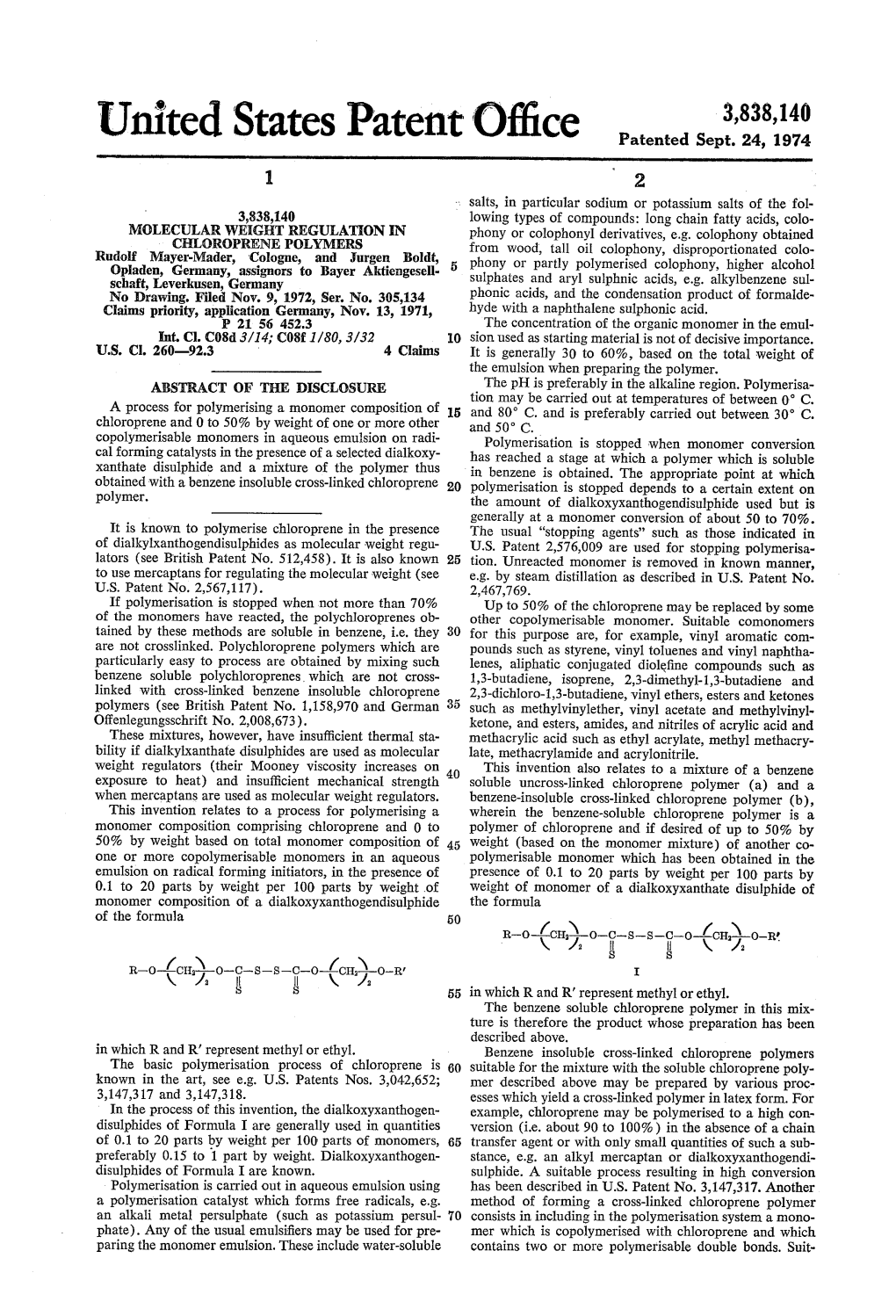

United States Patent Office Patented Sept

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Comparative Durability and Abrasion Resistance of Natural and Synthetic

