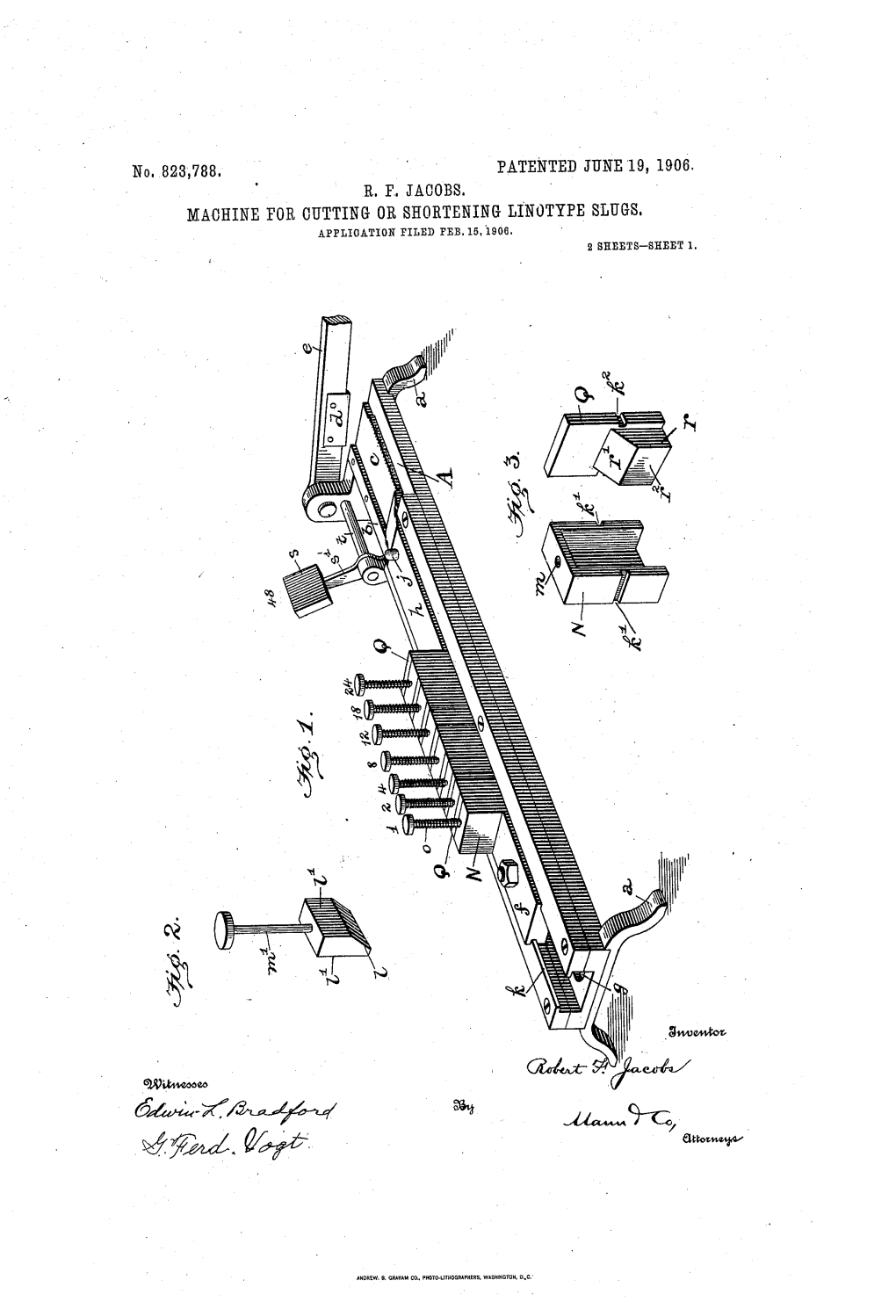

Machine for Outting Or Shortening Linotype Slugs. Application Filed Feb, 15, 1906

