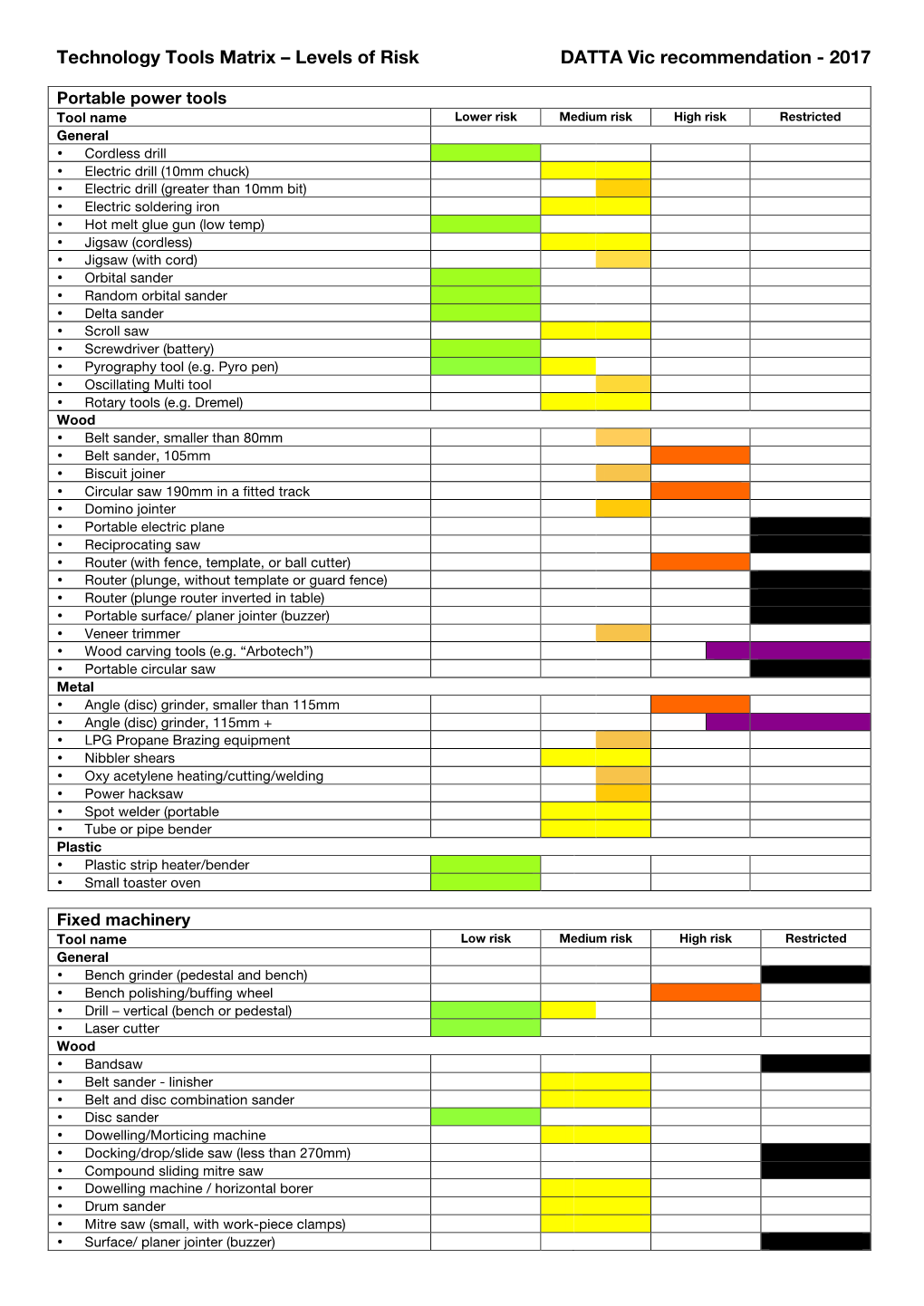

Technology Tools Matrix – Levels of Risk DATTA Vic Recommendation - 2017

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Mining & Heavy Machinery Catalog

