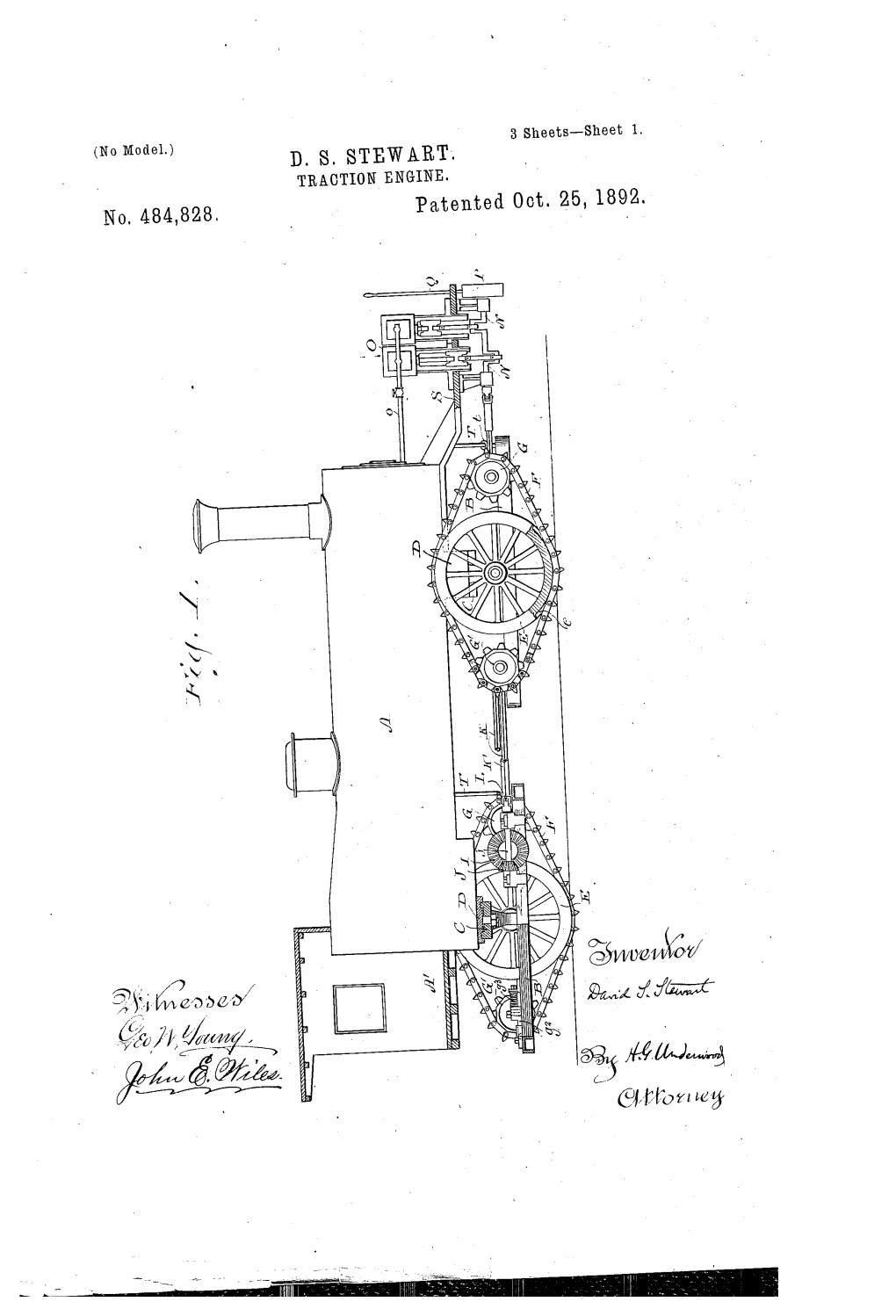

Patented Oct. 25, 1892

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Auction of Steam Engines, Vehicles, Workshop Machinery and Consumables Antique & Vintage Items, Books, Literature & Bygones

