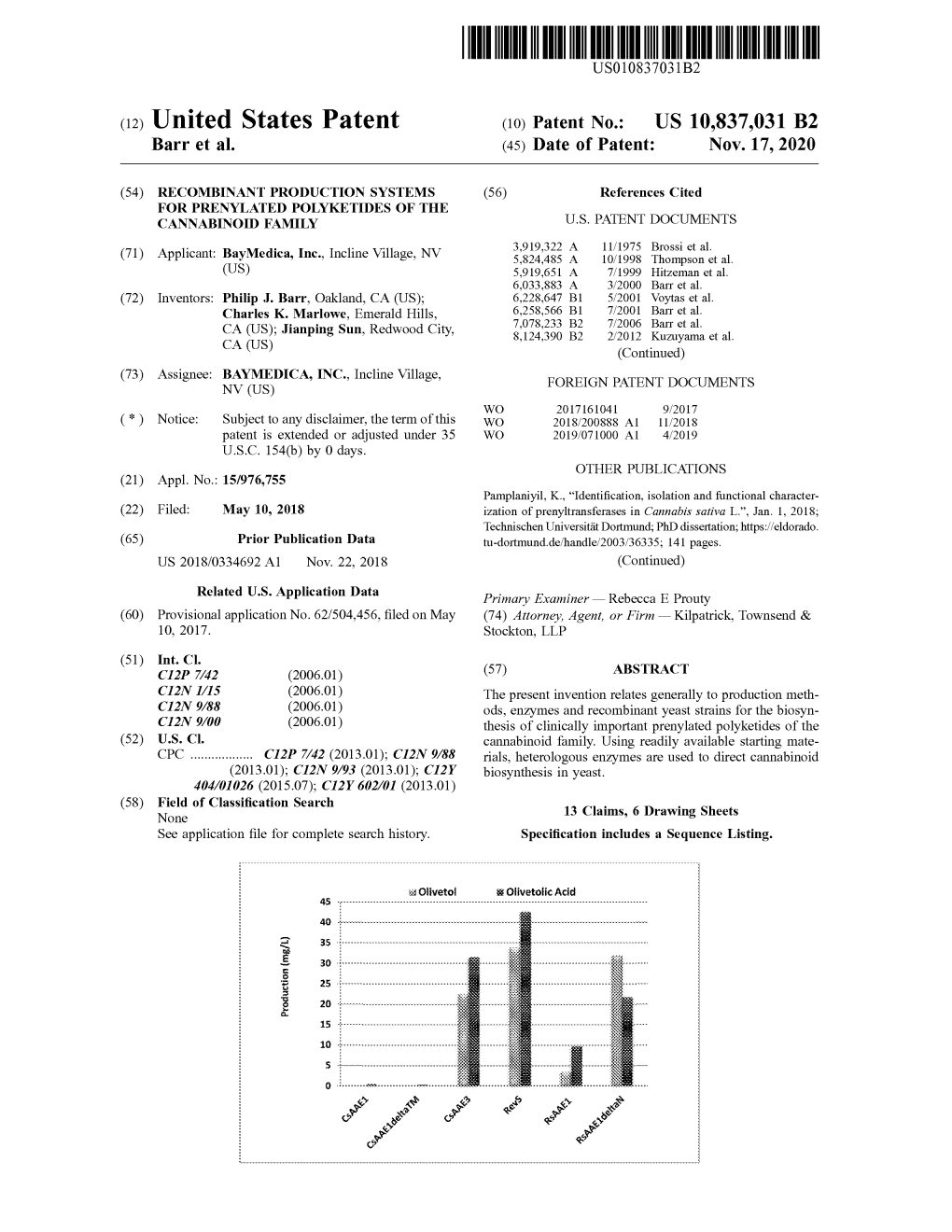

Csaaeldeltatm RSAAE1 Rsaaeldeltan

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Seed of Industrial Hemp (Cannabis Sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition

