Safety Practices for Working with Beryllium Oxide Products (SF301)

Total Page:16

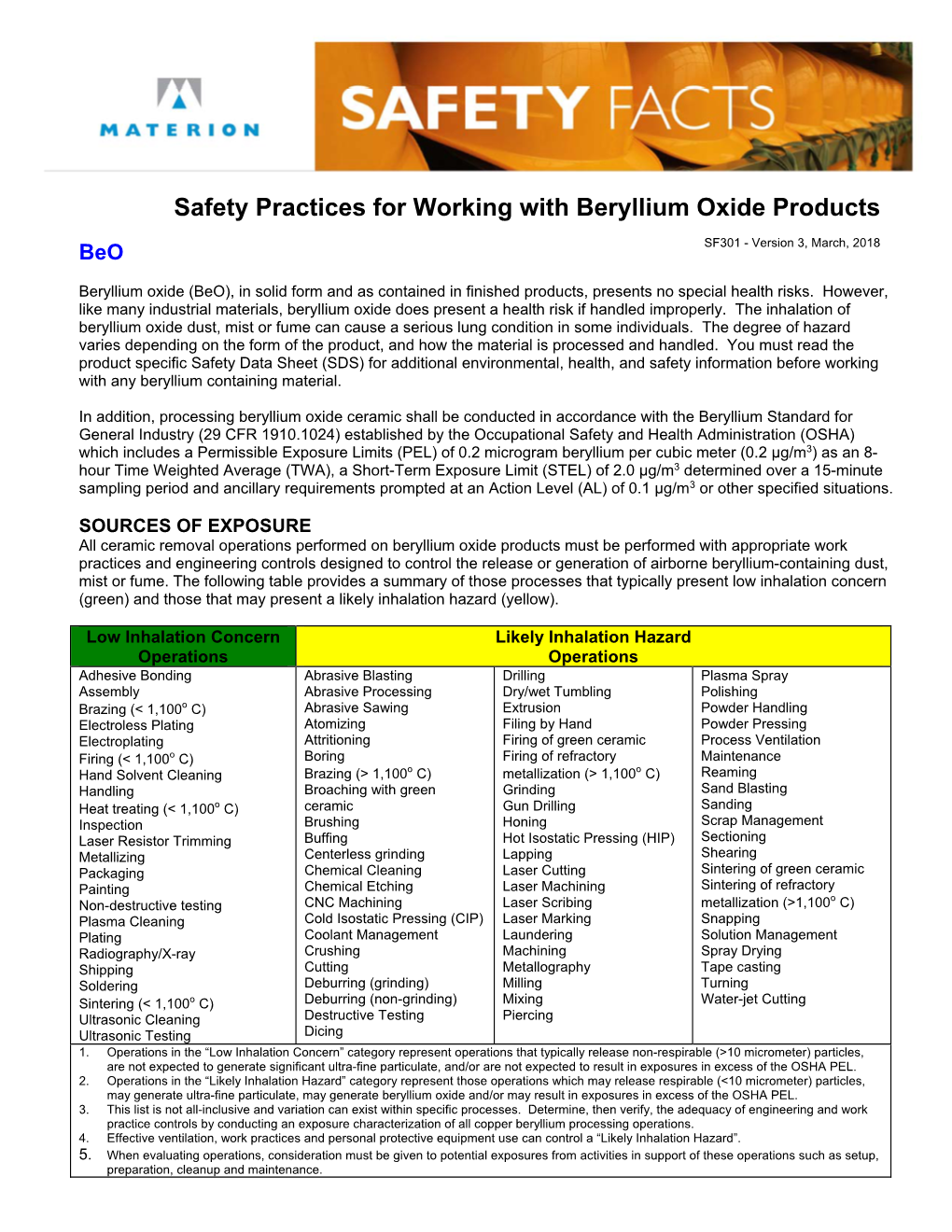

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

[email protected] +1-703-527-3887 (International) Website

Date of Issue: 17 June 2015 SAFETY DATA SHEET 1. SUBSTANCE AND SOURCE IDENTIFICATION Product Identifier SRM Number: 1877 SRM Name: Beryllium Oxide Powder Other Means of Identification: Not applicable. Recommended Use of This Material and Restrictions of Use This Standard Reference Material (SRM) is intended for use in laboratory analysis and health research for the development and validation of analytical methods and instruments used to determine beryllium, as well as for proficiency testing of laboratories involved in beryllium determinations. A unit of SRM 1877 consists of one bottle containing 20 g of beryllium oxide powder. Company Information National Institute of Standards and Technology Standard Reference Materials Program 100 Bureau Drive, Stop 2300 Gaithersburg, Maryland 20899-2300 Telephone: 301-975-2200 Emergency Telephone ChemTrec: FAX: 301-948-3730 1-800-424-9300 (North America) E-mail: [email protected] +1-703-527-3887 (International) Website: http://www.nist.gov/srm 2. HAZARDS IDENTIFICATION Classification Physical Hazard: Not classified. Health Hazard: Acute Toxicity, Inhalation Category 2 Skin Corrosion/Irritation Category 2 Serious Eye Damage/Irritation Category 2B Skin Sensitization Category 1 Carcinogenicity Category 1A STOT-Repeat Exposure Category 1 Label Elements Symbol Signal Word DANGER Hazard Statement(s) H330 Fatal if inhaled. H315+H320 Causes skin and eye irritation. H317 May cause an allergic skin reaction. H350 May cause lung cancer. H372 Causes damage to lungs through prolonged or repeated inhalation. Precautionary Statement(s) P201 Obtain special instructions before use. P202 Do not handle until all safety precautions have been read and understood. P260 Do not breathe dust. P264 Wash hands thoroughly after handling. -

