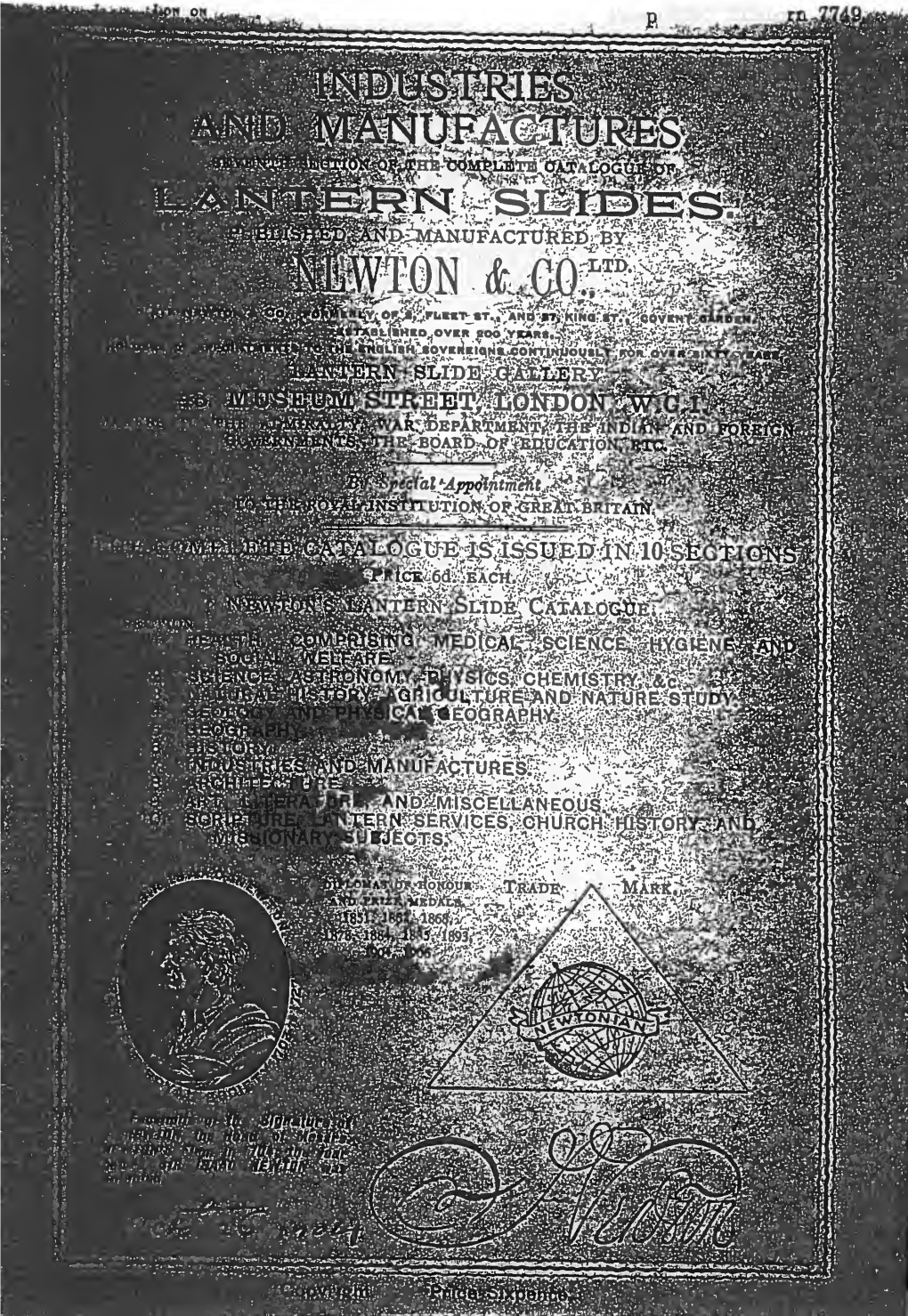

Newton's Lantern Slide Catalogue: Section 7 -- Industries And

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Imperial Airways

IMPERIAL AIRWAYS 1 ARMSTRONG WHITWORTH. AW.XV Atlanta, G-ABPI, Imperial Airways. Photograph, 9 x 14 cm. 6,00 2 ARMSTRONG WHITWORTH. G-ADSR, Ensign Imperial Airways, air to air. Photograph, 9 x 14 cm. 6,00 3 ARMSTRONG WHITWORTH. AW15 Atlanta, G-ABPI, Imperial Airways, air to air, 1932. Photograph, 9 x 14 cm. 6,00 4 ARMSTRONG WHITWORTH. Argosy I, G-EBLF, Imperial Airways, 1929. Photograph, 9 x 14 cm. 6,00 5 ARMSTRONG WHITWORTH. Ensign, G-ADSR, Imperial Airways, 1937. Photograph, 9 x 14 cm. 6,00 6 ARMSTRONG WHITWORTH. Atlanta, G-ABTL, Astraea Imperial Airways, Royal Mail GR. Photograph, 9 x 14 cm. 6,00 7 ARMSTRONG WHITWORTH. Atalanta, G-ABTK, Athena, Imperial Airways. Photograph, 9 x 14 cm. 6,00 8 ARMSTRONG WHITWORTH. AW Argosy, G-EBLO, Imperial Airways. Photograph, 9 x 14 cm. 6,00 9 ARMSTRONG WHITWORTH. AW Ensign, G-ADSR, Imperial Airways, air to air. Photograph, 9 x 14 cm. 6,00 10 ARMSTRONG WHITWORTH. Ensign, G-ADSR, Imperial Airways, air to air. Photograph, 9 x 14 cm. 6,00 11 ARMSTRONG WHITWORTH. Argosy I, G-EBOZ, Imperial Airways. Photograph, 9 x 14 cm. 6,00 12 ARMSTRONG WHITWORTH. AW 27 Ensign, G-ADSR, Imperial Airways, air to air. Photograph, 9 x 14 cm. 6,00 13 AVRO. 652, G-ACRM, Imperial Airways. Photograph, 9 x 14 cm. 6,00 14 AVRO. 652, G-ACRN, Imperial Airways. Photograph, 9 x 14 cm. 6,00 15 AVRO. Avalon, G-ACRN, Imperial Airways. Photograph, 9 x 14 cm. 6,00 16 BENNETT, D. C. -

The Connection

The Connection ROYAL AIR FORCE HISTORICAL SOCIETY 2 The opinions expressed in this publication are those of the contributors concerned and are not necessarily those held by the Royal Air Force Historical Society. Copyright 2011: Royal Air Force Historical Society First published in the UK in 2011 by the Royal Air Force Historical Society All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopying, recording or by any information storage and retrieval system, without permission from the Publisher in writing. ISBN 978-0-,010120-2-1 Printed by 3indrush 4roup 3indrush House Avenue Two Station 5ane 3itney O72. 