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

IBM Selectric IT, with Manual, Ribbon, and Correction Tape

BART Q2B2 No. 1-2 Typewriters. No.1 Manual typewriter: Remington, 1965 with library keyboard. 23 x 36 x 49 em. No. 2 Electric typewriter: IBM Selectric IT, with manual, ribbon, and correction tape. 19 X 39 X 52 Cffi., in box, 32 X 46 X 66 CIDo BART Q2C3 No.1 Computers No. la Apple lie computer, CPU with drives 1 and 2, and cable connections No. lal Owner's manual No. la2 Installation manual No. la3 DOS User's manual No. la4 DOS Programmer's manual No. laS Appleworks Tutorial No. la6 80-Column Text card manual No. la7 Extended SO-Column Text and supplement No. laS Applesoft Tutorial No. la9 Appleworks startup training discs No. lalO Screenwriter II word processing manual No. lall Hayes Micro-modem lie manual No. 1b Apple Monitor ill No. lbl Owner's manual No. lc Daisy wheel printer: Brother HR 15, with tractor feed, cable, and ribbons No. lcl Instruction manual No. lc2 Instruction manual model HR 15 No. lc3 User's manual No. lc4 Tractor Feeder instruction manual I ART c No. la- lb in box, 54x49x56 em. Q2(il3 No. le in box, 19x39x48 em. No.1 Gift ofRiehard Ogar. BART Q2C34 No.1 Computer software manuals. No.1 WordPerfect. No.la Reference version 5.2 No.lb Shared applications version 1.3 No.lc Workbook for Windows version 5.2 No. ld Program discs In box, 23 x 10 x 20 em. BART Q2S2 No.1 Supplies. No.1 Carbon paper, black, standard weight and size, 8 x 11 inches/Middletown, CT.: Remington Rand, 1960? On manufacturer's box: reproduction in blue of seal bearing legend: THE UNNERSITY OF CALIFORNIA 1868 LET THERE BE LIGHT. -

The Building of a Book

•^. f. THE BUILDING OF A BOOK THE BUILDING OF A BOOK A SEKIES OF PRACTICAL ARTI- CLES WRITTEN BY EXPERTS IN THE VARIOUS DEPARTMENTS OF BOOK MAKING AND DISTRIBUTING WITH AN INTRODUCTION BY THEODORE L. DE VINNE EDITED BY FREDERICK H. HITCHCOCK THE GRAITON PRESS PUBLISHERS NEW YORK COPTEIGHT, 1906, Bt the GRAFTON PRESS. Published December, 1906. ©etiicatctj TO RE.VDERS AND LOVERS OF BOOKS THROUGHOUT THE COUNTRY FOREWORD " The Building of a Book " had its origin in the wish to give practical, non-technical infor- mation to readers and lovers of books. I hope it will also be interesting and valuable to those persons who are actually engaged in book mak- ing and selUng. All of the contributors are experts in thoir respective departments, and hence write with authority. I am exceedingly grateful to them for their very generous efforts to make the book a success. THE EDITOR. vU ARTICLES AND CONTRIBUTORS Introduction 1 By Theodore L. De Vinne, of Theodore L. De Vinne & Company, Printers, New York. The Author 4 By George W. Cable, Author of " Grandissimes," "The Cavalier," and other books. Resident of Northampton, Massachusetts. The Literary Agent 9 By Paul R. Reynolds, Literary Agent, New York, representing several English publishing houses and American authors. The Literary Adviser 16 By Francis W. Halsey, formerly Editor of the Nexo York Times Saturday Itevieio of Books, and literary adviser for D. Appleton & Company. Now literary adviser for Funk & Wagnalls Company, New York. The Manufacturing Department ... 25 By Lawton L. Walton, in charge of the manu- facturing department of The Macmillan Company, Publishers, New York. -