Corrosion of Refractories by Denis A

A Chapter in the Refractories Handbook, edited by Charles A. Schacht, and to be published by Marcel Dekker, Inc., New York, NY 10016 Corrosion of Refractories by Denis A. Brosnan, PhD, PE Clemson University Clemson, SC 29634-0971 Introduction Refractories are used at elevated temperatures for structural purposes and they are used in many cases to contain a high temperature corrosive environment. This corrosive environment usually contains liquid (melted) phases that participate in chemical reactions with the refractory at the elevated temperatures resulting in refractory consumption or wear. It is usually not immediately obvious, but the oxidation and reduction state of the environment (as “redox” conditions or oxygen “activity”) can participate in and influence the chemical reactions that take place. Along with chemical reactions during corrosion, physical changes occur that may be accelerated by the corrosion process. Corrosion of refractories can be defined for the purposes of this discussion as follows: Corrosion of Refractories – refractory wear by loss of thickness and mass from the exposed face of the refractory as a consequence of chemical attack by a corroding fluid in a process in which the refractory and the corroding fluid react approaching chemical equilibrium in the zone of contact between the refractory and the fluid. It is an essential point that corrosion reactions proceed in a direction toward localized chemical equilibrium. This means that phase equilibrium diagrams can be used to analyze corrosion situations and to predict chemical strategies to minimize corrosion and wear rates. This gives persons interested in refractory corrosion two options. The first is to view corrosion as a chemical and physical process without a detailed application of phase equilibrium diagrams – called the “phenomenological approach”. -

