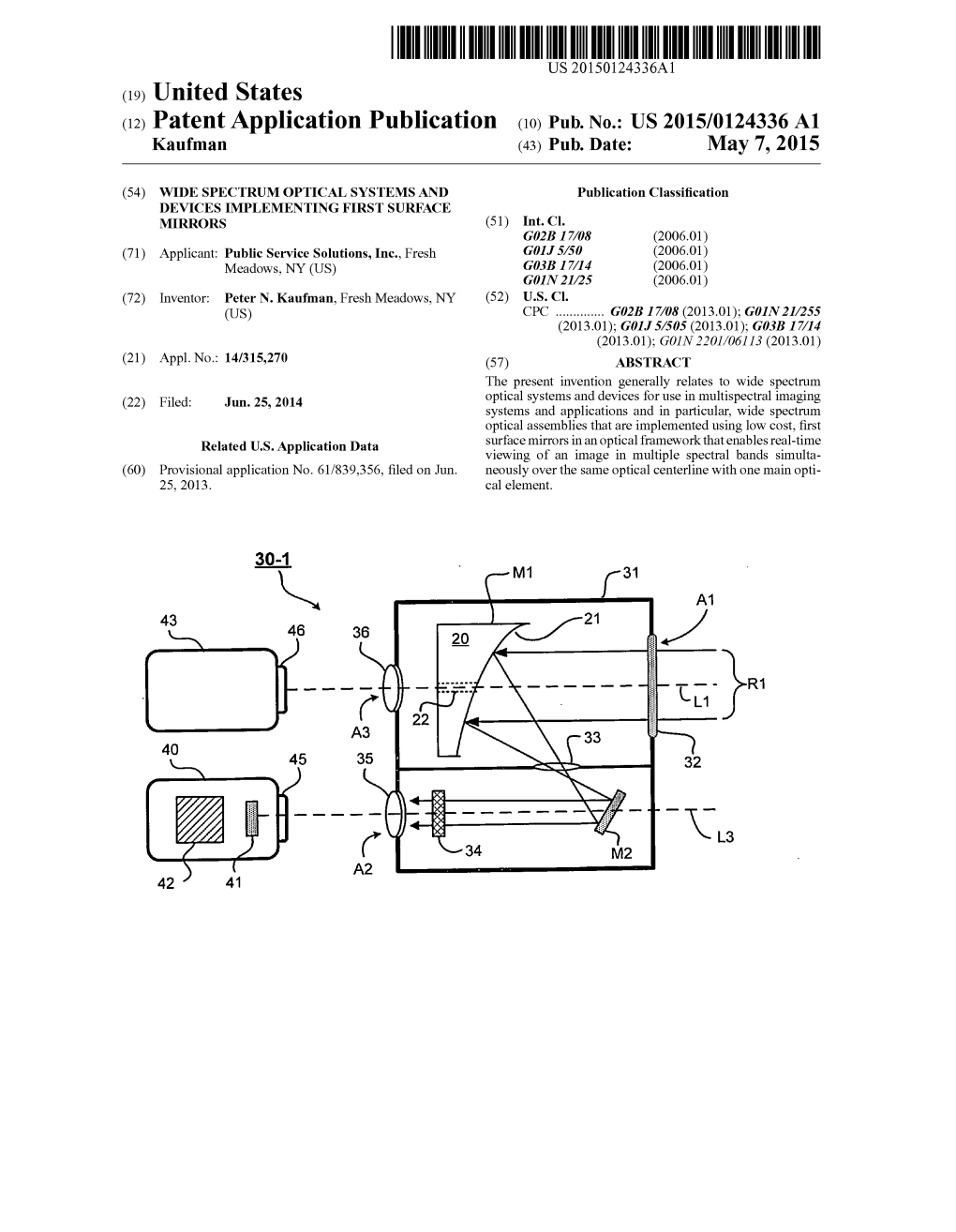

(12) Patent Application Publication (10) Pub. No.: US 2015/0124336A1 Kaufman (43) Pub

