Copper Basin Mining District Site Case Study

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Tectonic Alteration of a Major Neogene River Drainage of the Basin and Range

University of Montana ScholarWorks at University of Montana Graduate Student Theses, Dissertations, & Professional Papers Graduate School 2016 TECTONIC ALTERATION OF A MAJOR NEOGENE RIVER DRAINAGE OF THE BASIN AND RANGE Stuart D. Parker Follow this and additional works at: https://scholarworks.umt.edu/etd Part of the Tectonics and Structure Commons Let us know how access to this document benefits ou.y Recommended Citation Parker, Stuart D., "TECTONIC ALTERATION OF A MAJOR NEOGENE RIVER DRAINAGE OF THE BASIN AND RANGE" (2016). Graduate Student Theses, Dissertations, & Professional Papers. 10637. https://scholarworks.umt.edu/etd/10637 This Thesis is brought to you for free and open access by the Graduate School at ScholarWorks at University of Montana. It has been accepted for inclusion in Graduate Student Theses, Dissertations, & Professional Papers by an authorized administrator of ScholarWorks at University of Montana. For more information, please contact [email protected]. TECTONIC ALTERATION OF A MAJOR NEOGENE RIVER DRAINAGE OF THE BASIN AND RANGE By STUART DOUGLAS PARKER Bachelor of Science, University of North Carolina-Asheville, Asheville, North Carolina, 2014 Thesis Presented in partial fulfillment of the requirements for the degree of Master of Science in Geology The University of Montana Missoula, MT May, 2016 Approved by: Scott Whittenburg, Dean of The Graduate School Graduate School James W. Sears, Committee Chair Department of Geosciences Rebecca Bendick Department of Geosciences Marc S. Hendrix Department of Geosciences Andrew Ware Department of Physics and Astronomy Parker, Stuart, M. S., May, 2016 Geology Tectonic alteration of a major Neogene river drainage of the Basin and Range Chairperson: James W. -

Copper Basin Mining District Is the Former Site of Extensive Copper and Sulfur Mining Operations Dating Copper Basin Mining District Site Back for More Than 150 Years

