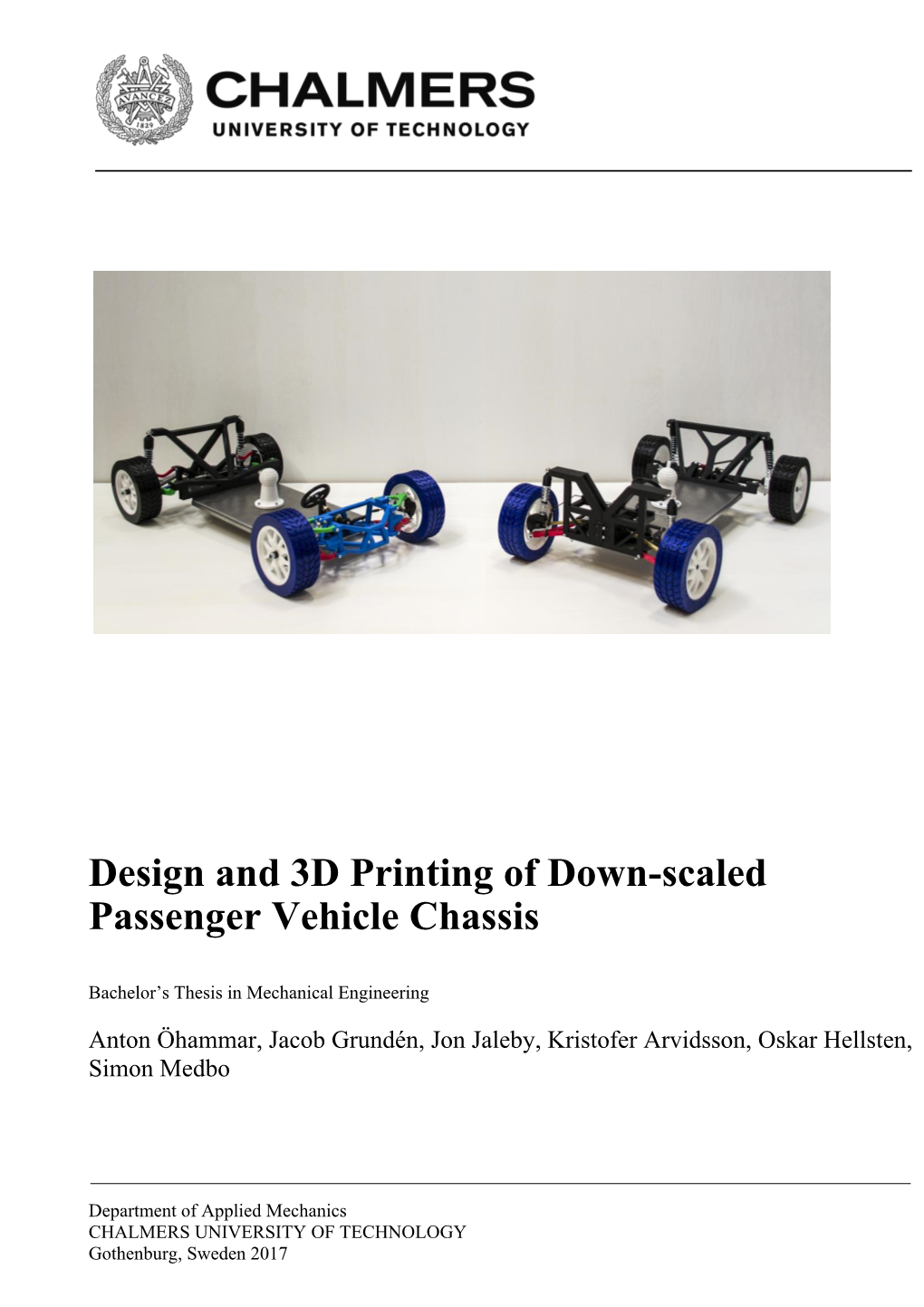

Design and 3D Printing of Down-Scaled Passenger Vehicle Chassis

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Development and Analysis of a Multi-Link Suspension for Racing Applications