Exposure Data

BERYLLIUM AND BERYLLIUM eOMPOUNDS Beryllium and beryllium compounds were considered by previous Working Groups, In 1971,1979 and 1987 (lARe, 1972, 1980, 1987a). New data have since become available, and these are included in the present monograph and have been taken into consideration In the evaluation. The agents considered herein Include (a) metallic beryllium, (b) beryllium- aluminium and -copper alloys and (c) some beryllum compounds. 1. Exposure Data 1.1 Chemical and physical data and analysis 1.1.1 Synonyms, trade names and molecular formulae Synonyms, trade names and molecular formulae for beryllium, beryllum-aluminium and -copper alloys and certain beryllium compounds are presented in Thble 1. The list is not exhaustive, nor does it comprise necessarily the most commercially important beryllum- containing substances; rather, it indicates the range of beryllum compounds available. 1. 1.2 Chemical and physical properties of the pure substances Selected chemical and physical properties of beryllium, beryllum-aluminium and -copper alloys and the beryllium compounds covered in this monograph are presented in Thble 2. The French chemist Vauquelin discovered beryllium in 1798 as the oxide, while analysing emerald to prove an analogous composition (Newland, 1984). The metallc element was first isolated in independent experiments by Wöhler (1828) and Bussy (1828), who called it 'glucinium' owing to the sweet taste of its salts; that name is stil used in the French chemical literature. Wöhler's name 'beryllum' was offcially recognized by IUPAe in 1957 (WHO, 1990). The atomic weight and corn mon valence of beryllum were originally the subject of much controversy but were correctly predicted by Mendeleev to be 9 and + 2, respectively (Everest, 1973). -

Untraditional Synthesis of Boron-Containing Superhard and Refractory Materials - a Review B

G.J. E.D.T., Vol. 2(1) 2013:21-26 ISSN 2319 – 7293 UNTRADITIONAL SYNTHESIS OF BORON-CONTAINING SUPERHARD AND REFRACTORY MATERIALS - A REVIEW B. Agyei-Tuffour1,2, E. Annan1,2, E. R. Rwenyagila1, E. Ampaw1, E. Arthur1, K. Mustapha1, S. Kolawole1, W. O. Soboyejo1,3, & D. D. Radev1,4 1Department of Materials Science and Engineering, African University of Science and Technology, Abuja-Nigeria 2Department of Materials Science and Engineering, Private Mail Bag, University of Ghana, Legon-Accra. 3Department of Mechanical and Aerospace Engineering, Princeton University, USA. 4Institute of General and Inorganic Chemistry, Bulgaria Academy of Sciences, Sofia-Bulgaria Abstract Boron-containing ceramics find large application in production of superhard and high-temperature materials with application in nuclear and aerospace techniques, military industry etc. The synthesis methods are decisive for the complexity of chemical, morphological and technological properties of these materials. The traditional high-temperature synthesis methods have some disadvantages leading to inconstancy of the product composition due to the boron evaporation, degradation of the furnace materials and contamination of the products, high energy losses etc. Here we show the advantages of some untraditional synthesis methods like direct mechanical synthesis and self propagating high-temperature synthesis (SHS) in the production of titanium diboride (TiB2), zirconium diboride (ZrB2) and production of dense boron carbide (B4C) based materials. Using SEM, TEM, XRD and analytical chemical methods, it was shown that diborides of titanium and zirconium have appropriate properties for production of dense ceramic materials. Using the method of mechanically-assisted sintering high-dense B4C-based ceramic materials was obtained. It was shown that the mechanical properties of materials obtained by pressureless sintering are close or overcome the corresponding properties of boron carbide densified by the method of hot pressing. -

Research Memorandum

RM ESOG21 NACA RESEARCH MEMORANDUM SO:ME PROPER TIES OF BER YLLIUM OXIDE AND BERYLLIUM OXIDE - COLUMBIUM CERAMALS By C. F. Robards and J. J. Gangler " Lewis Flight Propulsion Laboratory Cleveland, Ohio NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS WASHINGTON March 2 , 1951 NACA RM E5OG21 NATIONAL ADVISORY COMMITTEE FOR AERONAUTICS RESEARCH MEMORANDUM SOME PROPERTIES OF BERYLLIUM OXIDE AND BERYLLIUM OXIDE - COLUMBIUM CERAMALS By C. F. Robards and J. J . Gangler SUMMARY Because of the potentially excellent refractory properties of beryllium oxide, a brief investigation was made of its short time tensile strength at a temperature of 18000 F and relative thermal-shock resistance from temperatures of 18000 and 2000° F to room temperature. The effect of additions of 2, 5, 8, 10, 12, and 15 percent by weight of columbium metal on the thermal-shock resistance of beryllium oxide was studied. Metallographic examination indicated that the metallic phase coalesced into pockets. Beryllium oxide had a tensile strength as high as 6160 :9ounds per square inch at 18000 F. The original columbium underwent a phase change, as indicated by X-ray analysis of the ceramals. The addition of columbium up to 15 percent by weight failed to improve the resistance to thermal shock. The phase change and the failure of the columbium to 'vet the beryllium oxide may explain the poor thermal-shock resistance of these ceramals. INTRODUCTION Beryllium oxide BeO has the highest thermal-shock resistance of the better-known oxide bodies. In an effort to extend the life of this material in thermal shock, an attempt was made at the NACA Lewis laboratory to use a metallic binder in the manner that has been successful in the carbide-tool industry. -

