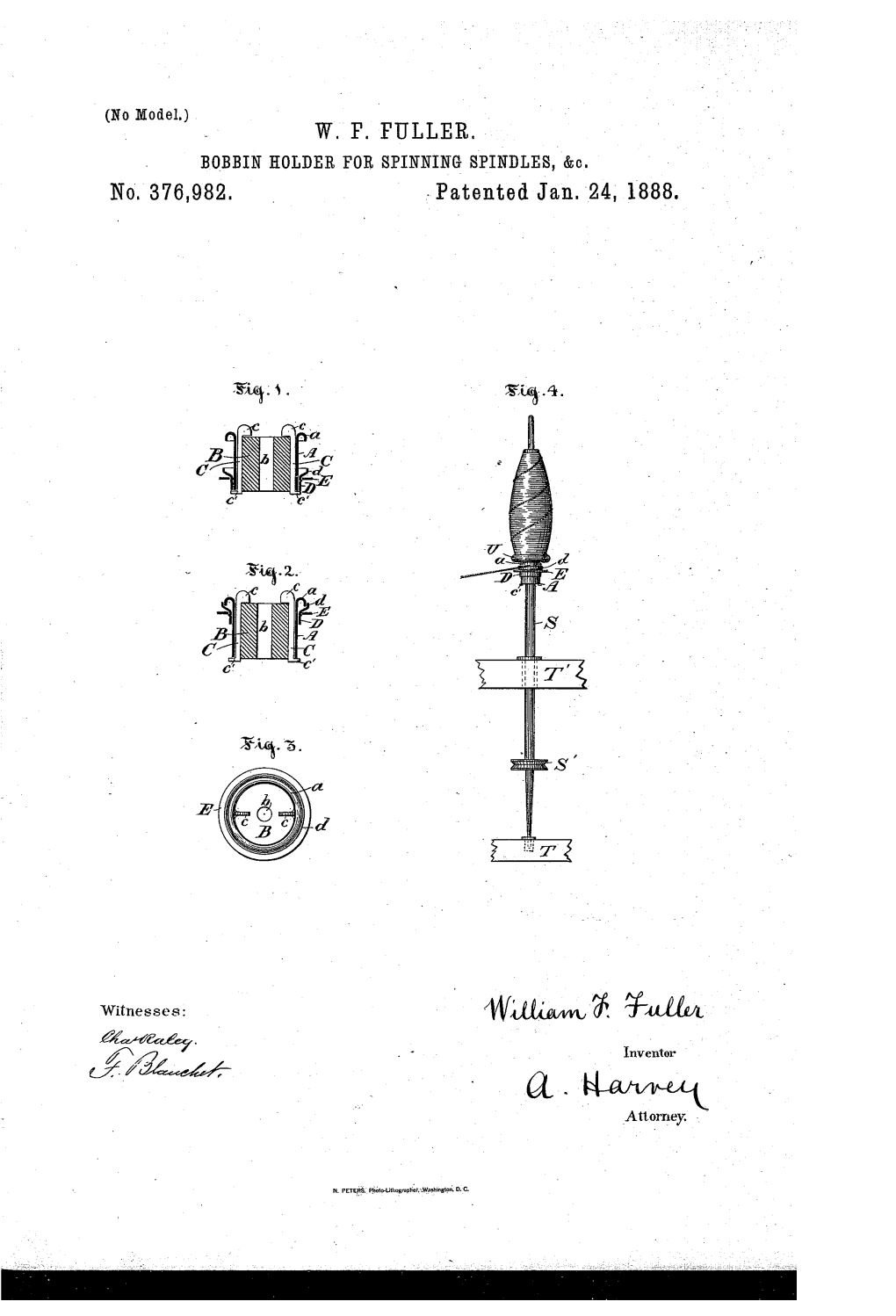

BOBBIN HOLDER for SPINNING Spindles, &C

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Hand Needles & Accessories Guide