Mining& Construction www.cp.com Heavy Machinery Maintenance Our History Decades of innovation Founded over 110 years ago, Chicago Pneumatic has 1901 First single-valve pneumatic hammer a strong history of constantly looking for new ways to meet your 1904 First electric tools and railway speed needs, today and tomorrow. recorder Way back in 1889 John W. Duntley realized that construction workers 1910 Quarry drills in particular had a need for many tools that weren’t yet available. 1911 Engines for cars and trucks He founded Chicago Pneumatic Tool Company and set out on a lifelong mission to provide all types of industries and companies the 1912 Simplate valve tools necessary for their success. 1912 Two-cycle semi-diesel engine for compressors Over the years Duntley grew the company through product innovation, always insisting on . The name Chicago 1925 Rotary oil-well drilling equipment product quality and reliability Pneumatic became known and appreciated by workers around the world 1925 Engine manufacturing for durable, reliable tools that made tough jobs easier and were designed to meet specifi c needs. 1939 First impact wrench 1943 “Rosie the Riveter” appears in Today, Chicago Pneumatic is a global brand that offers this “We Can Do It” image and products for almost every industry and countless on Norman Rockwell’s famous Saturday Evening Post cover, applications. We’re proud to say Chicago Pneumatic holding a Chicago Pneumatic still stands for reliability, durability and customer value. riveting hammer on her lap 1957 Portable broach puller, Building on success construction impact wrenches From production to maintenance or repair work, your experience of our tools, compressors, and construction 1960's Tools customized for Boeing 737 and 747, Lockheed L1011 and C5A, Douglas DC-10, equipment is key to our product development and new Concorde continued success. -

New-AV-CATALOG.Pdf

Contents About AirVANTAGE™ Tools ............................................................................................................................1 Warranty Information .......................................................................................................................................1 Tool Operation .................................................................................................................................................1 Please Read and Comply with ........................................................................................................................1 Proper Use of Tool ...........................................................................................................................................1 Personal Safety Equipment .............................................................................................................................1 Work Stations ..................................................................................................................................................1 AV Sander Owner’s Manuals On-line ..............................................................................................................1 Operating Instructions for Air Tools ..................................................................................................................2 Air System Recommendation ..........................................................................................................................2 Electric -

Corian® Solid Surface Tools and Accessories

CORIAN® SOLID SURFACE FABRICATION/INSTALLATION FUNDAMENTALS NA/ENGLISH CORIAN® SOLID SURFACE TOOLS AND ACCESSORIES Introduction B. Router Bits This bulletin addresses the tools and accessories necessary for the Router bits should, at a minimum, be tipped with tungsten carbide. fabrication of Corian® Solid Surface. Polycrystalline diamond bits may be suitable in certain applications Overview utilizing CNC machinery. Corian® Solid Surface is fabricated with much of the same type of For day-to-day fabrication, you should have the following bits provided equipment used for woodworking. While woodworking tools can be in Table B-1. used to fabricate Solid Surface, there are tools that have been optimized TABLE B-1 for Solid Surface and will provide better results. Corian® Solid Surface is made of natural minerals and acrylic and cuts differently than wood. Task Tool/Bit Tools with sufficient power and proper cutting design will provide better General-Purpose Work e.g. 3/8" (10 mm) carbide-tipped single flute results and tool life time. This document provides a list of basic tools and edge and seam trimming, with 1/2" (12 mm) shank, 1/2" (12 mm) accessories used in fabricating Corian® Solid Surface. cutouts carbide-tipped double flute, etc. 1/2" (12 mm) carbide-tipped single Heavy-Duty Work: e.g. bulk flute with1 /2" (12 mm) shank A. Routers cutouts, banjo cuts polycrystalline diamond bit Routers should have sufficient power for the intended task. The following Detail Work: e.g. coving, carbide-tipped decorative bit with 1/2" routers are useful for general Solid Surface fabrication. edge treatment (12mm) shank • 11/2-hp (900 W) router HELPFUL HINTS • 2-hp (1400 W) router Only use quality tungsten carbide-tipped bits. -