Progress in Printing and the Graphic Arts During the Victorian

CORNELL UNIVERSITY LIBRARY BOUGHT WITH THE INCOME OF THE SAGE ENDOWMENT FUND GIVEN IN 1891 BY HENRY WILLIAMS SAGE Ik Cornell University Library The original of this book is in the Cornell University Library. There are no known copyright restrictions in the United States on the use of the text. http://www.archive.org/details/cu31924032192373 Sir G. Hayter, R./l. Bet* Majesty Queen Tictorta in Coronation Robes. : progress in printing and the 6raphic Hrts during the Victorian Gra. "i BY John Southward, Author of "Practical Printing"; "Modern Printing"; "The Principles and Progress of Printing Machinery"; the Treatise on "Modern Typography" in the " EncyclopEedia Britannica" Cgtii Edition); "Printing" and "Types" in "Chambers's Encyclopaedia" (New Edition); "Printing" in "Cassell's Storehouse of General Information"; "Lessons on Printing" in Cassell's New Technical Educator," &c. &c. LONDON SiMPKiN, Marshall, Hamilton, Kent & Co. Ltd. 1897. X^he whole of the Roman Cypc in tbta Booh has been set up by the Linotj^pe Composing Machine, and machined direct from the Linotj'pc Bars by 6eo. CH. loncs, Saint Bride Rouse, Dean Street, fetter Lane, London, e.C. ^ ^ ^ ^ ^ ^ ^ W Contents. ^^ Progress in Jobbing Printing Chapter I. Progress in Newspaper Printing Chapter II. Progress in Book Printing - Chapter III. Printing by Hand Press Chapter IV. Printing by Power Press Chapter V. The Art of the Compositor Chapter VI. Type-Founding Chapter VII. Stereotyping and Electrotyping Chapter VIII. Process Blocks Chapter IX. Ink Manufacture Chapter X. Paper-Making Chapter XI. Description of the Illustrations Chapter XII. ^pj progress in printing peculiarity about it It is not paid for by the person who is to become its possessor. -

Print Magazine: February 2012 Documenting the Twitter of 1886

32 PRINT 66.1 FEBRUARY 2012 DIALOGUE DOCUMENTING THE TWITTER OF 1886 Douglas Wilson is a 29-year-old Why a film on Linotype? Did you have any pre- a computer but completely mechanical. graphic designer and letterpress vious connection to printing or typesetting? Mergenthaler approached the problem of printer by trade, and Linotype: The I taught myself letterpress printing as part mechanizing typesetting from a different Film, a documentary about the of my B.F.A. senior-thesis project. During angle from anyone else. Once he solved it, amazing Linotype machine, is his that time, I visited a local letterpress trade a syndicate of newspaper owners tried to first movie. For the last year and shop and encountered my first Linotype. I remove him from his own company. a half, he and two friends have was instantly hooked. been researching the history of The more I researched the Linotype, the That sounds familiar. What was your goal in the Linotype, traveling from rural more I realized how very little information making this film? I felt the story needed to Iowa to the modern headquarters was out there. For such a common machine be told. For a machine that was as ubiqui- of the manufacturer, in Germany. that was once in every city in the world, tous as the Linotype, very few people know The result is a rich study of Ottmar the Linotype didn't have much written about it. As I further studied the invention Mergenthaler’s contraption, or recorded about it. It was as if everyone of the Linotype, I found a story as capti- whose importance is next to that became so wrapped up in the newer type- vating as Citizen Kane. -

