Pwr Transient Xenon Modeling and Analysis Using Studsvik Cms

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

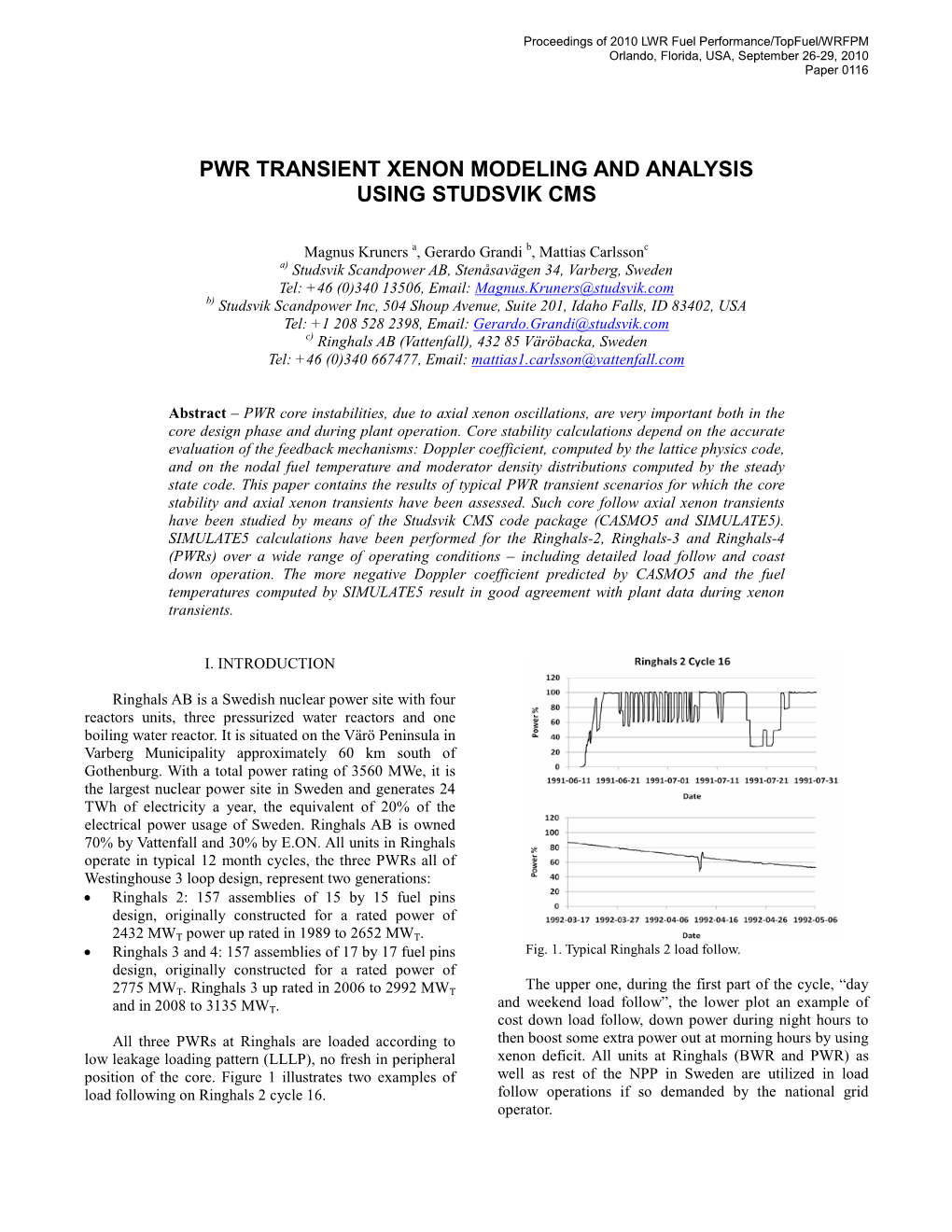

-

Invitation to Acquire Shares in Fortinova Fastigheter Ab (Publ)