Comparative Durability and Abrasion Resistance of Natural and Synthetic Latex Gloves Ryan Michel2 and Katrina Cornish1,2 Department of Horticulture and Crop Science, 2Department of Food, Agricultural and Biological Engineering, Ohio Agricultural Research and Development Center, The Ohio State University, Wooster, OH 44691 Abstract Medical gloves assist with the prevention of the spread of germs and are required to be worn when working with blood, body tissues, mucous membrane, and broken skin. They should provide good protection between hands and bio hazardous fluids to prevent contamination and promote safety of all healthcare workers and patients. Hence, it is critical for medical gloves to meet a standard performance criterion. Under ASTM D 3577 and D 3578, medical gloves have requirements they must meet in order to be sold and distributed as new gloves. However, there are no industry standards for gloves to meet while in use. The goal of this project was to develop a standard test for glove durability after their initial use. For the tests, gloves were worn by a mechanized prosthetic hand that was put under different conditions which are normally experienced by professionals in the medical field. This design was developed and later confirmed by Dr. Katrina Cornish: Design: Effects of media outside the glove Phosphate buffered saline (PBS), 70% ethanol, air Gloves Tested: Chloroprene, Latex 2, Nitrile, Polyvinyl Chloride and Latex 1 To evaluate glove durability during use, the gloves were immersed in different media before being subjected to contact with an abrasive surface. From this design, ranking of commercially available gloves are developed based on the time until failure of the gloves in these tests. -

Chemical Resistance List

Chemical Resistance List Resistance Substance Permeation Time/Level to Degradation Fluoro- natural chloro- nitrile/ nitrile carbon butyl latex prene chloroprene rubber NR CR CR NBR FKM IIR NR NR CR CR NBR NBR NBR NBR NBR FKM IIR IIR NBR NBR 395 450, 451 720, 722 717 727 730, 732 740, 741 743 754 764 890 897 898 chemical physical 403 706 723, 725 733, 836 742, 757 state 708 726 736 - 739 759 - 0 - 0 0 + 1-methoxy-2-propanol paste 4 2 2 3 4 4 B 1 3 4 6 6 - 0 - 0 0 + 1-methoxy-2-propyl acetate liquid 3 1 1 3 3 A B 2 3 6 6 - 0 0 - 0 + 1-methyl-2-pyrrolidone liquid 5 2 3 3 3 2 A B 1 3 3 6 6 - 0 + + + - 1,1,2-trichlorotrifluoroethane liquid 1 0 5 4 6 6 1 1 2 1 6 1 2 - - - - - - 1.2-epoxy ethane (ethylene oxide) liquid B A A A A 0 0 0 B 1 2 - - - - - - 1.2-epoxy propane (propylene oxide) liquid B A A A 1 A 0 0 0 B 1 2 + + + + + + 1.2-propanediol liquid 6 6 6 6 6 6 6 6 6 6 6 6 6 - + - + + 0 2-ethyl hexyl acrylate liquid 2 1 1 5 6 1 1 2 6 2 3 - 0 0 0 + + 2-mercaptoethanol liquid 3 2 4 4 4 4 1 1 3 6 6 6 - - - 0 0 - 2-methoxy-2-methyl propane liquid 1 B B 2 4 A 1 4 1 3 2 2 - - - - - 0 3-hexanone liquid 1 B 1 1 1 0 0 0 0 0 3 3 - - - - - 0 4-heptanone liquid 1 A 1 1 1 A 0 0 0 B 3 3 - - - - - + acetaldehyde liquid 1 1 1 1 B 0 0 0 A 0 6 6 0 0 0 - - + acetic acid anhydride liquid 6 3 3 3 3 2 A B 1 B 2 6 6 + + + + + + acetic acid, 10 % liquid 6 6 6 6 6 6 6 6 6 6 6 6 6 0 + + + + + acetic acid, 50 % liquid 5 4 6 6 6 2 4 6 6 6 6 - - - - 0 + acetic acid, conc. -

Download Author Version (PDF)