Instructed by Richard Sandercock Esq In the matter of his retirement sale. Note: the Fairground Heritage Trust Attraction goes on from strength to strength and is in no way affected by this sale. Auction of Steam Engines, Vehicles, Workshop Machinery and consumables Antique & Vintage Items, Books, literature & Bygones 2nd Revision All lot numbers for lots presently identified will remain the same but pictures and further lots may be added Saturday 21st October 2017 DINGLES FAIRGROUND HERITAGE CENTRE, MILFORD, LIFTON, DEVON, PL16 0AT Sale will commence at 10:00am prompt Directions: Follow the brown signs to Dingles Heritage Fairground from the A30 2 miles East of Lifton Village. (SatNav PL16 0AT) www.kivells.com FOREWORD This would have been the 25th annual collective auction to be held at Milford farm by Kivells in conjunction with Richard Sandercock. Richard purchased the strategically well placed Milford Farm in 1991 with the intention of opening his steam collection to the public in the first museum buildings and utilising the workshop facilities to relocate his R. Dingle & Sons contracting business from their historical site in Stoke Climsland. The museum evolved into what is now The Fairground Heritage Trust collection and visitor attraction and the workshop was to become a centre of excellence for the repair and rebuilding of steam engines with Clive Gibbard working under Richard’s direction. Clive has recently retired and moved away and Richard has decided the moment is right to close the workshop business and sell the equipment and stores. That raised the question of who would look after his long cherished engine Conqueror. -

Charles Burrell & Sons Limited

Charles Burrell & Sons Limited Administrative History Joseph Burrell founded the business in the late 1770s, setting up originally as a general smith and repairer of agricultural tools in Thetford. He produced ploughs, harrows and rakes. Early in the 19 th century, with his brothers, James and William, he began designing his own patent agricultural machinery. In 1803 his 'improved drill for sowing crushed oat cake manure with wheat, turnips etc' won a silver cup at the Holkham sheep-shearing festival (a forerunner of the great agricultural shows). A small iron and brass foundry was started under James and continued at the St Nicholas foundry. One of James's sons, James junior, had a small shop and foundry, while the other son Charles inherited the family firm. Charles (grandson of the founder) was 20 when he took over in 1837, and was to see the name of Burrell become world-famous during his 69-year 'reign' to his death in 1906. Charles Burrell & Sons, steam and agricultural machinery manufacturers were the first to introduce a practical heavy duty traction engine for use on roads. The firm produced traction engines, steam rollers and ploughing engines. More than 4,000 engines left the works during the life of the firm and many were put in countries around the world. In 1848 Burrell's produced their own single cylinder (SC) portable in 1848 which they exhibited at the Royal Agricultural Show. The firm continued to manufacture other agricultural machinery, and produced the first combined threshing and finishing machine about this time. Burrell joined forces with engineer, James Boydell, to produce the first practical traction engine, a self-moving road engine for pulling loads. -

George Dawson Collection

George Dawson Collection Monographs and Articles 178B15 Photographs and Postcards 178C30 and 178C63 Audio Tapes and Cassettes 178E8 Newspaper Cuttings 178G11 Programmes 178K3 Handbills 178T6 178B15.1 George Dawson An old man’s tale – George Dawson’s memories of Kendal fairs No date Unpublished typescript 2pp George Dawson collection 178C30 Dawson (George). [32 albums of black and white and colour prints and postcards by various photographers]. 2315 prints in all. Very largely identified and dated. Donated by Kevin Scrivens. 178C63 Dawson (George). [223 black and white and colour photographs relating to circuses, circus transport and circus model making 1930-1980]. Largely identified and dated. Donated by Graham Downie / Fairground Association of Great Britain. 178E8.1 Dawson (George) Organ music 5 10” 78rpm vinyl recordings Regal Records Donated by George Dawson 178G11.1-5 George Dawson 5 folders of newspaper cuttings 1. 54 cuttings relating to fairgrounds and rallies in the Cumbria area 2. 172 Cuttings relating to traction engines and some historic photographs 3. 41 cuttings relating to diesel transport, advertisements for rides and engines and models 4. 146 cuttings relating to fairground rides, machines and organs 5. 64 cuttings from the World’s fair relating chiefly to tractions engines, various dates. George Dawson collection 178G11.6 36 pages of newspaper cuttings relating chiefly to traction engines George Dawson collection 178G11.7 Large album of cuttings from World’s Fair newspaper to 1978. Compiled in collaboration with Alf Lamb George Dawson collection 178G11.8 Large album of cuttings from World’s Fair newspaper consisting of articles written by RA Taylor documenting the history of machines and show families. -