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Beauty Redefined, Entropy, and Breakthrough MY PRECIOUS

Beauty Redefined, Entropy, and Breakthrough MY PRECIOUS contents Go Wide 76 Beauty Redefined The Sigma 10-20mm 68 You Are Beautiful By Dave Markowski Making Things Better, One Sticker at a Time Interview by Julie Jackson I admit it. When I got my first digital (without going all the way to fisheye), shots can also benefit and yield some SLR, I didn’t have a clue what I was and I almost never find myself cursing excellent results. I’ve done quite a few 70 Pretty Is Boring doing. So I started asking the question because something isn’t fitting in the shots of the college campus where I Photos of Strong Women by Mark Velasquez that gives seasoned shooters facial tics: frame quite right. currently work, and clients have been “What lens should I get?” I do quite a bit of nighttime long very pleased with the dramatic angles 94 Photographing Female Models The advice I got was simple: exposure photography, so the lack of that an ultra-wide gives. Ten Tips by Kimberly Millard “Figure out what you shoot most, and a set aperture isn’t really an issue. The Since I got the Sigma 10-20mm, get the lens that will help you capture Sigma is great for the nontraditional it rarely leaves my camera. So if you’ve it best.” So I used my kit lens for a few candid-portrait photographer as well. got a hankerin’ for some ultra-wide 96 Diversity Decontextualized months, and found myself shooting You can really get some neat effects at action, give the Sigma a try. -

Macro References and Glossary Ofterms.Docx

Glossary of terms for Macro Photography Achromatic lens A lens that brings at least two wavelengths (typically red and blue) into focus in the same plane, thereby limiting the effects of chromatic and spherical aberration Airy disk and Airy pattern Descriptions of the best focused spot of light that a perfect lens with a circular aperture can make, limited by the diffraction of light Angle of view (AOV) The angular extent of a given scene that is imaged by a camera Aperture control filter An adapter that fits on the rear of a reversed lens to m anually control the aperture Astigmatism Light rays that propagate in two perpendicular planes have different foci Asymmetric lens A lens where the aperture appears to have different dimensions when viewed from the front and from the back Bellows A pleated light -tight ex ten sible part in a camera between the film plane and the lens Circle of confusion (CoC) The optical spot caused by a cone of light rays from a lens not coming to a perfect focus when imaging a point source (also known as a disk of confusion) Close focus distance See minimum focus distance Close -up lens A single or multi -element lens that fi ts on the filter t hread of a primary lens to increase magnification Close -up photography Images taken close to the subject typically with magnifications of ~0.1X to ~1X Coma or comatic aberration A lens aberration due to imperfections in a lens , or other components, that results in off-axis point sources appearing to have a tail (coma) similar to a comet Chromatic a berration (or An optical effect when a lens is unable to bring all wavelengths of colo ur to the same colour/purple fringing) focal plane, and/or when wavelengths of different colours are focused at different positions in the focal plane. -

Introduction to Differential Equations

Modern Optics, Prof. Ruiz, UNCA doctorphys.com Chapter H Solutions. Camera Lenses HW H1. Close-Up Photography. Courtesy Andrew Magill via Courtesy Wikipedia: Fg2 Flickr and Wikipedia You have there close-up lens attachments 1D , 2D , and 4D along with three extension tubes of lengths 12 mm , 20 mm , and 36 mm . You have an SLR camera with its standard 50 mm focal length lens. The most you can turn the focusing mechanism to focus close up gets you a maximum lens-to-film distance of si 60 mm , which allows you to bring a subject as si 60 1 close as so 300 mm for a magnification of M 0.2 . Even though you so 300 5 know that the optical quality due to aberrations will not be ideal, you thread on all three close-up attachments to the front of your lens and use all three extension tubes between the lens and the camera body. Calculate the closest you can bring an object now for photographing and determine the magnification for your image on the photo. While the lens projects an inverted and left-right flipped image, you simply turn the photo around and all looks good. Report your answers to two significant figures. Comment on your magnification comparing it to life size. HW H2. The Teleconverter I: Formula for Diverging Insert. A primary camera lens with focal length ffcamera 1 can be converted into a telephoto lens by inserting a diverging lens, the converter secondary lens with focal length f2 , between the primary lens and camera body. -