nutrients Review The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition Barbara Farinon * , Romina Molinari , Lara Costantini and Nicolò Merendino * Department of Ecological and Biological Sciences (DEB), Tuscia University, Largo dell’Università snc, 01100 Viterbo, Italy; [email protected] (R.M.); [email protected] (L.C.) * Correspondence: [email protected] (B.F.); [email protected] (N.M.) Received: 25 May 2020; Accepted: 23 June 2020; Published: 29 June 2020 Abstract: Hempseeds, the edible fruits of the Cannabis sativa L. plant, were initially considered a by-product of the hemp technical fibre industry. Nowadays, following the restorationing of the cultivation of C. sativa L. plants containing an amount of delta-9-tetrahydrocannabinol (THC) <0.3% or 0.2% (industrial hemp) there is a growing interest for the hempseeds production due to their high nutritional value and functional features. The goal of this review is to examine the scientific literature concerning the nutritional and functional properties of hempseeds. Furthermore, we revised the scientific literature regarding the potential use of hempseeds and their derivatives as a dietary supplement for the prevention and treatment of inflammatory and chronic-degenerative diseases on animal models and humans too. In the first part of the work, we provide information regarding the genetic, biochemical, and legislative aspects of this plant that are, in our opinion essential to understand the difference between “industrial” and “drug-type” hemp. In the final part of the review, the employment of hempseeds by the food industry as livestock feed supplement and as ingredient to enrich or fortify daily foods has also revised. -

A Polyketoacyl-Coa Thiolase-Dependent Pathway for the Synthesis of Polyketide Backbones

ARTICLES https://doi.org/10.1038/s41929-020-0471-8 A polyketoacyl-CoA thiolase-dependent pathway for the synthesis of polyketide backbones Zaigao Tan1,3, James M. Clomburg1,2, Seokjung Cheong1, Shuai Qian1 and Ramon Gonzalez 1,2 ✉ Polyketides found in nature originate from backbones synthesized through iterative decarboxylative Claisen condensations catalysed by polyketide synthases (PKSs). However, PKSs suffer from complicated architecture, energy inefficiencies, complex regulation, and competition with essential metabolic pathways for extender unit malonyl-CoA, all combining to limit the flux of polyketide biosynthesis. Here we show that certain thiolases, which we term polyketoacyl-CoA thiolases (PKTs), catalyse polyketide backbone formation via iterative non-decarboxylative Claisen condensations, hence offering a synthetic and effi- cient alternative to PKSs. We show that PKTs can synthesize polyketide backbones for representative lactone, alkylresorcinolic acid, alkylresorcinol, hydroxybenzoic acid and alkylphenol polyketide families, and elucidate the basic catalytic mechanism and structural features enabling this previously unknown activity. PKT-catalysed reactions offer a route to polyketide formation that leverages the simple architecture of thiolases to achieve higher ATP efficiencies and reduced competition with essential metabolic pathways, all of which circumvent intrinsic inefficiencies of PKSs for polyketide product synthesis. olyketides represent a large class of secondary metabolites that Here we show that enzymes other -

Phytocannabinoids: Origins and Biosynthesis

Phytocannabinoids Origins and Biosynthesis Gülck, Thies; Møller, Birger Lindberg Published in: Trends in Plant Science DOI: 10.1016/j.tplants.2020.05.005 Publication date: 2020 Document version Publisher's PDF, also known as Version of record Document license: CC BY-NC-ND Citation for published version (APA): Gülck, T., & Møller, B. L. (2020). Phytocannabinoids: Origins and Biosynthesis. Trends in Plant Science, 25(10), 985-1004. https://doi.org/10.1016/j.tplants.2020.05.005 Download date: 05. okt.. 2021 Trends in Plant Science Feature Review Phytocannabinoids: Origins and Biosynthesis Thies Gülck1,2,3,* and Birger Lindberg Møller1,2,3,* Phytocannabinoids are bioactive natural products found in some flowering Highlights plants, liverworts, and fungi that can be beneficial for the treatment of human Phytocannabinoids are bioactive terpe- ailments such as pain, anxiety, and cachexia. Targeted biosynthesis of cannabi- noids that were thought to be exclusive noids with desirable properties requires identification of the underlying genes to Cannabis sativa, but have now also been discovered in Rhododendron spe- and their expression in a suitable heterologous host. We provide an overview cies, some legumes, the liverwort genus of the structural classification of phytocannabinoids based on their decorated Radula,andsomefungi. resorcinol core and the bioactivities of naturally occurring cannabinoids, and we review current knowledge of phytocannabinoid biosynthesis in Cannabis, Many cannabinoids display promising non-hallucinogenic bioactivities that are Rhododendron,andRadula species. We also highlight the potential in planta determined by the variable nature of the roles of phytocannabinoids and the opportunity for synthetic biology approaches side chain and prenyl group defined by based on combinatorial biochemistry and protein engineering to produce canna- the enzymes involved in their synthesis. -