Case 10-20 Racine, WI 1917

Case 10-20 Racine, WI 1917 The late teens were a watershed for the This was not only Case’s first small gas J.I. Case Company, a time of enormous tractor but also their first Case four- activity as the company moved out of cylinder engine, which is the same the steam-traction engine market and engine used in the Case automobiles. into the growing gas-engine market. The company was particularly focused on the Like other popular models at that time, growing small-tractor market, with new the 10-20 had one large driving “bull” and innovative machinery coming out of wheel on the right, or furrow side, with the factory on a regular basis. its front steering wheel aligned with it on the right. The idler wheel on the left, or In 1915, Case’s first attempt at a small gas land side, had no differential, but could tractor was the Case 10-20. Following temporarily clutch into the live axle for the trends at the time, the 10-20 was extra traction if needed. An arrow was an unusual-looking three-wheeled, mounted above the front wheel which lightweight tractor that featured a four- pointed in the direction of travel. This cylinder vertical cross-mounted engine. was to aid the operator as he was seated behind the large drive wheel and had limited vision of the front of the machine. A true lightweight tractor for its time, This was not only the 10-20 weighed in at just over 5,000 Case’s first small gas pounds. -

Part 1 Engines in Steam Page 3 Part 2 Traction Engines Not Working Page 18 Part 3 Other Working

Part 1 Engines in Steam page 3 Part 2 Traction Engines not Working page 18 Part 3 Other Working ‘Machines’ that intrigued page 20 Part 4 Giant Miniature Engines page 24 Information taken from the 2021 Sheffield Steamfest Program & Guide, my observations and a number of websites. Errors and omissions are definitely a possibility so treat with care. Page 1 of 29 ‘Tasmania, in the steam era, was the breadbasket of Australia with our English ancestors farming our countryside with tried and true English practices. Just under half (69) of all the Marshall Sons & Co traction engines produced for the Australian market (148) were exported to Tasmania demonstrating the level of activity seen in this state. The number of engines in the state coupled with the expense of processing scrap in the dying days of steam left Tasmania rich in steam history. Many engines have been exported’ Chris Martin, Sheffield Steam & Heritage Centre, Chairman Page 2 of 29 Engines in Steam 1880 Fowler 8HP Traction Engine the world's oldest remaining Fowler traction engine builder’s number 4048 owned by Leigh & Cameron Burril Page 3 of 29 1929 Fowler 8NHP Compound Traction Engine Builder’s number 17211, 3 speed Road Locomotive ‘Lion’ class. First used by the Victorian Country Water Board in Central Victoria. The engine was then bought to Tasmania and sold to the Public Works Department. Most of its working life was spent in the north of the state driving stone crushers at the many quarries then operated by the PWD. In the late 1950s it was then put into storage until restoration started in the 1970s as an apprentice project. -

Part 1. Timeline in the Development of Agricultural Tractors and Power Units Note: the Italic Letters at the End of Each Entry Refer to the References