Development and analysis of a multi-link suspension for racing applications W. Lamers DCT 2008.077 Master’s thesis Coach: dr. ir. I.J.M. Besselink (Tu/e) Supervisor: Prof. dr. H. Nijmeijer (Tu/e) Committee members: dr. ir. R.M. van Druten (Tu/e) ir. H. Vun (PDE Automotive) Technische Universiteit Eindhoven Department Mechanical Engineering Dynamics and Control Group Eindhoven, May, 2008 Abstract University teams from around the world compete in the Formula SAE competition with prototype formula vehicles. The vehicles have to be developed, build and tested by the teams. The University Racing Eindhoven team from the Eindhoven University of Technology in The Netherlands competes with the URE04 vehicle in the 2007-2008 season. A new multi-link suspension has to be developed to improve handling, driver feedback and performance. Tyres play a crucial role in vehicle dynamics and therefore are tyre models fitted onto tyre measure- ment data such that they can be used to chose the tyre with the best characteristics, and to develop the suspension kinematics of the vehicle. These tyre models are also used for an analytic vehicle model to analyse the influence of vehicle pa- rameters such as its mass and centre of gravity height to develop a design strategy. Lowering the centre of gravity height is necessary to improve performance during cornering and braking. The development of the suspension kinematics is done by using numerical optimization techniques. The suspension kinematic objectives have to be approached as close as possible by relocating the sus- pension coordinates. The most important improvements of the suspension kinematics are firstly the harmonization of camber dependant kinematics which result in the optimal camber angles of the tyres during driving. -

Remove/Install Rack-And-Pinion Steering 11.3.10 MODEL 203 (Except 203.081 /084 /087 /092 /281 /284 /287 /292) MODEL 209

AR46.20-P-0600P Remove/install rack-and-pinion steering 11.3.10 MODEL 203 (except 203.081 /084 /087 /092 /281 /284 /287 /292) MODEL 209 P46.20-2123-09 1 Front axle carrier 23b Bolts, retaining plate to front axle 25 Steering coupling 1g Retaining plate carrier 25a Bolt, steering coupling to steering 10a Tie rod joints 23g Bolts, rack-and-pinion steering to shaft 21 Rubber bushing front axle carrier 25f Locking plate 23 Rack-and-pinion steering 23n Tapping plate 80a Lower steering shaft 23a Bolts, retaining plate to front axle 23q Oil lines retainer 105d Exhaust shielding plate carrier Modification notes 29.11.07 Value changed: Bolt, retaining plate of oil line to rack-and- Model 203 *BA46.20-P-1001-01F pinion steering Value changed: Bolted connection, rack-and-pinion *BA46.20-P-1002-01F steering to front axle carrier, 1st stage Value changed: Bolted connection of rack-and-pinion *BA46.20-P-1002-01F steering to front axle carrier, 2nd stage 30.11.07 Torque, retaining plate to front axle carrier incorporated Operation step 23, 24 *BA46.20-P-1004-01F Removing Danger! Risk of death caused by vehicle slipping or Align vehicle between columns of vehicle lift AS00.00-Z-0010-01A toppling off of the lifting platform. and position four support plates at vehicle lift support points specified by vehicle manufacturer. Danger! Risk of accident caused by vehicle starting Secure vehicle to prevent it from moving by AS00.00-Z-0005-01A off by itself when engine is running. Risk of itself. -

Design and FEA Analysis of a Double Wishbone Suspension System

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 08 Issue: 08 | Aug 2021 www.irjet.net p-ISSN: 2395-0072 Design and FEA Analysis of a Double Wishbone Suspension System Smit Shendge1, Heet Patel2, Yash Shinde3 1,2,3U.G. Student from the Department of Automobile Engineering at University of Wolverhampton, India ----------------------------------------------------------------------***--------------------------------------------------------------------- Abstract - In this research study an independent type 1. 1 Background suspension system is considered to be exact a double A double wishbone suspension system was introduced in wishbone suspension system used in racing vehicle is the year of 1930s which was later implemented by Citroen a considered. First research on existing double wishbone French automaker in its model Rosalie and Traction Avant suspension system is made to design a new double wishbone in year 1934. Later Packard Motor Car Company based in suspension system. A double wishbone suspension parts are Detroit; Michigan also implemented this suspension from designed in a CAD tool Onshape and assembled in the CAD year 1935 in its Packard One-Twenty model. Observing tool itself. This geometry is then imported to an analysis tool Double wishbone suspension system and Macpherson strut Simscale for FEA analysis or to be exact static and dynamic suspension system it feels like they are related to each other analysis. Materials of various parts are considered according but that’s not the case a Macpherson strut suspension to the standards and both the analysis are carried out to design inspiration was taken from the landing gears of an validate if the made suspension assembly is a good design in aeroplane which has similar setup like Macpherson and terms of strength. -