273 1 ROYAL AIR FORCE HISTORICAL SOCIETY President 8arshal of the Royal Air Force Sir 8ichael Beetham 4CB CBE DFC AFC Vice-President Air 8arshal Sir Frederick Sowrey KCB CBE AFC Committee Chairman Air Vice-8arshal N B Baldwin CB CBE FRAeS Vice-Chairman 4roup Captain J D Heron OBE Secretary 4roup Captain K J Dearman 8embership Secretary Dr Jack Dunham PhD CPsychol A8RAeS Treasurer J Boyes TD CA 8embers Air Commodore 4 R Pitchfork 8BE BA FRAes 3ing Commander C Cummings *J S Cox Esq BA 8A *AV8 P Dye OBE BSc(Eng) CEng AC4I 8RAeS *4roup Captain A J Byford 8A 8A RAF *3ing Commander C Hunter 88DS RAF Editor A Publications 3ing Commander C 4 Jefford 8BE BA 8anager *Ex Officio 2 CONTENTS THE BE4INNIN4 B THE 3HITE FA8I5C by Sir 4eorge 10 3hite BEFORE AND DURIN4 THE FIRST 3OR5D 3AR by Prof 1D Duncan 4reenman THE BRISTO5 F5CIN4 SCHOO5S by Bill 8organ 2, BRISTO5ES -

The 1825 Stockton & Darlington Railway

The 1825 S&DR: Preparing for 2025; Significance & Management. The 1825 Stockton & Darlington Railway: Historic Environment Audit Volume 1: Significance & Management October 2016 Archaeo-Environment for Durham County Council, Darlington Borough Council and Stockton on Tees Borough Council. Archaeo-Environment Ltd for Durham County Council, Darlington Borough Council and Stockton Borough Council 1 The 1825 S&DR: Preparing for 2025; Significance & Management. Executive Summary The ‘greatest idea of modern times’ (Jeans 1974, 74). This report arises from a project jointly commissioned by the three local authorities of Darlington Borough Council, Durham County Council and Stockton-on-Tees Borough Council which have within their boundaries the remains of the Stockton & Darlington Railway (S&DR) which was formally opened on the 27th September 1825. The report identifies why the S&DR was important in the history of railways and sets out its significance and unique selling point. This builds upon the work already undertaken as part of the Friends of Stockton and Darlington Railway Conference in June 2015 and in particular the paper given by Andy Guy on the significance of the 1825 S&DR line (Guy 2015). This report provides an action plan and makes recommendations for the conservation, interpretation and management of this world class heritage so that it can take centre stage in a programme of heritage led economic and social regeneration by 2025 and the bicentenary of the opening of the line. More specifically, the brief for this Heritage Trackbed Audit comprised a number of distinct outputs and the results are summarised as follows: A. Identify why the S&DR was important in the history of railways and clearly articulate its significance and unique selling point. -