INVITATION TO ACQUIRE SHARES IN FORTINOVA FASTIGHETER AB (PUBL) Distribution of this Prospectus and subscription of new shares are subject to restrictions in some jurisdictions, see “Important Information to Investors”. THE PROSPECTUS WAS APPROVED BY THE FINANCIAL SUPERVISORY Global Coordinator and Joint Bookrunner AUTHORITY ON 6 NOVEMBER 2020. The period of validity of the Prospectus expires on 6 November 2021. The obligation to provide supplements to the Prospectus in the event of new circumstances of significance, factual errors or material inaccuracies will not apply once the Prospectus is no longer valid. Retail Manager IMPORTANT INFORMATION TO INVESTORS This prospectus (the “Prospectus”) has been prepared in connection with the STABILIZATION offering to the public in Sweden of Class B shares in Fortinova Fastigheter In connection with the Offering, SEB may carry out transactions aimed at AB (publ) (a Swedish public limited company) (the “Offering”) and the listing supporting the market price of the shares at levels above those which might of the Class B shares for trading on Nasdaq First North Premier Growth Mar- otherwise prevail in the open market. Such stabilization transactions may ket. In the Prospectus, “Fortinova”, the “Company” or the “Group” refers to be effected on Nasdaq First North Premier Growth Market, in the over-the- Fortinova Fastigheter AB (publ), the group of which Fortinova Fastigheter counter market or otherwise, at any time during the period starting on the AB (publ) is the parent company, or a subsidiary of the Group, depending date of commencement of trading in the shares on Nasdaq First North Pre- on the context. -

Tätorter 2010 Localities 2010

MI 38 SM 1101 Tätorter 2010 Localities 2010 I korta drag Korrigering 2011-06-20: Tabell I, J och K, kolumnen Procent korrigerad Korrigering 2012-01-18: Tabell 3 har utökats med två tätorter Korrigering 2012-11-14: Tabell 3 har uppdaterats mha förbättrat underlagsdata Korrigering 2013-08-27: Karta 3 har korrigerats 1956 tätorter i Sverige 2010 Under perioden 2005 till 2010 har 59 nya tätorter tillkommit. Det finns nu 1 956 tätorter i Sverige. År 2010 upphörde 29 områden som tätorter på grund av minskad befolkning. 12 tätorter slogs samman med annan tätort och i en tätort är andelen fritidshus för hög för att den skall klassificeras som tätort. Flest nya tätorter har tillkommit i Stockholms län (16 st) och Skåne län (10 st). En tätort definieras kortfattat som ett område med sammanhängande bebyggelse med högst 200 meter mellan husen och minst 200 invånare. Ingen hänsyn tas till kommun- eller länsgränser. 85 procent av landets befolkning bor i tätort År 2010 bodde 8 016 000 personer i tätorter, vilket motsvarar 85 procent av Sveriges hela befolkning. Tätortsbefolkningen ökade med 383 000 personer mellan 2005 och 2010. Störst har ökningen varit i Stockholms län, följt av Skå- ne och Västra Götaland län. Sju tätorter har fler än 100 000 invånare – Stockholm, Göteborg, Malmö, Upp- sala, Västerås, Örebro och Linköping. Där bor sammanlagt 28 procent av Sveri- ges befolkning. Av samtliga tätorter har 118 stycken fler än 10 000 invånare och 795 stycken färre än 500 invånare. Tätorterna upptar 1,3 procent av Sveriges landareal. Befolkningstätheten mätt som invånare per km2 har ökat från 1 446 till 1 491 under perioden. -

Power to Gas

LOCATIONAL STUDY — POWER TO GAS RAPPORT 2015:120 ENERGIGASER OCH FLYTANDE DRIVMEDEL Locational study – Power to gas KARIN BYMAN ISBN 978-91-7673-120-8 | © 2015 ENERGIFORSK Energiforsk AB | Telefon: 08-677 25 30 | E-post: [email protected] | www.energiforsk.se Förord This project, performed during the period 01-05-2014 – 30-04-2015, has had a reference group consisting of the following persons, who have read and given their comments on the report: Johan Zettergren, Swedegas Saila Horttanainen, Swedegas Tina Helin, E.on. Gas Sverige Bertil Klintbom, Region Gotland Stefan Sandelin, Cementa Jens Melin, Falkenberg Energy Erik Persson, Piteå kommun Ulf Westerberg, Piteå Science Park Lars Göransson, Öresundskraft Anna-Karin Jannasch, Energiforsk (former Svenskt Gastekniskt Center) Martin Ragnar, Energiforsk (former Svenskt Gastekniskt Center) Lena Berglund, Energigas Sverige Björn Aronsson, The Swedish Hydrogen Association Anders Hjörnhede, SP Anna Alexandersson, SP The project has been financed by the following organisations: The Swedish Energy Agency through Energiforsk, The ÅForsk Foundation, Swedegas AB, E.on. Gas Sverige AB, The Region of Gotland, Falkenberg Energy AB, The County of Piteå, Cementa AB and Öresundskraft AB. 3 Summary The task was to identify a suitable location for a demonstration plant for Power to gas in Swe- den. The following three municipalities participated in the study; Gotland, Falkenberg and Piteå. They have in common large scale plans to expand wind power and aim for increased use of biofuels. Otherwise, the conditions in their energy systems differ regarding the infra- structure and local energy balances, illuminating the concept of Power to gas from different perspectives. In a large scale expansion of wind power, its share of the electricity production can become so large locally, that all the electricity cannot be consumed due to limitations in the electricity network. -