RSC Advances This is an Accepted Manuscript, which has been through the Royal Society of Chemistry peer review process and has been accepted for publication. Accepted Manuscripts are published online shortly after acceptance, before technical editing, formatting and proof reading. Using this free service, authors can make their results available to the community, in citable form, before we publish the edited article. This Accepted Manuscript will be replaced by the edited, formatted and paginated article as soon as this is available. You can find more information about Accepted Manuscripts in the Information for Authors. Please note that technical editing may introduce minor changes to the text and/or graphics, which may alter content. The journal’s standard Terms & Conditions and the Ethical guidelines still apply. In no event shall the Royal Society of Chemistry be held responsible for any errors or omissions in this Accepted Manuscript or any consequences arising from the use of any information it contains. www.rsc.org/advances Page 1 of 10Journal Name RSC Advances Dynamic Article Links ► Cite this: DOI: 10.1039/c0xx00000x www.rsc.org/xxxxxx ARTICLE TYPE Reverse Iodine Transfer Polymerization (RITP) of Chloroprene Jia Hui, Yan Shi,* Tao Li, Jie Wu and Zhifeng Fu Received (in XXX, XXX) Xth XXXXXXXXX 20XX, Accepted Xth XXXXXXXXX 20XX DOI: 10.1039/b000000x 5 State Key Laboratory of Chemical Resource Engineering, Beijing University of Chemical Technology, Beijing 100029, China E-mail: [email protected] Fax: +86-010-64423811; Tel: +86-010-64416783 10 Reversible-deactivation radical polymerization (RDRP) of chloroprene (2-chloro-1,3-butadiene, CP) using reverse iodine transfer polymerization (RITP) has been demonstrated for the first time. -

Vinyl Chloride Production

Vinyl Chloride Production Capstone Design Project Spring 2003 Chemical Engineering -University of Oklahoma Jeremy Dry Bryce Lawson Phuong Le Israel Osisanya Deepa Patel Anecia Shelton Vinyl Chloride Production Plant Table of Contents Section 1: Introduction............................................................................................5 Section 2: Available Processes ................................................................................5 2.1 Vinyl Chloride from Acetylene ...............................................................5 2.2 Vinyl Chloride from Ethane.....................................................................6 2.3 Vinyl Chloride from Ethylene .................................................................6 Section 3: Process Design ........................................................................................7 3.1 Thermodynamics......................................................................................7 3.2 Balanced Process Overview ....................................................................7 3.3 Balance Process Outline ..........................................................................7 3.4 Direct Chlorination Reactor Design.........................................................8 3.5 Direct Chlorination Process Simulation...................................................9 3.6 Direct Chlorination Control and Instrumentation....................................10 3.7 Oxychlorination Reactor Design..............................................................10 -

3,4-Dichlorobut-1-Ene Cas N°: 760-23-6

OECD SIDS 3,4-DICHLOROBUT-1-ENE FOREWORD INTRODUCTION 3,4-DICHLOROBUT-1-ENE CAS N°: 760-23-6 UNEP PUBLICATIONS OECD SIDS 3,4-DICHLOROBUT-1-ENE SIDS INITIAL ASSESSMENT PROFILE CAS No. 760-23-6 Chemical Name 3,4-Dichlorobut-1-ene Structural Formula CH2=CH-CHCl-CH2Cl RECOMMENDATIONS The chemical is a candidate for further work. SUMMARY CONCLUSIONS OF THE SIAR Human Health Oral LD50 and inhalation LC50 of 3,4-dichlorobut-1-ene (3,4-DCB) are about 940 mg/kg and 2100 ppm, respectively. Inhalation repeated dose study in rats conducted for 14 days, 6 hours/day, 5 days/week at doses of 104 mg/m3 (20 ppm) and 1037 mg/m3 (200 ppm) of 3,4-DCB. Relative liver weight increased and change in liver cell morphology was observed at 1037 mg/m3 dose. This chemical is slightly irritating to skin and eyes. Acute skin irritation in rabbits according to OECD TG 404 causes erythema but does not cause systemic intolerance reaction. Acute eye irritation study by instillation into the conjunctival sac of rabbits according to OECD TG 405 causes corneal opacity and conjunctival redness but does not cause systemic intolerance reaction. In an oral study in rats by OECD combined repeated dose and reproductive/developmental toxicity screening test [OECD TG 422] at doses of 0, 0.4, 2, 10 and 50 mg/kg/day for at least 44 days, organ weight and histopathological changes were induced. In males, absolute kidney weights were slightly increased with 10 mg/kg and absolute and relative weights of the liver and kidneys were increased with 50 mg/kg. -