Designing Microorganisms for Heterologous Biosynthesis of Cannabinoids Angelaˆ Carvalho1, Esben Halkjær Hansen1, Oliver Kayser2, Simon Carlsen1,∗ and Felix Stehle2

FEMS Yeast Research, 17, 2017, fox037 doi: 10.1093/femsyr/fox037 Advance Access Publication Date: 4 June 2017 Minireview MINIREVIEW Designing microorganisms for heterologous biosynthesis of cannabinoids Angelaˆ Carvalho1, Esben Halkjær Hansen1, Oliver Kayser2, Simon Carlsen1,∗ and Felix Stehle2 1Evolva Biotech A/S, Lersø Parkalle´ 42-44, 2100, Copenhagen, Denmark and 2Laboratory of Technical Biochemistry, Department of Biochemical and Chemical Engineering, TU Dortmund University, Emil-Figge-Str. 66, 44227 Dortmund, Germany ∗Corresponding author: Evolva Biotech A/S, Lersø Parkalle´ 42-44, 2100, Copenhagen, Denmark. Tel: +45-35-200-243; E-mail: [email protected] One sentence summary: In this review, the authors explore the use of synthetic biology as an alternative approach for the synthesis of pharmaceutical cannabinoids in a heterologous host organism. Editor: John Morrissey ABSTRACT During the last decade, the use of medical Cannabis has expanded globally and legislation is getting more liberal in many countries, facilitating the research on cannabinoids. The unique interaction of cannabinoids with the human endocannabinoid system makes these compounds an interesting target to be studied as therapeutic agents for the treatment of several medical conditions. However, currently there are important limitations in the study, production and use of cannabinoids as pharmaceutical drugs. Besides the main constituent tetrahydrocannabinolic acid, the structurally related compound cannabidiol is of high interest as drug candidate. From the more than 100 known cannabinoids reported, most can only be extracted in very low amounts and their pharmacological profile has not been determined. Today, cannabinoids are isolated from the strictly regulated Cannabis plant, and the supply of compounds with sufficient quality is a major problem. -

Recent Developments in Cannabis Chemistry

Recent Developments in Cannabis Chemistry BY ALEXANDER T. SHULGIN, Ph.D. The marijuana plant Cannabis sativa contains a bewildering Introduction array of organic chemicals. As is true with other botanic species, there are representatives of almost all chemical classes present, including mono- and sesquiterpenes, carbohy- drates, aromatics, and a variety of nitrogenous compounds. Interest in the study of this plant has centered primarily on the resinous fraction, as it is this material that is invested with the pharmacological activity that is peculiar to the plant. This resin is secreted by the female plant as a protective agent during seed ripening, although it can be found as a microscopic exudate through the aerial portions of plants of either sex. The pure resin, hashish or charas, is the most potent fraction of the plant, and has served as the source material for most of the chemical studies. The family of chemicals that has been isolated from this source has been referred to as the cannabinoid group. It is unique amongst psychotropic materials from plants in that there are no alkaloids present. The fraction is totally nitro- gen-free. Rather, the set of compounds can be considered as analogs of the parent compound cannabinol (I), a fusion product of terpene and a substituted resorcinol. Beyond the scope of this present review are such questions as the distribution of these compounds within the plant, the bo- tanic variability resulting from geographic distribution, the diversity of pharmacological action assignable to the several Reprinted from Journal of Psychedelic Drugs, vol. II, no. 1, 197 1. 397 398 Marijuana: Medical Papers distinct compounds present, and the various preparations and customs of administration. -