FREE Easy HAND NEEDLE SELECTION Threading Hand needles vary according to the shape of the EASY THREADING hand needles & eye, the length and point. The larger the needle General purpose needle with a slot in size, the shorter and finer the needle. Select the outer edge of eye for easy threading accessories guide type of needle for the type of project to be sewn, Embroidery then choose the size of needle for the weight of EMBROIDERY fabric and type of thread. Sharp needle with long eye for smocking, heirloom sewing, TYPES OF HAND NEEDLES Ball Point Glovers/ embroidery and crewel Leather BALL POINT GLOVERS/LEATHER Slightly rounded tip for sewing stretch Needle with triangular point for use and knit fabrics with leather, suede, vinyl and fur Beading Milliners BEADING MILLINERS Very fine, long needle with a small, round Long needle with small round eye eye for beadwork, sewing sequins, for gathering, pleating, basting and pearls, etc. Chenille Quilting millinery work Betweens CHENILLE QUILTING BETWEENS Large-eye needle with sharp point for Short needle with round eye for ribbon embroidery, candlewicking Cotton quilting and detailed handwork and crewel work Sharps Darners SHARPS COTTON DARNERS General purpose needle with sharp Long needle with sharp point and long eye point for sewing and applique for mending Tapestry Crewel TAPESTRY CREWEL Large-eyed needle with a blunt point Sharp needle with long eye for hand for cross stitch, needlepoint and for embroidery and crewel work Yarn stitching knitted items Darners DOLL Doll YARN DARNERS Long -

View in the Gem and Mineral Able As a Tablecloth in Four Sizes, Or As a ,A, ...__ Hall of Our National Museum of Natural Set of Four Striking Placemats

C. HEART PERFUME BOTTLE. Our pretty heart-shaped perfume bottle is Wlcome to the Smithsonian Allow 12-16 weeks for delivery. perfect for holding precious scents and her interest Our exclusive hand CabdogueforSpring1988 1. LOUNGE CHAIR: 3026. s1,150.00 (Members s1,035.00) blown glass perfume bottle with ground stopper features delicate pink hearts (s/h 76.00).* blossoming on graceful vines and is created by Zellique Art Glass of Califor· 2. OTTOMAN: 3027. s660.00 (Members s594.00) nia. The National Museum of American History includes art glass in its collec· On these pages you will find handsome reproductions, (s/h 44.55).* tions. Signed and dated. Approx. 4\4''h. 7167 s140.00 (Members s126.00) adaptations and other beautiful and useful items that reflect 3. LOVE SEAT: 3028. s1,875.00 (Members s1,687.50) (s/h 2.90). the rich diversity of the Smithsonian. As the world's largest (s/h 126.50).* complex of museums, art galleries and research facilities, it 4. SOFA: 3029. s2,500.00. (Members s2,250.00) D. HEART THIMBLE A Smithsonian exclusive by Simons Brothers. This encompasses the vast and varied elements of America's (s/h 162.00).* gold-plated sterling silver thimble with delicately pierced band is reproduced cultural, social, scientific and artistic heritage. 5. END TABLE: 3030. s475.00 (Members s427.50) from an original in our Mary Gallatin Hoppin Collection, which contains more Historical and educational information is provided on a (s/h 32.00).* than 400 unusual thimbles. A charming find for collectors. Approx. -

Specialist Collectors' Sale , Tue, 13 July 2021 9:00

Specialist Collectors' Sale , Tue, 13 July 2021 9:00 1 9ct gold charm bracelet with various novelty gold 17 Victorian silver vase of tapered cylindrical form and yellow metal charms £180-220 with embossed and pierced decoration on 2 9ct yellow and white gold bracelet with five white circular foot (lacking glass liner), by James gold double rope twist panels and yellow gold Dixon & Sons, Sheffield 1896. 11.5cm high £60- fittings. 20cm long £150-200 100 3 9ct gold circular open work ‘Ruth’ pendant on 18 Silver cigarette case with engine turned 9ct gold curb link chain. £250-300 decoration. Birmingham 1956 £60-100 4 Yellow and white metal Star of David pendant on 19 Victorian silver cased pocket watch with white 9ct gold chain £200-300 enamel dial, Roman numeral markers and subsidiary seconds dial, on silver watch chain 5 9ct gold Jewish heart shaped pendant on 18ct £40-60 gold chain £120-180 20 9ct gold flat curb link chain, 45.5cm long £150- 6 18ct gold diamond set black onyx plaque ring, 200 size L and 18ct gold signet ring, size R £80-120 21 9ct gold ball and fancy link chain, 59.5cm long 7 14ct gold wedding ring (stamped 585). Size Q £120-180 £40-60 22 Pair 9ct gold cufflinks, each oval panel engraved 8 9ct gold opal and ruby cluster ring, size N and with B and G £60-100 9ct gold emerald and opal flower head ring, size L½ £40-60 23 9ct gold heart pendant on 9ct gold chain, one other 9ct gold chain and 9ct gold watch bracelet 9 Two ladies' 9ct gold vintage wristwatches - parts £200-300 Accurist and Centaur, both on 9ct gold bracelets -