High-Temperature Properties of Magnesia-Refractory Brick Treated with Oxide and Salt Solutions

Q [R I 1898o I PLEASEDO NOT REMOVEFROM LIBRARY ()' ~ Bureau of Mines Report of Investigations/1985 ~ ~ High-Temperature Properties of Magnesia-Refractory Brick Treated With Oxide and Salt Solutions By James P. Bennett UNITED STATES DEPARTMENT OF THE INTERIOR Report of Investigations 8980 High-Temperature Properties of Magnesia-Refractory Brick Treated With Oxide and Salt Solutions By James P. Bennett UNITED STATES DEPARTMENT OF THE INTERIOR Donald Paul Hodel, Secretary BUREAU OF MINES Robert C. Horton, Director Research at the Tusca loo sa Research Center is carried out under a memorandum of agreement be tween . the Bureau of Mines, U.S. Department of the Interior, and the University of Alaba ma. Library of Congress Cataloging in Publication Data: Bennett, James P. (James Philip), 1951- High-temperature properties of magnesia-refractory brick treated with oxide and salt solutions. (Report of investigations 8980) Bi bl iography: p. 11. Supt. of Docs. no.: I 28.23: 8980. 1. Magnesia brick-Thermal properties. 2. Oxides. 3. Salt. 1. Title. II. Series: Report of investigations (United States. Bureau of Mines) ; 8980. TN23.C43 (TA418.26] 622s l669',821 85-600138 CONTENTS AbsIntroduction................................................................... tract ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2 Refractory brick and sample preparation........................................ 2 Treatment procedure--solutions and techniques.................................. 4 Results and discussion........................................................ -

Electric Arc Furnace (EAF) Refractory Concept Solutions

STEEL INDUSTRY ELECTRIC ARC FURNACES STEEL INDUSTRY CALDERYS PERFORMANCE YOU CAN TRUST For all industries with extreme temperatures and working conditions, Calderys is there for you. Combining a global network with local expertise, we offer customised solutions wherever you are: from monolithic refractory to bricks and precast shapes to a full range of engineering and installation services. KEY POINTS Over 100 years of refractory experience Over 2 300 employees across 33 countries 19 plants in 16 countries totaling 600 000 tons capacity Annual revenue of over € 500 million 1 Global Technology Centre and 15 Customisation Labs 150 major projects implemented every year Wholly-owned subsidiary of Imerys Group 2 STEEL INDUSTRY OUR VALUE TO THE STEELMAKING INDUSTRY The world leader in monolithic refractory solutions, Calderys has a full product and service portfolio to adapt to the refractory needs of steelmakers. We ensure that we propose products most suitable for your process requirements and deliver to you superior refractory performance and reliable services. We are able to do so by combining our innovative product range and modern installation techniques with end-to-end project management. Value Optimisation Offering tailor-made solutions that meet the commercial and technical requirements for optimal performance. Complete Refractory Solutions We offer a full range of refractory products to meet the process needs of modern Steelmaking. Technology Expertise Ensuring the best possible equipment availability and productivity at the lowest total refractory cost per ton of steel produced, whilst adhering to strict environmental and safety regulations in operations. 3 STEEL INDUSTRY CALDERYS A TRUSTED SUPPLIER IN THE STEEL INDUSTRY A world leader in Refractory Solutions, Calderys has the complete product and service portfolio for all applications. -