Black Arts, Printer's Devil and a Hellbox

Black Arts, Printer’s Devil and a Hellbox January 2015 Black Arts, Printer’s Devil and a Hellbox Volume 12 – Issue 1 By Dick Fox (Compiled from multiple internet sources, and personal experiences) By Dick Fox (Compiled from multiple internet sources, and personal experiences) The definition of a Printer’s devil – than apprentice in a printing It is our mission to identify, preserve accompanied me as we attended the 6 Annual Printer’s Fair at th and promote the historic establishment who performed a number of tasks, such as mixing tubs of legacy of the Temecula Valley and ink, fetching type, cleaning up after the journeymen (Continued printers, on or page attending 2) to educate the public about its to any other needed task. A number of famous men served as printers’ historical significance. devils in their youth, including Ben Franklin, Thomas Jefferson, Walt _____ Whitman, Mark Twain, Warren Harding, and Lyndon Johnson. 2015 Officers The origin of the term printer’s devil is not known with certainty. President Dick Fox Many theories exist of the phrases origin, such as: Printer’s devil may Vice President Rebecca Farnbach have come from the fact that areas of a printer’s apprentices’ skin Secretary Lisa Woodward Treasurer Roger Cudé inevitably would become stained black by the ink used in printing, and Past President Bonnie Martland black was associated with the “black arts”, the apprentice came to be Directors know as a devil. Cheryl Cady Lynn Cudé Another origin idea is tied to the fanciful belief among printers of Elaine Culverhouse old, that a special devil (the typographical personification of Titivillus) Elaine Eshom Jeffrey Harmon Bonnie Reed haunted every print shop, performing mischief such as inverting type, Myra Masiel-Zamora misspelling words or removing entire lines of completed work. -

Lahor and Technology in the Book Trades

The Quest for Autonomy and Discipline: Lahor and Technology in the Book Trades WILLIAM S. PRETZER JLHERE IS MUCH to be learned about the history of labor and technology in the book trades. There is also much to be learned/rom the history of labor and technology in the book trades. Understanding the production of printed goods and their components will not only help us understand the changing nature of demand, distribution, circulation, and impact of print, but these investigations will also increase our knowledge of general aspects of the American Industrial Revolution. Indeed, the history of the book trades should be seen as part of the larger history of American labor and technology. Much of this larger history is composed of the evolving character of conflict and conciliation in the workplace. And while the role of the plebeian classes as participants in the cul- ture of the printed word is a topic well worth exploring, the focus here is on the role of the producers of printed culture. Continuing through the third quarter of the nineteenth century, two themes stand out in this history. First is the quest for autonomy pursued by master artisans and capitalist employers in terms of their control over raw materials, product markets. This is a revised version of a paper presented at a needs-and-opportunities conference on the history of the book in American culture held at the American Antiquarian Society, November 1-3, 1984. I am grateful to Rollo G. Silver and Steven Rosswurm for their comments and to Kevin S. Baldwin for his research assistance. -

Arabic Hot Metal: the Origins of the Mechanisation of Arabic Typography

Arabic hot metal: the origins of the mechanisation of Arabic typography Article Accepted Version Nemeth, T. (2018) Arabic hot metal: the origins of the mechanisation of Arabic typography. Philological Encounters, 3 (4). pp. 496-523. ISSN 2451-9197 doi: https://doi.org/10.1163/24519197-12340052 Available at http://centaur.reading.ac.uk/87152/ It is advisable to refer to the publisher’s version if you intend to cite from the work. See Guidance on citing . Published version at: http://dx.doi.org/10.1163/24519197-12340052 To link to this article DOI: http://dx.doi.org/10.1163/24519197-12340052 Publisher: Brill All outputs in CentAUR are protected by Intellectual Property Rights law, including copyright law. Copyright and IPR is retained by the creators or other copyright holders. Terms and conditions for use of this material are defined in the End User Agreement . www.reading.ac.uk/centaur CentAUR Central Archive at the University of Reading Reading’s research outputs online Arabic Hot Metal The origins of the mechanisation of Arabic typography In the 1870s, Ottmar Mergenthaler (1854–1899), a German émigré to the United States, began to investigate and develop machines to facilitate typographic composition and justification – a goal that was pursued with mixed results by inventors for most of the nineteenth century.1 After a prolonged phase of trial and error, by 1886 the first functional machine was put to use at the New York Tribune newspaper, heralding the era of mechanised typesetting.2 The machine Mer- genthaler had developed, and its revolutionary concepts, transformed the practice of typogra- phy. -