R. & Louise A. Philip

R. & LOUISE A. PHILIP. SEWING-CASES. No. 174,976. Patented March 21, 1876. V S. S sS. SS. UNITED STATES PATENT OFFICE. ROBERT PHILIP AND LOUISE. A. PHILIP, OF SACRAMENTO, CALIFORNIA. IMPROVEMENT IN SEWING-CASES. Specification forming part of Letters Patent No. 124,976, dated March 21, 1876; application filed February 19, 1876. To all whom it may concern: to six or eight, the receptacles are numbered Be it known that we, RoBERT PHILIP and twice, in order to give all the numbers of LOUISE. A. PHILIP, of Sacramento, in the thread or twist most used in machine-sewing. county of Sacramento and State of California, On the inside of the box-cover K, in Fig. 1, have invented a new and useful Improvement the thimble, Scissors, and paper of needles are in Sewing-Cases, which improvement is, fully securely held by the spring-holders a, b, and c, set forth in the following specification, refer respectively. ence being had to the accompanying drawing. The needle-cushion d, Fig. 1, for sewingma The object of our invention is to hold and chine or common needles, is in the form of a secure, in a simple and convenient manner, in horseshoe, thus economizing space, and di a sewing-case or its equivalent, the most nec vided into sections, which are indicated in the essary implements of hand and machine-sew drawing by the numbers 1, 2, 3, 4, 56, and 7. ing, viz., spools, bobbins, scissors, thimble, and The label e in the inner curve of the cushion needles. is marked with numbers or letters correspond In Figure 1, A A are two bars, pivoted at ing with those of the needles on the cushion. -

Freshwater Bay Museum Advisory Committee

FRESHWATER BAY MUSEUM COMMITTEE AGENDA 4 DECEMBER, 2017 TOWN OF CLAREMONT FRESHWATER BAY MUSEUM ADVISORY COMMITTEE NOTICE OF MEETING A MEETING OF THE FRESHWATER BAY MUSEUM ADVISORY COMMITTEE TO BE HELD IN THE COUNCIL CHAMBERS AT 308 STIRLING HIGHWAY, CLAREMONT MONDAY 4 DECEMBER 2017 COMMENCING AT 5:00PM Liz Ledger Chief Executive Officer Date ___________________ Page (i) FRESHWATER BAY MUSEUM COMMITTEE AGENDA 4 DECEMBER, 2017 DISCLAIMER Persons present at this meeting are cautioned against taking any action as a result of any Committee recommendations until such time as those recommendations have been considered by Council and the minutes of that Council meeting confirmed. Page (ii) FRESHWATER BAY MUSEUM COMMITTEE AGENDA 4 DECEMBER, 2017 TABLE OF CONTENTS ITEM SUBJECT PAGE NO 1 DECLARATION OF OPENING/ANNOUNCEMENT OF VISITORS............. 2 2 RECORD OF ATTENDANCE/APOLOGIES ................................................ 2 3 ELECTION OF PRESIDING MEMBER ........................................................ 2 4 DISCLOSURE OF INTERESTS ................................................................... 2 5 CONFIRMATION OF MINUTES OF PREVIOUS MEETINGS ..................... 2 6 BUSINESS NOT DEALT WITH FROM A PREVIOUS MEETING ................ 2 7 REPORTS OF THE CEO ............................................................................. 4 7.1 PEOPLE AND PLACES ............................................................................... 4 7.1.1 FRESHWATER BAY EXECUTIVE MANAGER UPDATE .................. 4 7.1.2 MUSEUM OPERATIONS REPORT -