Design of Constant Velocity Coupling

Design of Constant Velocity Coupling Prof. A. A. Moghe1, Mr. Yuvraj Patil2, Mr. Mayur Pawar³, Mr. Akshaykumar Thaware4, Mr. Nitin Thorawade5 1Assistant Professor, 2,3,4,5UG Students Department of Mechanical Engineering Sppu, PVPIT, Pune, Mahrashtra, India ABSTRACT: A coupling is mechanical device used to connect two shafts together at their ends for the purpose of transmission of power. The basic role of couplings is to join two parts of rotating elements while permitting some degree of misalignment or end movement or both. Presently Oldham’s coupling and Universal joints are used for parallel offset power transmission and angular offset transmission. These joints have limitations on maximum offset distance, angle, speed and result in vibrations, noise and low efficiency (below 70%). These limitations can be overcome with Thompson constant velocity (CV) coupling which offers features like minimizing side loads, higher misalignment capabilities, more operating speeds, improved efficiency of transmission and many more. The constant velocity joint is an alteration in design that offers up to 18 mm parallel offset and 21-degree angular offset, at high speeds up to 2000 or 2500 rpm at 90% efficiency. This design lowers cost of production, space requirement and simply technology of manufacture as compared too present CVJ in market. This paper presents review on constant velocity joints/couplings design and optimization. Keywords: Thompson constant velocity joint, Optimization & design, Constant velocity couplings, Parallel Offset, Angular Offset, Power Transmission. [I] INTRODUCTION The basic function of a power transmission coupling is to transmit torque from an input/driving shaft to an output/driven shaft at a specified shaft speed. -

Installation and Operating Manual

Installation and Operating Manual (Translation of the original installation and operating manual) T… (with GPK) Turbo Coupling with Constant Fill, Connecting Coupling Type GPK (All-metal Disk Pack Coupling) including design as per Directive 2014/34/EU (ATEX directive) Version 10 , 2017-06-01 3626-011700 en, Protection Class 0: public Serial No. 1) Coupling type 2) Year of manufacture Mass (weight) kg Power transmission kW Input speed rpm mineral oil Operating fluid water Filling volume dm3 (liters) Number of screws z 3) Nominal response temperature of °C fusible plugs Connecting coupling type GPK Sound pressure level LPA,1m dB Installation position horizontal (max. 7°) Drive via outer wheel 1) Please indicate the serial number in any correspondence ( Chapter 18). 2) T...: oil / TW...: water. 3) Determine and record the number of screws z ( Chapter 10.1). Please consult Voith Turbo in case that the data on the cover sheet are incomplete. Turbo Coupling with constant fill (Connecting Coupling Type GPK) Contact Contact Voith Turbo GmbH & Co. KG Division Industry Voithstr. 1 74564 Crailsheim, GERMANY Tel. + 49 7951 32 599 Fax + 49 7951 32 554 [email protected] www.voith.com/fluid-couplings 3626-011700 en This document describes the state of de- 011700 sign of the product at the time of the - editorial deadline on 2017-06-01. / 3626 / 10 01 - 06 Copyright © by - Voith Turbo GmbH & Co. KG / 2017 / This document is protected by copyright. public 0: It must not be translated, duplicated (mechanically or electronically) in whole or in part, nor passed on to third parties without the publisher's written approval. -

SCCA® National Solo® Rules

SCCA® National Solo® Rules 2020 EDITION Sports Car Club of America® Solo® Department 6620 SE Dwight St. Topeka, KS 66619 (800) 770-2055 (785) 232-7228 Fax www.scca.com Copyright 2020 by the Sports Car Club of America, Inc®. All rights re- served. Except as permitted under the United States Copyright Act of 1976, no part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or by any information storage or retrieval system, without the prior written permission of the publisher. Forty-seventh printing, January, 2020. Published by: Sports Car Club of America, Inc.® 6620 SE Dwight St. Topeka, KS 66619 www.scca.com 1-800-770-2055 (785) 357-7222 The SCCA® National Solo® Rules may be downloaded from the SCCA® website at www.scca.com. Published in the United States of America. This book is the property of: Name _____________________________________________ Address ____________________________________________ City/State/Zip ________________________________________ Region _____________________________________________ Member # __________________________________________ SCCA Welcoming Environment Statement The Mission of the SCCA is to fuel a safe, fun and excit- ing motorsports experience for auto enthusiasts. Our Vision is to be the preferred motorsports community in the U.S., built on fun, shared passion and access to an exhilarating motorsports experience. In all its activities, the SCCA seeks to foster an atmosphere that encourages living the Values of the SCCA: Excellence – The Spirit of a Competitor Service – The Heart of a Volunteer Passion – The Attitude of an Enthusiast Team – The Art of Working Together Experience – The Act of Wowing our Community Stewardship – The Mindset of an Owner To that end, the SCCA strives to ensure that ALL partici- pants in its events and activities enjoy a welcoming en- vironment. -