Organic Toxic Substances Monitoring in Virginia

W&M ScholarWorks Dissertations, Theses, and Masters Projects Theses, Dissertations, & Master Projects 1983 Organic toxic substances monitoring in Virginia Robert Emile. Croonenberghs College of William and Mary - Virginia Institute of Marine Science Follow this and additional works at: https://scholarworks.wm.edu/etd Part of the Environmental Sciences Commons Recommended Citation Croonenberghs, Robert Emile., "Organic toxic substances monitoring in Virginia" (1983). Dissertations, Theses, and Masters Projects. Paper 1539616622. https://dx.doi.org/doi:10.25773/v5-vdbf-8m78 This Dissertation is brought to you for free and open access by the Theses, Dissertations, & Master Projects at W&M ScholarWorks. It has been accepted for inclusion in Dissertations, Theses, and Masters Projects by an authorized administrator of W&M ScholarWorks. For more information, please contact [email protected]. INFORMATION TO USERS This reproduction was made from a copy of a document sent to us for microfilming. While the most advanced technology has been used to photograph and reproduce this document, the quality of the reproduction is heavily dependent upon the quality of the material submitted. The following explanation of techniques is provided to help clarify markings or notations which may appear on this reproduction. 1.The sign or “target” for pages apparently lacking from the document photographed is “Missing Page(s)”. If it was possible to obtain the missing page(s) or section, they are spliced into the film along with adjacent pages. This may have necessitated cutting through an image and duplicating adjacent pages to assure complete continuity. 2. When an image on the film is obliterated with a round black mark, it is an indication of either blurred copy because of movement during exposure, duplicate copy, or copyrighted materials that should not have been filmed. -

Vinyl Chloride Production Senior Design Presentation

Vinyl Chloride Production Senior Design Presentation Group 10 Jeremy Dry Israel Osisanya Bryce Lawson Deepa Patel Phuong Le Anecia Shelton Project Purpose To design an environmentally safe vinyl chloride production plant. Questions: What is Vinyl Chloride? How its being produced? How much does it cost to be environmentally friendly? Vinyl Chloride 99% of VCM is used to manufacture polyvinyl chloride (PVC). PVC consumption is second to low density polyethylene. VCM production results in a number of unwanted by-products. VCM Plant Emissions in the United States 0.0008 0.0007 0.0006 0.0005 0.0004 0.0003 lb/lb VCM product 0.0002 0.0001 0 123456789 1 Formosa-LA 4 Georgia Gulf-LA 7 Borden-LA 2 Oxyvinyls-D-TX 5 Westlake Monomers-KY 8 Dow-LA 3 Oxyvinyls-L-TX 6 Formosa-TX 9 Dow-TX Manufacturing Methods Vinyl Chloride from Acetylene Vinyl Chloride from Ethane Vinyl Chloride from Ethylene (Direct Route) Vinyl Chloride from Ethylene (EDC) Balanced Process for Vinyl Chloride Production Direct chlorination CH2CH2 + Cl2 → ClCH2CH2Cl (EDC) Oxychlorination CH2CH2 + 2 HCl + ½ O2 → EDC+ H2O EDC pyrolysis 2 EDC → 2 CH2CHCl (VCM) + 2 HCl Overall reaction 2 CH2CH2 + Cl2 + ½ O2 → 2 CH2CHCl + H2O •No generation of HCl •95% of the world’s VCM is produced utilizing the balanced process Balanced Process for Vinyl Chloride Production HCl recycle Air or O2 Light ends Oxy- chlorination VCM Ethylene EDC EDC purification purification pyrolysis VCM EDC recycle Direct Cl chlorination 2 Heavy ends Direct Chlorination and Oxychlorination P&ID CAUSTIC SCRUBBERS OXYDC REACTOR -