373-222 FM Chap 01.Qxd

TOOLS AND ACCESSORIES ROUTERS 1.1 There is no absolute recommendation as to which brand of router you should use to work with Corian®. ROUTERS However, in day-to-day fabrication, you would be well-equipped to have the following power hand tools: 1 1 /2-hp router 2-hp router 3-hp router 3-hp plunge base router Some companies seeking higher productivity have made further investments: C.N.C. router shaper panel saw V-groover water-cooled diamond-tipped saw Refer to Table 1.1.A below for a guideline of approximate router power recommendations for common tasks: Table 1.1.A TASK MINIMUM POWER General-Purpose Work: 2+ hp e.g., edge and seam trimming, cutouts Heavy-Duty Work: 3+ hp e.g., bulk cutouts, banjo cuts, coving 1 Detail Work: 1 /2 hp e.g., edge treatment Note: Router power output will vary depending on the brand of machinery. Helpful Hints: The key element in choosing which router is most suitable for varying tasks is the quality of cut and the overall wear and tear on valuable machinery. Corian® is made of natural minerals and acrylic resin and is, therefore, very tough on blades and motors. The listed recommendations above are based on maximizing maintenance on routers in day-to-day operations. CHAPTER 1 1 UPDATE 8/07 TOOLS AND ACCESSORIES ROUTER BITS SAWS & BLADES 1.2 Router bits should, at a minumum, be tipped with tungsten carbide. Polycrystalline diamond bits may be suitable in certain applications utilizing ROUTER BITS CNC machinery. For day-to-day fabrication, you should have the following: 3 1 /8” (10 mm) carbide-tipped single flute with /2” (13 mm) shank 3 1 1 /8”– /2” (10–13 mm) carbide-tipped double flute with /2” (13 mm) shank carbide-tipped decorative bits 1 /2” (13 mm) shank with roller bearing (profile bit) Table 1.2.A TASK: TOOL/BIT 3 General-Purpose Work /8” (10 mm) carbide-tipped single 1 e.g., edge and seam trimming, cutouts flute with /2” (13 mm) shank 1 /2” (13 mm) carbide-tipped double flute, etc. -

31St Annual Woodworking & Power Tool Show

31st Annual Woodworking & Power Tool Show Friday February 19th 8am-5pm & Saturday February 20th 8am-3:30pm Sioux Falls Location Only 3020 W. 12th St. Sioux Falls, SD M18 FUEL $100 OFF TRADE-IN M18 Fuel 1/2” M18 Fuel Hammer Drill/Driver Drill/Impact 2803-22 2997-22 *Additional Kits Available* See Store for Details. NOW $179.99 NOW $299.99 FREE BATTERY WITH PURCHASE OF SELECT BARE TOOLS!! See Page 16 for Details M18 Fuel 7-1/4” Dual M18 Fuel 8-1/4” Table M18 Fuel 12” Dual Bevel Sliding Saw with One Key Bevel Sliding Compound 2736-20BAT8.0 Compound Miter Saw $449.00 Miter Saw 2733-20BAT8.0 2739-20BAT8.0 $449.00 $699.00 Get a Free XC8.0 Battery Get a Free XC8.0 Battery Get a Free XC8.0 Battery with Purchase of Saw with Purchase of Saw with Purchase of Saw Seminars hosted by Vondriska Woodworks & Ben Brunick on Sharpening, Casting & Deep Pours with Epoxy, & Creating Your Own Wood Veneer. See page three for more times and additional details. Professional Table Saw with 52” Fence Industrial Table Saw with 52” Fence 3hp, 1ph, 230v 5hp, 1ph, 230v PCS31230/TGP2-FRT52A ICS51230/TGI2-FRT52A $3149.00 $4599.00 10” Jobsite Pro Saw Cast Iron Router Table Includes Mobile Stand, Active Dust RT-FS... $819.00 Collection Blade Guard and Router Lift High/Low Fence RT-LFT... $399.00 JSS-120A60 $1399.99 Replacement 48” Sliding Folding Outfeed Dado Lock Brake Cartridges Crosscut Table Table Down Starting At TSA-SA48 TSA-FOT TSI-DLD $79.00 $1199.00 $79.00 $49.00 WOODWORKING SEMINARS FRIDAY & SATURDAY Vondriska Woodworks Casting & Deep Pours with Epoxy- Friday 9am- 12pm Saturday 12:30pm- 3:30pm Sharpening- Friday- 1pm- 4pm Saturday- 8:30am- 11:30am CASTING AND DEEP POURS WITH EPOXY There are lots of creative things you can do with epoxy, including casting and deep pours. -