Mamiya 645 200Mm F2.8 APO Review

16/08/2018 REVIEW | Mamiya 645M 200mm F2.8 APO PEBBLE PLACE REVIEWS - Medium Format - Mamiya 645M 200mm F2.8 APO Telephoto Lens HOME REVIEWS Rangefinder SLR Medium Format Accessories GEAR TALK LEICA db CONTAX db MAMIYA 645M 200MM F2.8 TELEPHOTO LENS My Facebook Page PICTURES Like 0 Updated June 19, 2018 Production Early 1980’s to 2002 Lens Composition 7 Elements in 5 Groups Floating Element No Angular Field of View 20˚ at infinity Actual Field of View 124mm (35mm Equivalent, on a 645 film negative) Minimum Focus 2.5 Meters / 8.2 Feet Aperture 8 Blades, Octagonal F-Stop Scale F2.8 to F22; full stop detents Filter Size 77mm Lens Cap 77mm Mamiya 645M 200mm F2.8 APO Lens Hood Built-in (slides into place) plus Screw-on Extension Phase One P65+ • F8 • 4-Sec • ISO 50 Weight 1107 Grams / 2.43 pounds (without caps) Lens Size 91mm Wide x 143.5mm Long OVERVIEW The Mamiya 645M 200mm F2.8 APO was designed for use on the Mamiya M645, M645-1000S, M645 J 645 Super and M645 PRO. While those cameras are long since discontinued, the Mamiya 200mm F2.8 APO's mounts directly to today’s modern Mamiya / Phase One 645AF bodies. These days I use the Mamiya 200mm F2.8 APO via the Leica S-Adapter Mamiya on the Leica S Typ 006, and have found the Mamiya 200mm APO to be outstanding portrait lens and equally adept Mamiya 645M 200mm F2.8 APO Phase One P65+ • F8 • 1/125 • ISO 50 as a landscape lens. -

Single Lens Off-Chip Cellphone Microscopy

Single Lens Off-Chip Cellphone Microscopy Aydın Arpa Gordon Wetzstein Douglas Lanman Ramesh Raskar MIT Media Lab MIT Media Lab MIT Media Lab MIT Media Lab Abstract Within the last few years, cellphone subscriptions have widely spread and now cover even the remotest parts of the planet. Adequate access to healthcare, however, is not widely available, especially in developing countries. We propose a new approach to converting cellphones into low-cost scientific devices for microscopy. Cellphone mi- croscopes have the potential to revolutionize health-related screening and analysis for a variety of applications, includ- ing blood and water tests. Our optical system is more flex- ible than previously proposed mobile microscopes and al- lows for wide field of view panoramic imaging, the acquisi- tion of parallax, and coded background illumination, which optically enhances the contrast of transparent and refrac- tive specimens. 1. Introduction Today, an estimated six billion cellphone subscriptions exist worldwide with about 70% of those in developing countries (www.itu.int/ict/statistics). However, developing countries often suffer from a lack of access to adequate healthcare, which is party due to the cost and training as- sociated with high-tech scientific instruments required for medical analysis. We present a low-cost portable micro- scope that uses a cellphone camera and a simple, secondary lens that is placed on top of the specimen. As illustrated in Figure 1. Illustration of our cellphone microscope in the field. The Figure 1, our device can be used in the field, for instance data captured by this versatile and low-cost platform can either to analyze water sources for potential contamination, and be analyzed directly on the phone or remotely, for instance by a can either directly process the captured data or transmit it medical doctor in a hospital. -