Balgö Uppvisar Ett Naturskönt Odlingslandskap Med Många Tydliga Balgö Spår Efter Den Omfattande Jordbruksverksamhet Som Tidigare Bedri- Vits På Ön

206 20 Balgö uppvisar ett naturskönt odlingslandskap med många tydliga Balgö spår efter den omfattande jordbruksverksamhet som tidigare bedri- vits på ön. Balgö var bebodd året runt till 1966. Idag består ön av Lindbergs socken ett bitvis kargt betespräglat kulturlandskap i yttersta kustbandet. De varierade naturbetesmarkerna utgör historiska biotoper med mycket höga natur- och kulturvärden. Till miljön hör fina stenmu- rar samt en välbevarad gårdsbebyggelse, med bl.a. två manbyggna- der samt två mäktiga ladugårdar från sent 1800-tal. I strandnära lägen ligger fornlämningar som gravrösen och tomtningar. Balgö utgör ett ovanligt fint exempel på ett skärgårdsjordbruk, vars skif- tande historia avspeglar människors förmåga till försörjning i en utsatt miljö. Ön har därtill en spännande historia, bl.a. som plats för nordiska kungamöten under medeltid. 207 Balgö ligger i yttersta kustbandet cirka en kilometer utanför Tångaberg och är med sina 250 hektar landområde den största av Hallands öar. Det i sydväst liggande Grässkär är skilt från huvudön med ett vadbart sund. Balgö har ett varierat och innehållsrikt odlingslandskap, med mån- ga välbevarade markslag och spår efter äldre tiders jordbruksaktiviteter, vilka åt- minstone går tillbaka till 1600-talet. Be- byggelsen ligger samlad på en tomt cen- tralt på ön, väl avgränsad mot omgivande marker av vällagda stenmurar. Landskapet på det flacka Balgö består av en mosaik av betade f.d. åker- och Balgö ligger strax utanför Tångaberg. Ön präglas numera av ett betat stenmurslandskap. Inägomarken låg på öns norra del och i söder bredde utmarken ut sig. gräsmarker samt utmarker. Naturbe- tesmarken utgörs bl.a. av hällmarkshe- dar med ljung och enbuskar, torr- och friskängar, strandängar samt kala klap- perstensfält och strandvallar. -

Varberg Living Cities – Competition Brief

Europan is a biennial competition for young architects under 40 EUROPAN 16 years of age. VARBERG LIVING CITIES – COMPETITION BRIEF ”Transformation of a traffic barrier into a living town street for people” VARBERG 1 2 C www.europan.se Visit our website: 16 EUROPAN Page: ONTENT 04 INTRODUCTION 05 URBAN CONTEXT 08 E16 THEME 10 STUDY SITE (MARKED IN RED) 12 PROJECT SITE (MARKED IN YELLOW) 14 TASK 16 MISCELLANEOUS 17 REFERENCES 19 APPENDIX GENERAL INFORMATION Site Representative Jury evaluation Maria Söderlund With the participation of the site Municipality of Varberg representatives. Actor involved Post-competition intermediate Municipality of Varberg procedure Presentation of the rewarded ”Team representative” teams to the site representatives, Architect, landscape architect or followed by a discussion. urban planner The ambition of the municipality Expected skills regarding the is to involve the prize winning site’s issues and characteristics team(s) in an implementation Architecture, landscape process. architecture, urban planning Assignment after the competition Communication The prize winning team(s) will Anonymous local exhibition after continue the work with the the 1st jury round. competition assignment in a workshop with the municipality, After the competition there will with an option for further work be a public prize ceremony, towards an implementation of the a catalogue of results will be proposal, including workshops, produced, and the winners will various planning documents, be published on the website of illustrations, drawings and citizen Architects Sweden. dialogues. 3 3 INTRODUCTION PARTICIPATE IN EUROPAN 16! INTRODUCTION VARBERG The Municipality of Varberg Varberg is a steadily growing and Europan Sweden would city in an expansive region. -