SPRING 2015 - Volume 62, Number 1 Call for Papers Violent Skies: the Air War Over Vietnam a Symposium Proposed for October 2015

SPRING 2015 - Volume 62, Number 1 WWW.AFHISTORICALFOUNDATION.ORG Call For Papers Violent Skies: The Air War Over Vietnam A Symposium Proposed for October 2015 Four military service historical foundations—the Air Force Historical Foundation, the Army Historical Foundation, the Marine Corps Heritage Foundation, and the Naval Historical Foundation—recognize that a half century has passed since the United States became militarily engaged in Southeast Asia, and hope to sponsor a series of conferences involving scholars and veterans, aimed at exploring aspects and conse- quences of what once was known as America’s Longest War. For the first conference in the series, since all military services employed their combat aircraft capabilities in that conflict, the leaders of the four nonprofit organizations agree that the air war over Southeast Asia offers a compelling joint topic for reflective examination and discus- sion. The intent is to host a symposium on this subject in the national capital region on Thurs- day and Friday, October 15 and 16, 2015, potentially extending into Saturday, October 17. Other stakeholder organizations will be approached to join as co-sponsors of this event. The organizers of the symposium envision plenary and concurrent sessions to accommodate a wide va- riety of topics and issues. Panel participants will be allotted 20 minutes to present their research or discuss their experiences. A panel chair will be assigned to provide commentary and moderate discussion. Com- menters from academia, veterans, Vietnamese émigrés, and scholars from the region may be invited to pro- vide additional insights. Panel/Paper proposals may employ both chronological and topical approaches: Examples of chronological subjects can include: U.S. -

TEED!* * Find It Lower? We Will Match It

Spring 2018 BRINGING HISTORY TO LIFE Kits & Accessories NEW! USS HAWAII CB-3 PG.45 PANTHER See page 3 Books & Magazines for details on this exciting new kit. NEW! PANTHER TANK IN ACTION PG. 3 Tools & Paint EVERYTHING YOU NEED FOR MODELMAKING PGS. 58-61 Model Displays OVER 75 NEW KITS, BOOKS MARSTON MAT pg. 24 LOWEST PRICE GUARANTEED!* & ACCESSORIES INSIDE! * * See back cover for full details. Order Today at WWW.SQUADRON.COM or call 1-877-414-0434 Dear Friends, Now that we’ve launched into daylight savings time, I have cleared off my workbench to start several new projects with the additional evening light. I feel really motivated at this moment and with all the great new products we have loaded into this catalog, I think it is going to be a productive spring. As the seasons change, now is the perfect time to start something new; especially for those who have been considering giving the hobby a try, but haven’t mustered the energy to give it a shot. For this reason, be sure to check out pp. 34 - our new feature page especially for people wanting to give the hobby a try. With products for all ages, a great first experience is a sure thing! The big news on the new kit front is the Panther Tank. In conjunction with the new Takom (pp. 3 & 27) kits, Squadron Signal Publications has introduced a great book about this fascinating piece of German armor (SS12059 - pp. 3). Author David Doyle guides you through the incredible history of the WWII German Panzerkampfwagen V Panther. -

Historic Environment Audit for the S&DR 1830 Branch Line To

Historic Environment Audit for the S&DR 1830 Branch Line to Middlesbrough On behalf of Middlesbrough Council April 2018 The Stockton & Darlington Railway – Middlesbrough Branch Line Historic Environment Audit The Stockton & Darlington Railway – Middlesbrough Branch Line Historic Environment Audit Summary This report commissioned by Middlesbrough Council takes forward one of the recommendations from the S&DR Heritage Audit prepared in 2016 on behalf of the County Durham, Stockton and Darlington authorities to extend the project along the S&DR branch lines which dated between 1825 and 1830. The audit is designed to pull together key and core information to inform future development work along the route of the 1830 Middlesbrough branch line. The report also includes recommendations for heritage led regeneration along the 1830 corridor and the site of the world’s first planned railway town at St. Hilda’s; this includes enhanced access with interpretation along the 1830 route and distinctive high quality residential uses on the site of the planned new town and new sustainable uses for the surviving new town buildings such as the Old Town Hall, The former Ship Inn and the Captain Cook inn. Figure 1. The route of the 1830 S&DR branch line from Bowesfield Lane in Stockton to Middlesbrough terminating at a new port on the Tees Historic Background Middlesbrough before 1830 comprised a farm surrounded by swampy marshland. Earlier it had been the location of a monastic cell originally founded in 686 A.D. and dedicated to St. Archaeo-Environment Ltd for Middlesbrough Council 2 The Stockton & Darlington Railway – Middlesbrough Branch Line Historic Environment Audit Hilda. -