Single Lens Off-Chip Cellphone Microscopy

Single lens off-chip cellphone microscopy The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Arpa, Aydin, Gordon Wetzstein, Douglas Lanman, and Ramesh Raskar. “Single lens off-chip cellphone microscopy.” In 2012 IEEE Computer Society Conference on Computer Vision and Pattern Recognition Workshops, Providence, RI, 16-21 June 2012. p. 23-28. Institute of Electrical and Electronics Engineers, 2012. As Published http://dx.doi.org/10.1109/CVPRW.2012.6239195 Publisher Institute of Electrical and Electronics Engineers Version Author's final manuscript Citable link http://hdl.handle.net/1721.1/80831 Terms of Use Creative Commons Attribution-Noncommercial-Share Alike 3.0 Detailed Terms http://creativecommons.org/licenses/by-nc-sa/3.0/ Single Lens Off-Chip Cellphone Microscopy Aydın Arpa Gordon Wetzstein Douglas Lanman Ramesh Raskar MIT Media Lab MIT Media Lab MIT Media Lab MIT Media Lab Abstract Within the last few years, cellphone subscriptions have widely spread and now cover even the remotest parts of the planet. Adequate access to healthcare, however, is not widely available, especially in developing countries. We propose a new approach to converting cellphones into low-cost scientific devices for microscopy. Cellphone mi- croscopes have the potential to revolutionize health-related screening and analysis for a variety of applications, includ- ing blood and water tests. Our optical system is more flex- ible than previously proposed mobile microscopes and al- lows for wide field of view panoramic imaging, the acquisi- tion of parallax, and coded background illumination, which optically enhances the contrast of transparent and refrac- tive specimens. -

SIGMA-Lens-English.Pdf

LENS TECHNOLOGY Sigma lens technology--what photographers always rely on when they want to express themselves through images. Sigma is always developing state-of-the-art optical technology to draw out the maximum possibilities of single-lens reflex cameras and give photographers the tools they need to do exactly what they want, and the fruits of that development are embodied in each and every Sigma lens. Ⅵ SIGMA High-Performance Lens Series DC Lens These are dedicated digital SLR camera lenses with an image circle designed to suit image sensors that correspond to APS-C size. In- house technology accumulated through the development of our digital SLR camera was used to optimize optical performance for our digital lenses. This is a high-performance lens series that fuses technology such as lens power layout and coating design with the know-how Sigma has built up over many years of developing interchangeable lenses for SLR cameras. By reducing the diameter of the image circle, Sigma has achieved a more compact, lightweight lens series. * An image sensor larger than those corresponding to the APS-C size cannot be used in digital SLR cameras, 35 mm SLR cameras, or APS film SLR cameras. If such an element is used, vignetting will occur on the picture surface. The angle of view varies depending on which camera model the lens is used with. 35mm format is approximately 1.5 - 2.0 times the focal length of the lens being used. DG Lenss These are high-performance lenses optimized for digital cameras. They are ideal not only for 35 mm digital SLR cameras and film digital SLR cameras but also for APS-C digital SLR cameras. -

SANE and the Hydra Privacy Card® Digital Attaché Confidentiality and Legal Admissibility in a Sexual Assault Nurse Examiner Program

TRUSTED MOBILITY SOLUTIONS SANE and the Hydra Privacy Card® Digital Attaché Confidentiality and Legal Admissibility in a Sexual Assault Nurse Examiner Program In cases of sexual assault or domestic violence, it is the country are now creating Sexual Assault Nurse vitally important to satisfy two potentially conflicting Examiner (SANE) units to deal with these issues. goals. The patient’s urgent medical needs must be attended to, but at the same time a physical SPYRUS, Inc., is a manufacturer of cryptographic examination must be conducted and evidence products originally designed and marketed to the US gathered for possible prosecution. To a woman who military. Protecting the confidentiality and integrity has already been violated, the collection of the most of digital data is a SPYRUS core competency that fits intimate photographs and physical evidence can nicely with evidence-handling requirements. This cause her to feel violated again. It is important to match led to a partnership with the SANE program respect the patient’s privacy while at the same time at Holy Cross Hospital in Taos, New Mexico, which ensuring that any evidence collected will withstand a began in January, 2011. legal challenge if the case is ever taken to court. This effort is the first-ever field trial of the SPYRUS Because a sexual assault examination typically Hydra Privacy Card® (Hydra PC™) Digital Attaché™ takes place within a healthcare facility, the strict USB encryption and authentication device in a confidentiality requirements of the Health Insurance clinical setting. The Hydra PC Digital Attaché can act Portability and Accountability Act (HIPAA), Health like an encrypting USB flash drive to provide both Information Technology for Economic and Clinical confidentially and integrity, but it is also much more. -

