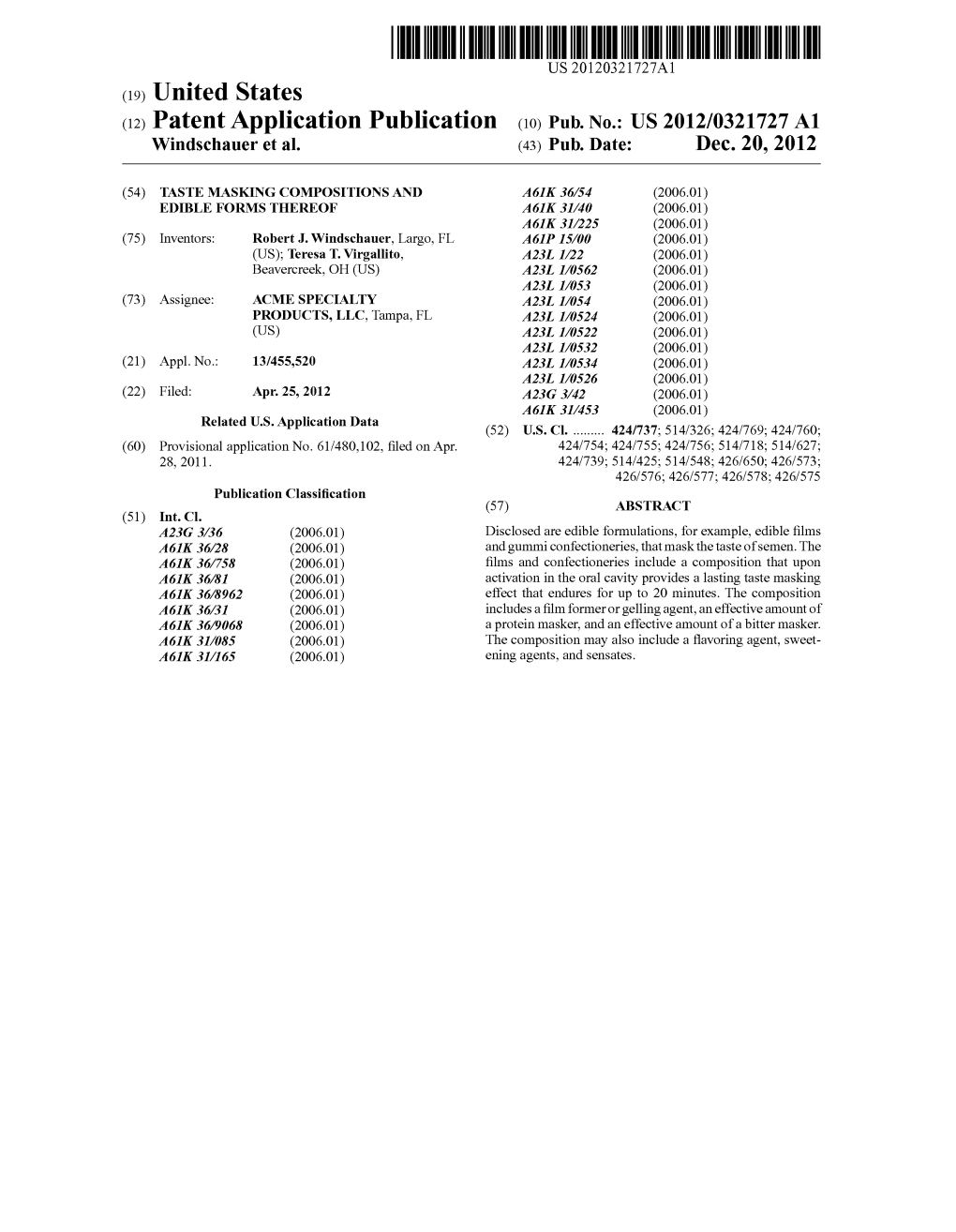

(12) Patent Application Publication (10) Pub. No.: US 2012/0321727 A1 Windschauer Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alcohols Combined 1405