4-H 168 Sewing for Fun : Leader's Guide

University of Nebraska - Lincoln DigitalCommons@University of Nebraska - Lincoln Nebraska 4-H Clubs: Historical Materials and 4-H Youth Development Publications 1986 4-H 168 Sewing for Fun : Leader's Guide Follow this and additional works at: http://digitalcommons.unl.edu/a4hhistory "4-H 168 Sewing for Fun : Leader's Guide" (1986). Nebraska 4-H Clubs: Historical Materials and Publications. 338. http://digitalcommons.unl.edu/a4hhistory/338 This Article is brought to you for free and open access by the 4-H Youth Development at DigitalCommons@University of Nebraska - Lincoln. It has been accepted for inclusion in Nebraska 4-H Clubs: Historical Materials and Publications by an authorized administrator of DigitalCommons@University of Nebraska - Lincoln. RD2134 40677 Nebraska Cooperative Extension Service 4-H 168 Leader's Guide ~ Issued in furtherance of Cooperative Extension work, Acts of May 8 and June 30, 1 914, in cooperation with the {~\ ...,... U.S. Department of Agriculture. Leo E. Lucas, Director of Cooperative Extension Service, University of Nebraska, : . · ~ Institute of Agriculture and Natural Resources. • • • ........~ The Cooperative Extension Service provides information and educattonal programs to all people wtthout regard to race, color. nattonal or~gtn , sex or hand•cap. Sewing for Fun Introduction Four-H'ers enroll in sewing projects because they Congratulations on assuming the role of a 4-H sewing want to learn to sew. They want articles they can use project leader. Teaching young people to sew is a satis and enjoy. If leaders always expect perfection, members fying activity in which you can take part. Like most 4-H may be discouraged and lose interest. -

232-Florida Souvenirs-R.Indd

Souvenirs 232-FL31174 FL Magnet PVC Festive Price: $2.00 Retail: $3.99 w(h31247*NLLROk(U Lynco Distribution Inc. dba Lynco Products™ 1410 11th St. West Milan, IL 61264 www.lyncoproducts.net Toll Free: Local: Fax 800.758.9244 309.787.2300 309.787.3200 2010-07-Florida Souvenirs 232-FL31164 232-FL21268 232-FL24248 232-FL23385 FL Bell Elements FL K/C Beaded FL K/C Glitter Peace Symbol FL K/C Lucite Retail: $4.99 Retail: $3.99 Retail: $4.99 Map Flag w(h31247*NLLQOl(V w(h31247*MLMQSt(y w(h31247*MOMOSs(x Retail: $3.99 w(h31247*MNNSPl(V 232-FL21293 232-FL23387 232-FL23776 232-FL25209 FL K/C Lucite State Map FL K/C Metal Heart Locket FL K/C Spinner Rhines. FL Lapel Pin Retail: $3.99 Retail: $5.99 Retail: $5.99 Elements w(h31247*MLMTNl(V w(h31247*MNNSRp(u w(h31247*MNRRQr(w Retail: $3.99 w(h31247*MPMKTs(x 232-FL31571 232-FL32344 232-FL32344 232-FL31166 FL Magnet 2D Elements FL Magnet 2D Map Flag FL Magnet FL Mug Elements Retail: $3.99 Retail: $3.99 2D State Map Retail: $5.99 w(h31247*NLPRLr(w w(h31247*NMNOSo(Y Retail: $3.99 w(h31247*NLLQQp(u w(h31247*NMNOOq(v 232-FL32345 232-FL21267 232-FL31171 232-FL31172 FL Mug State Map FL Playing Cards FL Shooter Multi Clr Stars FL Shooter Tipsy Retail: $5.99 Retail: $3.99 Retail: $5.99 Retail: $5.99 w(h31247*NMNOPn(X w(h31247*MLMQRm(W w(h31247*NLLRLt(y w(h31247*NLLRMq(v 232-FL25309 232-FL18009 232-FL32348 232-FL31170 FL Shot Glass 3 View FL Shot Glass Elements FL Shot Glass Frosted FL Shot Glass Retail: $3.99 Retail: $3.99 Retail: $3.99 Multi Stars w(h31247*MPNKTp(u w(h31247*LSKKTo(Y w(h31247*NMNOSo(Y Retail: $3.99 w(h31247*NLLRKm(W 232-FL32349 232-FL32350 232-FL25109 232-FL31167 FL Shotglass State Map FL Shotglassr Tipsy FL Spoon Elements FL Thimble Elements Retail: $3.99 Retail: $4.99 Retail: $5.99 Retail: $3.99 w(h31247*NMNOTl(V w(h31247*NMNPKr(w w(h31247*MPLKTl(V w(h31247*NLLQRm(W Item # Pk. -