ELMER KEISER BOLTON June 23, 1886-Jidy 30, 1968

NATIONAL ACADEMY OF SCIENCES E LMER KEISER BOLTON 1886—1968 A Biographical Memoir by RO BE R T M. J O Y C E Any opinions expressed in this memoir are those of the author(s) and do not necessarily reflect the views of the National Academy of Sciences. Biographical Memoir COPYRIGHT 1983 NATIONAL ACADEMY OF SCIENCES WASHINGTON D.C. ELMER KEISER BOLTON June 23, 1886-Jidy 30, 1968 BY ROBERT M. JOYCE LMER KEISER BOLTON was one of the outstanding leaders E of industrial research. He became an industrial re- search director at a time when research was only beginning to be a significant factor in the chemical industry. There were no models for this new role, and Bolton's concepts of direct- ing industrial research were in large measure those that he formulated himself, reflecting his vision and drive to achieve important commercial goals. The record of industrial products developed by Du Pont research organizations that he directed is impressive; it in- cludes synthetic dyes and intermediates, flotation chemicals, rubber chemicals, neoprene synthetic rubber, nylon synthetic fiber, and Teflon® polytetrafluoroethylene resin. His leader- ship in bringing these developments to fruition was always apparent to management and to those he directed, but be- cause of his characteristic self-effacement his name is not widely associated with these accomplishments. Throughout his career he supported and encouraged his technical person- nel. Most important, he had the knack of picking the right time and direction to take in moving a research lead into development. Many of his decisions proved crucial to the ultimate success of these ventures. -

What Is Showa Denko Chloroprene?

Polychloroprene Rubber 2 What is Showa Denko Chloroprene? Well balanced elastomer CR Elasticity Oxidation resistance Heat resistance Oil resistance Showa Denko Chloroprene CR CR CR CR (CR) is a type of synthetic NR NR NR NR rubber used as an elastomer SBR SBR SBR SBR NBR NBR NBR NBR in the automotive (belts and EPDM EPDM EPDM EPDM hoses), construction (waterproofing and sealing), Poor Excellent Poor Excellent Poor Excellent Poor Excellent wire and cable, adhesives, and countless other industries. Showa Denko Chloroprene has been Low temperature resistance Compression set Gas transmission resistance Weather resistance produced for over 50 years and continues to expand CR CR CR CR NR NR NR NR its application fields. The properties of Showa SBR SBR SBR SBR Denko Chloroprene is highlighted by the a wide range NBR NBR NBR NBR EPDM EPDM EPDM EPDM of resistances to sun, ozone, and weathering, many Poor Excellent Poor Excellent Poor Excellent Poor Excellent oils and chemicals, low and high temperatures, flame, and toughness against abrasion and general Ozone resistance Abrasion resistance Insulation resistance Flame resistance wear. The versatile properties have long been the CR CR CR CR key to Showa Denko Chloroprene’ s utility as a NR NR NR NR SBR SBR SBR SBR multi-purpose rubber. The product is available in NBR NBR NBR NBR over 40 grades, produced as either a dry chip or EPDM EPDM EPDM EPDM aqueous dispersion (Latex). Poor Excellent Poor Excellent Poor Excellent Poor Excellent *These figures are only for reference purposes and therefore do not -

Toxicological Review (PDF)

