray $45 8 Bruschettas $40 (Blackstone only) Fresh Tomato, Salmon, Pig/Fig, Warm Apple, Bacon Seasonal fruit with dipping sauce Vegetable Tray $45 Pulled Pork Sliders $60 Seasonal vegetable with dipping sauce BBQ sous vide pulled pork on brioche bun Red Pepper Hummus * $30 Mac & Cheese $60 Hummus with sliced cucumber & flatbread chips Radiatore, cheese sauce, topped cheddar & gruyere Spinach Artichoke Dip * $60 Mini Quiches $55 Blend of cheeses, artichoke hearts & spinach Homemade, meat or veggie quiches Smoked Salmon Tray * $65 Salad $30 Smoked salmon, lemon caper aioli & garlic bread Corkscrew Chopped (Lemon & Balsamic Vinaigrette) Shrimp Cocktail $65 Chocolate Truffles $30 Tail-on shrimp served with homemade cocktail sauce Truffles. The perfect one bite dessert! Thai Chicken Skewers $95 Flourless Chocolate Cake $60 White chicken with house-made peanut sauce *Items served with bread Meatballs $65 Warm meatballs tossed in house-made BBQ sauce Contact Information [email protected] [email protected] Rockbrook Phone: 402-991-2927 Blackstone Phone: 402-933-3150 Private Party Drink Packages Wine Beer - $5/per bottle Riesling (Sweet White), Chardonnay (Dry White), Pinot We offer 4 beer bottle options. -

COCKTAILS - - - Section One

CAFE ROYAL COCKTAIL BOOK Compiled by W. J. TARLING Illustrated by FREDERICK CARTER Decorated by THE CHEVRON STUDIO PUBLICATIONS FROM PALL MALL LTD 43 DUKE STREET, ST. JAMES', LONDON, S.W.i MADE AND PRINTED IN GREAT BRITAIN BY THE SIDNEY PRESS LTD., LONDON AND BEDFORD [Sketched by Wykeham Studios ALL Royalties derived by W. J. Tarling from this book are to be equally divided between The United Kingdom Bartenders' Guild Sickness Benefit Fund and The Cafe Royal Sports Club Fund. Contents COCKTAILS - - - Section One OTHER DRINKS - - Section Two INDEX to names of cocktails whose vast number prevents inclusion of . recipes in this book - - - Section Three GLOSSARY - - - Section Four Coronation Edition 1937 Preface O compile this book of Cocktails has been no easy task since it has entailed minutely examining over four thousand recipes, and to keep the book within reasonable bounds it has been only possible to give a selection of the most suitable cocktails. The majority of recipes are the originals of Members of the United Kingdom Bartenders' Guild, of which I have the honour to be President, and I can assure my readers that if they will follow these recipes carefully they will be able to enjoy many drinks with which they were hitherto unacquainted. Careful observation has shown that at the majority of Cocktail parties there is little variation in the cocktails offered, and each party is apt to have a monotonous repetition of Martini, Bronx, Manhattan, and White Lady Cocktails, all, I grant, very good cocktails indeed, but just as apt to be dull as continuous dinners at which the same soup, fish, meat and sweet are served. -

Bartender Job Analysis for the Pub*

Bartender Job Analysis for the Pub* By Michelle Allen Sean Enright Nathan Jansch Daniel Lehmann Greg Schaefer Note: This was an excellent paper at its time, but many of the requirements have since changed a bit. So look at it for general ideas, but not for details. Management 4020 Professor Rossé December 7, 1999 * Not really the name of the establishment xxxxxx Pub xxxxxxxx Boulder, CO 80302 Dear Mr. xxxxxx, Thank you for allowing us to complete a job analysis on the bartender position at the Pub. We have all learned some very valuable information about the hiring process this semester in our hiring class at CU, and your allowing us to evaluate the bartender position has greatly aided in that learning process. The bartending position at the Pub restaurant and bar requires a number of critical attributes and skills in to properly fulfill the restaurant’s desire to serve its guests. Because of the relatively small size of the restaurant and high demand on restaurant’s services, the bartending position requires a fully competent and capable person to fill the position. With a wide array of potential responsibilities, and because of the Pub’s desire to serve their patrons in the best manner possible, we have developed a system to better identify bartending candidates for this establishment. Rather than basing the application review process solely upon interviews (which is a common hiring method), this system incorporates a number of components in order to obtain a complete and accurate assessment of potential bartending employees. This system utilizes the best elements of an application, interviews, work samples, and other review elements to select the best applicants for the job. -

Highly Recommended Non-Chain Restaurants in Bonita Springs, Naples, Ft

Highly Recommended Non-Chain Restaurants in Bonita Springs, Naples, Ft. Myers All phone numbers are 239 area codes HYATT Tanglewood (American cuisine and grill) ext. 4290 Tarpon Bay (Seafood; steaks; ceviche) ext. 4295 ITALIAN / MEDITERRANEAN Angelina’s Restaurant 24041 S. Tamiami Trail, Bonita Springs 390-3187 Elegant dining; homemade Italian cuisine from freshest ingredients. Over 400 wine selections. Hours: 4:00-10:00 pm. Close Mondays in summer. On S. Tamiami Trail (US 41) l, ½ mile South of Coconut Point, across from Landmark Ship. South Folk Grille 23161 Village Shops Way, Estero 992-5040 Modern American bistro with Italian touches. Gourmet cuisine. Wine and beer. Music Thu.-Sat. Divieto Ristorante 23161 Village Shops Way 390-2977 Casual Italian with an upscale atmosphere, and a decor reminiscent of the 1920’s. Fine cuisine. In the Coconut Point Mall, 2 miles from Resort – use first right turn off US 41. Tony Sacco’s Coal Oven Pizza 8001 Plaza del Lago, Estero 948-6697 In the In the Coconut Point Mall – use second right turn off US 41, over the bridge, by the Turtle Ponds. La Fontanella Ristorante 24600 S. Tamiami Trail, Bonita Springs 498-6808 Gourmet Italian, Tuscany cuisine. Wine and Beer only. DeRomo’s Restaurant 26815 South Bay Drive, Bonita Springs 325-3583 Indoor/Outdoor dining. Bright, upscale fresh Italian cuisine. Gourmet market on premises. South 3 miles to Promenade; turn right on South Bay Drive, then left onto service drive to parking. Molino’s Italian Ristorante 26841 South Bay Drive, Bonita Springs 992-7025 Gourmet Italian cuisine. Indoor / outdoor dining.