What Is Delta-8 THC?? Cannabinoid Chemistry 101

What is Delta-8 THC?? Cannabinoid Chemistry 101 National Conference on Weights and Measures Annual Meeting - Rochester, NY Matthew D. Curran, Ph.D. July 21, 2021 Disclaimer Just to be clear… • I am a chemist and not a lawyer so: • This presentation will not discuss the legal aspects of Δ8-THC or DEA’s current position. • This presentation will not discuss whether Δ8-THC is considered “synthetic” or “naturally occurring.” • This is not a position statement on any issues before the NCWM. • Lastly, this should only be considered a scientific sharing exercise. Florida Department of Agriculture and Consumer Services 2 Cannabis in Florida Cannabis Syllabus • What is Cannabis? • “Mother” Cannabinoid • Decarboxylation • Relationship between CBD and THC • What does “Total” mean? • Dry Weight vs. Wet Weight • What does “Delta-9” mean? • Relationship between “Delta-8” and “Delta-9” • CBD to Delta-8 THC • Cannabinoid Chemistry 202… Florida Department of Agriculture and Consumer Services 3 Cannabis Cannabis • Cannabis sativa is the taxonomic name for the plant. • The concentration of Total Δ9-Tetrahydrocannabinol (Total Δ9-THC) is critical when considering the varieties of Cannabis sativa. • Hemp – (Total Δ9-THC) 0.3% or less • Not really a controversial term, “hemp” • Marijuana/cannabis – (Total Δ9-THC) Greater than 0.3% • Controversial term, “marijuana” • Some states prohibit the use of this term whereas some states have it in their laws. • Some states use the term “cannabis.” • Not italicized • Lower case “c” Florida Department of Agriculture and -

Medically Useful Plant Terpenoids: Biosynthesis, Occurrence, and Mechanism of Action

molecules Review Medically Useful Plant Terpenoids: Biosynthesis, Occurrence, and Mechanism of Action Matthew E. Bergman 1 , Benjamin Davis 1 and Michael A. Phillips 1,2,* 1 Department of Cellular and Systems Biology, University of Toronto, Toronto, ON M5S 3G5, Canada; [email protected] (M.E.B.); [email protected] (B.D.) 2 Department of Biology, University of Toronto–Mississauga, Mississauga, ON L5L 1C6, Canada * Correspondence: [email protected]; Tel.: +1-905-569-4848 Academic Editors: Ewa Swiezewska, Liliana Surmacz and Bernhard Loll Received: 3 October 2019; Accepted: 30 October 2019; Published: 1 November 2019 Abstract: Specialized plant terpenoids have found fortuitous uses in medicine due to their evolutionary and biochemical selection for biological activity in animals. However, these highly functionalized natural products are produced through complex biosynthetic pathways for which we have a complete understanding in only a few cases. Here we review some of the most effective and promising plant terpenoids that are currently used in medicine and medical research and provide updates on their biosynthesis, natural occurrence, and mechanism of action in the body. This includes pharmacologically useful plastidic terpenoids such as p-menthane monoterpenoids, cannabinoids, paclitaxel (taxol®), and ingenol mebutate which are derived from the 2-C-methyl-d-erythritol-4-phosphate (MEP) pathway, as well as cytosolic terpenoids such as thapsigargin and artemisinin produced through the mevalonate (MVA) pathway. We further provide a review of the MEP and MVA precursor pathways which supply the carbon skeletons for the downstream transformations yielding these medically significant natural products. Keywords: isoprenoids; plant natural products; terpenoid biosynthesis; medicinal plants; terpene synthases; cytochrome P450s 1. -

An Iterative Type I Polyketide Synthase Initiates the Biosynthesis of the Antimycoplasma Agent Micacocidin

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Elsevier - Publisher Connector Chemistry & Biology Article An Iterative Type I Polyketide Synthase Initiates the Biosynthesis of the Antimycoplasma Agent Micacocidin Hirokazu Kage,1 Martin F. Kreutzer,1 Barbara Wackler,2 Dirk Hoffmeister,2 and Markus Nett1,* 1Junior Research Group ‘‘Secondary Metabolism of Predatory Bacteria’’, Leibniz Institute for Natural Product Research and Infection Biology, Hans-Kno¨ ll-Institute, Beutenbergstrasse 11a, 07745 Jena, Germany 2Department of Pharmaceutical Biology at the Hans-Kno¨ ll-Institute, Friedrich Schiller Universita¨ t Jena, 07745 Jena, Germany *Correspondence: [email protected] http://dx.doi.org/10.1016/j.chembiol.2013.04.010 SUMMARY under macrolide therapy have been described (Averbuch et al., 2011; Cardinale et al., 2011; Itagaki et al., 2013). Micacocidin is a thiazoline-containing natural pro- Micacocidin is a new antibiotic that exerts strong inhibitory duct from the bacterium Ralstonia solanacearum effects in the nanomolar range against several Mycoplasma that shows significant activity against Mycoplasma species, including M. pneumoniae (Kobayashi et al., 1998). pneumoniae. The presence of a pentylphenol moiety In vivo efficacy after oral administration was demonstrated in distinguishes micacocidin from the structurally chicken that had been infected with M. gallisepticum (Kobayashi related siderophore yersiniabactin, and this residue et al., 2000). The thiazoline-containing natural product micaco- cidin is structurally closely related to the siderophore yersinia- also contributes to the potent antimycoplasma bactin (Drechsel et al., 1995), and cellular uptake studies effects. The biosynthesis of the pentylphenol moiety, suggest that it might also be involved in iron acquisition of the as deduced from bioinformatic analysis and stable producing bacterium Ralstonia solanacearum (Kreutzer et al., isotope feeding experiments, involves an iterative 2011). -