The Museum of Printing History Offers Hands-On Learning Opportunities for Students of All Ages

Welcome The Museum of Printing History offers hands-on learning opportunities for students of all ages. Visits to the Museum are appropriate for a wide range of subjects, whether the focus is science and technology or English Language Arts, history or fine arts and crafts. With exhibitions dedicated to the development of essential technologies, American and Texas history, the traditions of Western literature and art – as well as working galleries for crafts such as papermaking, printmaking, and bookbinding – the visiting student will encounter scholars and artists who are gifted at bringing the past to life. Museum of Printing History tours are customizable to the needs of any class. Discuss a course or unit topic with our Curator or Artist-in-Residence to develop a tour which fits the subject matter that the students are currently exploring. If suitable for the size of your group, it is also possible to introduce hands-on projects, such as a session printing in our lithography studio with Houston artist Charles Criner, or an introduction to book construction and history with one of our bookbinders. In addition to regularly scheduled classes, the Museum of Printing History can work with your school or community group to schedule workshops on a wide range of topics relating to the art of the book. We have a list of workshops available on demand, or we may work together to design something special for your group. For questions, or to schedule your outreach workshop, please contact Amanda Stevenson, Curator, [email protected], 713-522-4652, ext. 207. Contents Preparing for your Visit Maps & Directions 2 Tour Information 3 Museum Overview 4 Pre-Visit Discussions 5 Museum & Post Visit Activities 11 1 Preparing for Your Visit Convenient to downtown and to all major freeways, the Museum is located at 1324 West Clay, between Waugh Drive and Montrose, just south of Allen Parkway. -

Museum Printing

MOPSummer:Layout 1 5/3/11 4:42 PM Page 1 Museum OF the Printing GalleyVolume 32 • Issue 2 • Summer 2011 DEDICATED TO PRESERVING THE PAST OF PRINTING AND ALL OF ITS RELATED CRAFTS Message From The President In This Issue or the last two years we have been fortunate to have a Colonial print shop on We Get Questions—Members and loan, complete with an English Common Press. Gary Gregory, founder of others ask about presses and other F“Lessons on Liberty” and a member of the Museum’s Board, supported this print paraphernalia. Pages 3 and 3 exhibit in many ways. Gary has now found an appropriate home for this historically- accurate print ship at the Clough House, adjacent to Old North Church. The Printing Museum Type Sale—A great oppor- Office of Edes & Gill is Boston’s colonial-era printing experience and visitors will have tunity to find type, presses, and the opportunity to engage living historians working the printers’ trade in pre-revolu- other printing material. Saturday, tionary Boston. If you are in Boston, visit Gary and also make a trip to North Andover June 11th. Page 4. and visit the Museum. Over the winter, our gang painted and tiled the second floor conference room. Gutenberg was an Idiot—It took a They also kept the 20-year old boiler operating. while to get the type right for the The Museum’s Library Advisor, Brian Frykenberg arranged with OPALS (OPen- Bible. Page 5 source Automated Library System) to allow web-based public access to electronic records of the Museum’s books and ephemera. -