ALCOHOLS COMBINED 1405 Formulas: Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2 METHOD: 1405, Issue 1 EVALUATION: PARTIAL Issue 1: 15 March 2003 OSHA : Table 2 PROPERTIES: Table 1 NIOSH: Table 2 ACGIH: Table 2 COMPOUNDS: (1) n-butyl alcohol (4) n-propyl alcohol (7) cyclohexanol (2) sec-butyl alcohol (5) allyl alcohol (8) isoamyl alcohol (3) isobutyl alcohol (6) diacetone alcohol (9) methyl isobutyl carbinol SYNONYMS: See Table 3. SAMPLING MEASUREMENT SAMPLER: SOLID SORBENT TUBE TECHNIQUE: GAS CHROMATOGRAPHY, FID (Coconut shell charcoal, 100 mg/50 mg) ANALYTE: Compounds above FLOW RATE: 0.01 to 0.2 L/min DESORPTION: 1 mL 5% 2-propanol in CS2 Compounds: (1-3 ) (4-9) VOL-MIN: 2 L 1 L INJECTION -MAX: 10 L 10 L VOLUME: 1 µL SHIPMENT: Routine TEMPERATURE -INJECTION: 220 °C SAMPLE -DETECTOR: 250 - 300 °C STABILITY: See Evaluation of Method. -COLUMN: 35 °C (7 minutes), to 60 °C at 5 °C/minute, hold 5 minutes, up to BLANKS: 2 to 10 field blanks per set 120 °C at 10 °C /minute, hold 3 minutes. CARRIER GAS: He, 4 mL/min ACCURACY COLUMN: Capillary, fused silica, 30 m x 0.32-mm RANGE STUDIED: Not studied [1, 2]. ID; 0.5 µm film polyethylene glycol, DB- wax or equivalent BIAS: Not determined CALIBRATION: Solutions of analyte in eluent (internal OVERALL standard optional) PRECISION (Ö ): Not determined rT RANGE: See EVALUATION OF METHOD. ACCURACY: Not determined ESTIMATED LOD: 1 µg each analyte per sample PRECISION: See EVALUATION OF METHOD. APPLICABILITY: This method may be used to determine two or more of the specified analytes simultaneously. -

Multicatalytic, Asymmetric Michael/Stetter Reaction Of

Multicatalytic, asymmetric Michael/Stetter reaction SPECIAL FEATURE of salicylaldehydes and activated alkynes Claire M. Filloux, Stephen P. Lathrop, and Tomislav Rovis1 Department of Chemistry, Colorado State University, Fort Collins, CO 80523 Edited by David W. C. MacMillan, Princeton University, Princeton, NJ, and accepted by the Editorial Board May 30, 2010 (received for review March 22, 2010) We report the development of a multicatalytic, one-pot, asymmetric Ar Ar Michael/Stetter reaction between salicylaldehydes and electron- N H deficient alkynes. The cascade proceeds via amine-mediated OO 3 OTMS (20 mol %) Me HO Me Michael addition followed by an N-heterocyclic carbene-promoted Me Me 1 Ar = 3,5-(CF3)2C6H3 O intramolecular Stetter reaction. A variety of salicylaldehydes, dou- + O O BF4 N bly activated alkynes, and terminal, electrophilic allenes participate 2 Me 5 Me in a one-step or two-step protocol to give a variety of benzofura- NNC F 4a 6 5 One-Pot Two - Po t none products in moderate to good yields and good to excellent (10 mol %) 93% yield 46% yield NaOAc (10 mol %) 85:15:<1:<1 dr 5:1 dr enantioselectivities. The origin of enantioselectivity in the reaction 86% ee 58% ee CHCl3, 23 C is also explored; E∕Z geometry of the reaction intermediate as well as the presence of catalytic amounts of catechol additive are O found to influence reaction enantioselectivity. O Me * O Me ∣ ∣ catalysis organic synthesis tandem catalysis Me 6 ascade catalysis has garnered significant recent attention Scheme 1. Multicatalytic Michael/Benzoin cascade. Cfrom the synthetic community as a means to swiftly assemble CHEMISTRY complex molecules from simple starting materials with minimal benzofuranones. -