Basic Sewing Supplies 1

Basic Sewing Supplies 1 Basic Sewing Supplies Rotary cutter Self-healing cutting mat Ruler with grid Rotary cutter safety glove Dressmaking ham Press cloth Sleeve roll or board Tailor board Basic sewing tools are needed for beginning items. A few Needle press board/pad are essential to use in constructing a sewn item. As you progress in your sewing skills, you may want to include Press mitt other supplies for more advanced projects. Other supplies make the process easier. Visit your local fabric store or Sewing Kit Glossary browse the internet for additional supplies. As you get your supplies check them off. Basic Supplies Needed: Basic Supplies Straight pins—Select steel pins that are sharp. Dull pins can damage fabrics. Ballpoint pins can be used on knitted Needed: fabrics. Long pins with flat heads can be used on fleece or open weave fabrics. Straight Pins Pin cushion Sharp shears (for cutting fabric) Tape measure Seam ripper Sewing supply container Optional: Pin cushion—There are a variety of pin cushions available. A magnetic pin cushion helps hold pins in place. Hem (seam) gauge A wrist pin cushion keeps pins accessible. Marking pen/pencil or chalk Small scissors (for clipping threads) Hand sewing needles Thimble Advanced Project Supplies: Point turner Basic Sewing Supplies 2 Dressmaker shears (for cutting fabric)—For best results Optional: in cutting fabric select shears that are sharp. Bent handle shears allows the fabric to lay flat while cutting. Left-hand Hem (seam) gauge—Select a metal gauge with double shears are available. Shears are available in a variety of pointed slider. -

4-H CDM Skill-A-Thon Sewing & Clothing ID

4-H CDM Skill-a-Thon Sewing & Clothing ID The photos shown here are only one option of what an item may look like. Other options are available. Revised November 2020 Batik - Indonesian technique of wax resist dyeing applied to whole cloth. This technique originated from Java, Indonesia. It is made either by drawing dots and lines of the resist with a spouted tool called a tjanting, or by printing the resist with a copper stamp called a cap. Broadcloth - A very lightweight, smooth, flat looking fabric, with no pattern in the weave of the threads. It is similar in quality to pinpoint fabric but has less texture. This usually means it is slightly more transparent and not as shiny as the pinpoint. Chambray - A plain weave fabric woven with a colored yarn in the warp and a white yarn in the weft. Corduroy - A fabric with a distinct pattern, a “cord” or wale. It is mostly composed of tufted cords, sometimes exhibiting a channel (bare to the base fabric) between the tufts. Cotton - A fabric made from the fiber of its namesake plant. It is good for first time sewers to use because it’s easy to work with and used for everyday clothing. Eyelet - A type of fabric that has holes that are edged using a buttonhole stitch. The holes are precisely sized and situated to create a pattern or patterns, often floral designs or abstract geometric arrangements. Faux Fur - A fabric fashioned to simulate genuine animal hair. It is known as a pile fabric and is typically made from polymeric fibers that are processed, dyed, and cut to match a specific texture and color. -