Lens Mount - Wikipedia, the Free Encyclopedia

Lens mount - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Lens_mount From Wikipedia, the free encyclopedia A lens mount is an interface — mechanical and often also electrical — between a photographic camera body and a lens. It is confined to cameras where the body allows interchangeable lenses, most usually the rangefinder camera, single lens reflex type or any movie camera of 16 mm or higher gauge. Lens mounts are also used to connect optical components in instrumentation that may not involve a camera, such as the modular components used in optical laboratory prototyping which join via C-mount or T-mount elements. A lens mount may be a screw-threaded type, a bayonet-type, or a breech-lock (friction lock) type. Modern still camera lens mounts are of female lens mount of an Minolta XD-7 the bayonet type, because the bayonet mechanism precisely aligns with male mount of Minolta mechanical and electrical features between lens and body. Screw-threaded MC-Rokkor 58mm 1:1.4 lens mounts are fragile and do not align the lens in a reliable rotational position, yet types such as the C-mount interface are still widely in use for other applications like video cameras and optical instrumentation. Bayonet mounts generally have a number of tabs (often three) around the base of the lens, which fit into appropriately sized recesses in the lens mounting plate on the front of the camera. The tabs are often "keyed" in some way to ensure that the lens is only inserted in one orientation, often by making one tab a different size. -

Telephoto Zoom Lens

Sigma has refined optical technology, LENS TECHNOLOGY in order to fully realize the possibilities Sigma lens technology enables the photographer to express his own sensitivity through images. of single lens reflex cameras and to respond exactly to the demands of the photographer, helping him to bring his visions to reality. Sigma’s huge choice of lenses enables photo enthusiasts to maximize their creativity. Each and every Sigma lens offers optimum optical performance and smooth handling characteristics through a combination of experience and advanced technology. Sigma’s design and precision engineering helps photographers to maximize their true creativity by fulfilling the full potential of their cameras. The high quality lens series of Sigma. SIGMA Advanced Lens Technology. EX Lens: Aspherical Lens: Rear Focus: The exterior of this lens is EX-finished to denote the superior build and The aspherical lens complex allows freedom of design, improved This lens is equipped with a system that moves the rear lens group for high- optical quality and to enhance its appearance. performance, a reduced number of component lenses and a compact size. speed, silent focusing. DG Lens: APO Lens: Inner Focus: These are large-aperture lenses with wide angles and short minimum In order to attain the highest quality images, the APO lens has been made To ensure stability in focusing, this lens moves the inner lens group or focusing distances. With an abundance of peripheral illumination, they are using special low-dispersion (SLD) glass and is designed to minimize color groups without changing the lens’ physical length. ideal lenses for Digital SLR Cameras whilst retaining suitability for aberration. -

![United States Patent [191 [111 4,362,366 Gottschalk [45] Dec](https://docslib.b-cdn.net/cover/4233/united-states-patent-191-111-4-362-366-gottschalk-45-dec-9204233.webp)