Router Table

Router Table Read This Important Safety Notice To prevent accidents, keep safety in mind while you work. Use the safety guards installed on power equipment; they are for your protection. When working on power equipment, keep fingers away from saw blades, wear safety goggles to prevent injuries from flying wood chips and sawdust, wear hearing protection and consider installing a dust vacuum to reduce the amount of air- borne sawdust in your woodshop. Don’t wear loose clothing, such as neckties or shirts with loose sleeves, or jewelry, such as rings, necklaces or bracelets, when working on power equipment. Tie back long hair to prevent it from getting caught in your equipment. People who are sensitive to certain chemicals should check the chemical con- tent of any product before using it. Due to the variability of local conditions, construction materials, skill levels, etc., neither the author nor Popular Woodworking Books assumes any responsibility for any accidents, injuries, damages or other losses incurred resulting from the mate- rial presented in this book. The authors and editors who compiled this book have tried to make the con- tents as accurate and correct as possible. Plans, illustrations, photographs and text have been carefully checked. All instructions, plans and projects should be carefully read, studied and understood before beginning construction. Prices listed for supplies and equipment were current at the time of publica- tion and are subject to change. Metric Conversion Chart to convert to multiply by Inches. Centimeters. 2.54 Centimeters. Inches . 0.4 Feet. Centimeters. 30.5 Centimeters. Feet. 0.03 Yards. -

3M™ Power Tools and Accessories

3M™ Power Tools and Accessories A full family of innovative tools to optimize abrasive performance and maximize productivity. 3M™ Replacement Parts Benefits • Detailed schematic and parts list found in the tool instruction manual make it easy to identify the part(s) you need • Each and every part is available individually and in stock • Replacement parts are easy to find and order online 24/7 at 3M.com/PowerTools • Genuine 3M replacement parts will provide new tool performance after maintenance and repair tasks are performed Genuine 3M™ Replacement Parts are engineered specifically for your 3M™ Power Tools. All replacement parts meet the same specifications and design criteria as the original components. You can be assured the replacement parts will be identical in terms of fit, form, and function in comparison to the original parts, which will get your 3M™ Power Tools back in action. Table of Contents Metalworking Tools and Accessories .................................................................................................................................... 2–14 Metalworking Performance Comparison .......................................................................................................................................2 3M™ Cut-Off Wheel Tools .................................................................................................................................................................2 3M™ Grinders — Type 27 ..................................................................................................................................................................3 -

REPAIR SOLUTIONS ACCESSORIES TECHNICAL SERVICES Composite Repair Technology EQUIPMENT MATERIALS About HEATCON Composite Systems