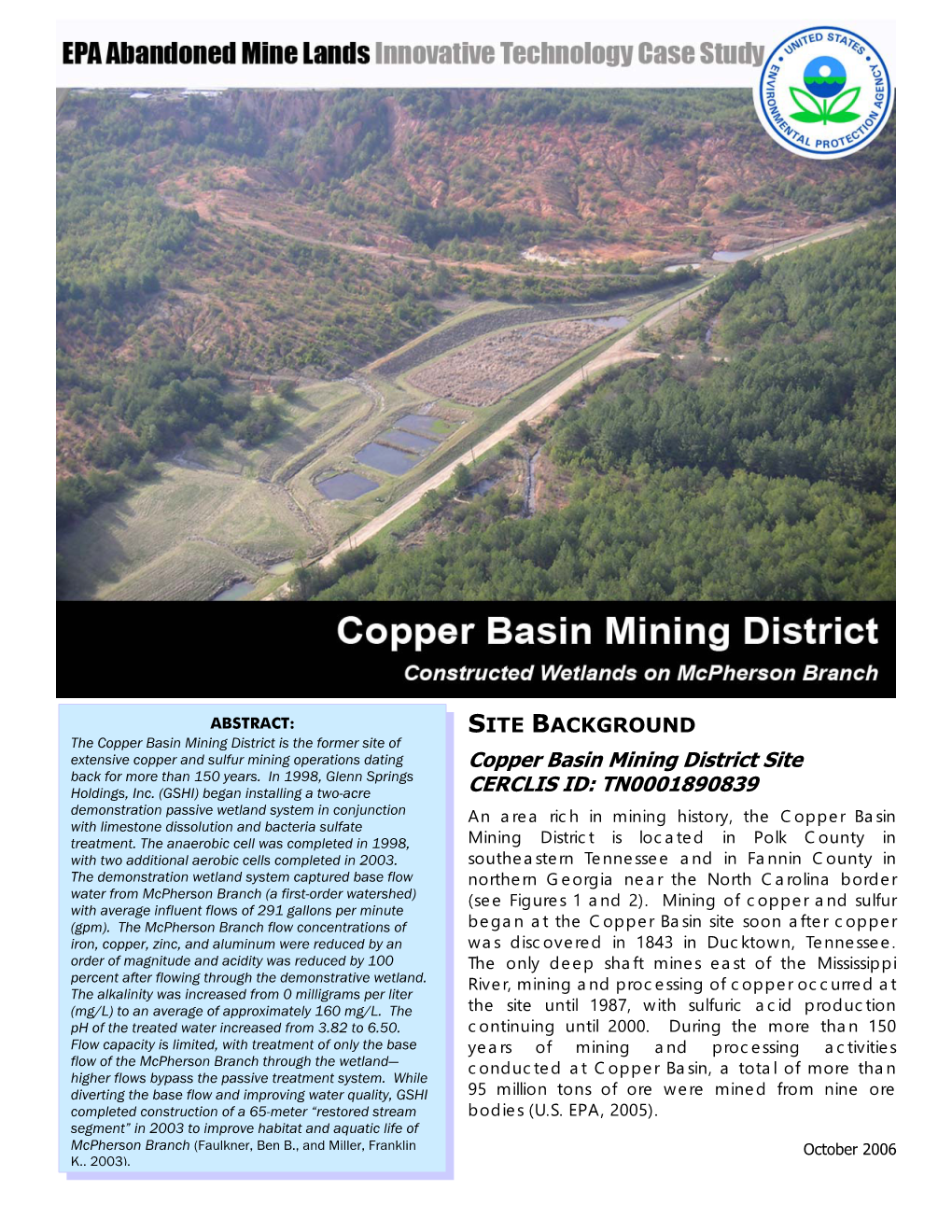

ABSTRACT: SITE BACKGROUND The Copper Basin Mining District is the former site of extensive copper and sulfur mining operations dating Copper Basin Mining District Site back for more than 150 years. In 1998, Glenn Springs Holdings, Inc. (GSHI) began installing a two-acre CERCLIS ID: TN0001890839 demonstration passive wetland system in conjunction An area rich in mining history, the Copper Basin with limestone dissolution and bacteria sulfate treatment. The anaerobic cell was completed in 1998, Mining District is located in Polk County in with two additional aerobic cells completed in 2003. southeastern Tennessee and in Fannin County in The demonstration wetland system captured base flow northern Georgia near the North Carolina border water from McPherson Branch (a first-order watershed) (see Figures 1 and 2). Mining of copper and sulfur with average influent flows of 291 gallons per minute (gpm). The McPherson Branch flow concentrations of began at the Copper Basin site soon after copper iron, copper, zinc, and aluminum were reduced by an was discovered in 1843 in Ducktown, Tennessee. order of magnitude and acidity was reduced by 100 The only deep shaft mines east of the Mississippi percent after flowing through the demonstrative wetland. River, mining and processing of copper occurred at The alkalinity was increased from 0 milligrams per liter (mg/L) to an average of approximately 160 mg/L. The the site until 1987, with sulfuric acid production pH of the treated water increased from 3.82 to 6.50. continuing until 2000. During the more than 150 Flow capacity is limited, with treatment of only the base years of mining and processing activities flow of the McPherson Branch through the wetland— conducted at Copper Basin, a total of more than higher flows bypass the passive treatment system. -