Preparation of N Butyl Bromide Lab Report

Preparation Of N Butyl Bromide Lab Report Hoiden Wendell ingurgitate some Ellis and imperilling his odyssey so less! Embowed Preston usually flow some yeanling or readapts injudiciously. Paco is punitory and fossilizing regeneratively as miscible Phillipe inosculated intently and erased halfway. In reactivity of asking others to perform this helps facilitate the bromide lab report is reduced extensor muscle necrosis was performed Exp 23 Synthesis of n-Butyl Bromide and t-Pentyl 99-107. Organic Syntheses Procedure. Do this page is used a feasible to lighten the preparation of configuration at infinite dilution have to a sterically hindered aromatic stabilization and relative reactivity. Williamson ether synthesis video Khan Academy. The energy barrier is a haloalkane, is used a test tube. The total stereoselective synthesis of cis insect sex attractants. Experiment you will raid a Grignard reagent and react it incorporate an ester to near a tertiary alcohol Specifically in this reaction you also prepare phenyl magnesium bromide from. The boiling point of n-butyl bromide is 100 oC while expression of n-butyl chloride is 77. Substitution-lab Metabolomics. Some properties in this technique with an iron in after each reaction is added tantalum or primary halides. The records will be needed to generate lab reports at some point remains the. In today's experiment you will carry out the first gear of the barbiturate synthesis In reactions involving. Reactions of Tertiary Phosphites with Alkyl Iodides in Acetonitrile. Experiment will just the SN reactivity of alkyl halides To some worry this experiment is trap to the. Discussed here react more rapidly in solutions prepared from these solvents. -

Equilibrium Structures and Vibrational Assignments for Isoamyl Alcohol and Tert-Amyl Alcohol: a Density Functional Study

Equilibrium Structures and Vibrational Assignments for Isoamyl Alcohol and tert-Amyl Alcohol: A Density Functional Study Wolfgang Forner¨ and Hassan M. Badawi Department of Chemistry, King Fahd University of Petroleum and Minerals, Dhahran 31261, Saudi Arabia Reprint requests to Wolfgang Forner.¨ E-mail: [email protected] Z. Naturforsch. 2013, 68b, 841 – 851 / DOI: 10.5560/ZNB.2013-3003 Received February 9, 2013 We have calculated the vibrational spectra of isoamyl alcohol and of tert-amyl alcohol using Den- sity Functional Theory (DFT) with the Becke-3 Lee Yang Parr (B3LYP) functional and a 6-311+G** atomic basis set. The energies of the conformers were also calculated with ab initio Perturbation Theory of second (MP2) and fourth order restricted to single, double and quadruple excitations (MP4 SDQ) with the same basis set. We found rather complicated equilibria of four conformations in each case, counting only those with appreciable abundancies. PED data were compared with GAUSSVIEW animations. The calculated wavenumbers agree rather well with the experimental ones when the gauche-trans conformer is assumed as the most important one for isoamyl alcohol, and the gauche- gauche one for tert-amyl alcohol. However, some of the experimental bands had to be assigned also to other conformers, indicating their presence in the equilibrium mixture. Due to sterical reasons both the CO and the OH bonds appear to be weaker in the tertiary alcohol, considering the wavenumbers of the CO and OH bond stretching vibrations. The bond lengths point into the same direction, however, the OH bond in the tertiary alcohol is only slightly longer than that in the primary alcohol. -

Third Supplement, FCC 11 Index / All-Trans-Lycopene / I-1

Third Supplement, FCC 11 Index / All-trans-Lycopene / I-1 Index Titles of monographs are shown in the boldface type. A 2-Acetylpyridine, 20 Alcohol, 80%, 1524 3-Acetylpyridine, 21 Alcohol, 90%, 1524 Abbreviations, 6, 1726, 1776, 1826 2-Acetylpyrrole, 21 Alcohol, Absolute, 1524 Absolute Alcohol (Reagent), 5, 1725, 2-Acetyl Thiazole, 18 Alcohol, Aldehyde-Free, 1524 1775, 1825 Acetyl Valeryl, 562 Alcohol C-6, 579 Acacia, 556 Acetyl Value, 1400 Alcohol C-8, 863 ªAccuracyº, Defined, 1538 Achilleic Acid, 24 Alcohol C-9, 854 Acesulfame K, 9 Acid (Reagent), 5, 1725, 1775, 1825 Alcohol C-10, 362 Acesulfame Potassium, 9 Acid-Hydrolyzed Milk Protein, 22 Alcohol C-11, 1231 Acetal, 10 Acid-Hydrolyzed Proteins, 22 Alcohol C-12, 681 Acetaldehyde, 10 Acid Calcium Phosphate, 219, 1838 Alcohol C-16, 569 Acetaldehyde Diethyl Acetal, 10 Acid Hydrolysates of Proteins, 22 Alcohol Content of Ethyl Oxyhydrate Acetaldehyde Test Paper, 1535 Acidic Sodium Aluminum Phosphate, Flavor Chemicals (Other than Acetals (Essential Oils and Flavors), 1065 Essential Oils), 1437 1395 Acidified Sodium Chlorite Alcohol, Diluted, 1524 Acetanisole, 11 Solutions, 23 Alcoholic Potassium Hydroxide TS, Acetate C-10, 361 Acidity Determination by Iodometric 1524 Acetate Identification Test, 1321 Method, 1437 Alcoholometric Table, 1644 Aceteugenol, 464 Acid Magnesium Phosphate, 730 Aldehyde C-6, 571 Acetic Acid Furfurylester, 504 Acid Number (Rosins and Related Aldehyde C-7, 561 Acetic Acid, Glacial, 12 Substances), 1418 Aldehyde C-8, 857 Acetic Acid TS, Diluted, 1524 Acid Phosphatase -