OK Shaft Couplings Contents

OK shaft couplings Contents The clever connection 3 OK couplings explained 4 OKCX and OKFX – friction-coated shaft coupling from SKF 6 More than 50 000 connections 8 Shaft couplings OKC 045 – 090 9 OKC 100 – 190 10 OKC 200 – 400 11 OKC 410 – 490 12 OKC 500 – 520 12 OKC 530 – 1000 13 Friction-coated shaft couplings OKCX 100 – 210 14 OKCX 220 – 490 15 OKCX 500 – 690 16 OKCX 700 – 900 17 Flange couplings OKF 100 – 300 18 OKF 310 – 700 19 Hydraulic rings and propeller nuts OKTC 245 – 790 20 Your individual offer 21 Tailor-made OK couplings 22 Power transmission capacity 23 Shafts 24 Conversion tables 24 Hollow shafts for OKC couplings 25 Hollow shafts for OKF couplings 25 Modular equipment for mounting and dismounting 26 Oil 28 Approved by all leading classiication societies 28 Locating device for outer sleeve and nut 29 Mounting arrangements for OK couplings 29 The SKF Supergrip Bolt cuts downtime 30 22 The clever connection When using OK couplings for shaft connections, you are gaining ben- When the outer sleeve has reached its inal position, an interference eit from the advantages of our powerful oil injection method it is created just as if the outer sleeve had been heated and shrunk on But no heat is required, and the coupling can be removed as eas- Preparation of the shaft is simple There are no keyways to machine, ily as it was mounted no taper and no thrust ring This powerful use of friction enables the OK coupling to transmit When mounting OK coupling, a thin inner sleeve with a tapered outer torque and axial loads over the entire -

Getting Started with Lotus Suspension Analysis

VERSION 5.01 GETTING STARTED WITH LOTUS SUSPENSION ANALYSIS VERSION 5.04 The information in this document is furnished for informational use only, may be revised from time to time, and should not be construed as a commitment by Lotus Cars Ltd or any associated or subsidiary company. Lotus Cars Ltd assumes no responsibility or liability for any errors or inaccuracies that may appear in this document. This document contains proprietary and copyrighted information. Lotus Cars Ltd permits licensees of Lotus Cars Ltd software products to print out or copy this document or portions thereof solely for internal use in connection with the licensed software. No part of this document may be copied for any other purpose or distributed or translated into any other language without the prior written permission of Lotus Cars Ltd. ©2015 by Lotus Cars Ltd. All rights reserved. CONTENTS 1 - INTRODUCING LOTUS SUSPENSION ANALYSIS 1.1 Overview ..................................................................................1 1.2 What is Lotus Suspension Analysis? .......................................2 1.3 Normal Uses of Lotus Suspension Analysis.............................2 1.4 Overall Concepts......................................................................2 1.5 Coordinate system ...................................................................3 1.6 Default Sign convention ...........................................................3 1.7 About the Tutorials ...................................................................4 2 - GETTING STARTED -

High Precision Rack and Pinion Main Features High Precision High Loading High Speed Low Noise Long Life-Time Quick Delivery

High Precision Rack and Pinion Main Features High Precision High Loading High Speed Low Noise Long Life-Time Quick Delivery APEX is the ONLY ONE manufacturer worldwide who produces rack strictly according to specifications regarding : Geometrical Tolerance of all Dimensions Defined Straightness, Parallelism and Perpendicularity Helical Angle and Pressure Angle with Tolerance Defined Surface Roughness of Teeth Defined Hardness and Thickness of the Hardened Layer on the Teeth. APEX is also the ONLY ONE of the world leading brands who designs and produces rack, pinion and gearbox by its own, and provides well coordinated high-quality transmission sets to fulfill different industrial requirements. 1 Content Requirement of High-Precision Rack Page 3 Declaration of Tolerance 7 Induction Hardening for Rack 11 Heat-Treatment for Pinion 12 Rack Quality and Application 13 Rack Order Code 14 Rack with Helical Teeth 15 Rack with Helical Teeth ( with Linear-Guide Interface, 90° Type ) 27 Rack with Helical Teeth ( with Linear-Guide Interface, 180° Type ) 28 APEX High Precision Pinion 29 APEX Pinion with Curvic Plate 30 Pinion Order Code 31 Pinion with Helical Teeth ( Curvic Plate / EN ISO 9409-1-A ) 32 Pinion with Helical Teeth ( Welded Plate / EN ISO 9409-1-A ) 37 Pinion with Helical Teeth ( Teeth Plate / EN ISO 9409-1-A ) 43 Pinion with Helical Teeth ( DIN 5480 / Spline ) 48 Pinion with Helical Teeth ( Keyway for APEX AF- / PII-Series ) 50 Pinion with Helical Teeth ( Keyway ) 52 Pinion with Helical Teeth ( Long Shaft with Keyway for Hollow-Shaft ) -