Geologic Map of the Fish Creek Reservoir 7.5' Quadrangle, Blaine County, Idaho

Geologic Map of the Fish Creek Reservoir 7.5’ Quadrangle, Blaine County, Idaho Scientific Investigations Map 3191 U.S. Department of the Interior U.S. Geological Survey Idavada volcanics measured section Fish Creek Reservoir dam West Fork Fish Creek CRATER Fish Creek NORTH Fish Creek Reservoir Road Mcb FRONT COVER: View looking west from low hill on east side of Fish Creek (see red star on geologic map), showing Fish Creek dam and reservoir, nearly dry; location of measured section (white dashed line on ridge) of lower Paleozoic carbonate rocks (Skipp and Sandberg, 1975); rim of crater, source for basalt flow of Snake River Group, and the junction of Fish Creek and West Fork of Fish Creek. Flat-lying distant caprock on Wood River Formation is rhyolitic ignimbrite of Miocene Idavada Volcanics. Mcb = Copper Basin Group Geologic Map of the Fish Creek Reservoir 7.5´ Quadrangle, Blaine County, Idaho By Betty Skipp and Theodore R. Brandt Scientific Investigations Map 3191 U.S. Department of the Interior U.S. Geological Survey U.S. Department of the Interior KEN SALAZAR, Secretary U.S. Geological Survey Marcia K. McNutt, Director U.S. Geological Survey, Reston, Virginia: 2012 For more information on the USGS—the Federal source for science about the Earth, its natural and living resources, natural hazards, and the environment, visit http://www.usgs.gov or call 1–888–ASK–USGS. For an overview of USGS information products, including maps, imagery, and publications, visit http://www.usgs.gov/pubprod To order this and other USGS information products, visit http://store.usgs.gov Any use of trade, product, or firm names is for descriptive purposes only and does not imply endorsement by the U.S. -

Maintaining and Industrial Peace in the East Tennessee Copper Basin from the Great War Through the Second World War

Georgia State University ScholarWorks @ Georgia State University History Dissertations Department of History 3-19-2010 Removing Reds from the Old Red Scar: Maintaining and Industrial Peace in the East Tennessee Copper Basin from the Great War through the Second World War William Ronald Simson Georgia State University Follow this and additional works at: https://scholarworks.gsu.edu/history_diss Part of the History Commons Recommended Citation Simson, William Ronald, "Removing Reds from the Old Red Scar: Maintaining and Industrial Peace in the East Tennessee Copper Basin from the Great War through the Second World War." Dissertation, Georgia State University, 2010. https://scholarworks.gsu.edu/history_diss/17 This Dissertation is brought to you for free and open access by the Department of History at ScholarWorks @ Georgia State University. It has been accepted for inclusion in History Dissertations by an authorized administrator of ScholarWorks @ Georgia State University. For more information, please contact [email protected]. REMOVING REDS FROM THE OLD RED SCAR: MAINTAINING AN INDUSTRIAL PEACE IN THE EAST TENNESSEE COPPER BASIN, FROM THE GREAT WAR THROUGH THE SECOND WORLD WAR by WILLIAM R. SIMSON ABSTRACT This study considers industrial society and development in the East Tennessee Copper Basin from the 1890s through World War II; its main focus will be on the primary industrial concern, Tennessee Copper Company (TCC 1899), owned by the Lewisohn Group, New York. The study differs from other Appalachian scholarship in its assessment of New South industries generally overlooked. Wars and increased reliance on organic chemicals tied the basin to defense needs and agricultural advance. Locals understood the basin held expanding economic opportunities superior to those in the surrounding mountains and saw themselves as participants in the nation’s industrial and economic progress, and a vital part of its defense. -