Toxicological Profile for Beryllium

BERYLLIUM 19 3. HEALTH EFFECTS 3.1 INTRODUCTION The primary purpose of this chapter is to provide public health officials, physicians, toxicologists, and other interested individuals and groups with an overall perspective on the toxicology of beryllium. It contains descriptions and evaluations of toxicological studies and epidemiological investigations and provides conclusions, where possible, on the relevance of toxicity and toxicokinetic data to public health. A glossary and list of acronyms, abbreviations, and symbols can be found at the end of this profile. 3.2 DISCUSSION OF HEALTH EFFECTS BY ROUTE OF EXPOSURE To help public health professionals and others address the needs of persons living or working near hazardous waste sites, the information in this section is organized first by route of exposure (inhalation, oral, and dermal) and then by health effect (death, systemic, immunological, neurological, reproductive, developmental, genotoxic, and carcinogenic effects). These data are discussed in terms of three exposure periods: acute (14 days or less), intermediate (15–364 days), and chronic (365 days or more). Levels of significant exposure for each route and duration are presented in tables and illustrated in figures. The points in the figures showing no-observed-adverse-effect levels (NOAELs) or lowest-observed-adverse-effect levels (LOAELs) reflect the actual doses (levels of exposure) used in the studies. LOAELS have been classified into "less serious" or "serious" effects. "Serious" effects are those that evoke failure in a biological system and can lead to morbidity or mortality (e.g., acute respiratory distress or death). "Less serious" effects are those that are not expected to cause significant dysfunction or death, or those whose significance to the organism is not entirely clear. -

"Beryllium Oxide Digestion Optimization at the Savannah River Site"

"Beryllium Oxide Digestion Optimization at the Savannah River Site" by Davin Jagnandan November, 2002 ==' ¥---- ; A paper submitted to the faculty of the University of North Carolina at Chapel Hill in partial fulfillment of the requirements for the degree of Master of Public Health in the School of Public Health Abstract Chronic beryllium disease (CBD) is a debilitating lung disorder affecting an estimated 4.6% of past nuclear weapons and beryllium manufacturing workers. The Chronic Beryllium Disease Prevention Program, as set up by the U.S. Department of Energy (DOE), establishes guidelines for maintaining acceptable exposure levels in all beryllium manufacturing facilities. These exposure levels are based on the measuring of total beryllium which includes beryllium metal, beryllium salts, beryllium alloys and beryllium oxide. The most sensitive detection instruments used in industrial hygiene sampling measure beryllium in a solubilized form . Beryllium oxide, in particular, has been shown to resist solubilization unless it is performed in the presence of strong acid(s). This poses a problem for industrial hygienists because beryllium oxide has been shown to have a high level oftoxicity due to its small size and moderate solubility. The current Ip digestion method (EPA 3050B) for all metals at the Savannah River Site 1 involves the use of nitric and hydrochloric acids. It was hypothesized that 1 this method was inadequate for the complete digestion of beryllium oxide. This study examines this issue by comparing method 3050B with two other acid digestion methods. Once the most effective of the three methods was determined, optimization factors such as settling time, heating/reflux time, and hydrogen peroxide addition were examined. -

Criteria for a Recommended Standard

Background photo on cover by James Lockey, M.D.: Photomicrograph of a rat lung in inhalation studies with airborne fibers. Inset photo on cover, courtesy of Kevin H. Dunn: NIOSH industrial hygienist performing air sampling to evaluate engineering controls in simulated work ac- tivities using RCF materials. Criteria for a Recommended Standard Occupational Exposure to Refractory Ceramic Fibers DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention National Institute for Occupational Safety and Health This document is in the public domain and may be freely copied or reprinted. Disclaimer Mention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH). In addition, citations to Web sites external to NIOSH do not constitute NIOSH endorsement of the sponsoring organizations or their programs or prod- ucts. Furthermore, NIOSH is not responsible for the content of these Web sites. Ordering Information To receive documents or other information about occupational safety and health topics, contact NIOSH at NIOSH Publications Dissemination 4676 Columbia Parkway Cincinnati, OH 45226–1998 Telephone: 1–800–35–NIOSH (1–800–356–4674) Fax: 1–513–533–8573 E-mail: [email protected] or visit the NIOSH Web site at www.cdc.gov/niosh DHHS (NIOSH) Publication No. 2006–123 May 2006 Safe • Healthier • PeopleTM ii Refractory Ceramic Fibers Foreword When the U.S. Congress passed the Occupational Safety and Health Act of 1970 (Public Law 91– 596), it established the National Institute for Occupational Safety and Health (NIOSH). Through the Act, Congress charged NIOSH with recommending occupational safety and health standards and describing exposure limits that are safe for various periods of employment. -