Discover Falkenberg

2019 GUIDEUPPTÄCK FALKENBERG | DISCOVER FALKENBERG falkenberg.se 2019 GUIDE O ISC VE D R 20 PLATSER | PLACES 24 MUSÉER | MUSEUMS 26 AKTIVITETER | ACTIVITIES 32 BADA & SIMMA | BATHING & SWIMMING 34 FAMILJENÖJEN | FAMILY FUN 36 NATUREN | NATURE 40 ÄTA UTE | EAT & DRINK Res med OPPIN APPEN och få SH G 48 SHOPPING | SHOPPING HAT’S O 15 % W N rabatt 50 VAD HÄNDER | WHAT´S ON E TO ER ST H A Y W RES MED RABATT! Med vår mobilapp har du din egen biljettautomat i fickan och du betalar lätt 56 SOVA ÖVER | WHERE TO STAY med bankkort, Swish eller mot faktura. Du får alltid 15 procent rabatt när du köper mobilbiljett inom Halland. MA OR TIO F N Läs mer om fördelarna och möjligheterna med mobilappen på hallandstrafiken.se IN 63 BRA ATT VETA | PRACTICAL INFORMATION TRAVEL WITH DISCOUNT! With our mobile app you have your own ticket machine in your pocket and you pay by debit card, Swish or invoice. You always get a 15 percent discount when you buy a mobile ticket in Halland. Learn more about the benefits and opportunities of the mobile app at hallandstrafiken.se Innehåll och grafisk form: Destination Falkenberg. Foto: Hidvi Group, Destination Falkenberg och Region Halland. Text: Alex Bennheden och Destination Falkenberg. Tryck: Printografen, Halmstad, april 2019. falkenberg.se 3 VÄLKOMMEN TILL FALKENBERG WELCOME TO FALKENBERG I hjärtat av Halland ligger Falkenberg och här finns fullt av smultronställen som väntar på att upptäckas. Kom och ta del av en kust som är kantad av underbara sandstränder eller upplev Ätrans slingrande väg genom ett böljande skogslandskap. -

A Master Thesis at Chalmers Architecture By: Anders Winlöf 2009/2010 Examinator: Morten Lund (CTH) Tutor: Fredrik Olson (Metro Arkitekter) See You in September!

A Master Thesis at Chalmers Architecture By: Anders Winlöf 2009/2010 Examinator: Morten Lund (CTH) Tutor: Fredrik Olson (Metro Arkitekter) See You in September! ABSTRACT CONTENT The lack of energy is not a problem. Renewable energy 1 Abstract/Content sources can provide our planet’s energy consumption 3 What?/Why?/How? up to 15.000 times. When we choose to fully harness these energy sources new possibilities will rise. 5 Program This Master Thesis asks: How can we create architecture 7 Process that is built by energy and what are the advantages? Research Due to a wave power plant, the project offers facilities 8 Varberg for wave surfers in the sand dunes of Kåsa, Varberg. It 10 Surfing is designed by premises of the wind, materialized by 12 Weather sand and powered by the waves. Since the surf season 14 Wave Power in Sweden is limited the facilities only exist during fall & winter. When spring arrives, the power is turned off 16 Sand Dunes and the structure cease to exist. 18 Wind Study Result That is why my project is called See You in 20 Introduction September! 21 Research 22 Wind/Sand/Water 23 Mixed Elements 24 Context 25 Seasons 26 Exterior 27 Spaces 28 Interior 29 Material 30 Model Anders Winlöf 2010.01.21 31 Conclusion 2 WHAT? WHY? HOW? ‘See you In September!’ proposes a The city of Varberg has during the last century In contrary to the hi-tech systems, the combination of highly technical systems had a strong cultural connection to the architecture is a low tech solution that brings that create a synergy effect which handles ocean. -