Geologic Map of the Southern Portion of the Clayton Quadrangle, Custer

IDAHO GEOLOGICAL SURVEY TECHNICAL REPORT 20-02 BOISE-MOSCOW IDAHOGEOLOGY.ORG KROHE AND OTHERS CORRELATION OF MAP UNITS Cash Creek Quartzite (middle Cambrian)—Quartzite, gray to 4TA09: Cambrian quartzite of Cash Creek (Єc) 5TA09: Ordovician Kinnikinic Quartzite (Ok) EOLOGIC AP OF THE OUTHERN ORTION OF THE LAYTON UADRANGLE, USTER OUNTY, DAHO Cc light-gray on weathered surface, light-gray to off-white on fresh G M S P C Q C C I Unconsolidated Sedimentary and Mass Movement Deposits surface. Unit is fine to coarse grained with pebbly layers and lenses 30 1785 n= 86 n= 87 (Hobbs and Hays, 1990); grains are subrounded and moderately to 1860 20 poorly sorted. All sand is quartz, there is no feldspar. Unit is medium Qls Qal Qc Qcq QUATERNARY to thick-bedded, has blocky weathering and is a cliff former. Unit 25 Volcanic Rocks has sharp contacts with the overlying Єs and underlying Єcb. The -------Unconformity------- CENOZOIC unit is ~396 m thick. Nicholas J. Krohe, Daniel T. Brennan, Paul K. Link, David M. Pearson, and L. Trent Armstrong 15 Lower carbonate of Squaw Creek (middle to early Cambrian)— 20 Tcv TERTIARY Ccb 1958 Idaho State University, Department of Geosciences Eocene Carbonaceous siltite, dark-gray to light-gray on weathered surface, dark purplish-gray to light-gray to turquoise on fresh surface. Unit is 2020 (modified from Plate 1 in Krohe, 2016, ISU M.S. Thesis) Sedimentary Rocks fine to very fine grained and well sorted. Unit contains mainly quartz 15 sand with some micaceous and calcareous layers. Unit is strikingly 10 Copper Basin Thrust Sheet Number laminated to thinly bedded, weathers fissile to flaggy, and has an Number Clayton-Bayhorse Section MISSISSIPPIAN 2102 2691 oily sheen. -

Structural Reconstruction of Copper Basin, Battle Mountain District

STRUCTURAL RECONSTRUCTION OF THE COPPER BASIN AREA, BATTLE MOUNTAIN DISTRICT, NEVADA by David A. Keeler A Prepublication Manuscript Submitted to the Faculty of the DEPARTMENT OF GEOSCIENCES In Partial Fulfillment of the Requirements for the Degree of MASTER OF SCIENCE In the Graduate College THE UNIVERSITY OF ARIZONA 2010 1 Structural Reconstruction of the Copper Basin Area, Battle Mountain District, Nevada David A. Keeler* Newmont Mining Corp. P.O. Box 1657, Battle Mountain, NV 89820-1657 and Eric Seedorff Institute for Mineral Resources, Department of Geosciences University of Arizona, Tucson, AZ 85721-0077 *Corresponding author: email, [email protected] 2 Abstract The Copper Basin area of the Battle Mountain district in north-central Nevada contains a porphyry Mo-Cu deposit (Buckingham), several porphyry-related Au ± Cu deposits in skarn and silica-pyrite bodies (Labrador, Empire, Northern Lights, Surprise, Carissa), and three supergene Cu deposits (Contention, Sweet Marie, Widow). This study uses the results of field mapping, U- Pb dating of zircons from igneous rocks, and structural analysis to assess the age, original geometry, depth of emplacement, and degree of tilting and dismemberment of the Late Cretaceous and Eocene hydrothermal systems the Copper Basin area and the source of the supergene copper. The Copper Basin area consists primarily of clastic rocks of the Cambrian(?) Harmony Formation overlain unconformably by Pennsylvanian-Permian clastic and carbonate rocks of the Antler overlap sequence. On the eastern side of Copper Basin, the Antler overlap sequence is overlain by the late Eocene tuff of Cove Mine, in which the compaction foliation dips 15 to 25° east. -

Birth of the Mountains

As the Nation’s principal conservation agency, the Department of the Interior has responsibility for most of our nationally owned public lands and natural and cultural resources. This includes fostering sound use of our land and water resources; protecting our fish, wildlife, and biological diversity; preserving the environmental and cultural values of our national parks and historical places; and providing for the enjoyment of life through outdoor recreation. The Department assesses our energy and mineral resources and works to ensure that their development is in the best interests of all our people by encouraging stewardship and citizen par- ticipation in their care. The Department also has a major responsibility for American Indian reservation communities and for people who live in island territories under U.S. administration. Birth of the Mountains The Geologic Story of the Southern Appalachian Mountains Printed on recycled paper U.S. Department of the Interior U.S. Geological Survey WVA Roanoke VA KY Knoxville NC TN Asheville Chattanooga SC AL GA Atlanta Location of the Southern Appalachians Front and back covers. Great Smoky Mountains from Newfound Gap Road, Great Smoky Mountains National Park. Frontispiece. Creek at the Noah “Bud” Ogle Place on Cherokee Orchard Road, Great Smoky Mountains National Park. Birth of the Mountains The Geologic Story of the Southern Appalachian Mountains By Sandra H.B. Clark The mountains are the soul of the region. To understand the mountains is to know ourselves. Introduction WV Jefferson NF KY The Southern Appalachian Mountains include the Great Smoky Mountains VA National Park, the Blue Ridge Parkway, several National Forests, Cherokee NF TN Blue Ridge and numerous State and Parkway privately owned parks Great Smoky Mountains NP NC and recreation areas Cherokee NF Pisgah NF (fig. -