COMPOSITEREPAIR SOLUTIONS TECHNICAL EQUIPMENT SERVICES ACCESSORIES MATERIALS Innovating Solutions for the Advancement of Composite Repair Technology PRODUCT CATALOG PRODUCT About HEATCON Composite Systems Innovating Solutions for the Advancement of Composite Repair Technology HEATCON Composite Systems has been involved in the support of advanced composite repairs since 1981. For over 35 years, we’ve committed our time and product development to improving composite repair processes. As a leading global manufacturer and supplier of aerospace composite repair equipment, we provide a full range of hot bonders, accessories, technical and training services, and materials for the repair of composite structures. We specialize in working with Aircraft Manufacturers (OEMs), Defense Organizations, Commercial Airlines, and Maintenance Repair Organizations (MROs) by providing them with the expertise and tools to repair composite flight controls and other main aircraft parts. Our experience and knowledge allows us to continuously provide innovative solutions for the advancement of composite repair technology. ISO 9001:2015, AS9100D, AS9120B CERTIFIED VISION To be recognized as the leading provider of composite repair equipment, materials, training and technology to the composite repair industry. MISSION We believe that teamwork and customer satisfaction are the foundation of our continued success. We are committed through the skills of our employees to being a vibrant, innovative and responsive market leader in composite repair technology, materials, training, and heating solutions. We will uphold our reputation for quality, engineering expertise, customer support, and product value while maintaining a preferred supplier status with our customers. VALUES In all of our relationships we are committed to these primary values: • Honesty • Ethics • Accountability • Teamwork • Customer Satisfaction • Organizational Excellence • Niche Leadership HEATCON and its subsidiaries are committed to safety, quality and continual improvement in all areas of the organization. -

D04.22 Marine Rev3.Qxd:Layout 1

Dynabrade Tools for Reorder No. D04.22 the Marine Industry High-Quality Tools for Marine Manufacturing and Repair DYNABRADE TOOLS FOR Dynabrade Inc., world leader in the design and manufacture of unique abrasive power tools, is honored to showcase a product grouping designated for the marine industry and aftermarket. In this catalog are high-quality Dynabrade tools that 59039 Dynorbital-Spirit™ Random Orbital Sander moves abrasive offer countless application solutions disc in a small orbit of 3/32" (2 mm). This is ideal for patch repair on gel coat and clear coat, as the tight sanding pattern leaves a finish that for marine manufacturers and can be perfectly buffed in just one more step. Dynorbital-Spirit™ is also repair facilities. great for removing “print-through” patterns in fiberglass. Dynabrade durability means the Dynorbital-Spirit™ will last longer than other brands, and when repair is needed, our unique “Drop-In Motor” puts the tool back to work in minutes! 50321 Pistol-Grip Disc Sander easily removes excess fiberglass. This tool is also used for scuff sanding on the boat’s resin surface, preparing it for proper adhesion of buoyancy foam. 58000 Dynafine™ “Backsplash” Sander comes with 3/8" (10 mm) 52438 Vacuum Diamond Cut-Off Wheel Tool powers 5" (127 mm) radius sanding pad, ideal for reaching into corners, grooves and convex diameter diamond cut-off wheels (sold separately), to aggressively cut areas. Utilized for finesse sanding, gel coat touch-up and general spot through thick fiberglass over-wrap and fiber spray. Unique vacuum guard repair – a useful tool for every marine facility! diverts dust and debris to optional vacuum source. -

Pneumatic Tool Safety & Operating Guidelines

PNEUMATIC TOOL SAFETY & OPERATING GUIDELINES SECTION PAGE Safety - Signal Words/Symbols 2 General - Warnings/Cautions 3-6 Grinder - Warnings 7-9 Die Grinder - Warnings 10 Router - Warnings 11-12 Sander/Polisher - Warnings/Cautions 12-13 Drill - Warnings/Cautions 14 Power Brush - Warnings/Cautions 15-16 Reciprocating - Warnings/Cautions 17 Percussive - Warnings/Cautions 18 Threaded Fastener - Warnings/Cautions 18-19 DO NOT DISCARD! MAKE ACCESSIBLE TO ALL PERSONNEL INVOLVED IN THE CARE AND USE OF POWER TOOLS. 00001676 GENERAL AND TOOL SPECIFIC SECTIONS MUST BE READ AND UNDERSTOOD BEFORE OPERATING ANY PORTABLE PNEUMATIC TOOL! This document must be read and understood by operating personnel and safety manager. Protection to operating personnel, as well as adjacent areas, shall be maintained at all times. The user and/or the user's employer shall conduct a risk assessment of workplace hazards including exposure limits. Always comply with: General Industry Safety & Health Regulations (www.osha.gov), International Organization for Standardization (www.iso.org) and Regional Regulations.EN Standards for Hand Held Non-Electric Power Tools (www.cen.eu), American National Standards Institute (www.ansi.org), Compressed Air and Gas Institute (www.cagi.org). ADDITIONAL SAFETY REFERENCE MATERIALS ARE AVAILABLE AT WWW.DYNABRADE.COM SAFETY SIGNAL WORDS Indicates a hazardous situation that, if not avoided, will result in death or serious injury. DANGER This signal word is to be limited to the most extreme situations. Indicates a hazardous situation that, if not avoided, could result in death or WARNING serious injury. Indicates a hazardous situation that, if not avoided, could result in minor or moderate CAUTION injury. -