Letterpress Began in Europe in the 14Th Century As an Alternative To

pdffile.9.13 9/13/99 10:35 AM Page 1 CRANE’S on LETTERPRESS Letterpress began in Europe in the 14th century as an alternative to laborious calligraphy. Type was hand cast and individual characters were hand set into lines until machine set composition made the process easier. Today, many designers are returning to the craft of letterpress — printing from metal type and custom engraved plates — as a unique option to offset printing. Letterpress offers a tactile quality and nostalgic feel that can’t be achieved with any other technique. Crane’s paper, made from 100% cotton fibers, is the perfect match for the letterpress process. Together, they create a grace and elegance that leave a lasting impression. pdffile.9.13 9/13/99 10:35 AM Page 2 3 CHOOSING PAPER Crane‘s paper is made from 100% cotton fibers which sets it apart from ordinary papers. A totally renewable resource, cotton is strong and pliable which enables it to withstand the weight and pressure of the letterpress process. Since the ”bite“ that is characteristic of letterpress is the result of metal type or a photoengraved plate being impressed into the paper, it is important to choose a soft paper that can accentuate this effect. Beyond durability, the elegance of Crane’s 100% cotton paper does not go unnoticed. Only 100% cotton has a unique softness that is pleasing to the eye and the touch, making it the ideal paper for the highly aesthetic craft of letterpress. pdffile.9.13 9/13/99 10:35 AM Page 4 5 PREPARING ARTWORK Give your design a lift. -

Type-Composing Machines of the Past, the Present, and the Future

Type-Composing Machines of The Past, the Present, and the Future. A PAPER Read before the Balloon Society of Great Britain, at St. James’ Hall, October 3rd, 1890. by JOHN SOUTHWARD, Editor “Paper and Printing Trades Journal”; Author of “The Dictionary of Typography.”, “Practical Printing,” “The Principles and Progress of Printing Machinery” Article, “Typography” in “Encyclopaedia Britannica” and “Printing” in “Chambers’s Encyclopaedia” Examiner (1878) in Printing to City and Guilds of London Institute for the Advancement of Technical Education. [COPYRIGHT.] LEICESTER: RAITHBY, LAWRENCE & CO., LIMITED, DE MONTFORT PRESS, 1891. ADVERTISEMENT. The following Paper is given as it was originally written. Owing to shortness of time, some passages had to he omitted in the reading. THE visitor to the composing department of a printing office finds a number of operatives engaged upon a process that is, apparently, extremely monotonous and fatiguing. Standing before a pair of shallow wooden trays, known as cases, inclined desk-like, the compositor holds in his left hand what is called a composing-stick a little iron or brass frame, one side of which is movable, so that it may be adjusted to the required width of the page or column which the workman has to set up. The "copy" from which he works rests on the least-used part of the upper case. The practised compositor takes in several words at a glance provided the author writes an intelligible hand, which virtue is by no means universal. One by one, then, the compositor puts the letters of each word and sentence into his stick, securing each letter with the thumb of his left hand, which is, therefore continually travelling from the beginning to the end of the line. -

History of the Linotype Company, by Frank Romano

58 TUGboat, Volume 36 (2015), No. 1 Book review: History of the created an enormous number of typefaces, pioneered Linotype Company teletypesetting (again of huge importance for the newspaper business), experimented with phototype- Boris Veytsman setting and contributed to digital composition. The Frank Romano, History of the Linotype Company. experience of its engineers with precision mechanical RIT Press, 2014. 480 pp. Softcover, US$39.99. devices allowed the company to venture into other ISBN 978-1-933360-60-7. areas, including the production of bombsights and other armaments (especially during the wars). Frank Romano, now an Emeritus Professor with RIT, worked at Linotype for eight years. He has written a brilliant book about the company | not a dry list of milestones, but rather a work of love and appreciation. The book includes, in excerpts or in full, rare or previously unpublished documents, such as the autobiography of Ottmar Mergenthaler, man- uscripts, letters, earning reports, court filings, news- paper articles, brochures, author's own interviews, and many others. The book is lavishly illustrated, with hundreds of reproductions of samples, advertise- ments, photographs, books and other materials that Linotype published over 127 years of its existence. Few inventions changed the cultural and political landscape as profoundly as those involving cheap and quick copying of words. Gutenberg's movable type made books available to multitudes of people with enormous consequences for civilization. However, manual composition was still too slow and expensive to mass-produce cheap newspapers. The invention of hot-metal typesetting by Ottmar Mergenthaler and his contemporaries made printing much faster and cheaper.