Polk County: an Appalachian Perspective

University of Tennessee, Knoxville TRACE: Tennessee Research and Creative Exchange Supervised Undergraduate Student Research Chancellor’s Honors Program Projects and Creative Work 5-1990 Polk County: An Appalachian Perspective Jéanne M. Brooks University of Tennessee - Knoxville Follow this and additional works at: https://trace.tennessee.edu/utk_chanhonoproj Recommended Citation Brooks, Jéanne M., "Polk County: An Appalachian Perspective" (1990). Chancellor’s Honors Program Projects. https://trace.tennessee.edu/utk_chanhonoproj/53 This is brought to you for free and open access by the Supervised Undergraduate Student Research and Creative Work at TRACE: Tennessee Research and Creative Exchange. It has been accepted for inclusion in Chancellor’s Honors Program Projects by an authorized administrator of TRACE: Tennessee Research and Creative Exchange. For more information, please contact [email protected]. A §JPEC1LJRUM OF CHANGE SENKOR lPROlTJEC'f COLLEGE SCHOLARS TENNESSEE SCHOLARS lEANNE M. BROOKS APRIL 17, 1990 Appalachia: An Overview.................................................................... 1 Introduction Definitions of Appalachia The Appalachian Regional Commission The Tennessee Valley Authority Appalachian Coal Communities The Case Study: Polk County, Tennessee ................................... 1 7 History to 1978 1 Polk County: An Appalachian Perspective...... Similarities between coal c . les and e aSln The role of TV A and the ARC in Polk County Regional Development Development in Polk County Conclusion Pictures ofPolk County........ ...... ........ ....... .......... ..... ........ ....................... 6 0 Burra Burra Mine Site Landscape Around Ducktown Cherokee National Forest Tennessee Chemical Company Hiwasee Baptist Church Rafters on the Ocoee River This project would not have been possible without the help of Dr.John Gaventa, Dr. Jim Cobb, and Dr. Anne Mayhew. Having the opportunity to work with professors of their calibre has been a true thrill for me. -

Central Copper River Region, Alaska

A, Economic Geology, 48 Series Professional Paper NO. 41 B, Descriptive Geology, 60 DEPARTMENT OF THE INTERIOR UNITED STATES GEOLOGICAL SURVEY CHARLES D. WALCOTT, DIRECTOR GEOLOGY OF THE CENTRAL COPPER RIVER REGION, ALASKA WALTER C. XENDENHALL GOVERNMENT PRINTIKG OFFICE 1905 CONTENTS. Page. Letter of transmittal ...................................................................... 9 Introduction .............................................................................. 11 Organization and itinerary ................................................................. 13 Geography ............................................................................... 16 Chugach Mountains ............................................................... 17 Wrangell hlou~itains............................................................. 17 Alaska Range .................................................................... 19 Interior valley .................................................................... 19 Copper River and its tributaries ................................................... 20 Relations of geography to settlement ...................................................... 22 Geology .................................................................................. Geologic summary .................................................................... Description of formations ............................................................. Dadina schists .................................................................... Occurrence and -