Fulltekst (Pdf)

Mistra Urban Futures Report 2020:6 The Urban Station Community: Towards a Resource-efficient Transport System FINAL REPORT FOR THE YEARS 2017-2019 Anna Gustafsson & Ulf Ranhagen The Urban Station Community: Towards a Resource-efficient Transport System. FINAL REPORT FOR THE YEARS 2017-2019 Authors: Ulf Ranhagen & Anna Gustafsson Corresponding author: [email protected] © Mistra Urban Futures, 2020:6 www.mistraurbanfutures.org ISBN: 978-91-984166-4-0 Mistra Urban Futures is an international Centre for sustainable urban development. We believe that the coproduction of knowledge is a winning concept for achieving sustainable urban futures and creating accessible, green and fair cities. The Centre is hosted by Chalmers University of Technology and has five platforms in Cape Town, Kisumu, Gothenburg, Skåne and Sheffield-Manchester as well as a node in Stockholm. Mistra Urban Futures is financed by the research foundation Mistra and Sida, together with a consortium comprising: Chalmers University of Technology, the University of Gothenburg, the City of Gothenburg, the Gothenburg Region Associ- ation of Local Authorities (GR), IVL Swedish Environmental Research Institute, the County Administrative Board of Västra Götaland, and the Region of Västra Göta- land, along with funders on the various regional platforms. From 2020 Mistra Urban Futures continues into two different organisations. One being a new organisation under the name Centre for Sustainable Urban Futures, which is a continuation of the previous work of Mistra Urban Futures in Gothen- burg and Sweden. While the parts of the international work will be integrated within a new organisation Global Sustainable Futures. Both organisations are inte- grated under Gothenburg Centre for Sustainable Development (GMV), co-hosted by Chalmers University of Technology and Gothenburg University. -

Hugo Du Rietz by Linda Atkinson

LINDA ATKINSON HUGO DU RIETZ Swedish Noble, Architect, Farmer and a Founding Father of Gympie HUGO DU RIETZ SWEDISH NOBLE, ARCHITECT, FARMER, and A FOUNDING FATHER OF GYMPIE The Du Rietz Coat of Arms of the Swedish Noble Family LINDA ATKINSON First published 2018 by Gympie Regional Council PO Box 155, Gympie Queensland 4570 Australia Copyright: Gympie Regional Council This book is copyright. Apart from any fair dealing for the purposes of private study, research, criticism or review, as permitted under the Copyright Act, no part may be reproduced by any process without written permission. Enquiries should be made to the Gympie Regional Council. Printed by Cataloguing in Publication Data National Library of Australia Atkinson, Linda, 1949 - author Hugo Du Rietz: Swedish noble, architect, farmer and a founding father of Gympie. Bibliography. Includes Index. 1. Gympie (Qld.) - History 2. Du Rietz, Hugo Wilhelm – 1831-1908 ISBN 978-0-6480274-3-0 ISBN 978-0-6480274-4-7 (ebook) Title Page: The DeVries/Du Rietz Coat of Arms from the House of Nobility in Sweden i Hugo Du Rietz-Taken by unknown photographer; date unknown Hugo lived from 3 April 1831 to 9 August 1908 ii iii TABLE OF CONTENTS Chapter 1 The Foundations Chapter 2 The Noble House Chapter 3 Hugo Du Rietz comes to Australia Chapter 4 Du Rietz Family in Gympie and Related Information Chapter 5 Hugo Du Rietz-Successful Life in Gympie Chapter 6 Death of Hugo Du Rietz Chapter 7 Legacy for Gympie Bibliography Index iv Hugo Vilhelm Du Rietz v Foreword During 2013 I wrote a short history about Hugo Du Rietz’s significant life and architectural contribution to the town of Gympie. -

THE HALLAND MODEL Gothenburg Studies in Conservation 24 Gothenburg Studies in Conservation 24