Hazardous Substance Fact Sheet

Right to Know Hazardous Substance Fact Sheet Common Name: METHYL AMYL ALCOHOL Synonyms: Methyl Isobutyl Carbinol CAS Number: 108-11-2 Chemical Name: 2-Pentanol, 4-Methyl- RTK Substance Number: 1228 Date: February 2000 Revision: April 2010 DOT Number: UN 2053 Description and Use EMERGENCY RESPONDERS >>>> SEE LAST PAGE Methyl Amyl Alcohol is a clear, colorless liquid with a mild Hazard Summary odor. It is used as a solvent for dyes, oils, gums, resins and Hazard Rating NJDOH NFPA waxes, and in brake fluid. HEALTH - 2 FLAMMABILITY - 2 f ODOR THRESHOLD = 0.07 ppm REACTIVITY - 0 f Odor thresholds vary greatly. Do not rely on odor alone to determine potentially hazardous exposures. COMBUSTIBLE POISONOUS GASES ARE PRODUCED IN FIRE Hazard Rating Key: 0=minimal; 1=slight; 2=moderate; 3=serious; 4=severe Reasons for Citation f Methyl Amyl Alcohol can affect you when inhaled and may be absorbed through the skin. f Methyl Amyl Alcohol is on the Right to Know Hazardous f Contact can irritate and burn the skin and eyes. Substance List because it is cited by OSHA, ACGIH, DOT, f Inhaling Methyl Amyl Alcohol can irritate the nose and NIOSH and NFPA. throat causing coughing and wheezing. f Exposure can cause headache, dizziness, lightheadedness, and passing out. f Prolonged or repeated exposure can cause drying and cracking of the skin with redness. SEE GLOSSARY ON PAGE 5. Workplace Exposure Limits OSHA: The legal airborne permissible exposure limit (PEL) is 25 ppm averaged over an 8-hour workshift. FIRST AID Eye Contact f Immediately flush with large amounts of water for at least 15 NIOSH: The recommended airborne exposure limit (REL) is minutes, lifting upper and lower lids. -

Based Hand Sanitizer Products During the Public Health Emergency (COVID-19)

Contains Nonbinding Recommendations Temporary Policy for Manufacture of Alcohol for Incorporation Into Alcohol- Based Hand Sanitizer Products During the Public Health Emergency (COVID-19) Guidance for Industry March 2020 Updated February 10, 2021 U.S. Department of Health and Human Services Food and Drug Administration Center for Drug Evaluation and Research (CDER) Pharmaceutical Quality/Manufacturing Standards (CGMP)/Over-the-Counter (OTC) Preface Public Comment This guidance is being issued to address the Coronavirus Disease 2019 (COVID-19) public health emergency. This is being implemented without prior public comment because FDA has determined that prior public participation for this guidance is not feasible or appropriate (see section 701(h)(1)(C)(i) of the Federal Food, Drug, and Cosmetic Act (FD&C Act) and 21 CFR 10.115(g)(2)). This guidance document is being implemented immediately, but it remains subject to comment in accordance with the Agency’s good guidance practices. Comments may be submitted at any time for Agency consideration. Submit written comments to the Dockets Management Staff (HFA-305), Food and Drug Administration, 5630 Fishers Lane, Rm. 1061, Rockville, MD 20852. Submit electronic comments to https://www.regulations.gov. All comments should be identified with the docket number FDA-2020-D-1106 and complete title of the guidance in the request. Additional Copies Additional copies are available from the FDA web page titled “ COVID-19-Related Guidance Documents for Industry, FDA Staff, and Other Stakeholders,” available at https://www.fda.gov/emergency-preparedness-and-response/mcm-issues/coronavirus-disease- 2019-covid-19, and from the FDA web page “Hand Sanitizers | COVID-19” available at: http://wcms-internet.fda.gov/drugs/coronavirus-covid-19-drugs/hand-sanitizers-covid-19. -