Part 1. Timeline in the Development of Agricultural Tractors and Power Units Note: the italic letters at the end of each entry refer to the references. 1705 Atmospheric steam engine invented by Englishmen Thomas Newcomen, 1663- 1729, with John Calley (or Cawley), ??-1725, and partnered with Thomas Savery, c. 1650- 1725, for its application. EB EWB GI MWBD 1769 Steam, three-wheeled, road wagon built and demonstrated in France by Nicolas J. Cugnot, 1725-1804, first used for moving artillery pieces. DDI EB GI AT WOI 1769 Steam engine using a separate condenser patented by Scot James Watt, 1736- 1819, who is often credited as the inventor of the steam engine. This engine was manufac- tured from 1774-1806. ATEN EB EWB HT MWBD 1781 Steam engine that provided means of changing the motion of the piston to rotation for driving machinery patented by James Watt, 1736-1819. EB 1791 Gas engine using coal gas awarded British patent to John Barber of England. HFP 1792-1794 Steam carriage built by William Murdock, 1754-1839, an associate of James Watt, 1736-1819. EB 1794 Internal combustion gas engine using piston and cylinder patented in Great Britain by American Robert Street, 18th century, the gas being hydrogen-air mixtures or “illuminat- ing gas,” a vaporized gas from oil or coal. EB HFP MWBD 1799 Coal gas engine that compressed a mixture of gas and air before ignition patented and constructed by Frenchman Philippe Lebon, 1767-1804. HFP HI MWBD 1801, 1802 Practical steam (vertical boiler) vehicle (carriage) made by Englishman Rich- ard Trevithick, 1771-1833. -

Steam Roller D375, D376, D377 & Traction Engine D415, D416, D417

Assembly Instructions Steam Roller D375, D376, D377 & Traction Engine D415, D416, D417 Overview Stage 1, Front Part Stage 6, Boiler Assembly Operating instructions Stage 2, Burner Chamber Rear Stage 7, Burner, Front Connection Functioning of the original engine Stage 3, Burner Chamber Front Stage 8, Steering Mechanism The Energy Transformation Stage 4, Flywheel Shaft Stage 9, Rear Rollers History Stage 5, Cylinder Stage 10, Roof and Chimney Accessories Special Notes on the Assembly 1. The assembly takes approx. 3-4 hours. Please allow sufficient time in order to avoid too many interruptions. 2. This is a valuable, demanding model. The assembly requires quiet, concentration and manual dexterity. 3. These instructions are applicable to both the steam engine as well as the traction engine. Please refer to the relevant text/picture. 4. The assembly should be carried out on a clean even table, so that no parts are lost. 5. All parts have been checked several times and fit into each other. If something does not fit, do not use force but study the assembly instructions/illustrations again. 6. Before operating the steam engine, please read and observe the operating instructions carefully. 7. After longer periods of operation, individual screws might need tightening. Note: Brass and black/brass models. The brass parts are treated with a clear lacquer to prevent tarnishing. After usage and to prevent tarnishing, apply a further coat of clear lacquer. Text & illustrations: Wilesco Wilhelm Schröder GmbH & Co., Germany Assembly Instructions Steam Roller D375, D376, D377 & Traction Engine D415, D416, D417 Stage 1, Front Part Steam Roller Illustration 1 Illustration 2 1 2 x front rollers Push the two front rollers (1) onto the front axle (8). -