Copper Basin Mining District Case Study

Copper Basin Mining District Case Study Use of Cooperative Agreements Toward a Common Goal he Copper Basin Mining District has been heavily scarred by mining activities and is currently an area in transition. Once considered the Tlargest man-made biological desert in the nation, a 50-square mile tract of land was completely denuded following years of mining; farmers’ crops were destroyed by sulfur dioxide gas emissions from mining wastes; and creek waters were so acidic that no life flourished. In the 1970s, a biological survey found • Approximately 95 million tons of ore have only one living organism–an insect–in the waters downstream of the mining been processed in the mining district. area. Today, EPA, private companies, and the State of Tennessee are working • EPA, Tennessee, and private companies are together to reforest the land, clean the polluted waters, and stabilize and contain coordinating detailed investigations, com- munications, and cleanup efforts. mine wastes. On land that was once devoid of vegetation and clear waters, trees • A new wastewater treatment plant has have taken root and aquatic life is gradually returning. Tourists and locals alike removed approximately 6 million pounds of metals from the Davis Mill Creek in its fi rst enjoy white water raft trips in the nearby Ocoee river, scenic train excursions, two years of operation. and visits to a historic mining museum. It is only through coordinated efforts by EPA, the State of Tennessee, and private companies–with much input from the surrounding communities—that this turnaround is possible. With continued coordination and the ongoing work by all parties, the future for this mining area looks promising. -

New Evidence from the Copper Mountains, Nevada

Transition from Contraction to Extension in the Northeastern Basin and Range: New Evidence from the Copper Mountains, Nevada Jeffrey M. Rahl,1 Allen J. McGrew,2 and Kenneth A. Foland 3 Department of Geology, University of Dayton, Dayton, Ohio 45469-2364, U.S.A. ABSTRACT New mapping, structural analysis, and 40Ar/39Ar dating reveal an unusually well-constrained history of Late Eocene extension in the Copper Mountains of the northern Basin and Range province. In this area, the northeast-trending Copper Creek normal fault juxtaposes a distinctive sequence of metacarbonate and granitoid rocks against a footwall of Upper Precambrian to Lower Cambrian quartzite and phyllite. Correlation of the hanging wall with footwall rocks to the northwest provides an approximate piercing point that requires 8–12 km displacement in an ESE direction. This displaced fault slice is itself bounded above by another normal fault (the Meadow Fork Fault), which brings down a hanging wall of dacitic to rhyolitic tuff that grades conformably upward into conglomerate. These relationships record the formation of a fault-bounded basin between 41.3 and 37.4 Ma. The results are consistent with a regional pattern in which volcanism and extension swept southward from British Columbia to southern Nevada from Early Eocene to Late Oligocene time. Because the southward sweep of volcanism is thought to track the steepening and foundering of the downgoing oceanic plate, these results suggest that the crucial mechanisms for the onset of regional extension were probably changes in plate boundary conditions coupled with convective removal of mantle lithosphere and associated regional magmatism and lithospheric weakening. -

National Register of Historic Places Multiple Property Documentation Form

NPS Form 10-900-b OMB No. 1024^)018 (June 1991) United States Department of the Interior National Park Service National Register of Historic Places Multiple Property Documentation Form This form is used for documenting muttiple property groups relating to one or several historic contexts. See instructions in How to Complete the Multiple Property Documentation Form (National Register Bulletin 16B). Complete each item by entering the requested information. For additional space, use continuation sheets (Form 10-900-a). Use a typewriter, word processor, or computer to complete all items. New Submission Amended Submission A. Name of Multiple Property Listing Historic Resources of the Tennessee Copper Basin B. Associated Historic Contexts (Name ea«h historic context, identifying theme, geographical area, and chronological period for each.) Early Mining Development 1847-1878 Late Mining Development 1890-1987 Development of Communities 1850-1941 C. Form Prepared by name/title Karen L. Daniels/ Historic Preservation Planner organization Southeast Tennessee Development District date February 1992 street & number 25 Cherokee Boulevard telephone (615) 266-5781 Chattanooga city or town state Tennessee zip code 37405______ D. Certification As the designated authority .nder the National Historic Preservation Act of 1966, as amended. I hereby certify that this documentation form meets the National Register documentation standards and sets forth requirements for the listing of related properties consistent with the National Register criteria. This submission