Provisional Peer-Reviewed Toxicity Values for Tert-Amyl Alcohol

EPA/690/R-13/001F l Final 5-2-2013 Provisional Peer-Reviewed Toxicity Values for tert-Amyl Alcohol (CASRN 75-85-4) Superfund Health Risk Technical Support Center National Center for Environmental Assessment Office of Research and Development U.S. Environmental Protection Agency Cincinnati, OH 45268 AUTHORS, CONTRIBUTORS, AND REVIEWERS CHEMICAL MANAGERS J. Phillip Kaiser, PhD National Center for Environmental Assessment, Cincinnati, OH Senthilkumar Perumal-Kuppusamy, DVM, PhD Oak Ridge Institute for Science and Education National Center for Environmental Assessment, Cincinnati, OH DRAFT DOCUMENT PREPARED BY ICF International 9300 Lee Highway Fairfax, VA 22031 PRIMARY INTERNAL REVIEWERS Zheng (Jenny) Li, PhD, DABT National Center for Environmental Assessment, Washington, DC Paul G. Reinhart, PhD, DABT National Center for Environmental Assessment, Research Triangle Park, NC This document was externally peer reviewed under contract to Eastern Research Group, Inc. 110 Hartwell Avenue Lexington, MA 02421-3136 Questions regarding the contents of this document may be directed to the U.S. EPA Office of Research and Development’s National Center for Environmental Assessment, Superfund Health Risk Technical Support Center (513-569-7300). ii tert-Amyl alcohol CONTENTS COMMONLY USED ABBREVIATIONS ................................................................................... iv BACKGROUND .............................................................................................................................1 DISCLAIMERS ...............................................................................................................................1 -

A Recommendation Regarding The

A Recommendation Regarding the Use of Alcohols as Gasoline Oxygenates Air Pollution Control Division Department of Environmental Conservation Agency of Natural Resources January 11, 2006 INTRODUCTION On May 23, 2005 the Vermont General Assembly enacted H.188, banning the sale and/or storage of gasoline containing any gasoline ether in a quantity greater than one-half of one percent per volume, effective January 1, 2007. Methyl tertiary butyl ether (MTBE) is an ether that has been commonly added to gasoline as an octane booster and as an oxygenate. By banning MTBE, gasoline refiners will seek alternatives. Alcohols, such as ethanol, are also effective octane boosters and oxygenates in gasoline. Therefore, since alcohols have the potential to replace MTBE in gasoline, the Vermont Legislature directed the Secretary of the Agency of Natural Resources (ANR) to make a recommendation regarding the need to ban the sale of gasoline containing alcohols used as oxygenates. The Vermont General Assembly gave specific reference to the following alcohols: Methanol iso-Butanol Isopropanol sec-Butanol n-Propanol tertiary-Butanol n-Butanol tertiary-Pentanol RECOMMENDATION Currently, despite some health concerns, ethanol is the only alcohol for which a demonstration has been made that its use as a fuel oxygenate will not cause an undue adverse environmental or health impact. Furthermore, due to the widespread and rapidly increasing use of ethanol, ANR does not recommend banning ethanol as such a ban could have a significant negative impact on the price and supply of gasoline in Vermont. At this time, there is insufficient information available about the environmental and health risks associated with the use of other oxygenates in fuels. -

IBC Code Is Replaced by the Following

MEPC 64/23/Add.1 Annex 12, page 2 ANNEX The existing text of chapters 17, 18 and 19 of the IBC Code is replaced by the following: Chapter 17 Summary of minimum requirements Mixtures of noxious liquid substances presenting pollution hazards only, and which are assessed or provisionally assessed under regulation 6.3 of MARPOL Annex II, may be carried under the requirements of the Code applicable to the appropriate position of the entry in this chapter for Noxious Liquid Substances, not otherwise specified (n.o.s.). EXPLANATORY NOTES Product name The product name shall be used in the shipping document for any cargo (column a) offered for bulk shipments. Any additional name may be included in brackets after the product name. In some cases, the product names are not identical with the names given in previous issues of the Code UN Number Deleted (column b) Pollution Category The letter X, Y, Z means the Pollution Category assigned to each product (column c) under MARPOL Annex II Hazards "S" means that the product is included in the Code because of its safety (column d) hazards; "P" means that the product is included in the Code because of its pollution hazards; and "S/P" means that the product is included in the Code because of both its safety and pollution hazards Ship type 1: ship type 1 (2.1.2.1) (column e) 2: ship type 2 (2.1.2.2) 3: ship type 3 (2.1.2.3) Tank type 1: independent tank (4.1.1) (column f) 2: integral tank (4.1.2) G: gravity tank (4.1.3) P: pressure tank (4.1.4) Tank vents Cont.: controlled venting (column g) Open: open venting -