Team Traction Operator Examination And

Steam Traction Operator Certification and Examination Guide Effective: June 2021 Document Uncontrolled if Printed This document replaces all previous versions Revisions/updates to this document are reflected by a change in the above date Steam Traction Operator Certification and Examination Guide Syllabus The topics that follow are intended to be a study guide, and in no way implies that additional knowledge obtained from experience is not needed to successfully challenge the Steam Traction Operator Examination. 1. ACT AND REGULATION: The candidate is expected to be able to locate information relating to the plant registration and operator certification, operation, maintenance, inspection, and testing of the steam traction plant and its equipment resourcing the Technical Standards & Safety Act, the Operating Engineers Regulation and the Boilers and Pressure Vessels Regulation. 2. SAFETY: The candidate is expected to be able to fully explain the dangers associated with the operation of a steam traction plant and all its components, and state the precautions to be taken to minimize or prevent such dangers. 3. FUNDAMENTALS OF THERMODYNAMICS: a. Saturated and superheated steam, water, condensate, types of heat, temperature, BTU, pressure and its effect. 4. BOILER DESIGN AND TYPES: a. Components of Locomotive and Vertical style boilers, superheaters. b. Types of riveted joints and advantages of welded seams. c. Types and location of stays, methods of fitting boiler tubes. d. Difference between water and firetube boilers, advantages and disadvantages of watertube boilers and their primary safety differences. 5. BOILER OPERATION AND MAINTENANCE: a. Principles and causes of boiler explosions. b. Starting, shutting down, maintaining and laying up boilers. -

University Museums and Special Collections Service Page 1 of 95 TR DX1597 Engineering Drawings from Various Companies Including

University Museums and Special Collections Service TR DX1597 Engineering drawings from various companies including Dodman, Aveling and Porter Deposited by the Road Locomotive Society TR DX1597 DO1 Drawings TR DX1597 Drawing of a general arrangement & details of a drum lock for DO1/1 Dodman traction engine Drawing no. 206 1 doc 2 Sept 1905 TR DX1597 Drawing of a general arrangement & details of a drum lock for DO1/2 Dodman traction engine Drawing no. 206 1 doc 18 Jan 1906 TR DX1597 Drawing of a general arrangement of a Dodman traction DO1/3 engine Drawing no. 206 1 doc Sept 1905 TR DX1597 Drawing of Governor & details for a Dodman traction engine DO1/4 Drawing no. 206 1 doc c.1905-1906 TR DX1597 Drawing of a general arrangement of a Dodman traction DO1/5 engine Drawing no. 206 1 doc c.1905-1906 TR DX1597 Drawing of a general arrangement of a Dodman traction DO1/6 engine Drawing no. 206 1 doc c.1905-1906 Page 1 of 95 University Museums and Special Collections Service TR DX1597 Drawing of an arrangement of smokebox & Fore-Carriage DO1/7 plate for a Dodman traction engine Drawing no. 206 1 doc c.1905-1906 TR DX1597 Drawing of a boiler & Chimney for a Dodman traction engine DO1/8 Drawing no. 206 1 doc 29 Jun 1905 TR DX1597 Drawing of a boiler & chimney for a Dodman traction engine DO1/9 Drawing no. 206 1 doc 25 Mar 1904 TR DX1597 Drawing of a road wheels and gearing for a Dodman traction DO1/10 engine Drawing no. -

F T Dyer Collection D DYER

Museum of English Rural Life F T Dyer Collection D DYER RECORDS OF F T DYER The Collection covers the year’s 1866-1998. The physical extent of the collection is 83 Documents. Introduction Fred Dyer joined Ransomes Sims and Jefferies Ltd in September 1933 as an apprentice (the last one to be trained on steam engines). In 1943 he was appointed Plough Works Manager and during the second World War he was the Deputy Chief of Ransomes Orwell Works Fire Brigade. He was appointed General Works Manager for Ransomes Nacton Works in 1967, Chief Quality Controller and Engineering Manager in 1970 and Manager, Special Products, Design & Experimental Department in 1978. He retired in 1979. D DYER AD ADMINISTRATIVE RECORDS D DYER AD4 PREMISES RECORDS D DYER NOTES for a presentation relating to Ransomes Nacton Works AD4/1 and factory layout c1950 Page 1 of 17 Museum of English Rural Life D DYER AD8 GENERAL CORRESPONDENCE D DYER FILE of correspondence relating to the setting up of a plant in AD8/1 South Africa to manufacture Ransomes products 1958-1963 D DYER Relating to visit to Leon Claeys PVBA, Zedelgem, Belgium and AD8/2 Gebr.Claas Maschinenfabrik GMBH, Harsewinkel, Westfalen, West Germany 1962 (Jan-May) D DYER CORRESPONDENCE of F T Dyer AD8/2-6 D DYER Relating to visit to Le Progres Industriel, Lot, Belgium AD8/3 1964(Jun) D DYER Relating to visit to World Ploughing Championship and AD8/4 Kverneland Fabrikk, Norway 1964-1965 D DYER Relating to visit to Rasspe & Sohme, Solengen, West Germany AD8/5 1970(Dec)-1971(Jan) Page 2 of 17 Museum of English -