EPA/635/R-09/010F www.epa.gov/iris TOXICOLOGICAL REVIEW OF CHLOROPRENE (CAS No. 126-99-8) In Support of Summary Information on the Integrated Risk Information System (IRIS) September 2010 U.S. Environmental Protection Agency Washington, DC DISCLAIMER This document has been reviewed in accordance with U.S. Environmental Protection Agency policy and approved for publication. Mention of trade names or commercial products does not constitute endorsement or recommendation for use. ii TABLE OF CONTENTS LIST OF TABLES.................................................................................................................................... v LIST OF FIGURES ................................................................................................................................. ix LIST OF ABBREVIATIONS AND ACRONYMS ................................................................................ xi FOREWORD.........................................................................................................................................xiii AUTHORS, CONTRIBUTORS, AND REVIEWERS ......................................................................... xiv 1. INTRODUCTION ................................................................................................................................ 1 2. CHEMICAL AND PHYSICAL INFORMATION .............................................................................. 3 3. TOXICOKINETICS............................................................................................................................ -

Announcement of Acquisition of Chloroprene Rubber Business from Dupont, U.S

December 11, 2014 To Whom It May Concern DENKI KAGAKU KOGYO KABUSHIKI KAISHA MITSUI & CO., LTD. Announcement of Acquisition of Chloroprene Rubber Business from DuPont, U.S. DENKI KAGAKU KOGYO KABUSHIKI KAISHA (Headquarter: Chuo-ku, Tokyo; Shinsuke Yoshitaka, President & CEO, hereinafter “DENKA”) and MITSUI & CO., LTD. (Headquarter: Chiyoda-ku, Tokyo; Masami Iijima, President & CEO, hereinafter “Mitsui”) are pleased to announce that DENKA and Mitsui decided to establish Denka Performance Elastomer, a joint venture company with the capital ratio of 70% by DENKA and 30% by Mitsui (“DPE”), in the U.S., and to enter into an agreement with DuPont, an international diversified chemicals manufacturer, for an acquisition (the “Acquisition”) of DuPont’s business relating to the manufacture and sale of chloroprene rubber (“CR”) business (the “Subject Business”) and that DENKA and Mitsui entered into such agreement with DuPont on December 9, 2014. We aim to complete the Acquisition during the 1st half of 2015, subject to official approvals of competent authorities. * What is CR CR is a synthetic rubber which is easy to process and has a strong balance of excellent properties such as weather resistance, ozone resistance, oil resistance, abrasion resistance, flame retardance, heat resistance, etc. CR is used for a wide range of application such as transmission belts and automotive parts, foam rubber, adhesives, etc. There are two methods to manufacture CR, acetylene method and butadiene method, of which main raw materials differ. 1. Purpose of Acquisition In 1962, DENKA commenced the manufacture and sale of CR at the Omi plant (Itoigawa-city, Niigata) by using its own technology (acetylene method), and currently is one of the largest CR manufacturer supplying in approximately 80 countries worldwide. -

Universiv Micrdrilms International 300 N

INFORMATION TO USERS This reproduction was made from a copy of a document sent to us for microfilming. While the most advanced technology has been used to photograph and reproduce this document, the quality of the reproduction is heavily dependent upon the quality of the material submitted. The following explanation of techniques is provided to help clarify markings or notations which may appear on this reproduction. 1.The sign or “target” for pages apparently lacking from the document photographed is “Missing Page(s)”. If it was possible to obtain the missing page(s) or section, they are spliced into the film along with adjacent pages. This may have necessitated cutting through an image and duplicating adjacent pages to assure complete continuity. 2. When an image on the film is obliterated with a round black mark, it is an indication of either blurred copy because of movement during exposure, duplicate copy, or copyrighted materials that should not have been filmed. For blurred pages, a good image of the page can be found in the adjacent frame. If copyrighted materials were deleted, a target note will appear listing the pages in the adjacent frame. 3. When a map, drawing or chart, etc., is part of the material being photographed, a definite method of “sectioning” the material has been followed. It is customary to begin filming at the upper left hand comer of a large sheet and to continue from left to right in equal sections with small overlaps. If necessary, sectioning is continued again-beginning below the first row and continuing on until complete.