Using Dictyostelium Discoideum to Investigate the Mechanism of Action of Cannabigerol

Therapeutic cannabinoids: Using Dictyostelium discoideum to investigate the mechanism of action of cannabigerol Joseph Oddy Research thesis submitted for the degree of Doctor of Philosophy at the Royal Holloway University of London in May 2020 1 Declaration of Authorship I, Joseph Laurence Damstra-Oddy, hereby declare that the work presented in this thesis is my own unless otherwise stated, and that all published work has been acknowledged. Furthermore, I affirm that I have neither fabricated nor falsified the results reported herein. Signed: Date: 22/05/2020 2 Abstract Cannabis has been used to treat many diseases for centuries. Recent medical interest has focused on the potential of cannabinoids to treat diseases such as multiple sclerosis, epilepsy, and cancer where research has focused on investigating cannabidiol (CBD). However, other cannabinoids, such as cannabigerol (CBG), remain poorly characterised and are being explored as potential treatments. The molecular mechanisms by which cannabinoids treat diseases remain unclear, despite suggested targets including adenosine, mTOR, transient receptor potential transporters and cannabinoid receptors. This study aimed to identify molecular mechanisms of CBG, using Dictyostelium discoideum as a model system and translating results to a clinical setting. Initially, a targeted approach was undertaken where the effects of CBG on adenosine transport (and DNA methylation) was investigated. From this approach, CBG elevated DNA methylation in D. discoideum dependent upon adenosine transport via the equilibrative nucleoside transporter 1 (ENT1). In addition, an unbiased approach was taken in which screening of a mutant library for CBG resistance identified inositol polyphosphate multikinase (IPMK), a known regulator of mTOR activity, as a potential target. -

WO 2017/139496 Al 17 August 2017 (17.08.2017) P O P C T

(12) INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (19) World Intellectual Property Organization International Bureau (10) International Publication Number (43) International Publication Date WO 2017/139496 Al 17 August 2017 (17.08.2017) P O P C T (51) International Patent Classification: (81) Designated States (unless otherwise indicated, for every C12N 1/15 (2006.01) C12N 15/52 (2006.01) kind of national protection available): AE, AG, AL, AM, C12N 15/29 (2006.01) C12P 7/40 (2006.01) AO, AT, AU, AZ, BA, BB, BG, BH, BN, BR, BW, BY, C12N 15/31 (2006.01) C12P 7/22 (2006.01) BZ, CA, CH, CL, CN, CO, CR, CU, CZ, DE, DJ, DK, DM, DO, DZ, EC, EE, EG, ES, FI, GB, GD, GE, GH, GM, GT, (21) International Application Number: HN, HR, HU, ID, IL, IN, IR, IS, JP, KE, KG, KH, KN, PCT/US20 17/0 17246 KP, KR, KW, KZ, LA, LC, LK, LR, LS, LU, LY, MA, (22) International Filing Date: MD, ME, MG, MK, MN, MW, MX, MY, MZ, NA, NG, ' February 2017 (09.02.2017) NI, NO, NZ, OM, PA, PE, PG, PH, PL, PT, QA, RO, RS, RU, RW, SA, SC, SD, SE, SG, SK, SL, SM, ST, SV, SY, (25) Filing Language: English TH, TJ, TM, TN, TR, TT, TZ, UA, UG, US, UZ, VC, VN, (26) Publication Language: English ZA, ZM, ZW. (30) Priority Data: (84) Designated States (unless otherwise indicated, for every 62/293,050 February 2016 (09.02.2016) US kind of regional protection available): ARIPO (BW, GH, GM, KE, LR, LS, MW, MZ, NA, RW, SD, SL, ST, SZ, (71) Applicant: CEVOLVA BIOTECH, INC. -