THE HALLAND MODEL gothenburg studies in conservation 24 gothenburg studies in conservation 24 THE HALLAND MODEL A Trading Zone for Building Conservation in Concert with Labour Market Policy and the Construction Industry, Aiming at Regional Sustainable Development Christer Gustafsson © CHRISTER GUSTAFSSON, 2011 [email protected] isbn 978-91-7346-668-4 issn 0284-6578 Photographs by Christer Gustafsson Map by Monica Bülow Björk Subscriptions to the series and orders for individual copies sent to: Acta Universitatis Gothoburgensis, PO Box 222, SE 405 30 Göteborg, or to [email protected] Printed by Bulls Graphics AB Box 343 SE-301 08 Halmstad, Sweden Tel: +46 (0)35-14 41 50 Halmstad, Sweden, 2011 The publication is also available in full text at: http://hdl.handle.net/2077/28328 http://www.kulturmiljohalland.se/publikationer.jsp#header2 This publication has been produced with generous support from: Heritage Halland (Kulturmiljö Halland) and Region Halland. editor’s preface EDITOR’S PREFACE The present publication (GSC No. 24) is prepared by its author Ph.D. Christer Gustafsson as a volume in the academic series Gothenburg Studies in Conservation (GSC), after having been delivered as his doctoral dis- sertation, defended on October 22nd in 2009 at Chalmers University of Technology in Göteborg. Professor Dr. Luigi Fusco Girard, Dipartimento di Conservazione dei Beni Architettonici ed Ambientali at Università degli Studi di Napoli Federico II, was appointed as Faculty Opponent, involv- ing responsibility for the public examination of this doctoral research specimen. Hereby a thorough and critical scrutiny is included, by a much admired, eminent and internationally renowned expert in the compre- hensive fields of sustainable architectural and planned conservation and management of historic buildings and urban ambiences. -

11 Cities on 2 Wheels for 3 Years the Nordic Cycle Cities Project – Experience and Results

11 cities on 2 wheels for 3 years The Nordic Cycle Cities Project – Experience and results 1 Foreword Contents 11 Nordic communities join together to promote cycling Foreword .......................................................................................................................2 Cycling is a healthy and environmentally friendly transport mode; it im- proves public health and reduces CO2 emissions from transport. For this The Nordic Cycle Cities Concept ....................................................................... 4 reason 11 Nordic communities in Denmark, Norway and Sweden decided to join together in a cooperative venture to encourage cycling in the Kattegat- Bicycle Account ........................................................................................................ 6 Skagerak region. Bicycle Strategy ........................................................................................................ 8 The interregional project was co-financed by the European Regional Devel- opment Fund IVA program for the Kattegat-Skagerak region. Bicycle Action Plan ................................................................................................ 10 The participating municipalities were: Children on Bikes .....................................................................................................12 • Denmark: Frederikshavn (lead partner), Randers, Silkeborg, and Viborg • Norway: Sandefjord (Norwegian project owner) and Kristiansand Cycling to Work ........................................................................................................14 -

Varberg Tourist Guide

Eurotourism www.eurotourism.com Varberg Tourist Guide The four “Must See and Do’s” when visiting Varberg Varbergs Fortress Area Kallbadhuset (Bathing House) Fishing at Fladen Fun City Municipality Facts 01 Population 55 459 Area 913,86 km² Regional Center Varberg County Halland More Information 02 Internet www.varberg.se www.turist.varberg.se Newspapers Hallands Nyheter www.hn.se Tourist Bureaus Tourist Bureau Brunnsparken/Västra Vallgatan 39 Varberg +46 340-868 00 Photo: Shutterstock [email protected] www.turist.varberg.se Welcome to Varberg Notes 03 The seaside city of Varberg with Varberg’s sandy beach at Apelviken, the cliff beach at Fortress which is a landmark medieval castle, Getterön or the world famous nudist beaches. Emergency 112 offers you a wide variety of activities. Here you can sit on the Societetshusets (The Police 114 14 Society House) veranda and enjoy good food, Country Code +46 Here you can shop in the bustling market music and the local life. Varberg also has square every Wednesday and Saturday, or a long tradition as a health resort, and the Area Code 0340 visit the Bockstensmannen (Bocksten Man, tradition lives on at a couple of health resort medieval remains) at the fortress. Enjoy the hotels in the area. Eurotourism Media Group AB: Box 55157 504 04 Borås Sweden Tel +46 33-233220 Fax +46 33-233222 [email protected] Copyright © 2009 E.M.G. AB Protected by international law; any violation will be prosecuted. 1 An Independent Tourist Information Company Eurotourism www.eurotourism.com Tourist Guide Varberg See and Do Photo: Shutterstock Lilla Apelviken, ”Kåsa” Swimming Bathing Places Handicapped bathing.