Tire Couplings

Tire Couplings www.koreacoupling.co.kr Coupling Selection Coupling Selection How to Select Standard Selection The Standard Selection may be used for engine driven, motor, or turbine applications. The following information is required: • Application or equipment type (motor to pump, reducer to conveyor, etc.) • Shaft diameters (mm) • Gaps between shafts (mm) • Speed (RPM) • Horsepower or torque (Nm) 1. Rating : Determine system torque. Torque is calculated as follows : kW × 9,550 kW × 974 Ⅰ. Torque (Nm) = Ⅱ. Torque (Kg.m) RPM RPM 2. Service Factor : Determine appropriate service factor from page. 5-6 3. Minimum Coupling Rating : Determine the required minimum coupling rating as follows : Minimum Coupling Rating = Service Factor x Torque (Nm) 4. Type : Select the appropriate coupling type 5. Size : Trace the Toque column to find the value that is equal or greater than value from Step 3. 6. Check : Check speed (RPM), bore, gap and dimensions. Formula Selection The Standard Selection should be used for most coupling selections. The Formula Selection procedure below should be used for: • High Peak Loads. • Brake Applications (Brake disc or brake wheel is an integral part of coupling) Using the Formula Selection and providing system peak torque and frequency, duty cycle, and brake torque rating will allow for a more refined selection. 1. High Peak Loads : Use formula A or B for applications which involve motors with higher than normal torque characteristics. Applications should also be those with intermittent operations, including shock loading, inertia effects due to starting and stopping, system-induced repetitive high peak torques. System Peak Torque is the maximum torque that can exist in the system. -

MPTA-C7c-2010

MPTA-C7c-2010 Common Causes of Tire Coupling Failures INFORMATIONAL BULLETIN Effective October 2011 – New Address 5672 Strand Ct., Suite 2, Naples, FL 34110 MPTA-C7C-2010 Common Causes of Tire Coupling Failures Contributors Baldor-Dodge-Maska Greenville, SC www.baldor.com Emerson Power Transmission Maysville, KY www.emerson-ept.com Frontline Industries Irvington, NJ www.frontlineindustries.com Lovejoy, Inc. Downers Grove, IL www.lovejoy-inc.com Magnaloy Alpena, MI www.magnaloy.com Martin Sprocket & Gear, Inc. Arlington, TX www.martinsprocket.com Maurey Manufacturing Corp. Holly Springs, MS www.maurey.com Rexnord New Berlin, WI www.rexnord.com TB Wood’s Incorporated Chambersburg, PA www.tbwoods.com Disclaimer Statement This publication is presented for the purpose of providing reference information only. You should not rely solely on the information contained herein. Mechanical Power Transmission Association (MPTA) recommends that you consult with appropriate engineers and / or other professionals for specific needs. Again, this publication is for reference information only and in no event will MPTA be liable for direct, indirect, incidental, or consequential damages arising from the use of this information Abstract This publication is intended to provide users with a general overview of the most common causes of failure with elastomeric Tire couplings and their causes. Copyright Position Statement MPTA publications are not copyrighted to encourage their use throughout industry. It is requested that the MPTA be given recognition when any of this material is copied for any use. Foreword This Foreword is provided for informational purposes only and is not to be construed to be part of any technical specification. -

1967 Mustang Rear Suspension Redesign

1967 Mustang Rear Suspension Redesign A Baccalaureate thesis submitted to the Department of Mechanical and Materials Engineering College of Engineering and Applied Science University of Cincinnati in partial fulfillment of the requirements for the degree of Bachelor of Science in Mechanical Engineering Technology By Nicholas Crall April, 2016 Thesis Advisor: Professor Ahmed Elgafy, Ph.D. ii TABLE OF CONTENTS 1967 MUSTANG REAR SUSPENSION REDESIGN ............................................................ II TABLE OF CONTENTS ........................................................................................................ III LIST OF FIGURES ................................................................................................................ IV LIST OF TABLES .................................................................................................................. IV ABSTRACT ............................................................................................................................. V INTRODUCTION - PROBLEM STATEMENT AND INTERVIEW .................................... 6 PROBLEM STATEMENT........................................................................................................................................ 6 INTERVIEW ......................................................................................................................................................... 6 ORIGINAL DESIGN...............................................................................................................