European Patent Office U.S. Patent and Trademark Office

EUROPEAN PATENT OFFICE U.S. PATENT AND TRADEMARK OFFICE CPC NOTICE OF CHANGES 89 DATE: JULY 1, 2015 PROJECT RP0098 The following classification changes will be effected by this Notice of Changes: Action Subclass Group(s) Symbols deleted: C12Y 101/01063 C12Y 101/01128 C12Y 101/01161 C12Y 102/0104 C12Y 102/03011 C12Y 103/01004 C12Y 103/0103 C12Y 103/01052 C12Y 103/99007 C12Y 103/9901 C12Y 103/99013 C12Y 103/99021 C12Y 105/99001 C12Y 105/99002 C12Y 113/11013 C12Y 113/12012 C12Y 114/15002 C12Y 114/99028 C12Y 204/01119 C12Y 402/01052 C12Y 402/01058 C12Y 402/0106 C12Y 402/01061 C12Y 601/01025 C12Y 603/02027 Symbols newly created: C12Y 101/01318 C12Y 101/01319 C12Y 101/0132 C12Y 101/01321 C12Y 101/01322 C12Y 101/01323 C12Y 101/01324 C12Y 101/01325 C12Y 101/01326 C12Y 101/01327 C12Y 101/01328 C12Y 101/01329 C12Y 101/0133 C12Y 101/01331 C12Y 101/01332 C12Y 101/01333 CPC Form – v.4 CPC NOTICE OF CHANGES 89 DATE: JULY 1, 2015 PROJECT RP0098 Action Subclass Group(s) C12Y 101/01334 C12Y 101/01335 C12Y 101/01336 C12Y 101/01337 C12Y 101/01338 C12Y 101/01339 C12Y 101/0134 C12Y 101/01341 C12Y 101/01342 C12Y 101/03043 C12Y 101/03044 C12Y 101/98003 C12Y 101/99038 C12Y 102/01083 C12Y 102/01084 C12Y 102/01085 C12Y 102/01086 C12Y 103/01092 C12Y 103/01093 C12Y 103/01094 C12Y 103/01095 C12Y 103/01096 C12Y 103/01097 C12Y 103/0701 C12Y 103/08003 C12Y 103/08004 C12Y 103/08005 C12Y 103/08006 C12Y 103/08007 C12Y 103/08008 C12Y 103/08009 C12Y 103/99032 C12Y 104/01023 C12Y 104/01024 C12Y 104/03024 C12Y 105/01043 C12Y 105/01044 C12Y 105/01045 C12Y 105/03019 C12Y 105/0302 -

Bioengineering Studies and Pathway Modeling of the Heterologous Biosynthesis of Tetrahydrocannabinolic Acid in Yeast

Applied Microbiology and Biotechnology (2020) 104:9551–9563 https://doi.org/10.1007/s00253-020-10798-3 MINI-REVIEW Bioengineering studies and pathway modeling of the heterologous biosynthesis of tetrahydrocannabinolic acid in yeast Fabian Thomas1 & Christina Schmidt1 & Oliver Kayser1 Received: 2 June 2020 /Revised: 7 July 2020 /Accepted: 21 July 2020 / Published online: 12 October 2020 # The Author(s) 2020 Abstract Heterologous biosynthesis of tetrahydrocannabinolic acid (THCA) in yeast is a biotechnological process in Natural Product Biotechnology that was recently introduced. Based on heterologous genes from Cannabis sativa and Streptomyces spp. cloned into Saccharomyces cerevisiae, the heterologous biosynthesis was fully embedded as a proof of concept. Low titer and insuf- ficient biocatalytic rate of most enzymes require systematic optimization of recombinant catalyst by protein engineering and consequent C-flux improvement of the yeast chassis for sufficient precursor (acetyl-CoA), energy (ATP), and NADH delivery. In this review basic principles of in silico analysis of anabolic pathways towards olivetolic acid (OA) and cannabigerolic acid (CBGA) are elucidated and discussed to identify metabolic bottlenecks. Based on own experimental results, yeasts are discussed as potential platform organisms to be introduced as potential cannabinoid biofactories. Especially feeding strategies and limita- tions in the committed mevalonate and olivetolic acid pathways are in focus of in silico and experimental studies to validate the scientific