United States Patent [191 [111 4,362,366 Gottschalk [45] Dec

United States Patent [191 [111 4,362,366 Gottschalk [45] Dec. 7, 1982 [54] FOCAL LENGTH EXTENDER 3,871,748‘ 3A3; gay ................................... .. 358/420 ' 3,990,785 11/1 irose ............................... .. 35 420 [75] Inventor: Robert E. Gottschalk, Los Angeles, _ Camj 7 Primary Examiner—John K. Corbin r - Assistant Examiner-Rebecca D. Gass [73] Assignee: garlia‘vision, Incorporated, Tarzana, Attorney’ Agent, or Firm_Lyon & Lyon . a1 . " ' [57] ABSTRACT 21 A 1. No.: 172 939 [ 1 _pp , An improved focal length extender of the anamorphic [22] Filed: Jul- 28, 1930 type is disclosed for use in combination with a conven [51] Im. C1.-‘ ....... ..- ................................... .. G02B 13/08 90"?‘ Primary 1605- The lens System of the present in [52] us. Cl. _ . .. 350/420 Yemlon'comp?ses two Porno"?- A ?rst Porno" 18 P051 [53] Field of Search ....................................... .. 350/420 "(med "1 from of the convemlonal lens, ?ed a Second _ portion of the lens system of the present invention is [56] References Cited placed between the conventional lens and the ?lm Us~ PATENT DOCUMENTS plane. [The ?rst and second portions cooperate together 3 O 420 and with the conventional lens system to provide in """"""""""""" 3§0;420 creased focal length while at the same time providing 29915942 12/!959 Cook ............... n 350/420 relatively reduced mass and bulk at increased optical 2.940.372 6/1960 Ehrenhaft et al. 350/420 Speed 3,04l,935 7/1962 Jacobsen ......... .. 350/420 3,428,398 2/1969 Gottschalk ..................... 350/420 1 Claim, 4 Drawing Figures l/ [I 4__I_.5 ‘ \ [HI/,2’ 753/ J}\ \\\\\:\\\\ ”/’’,’l 1’ 1r \\\\\\\\: 1’ l/’ [I t \ Q41,’ ,1 22 l ' \‘\\\ I’, \\\\\\\ ’/,///, 20 g _ I’! \\\\ ’,f/ \\ \\ \ I ll/ / Q (I, \\ , // \\\\ (ll/l’ \\ \ 46 , I’, v ’ I ‘ It’, ‘\I‘ ’/’//» \ \\ I‘, I,’ I l . -

Stephen E 64520750, in Ven Tor

June 12, 1956 s. E. GARUTSO 2,749,820 MEANS OF PRODUCING THREE DIMENSIONAL PHOTOGRAPHIC FILM Filed Dec. 1, 1952 2 Sheets-Sheet 1 27' 1. - 566/p/glyne l 19 111-»1I | l l | | STEPHEN E 64520750, IN VEN TOR. BY June 12, 1956 S, E. GARUTSO 2,749,820 MEANS OF PRODUCING THREE DIMENSIONAL PHOTOGRAPHIC FILM Filed Dec. 1, 1952 2 Sheets-Sheet 2 lcécd/ P/ane 0/ aé/écf/l/e Secondary zfoca/fma' Igloo-1e e | i 13-»: I | | I l qskepuzwbi 642117.90, \ A I /~l4/ INVENTOR. BY JTmPA/Ey.I 2,749,820 Q Patented June 12, 1956 2 Figure 5 is a sectional view on the line 5—-5 of Figure 3, illustrating the relative positions of the vertical ?eld lenses and associated elements; 2,749,820 Figure 6 is a diagrammatic view of one of the ?eld MEANS OF PRODUCHN'G THREE DIIVIENSIONAL lenses, the main objective and prisms interposed between PHOTOGHIC FILM the ?eld lens and the main objective, with the path of light rays for both the ?eld lens and the objective shown Stephen E. Garutso, Hollywood, Calif. in dotted lines; and Application December 1, 1952, Serial No. 323,371 Figure 7 is an elevation of the focal plane of the main objective, showing images projectedthereon by the main 3 Claims. (Cl. 95-18) objective, and offset images likewise projected upon the focal plane, as a result of the ?eld lens arrangement shown in Figure 6. Referring now with particularity to the drawings, I The present invention relates to three dimensional pho 15 have provided a main objective 1, the form shown in the tography, and contemplates the provision of means several ?gures of the drawings being for illustrative pur adapted to photograph objects in such a manner as to pro poses only, and which is of the double convex type.