Heavy Metal Archive Workshop Marshalls, Sons and Company 5 December 2007

Heavy Metal archive workshop Marshalls, Sons and Company 5 December 2007 Museum of English Rural Life Redlands Road Reading RG1 5EX Tel: 0118 378 8660 [email protected] www.merl.org.uk About the Heavy Metal project ‘Heavy Metal’ is an archive project, funded by the Heritage Lottery Fund, the Road Locomotive Society and the University of Reading. The project started in January 2007 to encourage more people to use MERL’s steam engine and farm machinery manufacturers’ archives and to make them more accessible. Over many months, Museum staff and volunteers have sorted and catalogued a large range of archives. These include 10,000 engineering drawings produced by steam engine manufacturers, Charles Burrell and 2,500 from Wallis and Steevens. The volunteers, who include members of the Road Locomotive Society, also learnt conservation techniques enabling them to repackage glass negatives and preserve around 1,000 fragile drawings. A project archivist was employed to sort and produce an electronic catalogue of three major archive collections: Wallis and Steevens and agricultural machinery manufacturers’ International Harvester and Massey-Ferguson. These collections include technical literature, business and employee records, engineering drawings, photographs and advertising materials. When the electronic catalogues are complete, the list of MERL archives will be available for everyone online at the Access to Archives’ website – www.a2a.org.uk The project has also enabled MERL to digitise a number of fragile archives to preserve them for the future and make them easier to use. These include a number of Wallis and Steevens production registers, which are requested frequently, and 600 glass negatives on loan from the Road Locomotive Society. -

30Th Australian Miniature Traction Engine Rally

NORTHERN DISTRICTS M ODEL ENGINEERING SOCIETY (PERTH) INC. January — February 2019 30th Australian Miniature Traction Engine Rally EACH year the Australian Miniature Traction Engine Rally has come and gone and I have often thought about going to it. This year (2018) was the 30th annual rally, hosted by Cobdogla Steam Friends Society at Cobdogla Irrigation and Steam Museum located on the Murray River in South Australia. I had been there before and thoroughly enjoyed the informal friendly atmosphere of the place. So our air tickets and car hire were booked. Cobdogla is a pleasant 220km drive through the Barossa Valley but has only a caravan and camping site. However Barmera, a further 6km on, has plenty of accommodation. Cobdogla has the only Humphrey pumps in the Southern hemisphere. These pumps are something to behold and it's hard to imagine how the very water it The massive Fowler Z7 ploughing engine and the B6 crane dwarf the pumps is used as a 72 inch piston oscillating visiting miniature Foden steam wagon. 300 tons of water on a four stroke cycle up to nine More photos on page 3... strokes per minute and delivering 2600 gallons per stroke — 1.5 million gallons per hour! The pumps have no suction so they are below the The site also has a 2 foot gauge railway which runs for a level of the river and they push the water up 9 metres kilometre out into the vineyards and they had the 1906 which then gravitates out for irrigation. They were Bagnall saddle tank loco fired up on both days and took us fuelled by producer gas and as the local supply of for trips, together with the loco driver’s dog which insisted timber began to run out and the inevitable on coming along for each ride.