WOODSHOP SAFETY MANUAL Wood Shop Safety Manual

WOODSHOP SAFETY MANUAL WOOD SHOP SAFETY MANUAL Golden Rules of the Woodshop If you open it . Close it If you turn it on . Turn it off If you unlock it . Lock it If you checked it out . Check it in If you use it . Put it back in it’s proper place If you break it . Report it If you borrowed it . Return it If you glued it . Tag it with a name, date, and time If you make a mess . Clean it up If it is in the way . Move it If you moved it . Put it back If you are confused . Ask for help If you are unable to operate it . Get assistance WOOD SHOP SAFETY MANUAL Contents 1. General A. Woodshop Use B. Procedures C. Safety D. Emergency 2. Facilities A. Woodshop 3. Stationary Tool Safety A. Band Saw B. Belt/Disc Sander C. Spindle Sander D. Compound Miter Saw E. Drill Press F. Jointer/Planer G. Scroll Saw H. Table Saw J. Wood Lathe K. Bench grinder L. Router Table M. Vertical Mill 4. Hand Tool Safety A. Belt Sander B. Circular Saw C. Biscuit Joiner D. Drill E. Random Orbital Sander F. Grinder G. Jig Saw H. Power Planer J. Pneumatic guns K. Routers Warning Knowledge and understanding of rules and procedures are your responsibility. Visible Futures Lab Staff holds all rights to change and/or modify lab rules and protocol at any time or for any specific situation. All rules are strictly enforced. WOOD SHOP SAFETY MANUAL 1.General A. Woodshop Use • The VFL is open to current Graduate Students, Faculty, and Staff at SVA. -

Woodshop Safety Manual

CollegeCollege ofof ArchitectureArchitecture Safety Manual Contents I. General a. Woodshop Use b. Procedures c. Safety d. Emergency II. Facilities a. Woodshop III. Stationary Tool Safety a. Band Saw g. Panel Saw b. Belt/Disc Sander h. Planer c. Spindle Sander i. Scroll Saw d. Compound Miter Saw j. Table Saw e. Drill Press k. Wood Lathe f. Jointer IV. Hand Tool Safety a. Belt Sander g. Jig Saw b. Circular Saw h. Oscillating Spindle Sander c. Detail Sander i. Plate Joiner d. Drill j. Pneumatic guns e. Finishing Sander k. Random Orbital Sander f. Grinder l. Routers Warning: Knowledge and understanding of rules and procedures are your responsibility. Woodshop supervisor holds all rights to change and/or modify at any time or for any specific situation. All things are strictly enforced. 2 General a. Woodshop Use a. College of Architecture Students, Faculty, and Staff The woodshop is available for class projects. b. Woodshop Access Privileges will be extended after the completion of the safety course. c. Equipment access Safety clearance allows access to any machine or tool you are knowledgeable in. If you do not know the correct way to use a tool or machine ask for help. Misuse or abuse of a tool will suspend its availability. b. Procedures a. Safety Course Each person must watch the woodshop safety video, complete the safety quiz, and sign the User Safety Agreement. Each of these will be available online at . The safety quiz and user agreement must then be submitted to the woodshop supervisor in order for the quiz to be graded and the user agreement to be signed by the woodshop supervisor.