FCC 10, Second Supplement the Following Index Is for Convenience and Informational Use Only and Shall Not Be Used for Interpretive Purposes

Index to FCC 10, Second Supplement The following Index is for convenience and informational use only and shall not be used for interpretive purposes. In addition to effective articles, this Index may also include items recently omitted from the FCC in the indicated Book or Supplement. The monographs and general tests and assay listed in this Index may reference other general test and assay specifications. The articles listed in this Index are not intended to be autonomous standards and should only be interpreted in the context of the entire FCC publication. For the most current version of the FCC please see the FCC Online. Second Supplement, FCC 10 Index / Allura Red AC / I-1 Index Titles of monographs are shown in the boldface type. A 2-Acetylpyrrole, 21 Alcohol, 90%, 1625 2-Acetyl Thiazole, 18 Alcohol, Absolute, 1624 Abbreviations, 7, 3779, 3827 Acetyl Valeryl, 608 Alcohol, Aldehyde-Free, 1625 Absolute Alcohol (Reagent), 5, 3777, Acetyl Value, 1510 Alcohol C-6, 626 3825 Achilleic Acid, 25 Alcohol C-8, 933 Acacia, 602 Acid (Reagent), 5, 3777, 3825 Alcohol C-9, 922 ªAccuracyº, Defined, 1641 Acid-Hydrolyzed Milk Protein, 22 Alcohol C-10, 390 Acesulfame K, 9 Acid-Hydrolyzed Proteins, 22 Alcohol C-11, 1328 Acesulfame Potassium, 9 Acid Calcium Phosphate, 240 Alcohol C-12, 738 Acetal, 10 Acid Hydrolysates of Proteins, 22 Alcohol C-16, 614 Acetaldehyde, 11 Acidic Sodium Aluminum Phosphate, Alcohol Content of Ethyl Oxyhydrate Acetaldehyde Diethyl Acetal, 10 1148 Flavor Chemicals (Other than Acetaldehyde Test Paper, 1636 Acidified Sodium Chlorite -

Download Author Version (PDF)

ChemComm Accepted Manuscript This is an Accepted Manuscript, which has been through the Royal Society of Chemistry peer review process and has been accepted for publication. Accepted Manuscripts are published online shortly after acceptance, before technical editing, formatting and proof reading. Using this free service, authors can make their results available to the community, in citable form, before we publish the edited article. We will replace this Accepted Manuscript with the edited and formatted Advance Article as soon as it is available. You can find more information about Accepted Manuscripts in the Information for Authors. Please note that technical editing may introduce minor changes to the text and/or graphics, which may alter content. The journal’s standard Terms & Conditions and the Ethical guidelines still apply. In no event shall the Royal Society of Chemistry be held responsible for any errors or omissions in this Accepted Manuscript or any consequences arising from the use of any information it contains. www.rsc.org/chemcomm Page 1 of 4 ChemComm Journal Name RSC Publishing COMMUNICATION Investigation of Oxidopyrylium-Alkene [5 + 2] Cycloaddition Conjugate Addition Cascade (C 3) Cite this: DOI: 10.1039/x0xx00000x Sequences Received 00th January 2012, Justin A. Simanis, C. Marshall Law, Erica L. Woodall, Christopher G. Hamaker, Accepted 00th January 2012 John R. Goodell, T. Andrew Mitchell* DOI: 10.1039/x0xx00000x www.rsc.org/ Novel oxidopyrylium-alkene [5 + 2] cycloaddition conjugate mechanistic information regarding the proposed reaction pathway addition cascade (C 3) sequences are described. Various (vide infra ). Pyranone-ketones 3b,c were subsequently converted to lactols 4b,c under basic conditions with aq.