17 July 2019 at 9:30Am (Online from 10Am)

Antiques & General Wednesday 17 July 2019 at 9:30am (online from 10am) Downham Market | Auction Rooms £1 Buyers Notes: Viewing Times: Saturday 13 July 2019 (10am to 1pm) Tuesday 16 July 2019 (12noon to 6pm) Wednesday 17 July 2019 (8am to 10am) Light Refreshments: Available on sale days from Jen’s café Buyer’s Premium: 12.5% plus VAT (15% Inclusive) Bidding: Please register for a bidding number prior to bidding and clearly state your num- ber on a winning bid. Purchasers should satisfy themselves by physical inspection of lots before bidding as to the origin authenticity quality age weight size and general description – as lots are sold in their actual state with all faults imperfections or errors of descrip- tion. If physical inspection is not possible condition reports must be reviewed by purchasers in full before bids can be accepted. (please refer to full conditions of sale) Commission Bids: Commission bids are accepted subject to prospective purchaser having viewed the items. Payment: All payments must be paid for on the day of sale, unless special arrangement has been made with the Auctioneer. Payment by card, cheque or cash. For Money Laundering purposes, we are not allowed to take more than £7,500 from anyone without formal identification. (photo identity & bank cards will be required). Selling Rate: Between 120-150 lots an hour. Please ensure you are in the saleroom at least 20 minutes before you expect a lot to be offered in case we are ahead of schedule. Live Bidding: This auction has the facility for live internet bidding via www.the-saleroom.com or www.liveauctioneers.com from lots 300 onwards and will be subject to an addi- tional premium, please refer to their website for conditions. -

Sew EZ Model W338

Sew E-Z Model W338 Mini Sewing Machine Instruction Manual Please read the instruction manual carefully before operating the machine. Call Toll Free 800-331-3164 1 www.whitesewing.com Introduction Thread Spindle (C) Take Up Lever (D) Thread Spool (E) Bobbin Holder (V) Bobbin Winder Spindle (T) Tension Screw (Q) Handwheel (K) Bobbin Spindle (U) Speed Button (L) Needle Clamp Screw (O) ON/OFF Switch (A) Needle Clamp (P) Bobbin (S) Light Button Needle (R) Stitch Length Adjustment Button Foot Pedal Jack (M) Presser Foot (F) AC/DC Jack (DC 6V) Bobbin compartment (I) Bobbin Holder (J) Reverse Button Bobbin Winder Handler (W) Presser Foot Lever (G) Bobbin Cover Release Button (H) Battery Compartment (B) on underside of machine 2 Parts & Accessories AC/DC Adapter (DC 6V) Foot Pedal Jack (M) Accessories Needle Threader, Tape measure, Seam ripper, Needles, Thimble, Thread, Buttons, Pins, Scissors, Bobbins, Snaps 3 Battery Installation Battery Installation 1. Caution: Make certain the POWER SWITCH is in the off position before inserting the batteries. 2. Insert (4)AA batteries in the battery slot compartment in the bottom of the machine. Be certain the batteries are in the correct polarities as marked on the machine. Then replace the battery compartment cover. 4 Threading the machine Threading the machine 1. Raise thread spindle (C) by grasping the exposed top and pulling upward until thread spindle (C) is fully extended. 2. Place thread spool (E) on the thread spindle (C) as shown. 3. Pull thread from the thread 2 spool (E) on the thread spin- 1 dle (C) and put it through the thread holder (1) in the direc- tion toward front of machine. -

Little House Notions Catalog

LITTLE HOUSE NOTIONS CATALOG 2020 New Year’s Orimono Imports is proud to be the North American distributor for Little House products. We work closely with the company to bring traditional, new, and innovative notions for your sewing needs. Pricing sheet by request. THIMBLES Tortoise thimble #402004 – M #402005 – L Put-up: 5 units per size • Useful for quilting and general purpose stitching • Suitable for use with long fingernail • Lightweight brass • Adjustable for comfort • Medium or Large size White leather thimble with elastic #431010 – M #431011 – L Put-up: 5 units per size • Reinforced fingertip pad • Made of thick, soft leather and elastic • Comfortable to use • Medium or Large size “Denim” double leather thimble #431979 – L #431980 – M Put-up: 5 units per size • Exterior: sturdy cowhide; interior: soft deer leather • No seam on top, which makes it very comfortable on your fingertip • Medium or Large size Rubber grip thimble #432806 Put-up: 5 units per size Small (yellow), medium (pink), large (blue) • Two thimbles per package • Large hole on back of thimble to prevent sticking to fingernail • Small holes on front of thimble for ventilation Distributed through ORIMONO IMPORTS [2] www.orimonoimports.com [email protected] THIMBLES Ring thimble #432810 Put-up: 5 units • Antiqued brass • One size, adjustable • Worn on the upper part of middle or index finger to push needle through • Useful for sashiko and quilting Palm thimble #432811 Put-up: 5 units • Antiqued brass • One size, adjustable • Worn at the base of the middle finger