AISI | Electric Arc Furnace Steelmaking

http://www.steel.org/AM/Template.cfm?Section=Articles3&TEMPLATE=/CM/HTMLDisplay.cfm&CONTENTID=12308 Home Steelworks Home Electric Arc Furnace Steelmaking By Jeremy A. T. Jones, Nupro Corporation SIGN UP to receive AISI's FREE e-news! Read the latest. Email: Name: Join Courtesy of Mannesmann Demag Corp. FURNACE OPERATIONS The electric arc furnace operates as a batch melting process producing batches of molten steel known "heats". The electric arc furnace operating cycle is called the tap-to-tap cycle and is made up of the following operations: Furnace charging Melting Refining De-slagging Tapping Furnace turn-around Modern operations aim for a tap-to-tap time of less than 60 minutes. Some twin shell furnace operations are achieving tap-to-tap times of 35 to 40 minutes. 10/3/2008 9:36 AM http://www.steel.org/AM/Template.cfm?Section=Articles3&TEMPLATE=/CM/HTMLDisplay.cfm&CONTENTID=12308 Furnace Charging The first step in the production of any heat is to select the grade of steel to be made. Usually a schedule is developed prior to each production shift. Thus the melter will know in advance the schedule for his shift. The scrap yard operator will prepare buckets of scrap according to the needs of the melter. Preparation of the charge bucket is an important operation, not only to ensure proper melt-in chemistry but also to ensure good melting conditions. The scrap must be layered in the bucket according to size and density to promote the rapid formation of a liquid pool of steel in the hearth while providing protection for the sidewalls and roof from electric arc radiation. -

Nonmetallic Inclusions in the Secondary Aluminium Industry For

NONMETALLIC INCLUSIONS IN THE SECONDARY ALUMINUM INDUSTRY FOR THE PRODUCTION OF AEROSPACE ALLOYS Bernd Prillhofer1, Helmut Antrekowitsch1,2, Holm Böttcher3, Phil Enright4 1Christian Doppler Laboratory for secondary metallurgy of non-ferrous metals, Franz-Josef-Str. 18, Leoben, 8700, Austria 2Chair for non-ferrous metals, University of Leoben, Franz-Josef-Str. 18, Leoben, 8700, Austria 3AMAG rolling GmbH, post office box 32, Ranshofen, 5282, Austria 4N-Tec Limited, Watery Lane, Hook Norton, Oxfordshire, OX155NW, England Keywords: melt quality, Prefil®, process evaluation, operating windows Abstract All the investigations have been performed in co-operation with Austria Metall AG (AMAG), Austria and in part with N-Tec, Due to enormous growth of the secondary aluminum industry and England. the required increase in melt quality, the development of methods for inclusion removal has become highly important. To produce Process layout high quality aerospace alloys with very low inclusion contents, casthouses must analyze and optimize their production processes The casting facility at AMAG for the production of 7xxx series from the beginning to the end. Nowadays, there are several ingots consists of a single melting furnace, two casting furnaces, a methods available for process evaluation and the determination of SNIF P140, a ceramic foam filter unit and an electro magnetic inclusion level from one step to another. Furthermore, the most casting pit for 4 ingots (see Figure 1). important parameters for control of the final inclusion level have CFF Box to be investigated. Grain Refiner Addition • two horizontal 17‘‘ filter • amount of grain refiner This paper characterizes the change of the inclusion content for according to Opticast the alloy AA 7075 during standard casthouse processing.