Brooklands Aerodrome & Motor

BROOKLANDS AERODROME & MOTOR RACING CIRCUIT TIMELINE OF HERITAGE ASSETS Brooklands Heritage Partnership CONSULTATION COPY (June 2017) Radley House Partnership BROOKLANDS AERODROME & MOTOR RACING CIRCUIT TIMELINE OF HERITAGE ASSETS CONTENTS Aerodrome Road 2 The 1907 BARC Clubhouse 8 Bellman Hangar 22 The Brooklands Memorial (1957) 33 Brooklands Motoring History 36 Byfleet Banking 41 The Campbell Road Circuit (1937) 46 Extreme Weather 50 The Finishing Straight 54 Fuel Facilities 65 Members’ Hill, Test Hill & Restaurant Buildings 69 Members’ Hill Grandstands 77 The Railway Straight Hangar 79 The Stratosphere Chamber & Supersonic Wind Tunnel 82 Vickers Aviation Ltd 86 Cover Photographs: Aerial photographs over Brooklands (16 July 2014) © reproduced courtesy of Ian Haskell Brooklands Heritage Partnership CONSULTATION COPY Radley House Partnership Timelines: June 2017 Page 1 of 93 ‘AERODROME ROAD’ AT BROOKLANDS, SURREY 1904: Britain’s first tarmacadam road constructed (location?) – recorded by TRL Ltd’s Library (ref. Francis, 2001/2). June 1907: Brooklands Motor Circuit completed for Hugh & Ethel Locke King and first opened; construction work included diverting the River Wey in two places. Although the secondary use of the site as an aerodrome was not yet anticipated, the Brooklands Automobile Racing Club soon encouraged flying there by offering a £2,500 prize for the first powered flight around the Circuit by the end of 1907! February 1908: Colonel Lindsay Lloyd (Brooklands’ new Clerk of the Course) elected a member of the Aero Club of Great Britain. 29/06/1908: First known air photos of Brooklands taken from a hot air balloon – no sign of any existing route along the future Aerodrome Road (A/R) and the River Wey still meandered across the road’s future path although a footbridge(?) carried a rough track to Hollicks Farm (ref. -

The 1825 Stockton & Darlington Railway: Historic Environment Audit Appendix 2. West Auckland to Shildon. October 2016 (2019

The 1825 Stockton & Darlington Railway: Historic Environment Audit Appendix 2. West Auckland to Shildon. October 2016 (2019 revision) Archaeo-Environment for Durham County Council, Darlington Borough Council and Stockton Council. U rmaeo-Envimnment 11c1 Archaeo-Environment Ltd Marian Cottage Lartington Barnard Castle County Durham DL129BP TeVFax: (01833) 650573 Email: [email protected] Web: www.aenvironment.co.uk NOTE This report and its appendices were first issued in October 2016. Subsequently it was noted that some references to S&DR sites identified during fieldwork and given project reference numbers (PRNS) on an accompanying GIS project and spreadsheet had been referred to with the wrong PRN in the report and appendices. This revision of 2019 corrects those errors but in all other respects remains the same as that issued in 2016. The 1825 Stockton & Darlington Railway: Historic Environment Audit: West Auckland to Shildon. Introduction This report is one of a series covering the length of the 1825 Stockton & Darlington Railway. It results from a programme of fieldwork and desk based research carried out between October 2015 and March 2016 by Archaeo-Environment and local community groups, in particular the Friends of the 1825 S&DR. This report outlines a series of opportunities for heritage led regeneration along the line which through enhanced access, community events, improved conservation and management, can create an asset twenty-six miles long through areas of low economic output which will encourage visitors from across the world to explore the embryonic days of the modern railway. In doing so, there will be opportunities for public and private investment in providing improved services and a greater sense of pride in the important role the S&DR had in developing the world’s railways. -

Science Museum Library and Archives Science Museum at Wroughton Hackpen Lane Wroughton Swindon SN4 9NS

Science Museum Library and Archives Science Museum at Wroughton Hackpen Lane Wroughton Swindon SN4 9NS Telephone: 01793 846222 Email: [email protected] NAP Collection of miscellaneous records of the engineering company D. Napier & Son Compiled by Robert Sharp NAP Following a suggestion from the president of the Veteran Car Club in 1962, much valuable historical material of D Napier & Son Ltd was donated to the Museum's Transport Department in 1963-64. Additional material was donated when the company was taken over by the General Electric Company in late 1973. This material was transferred to the Archives Collection in 1989. NAP 1/38 to 1/43 comprises six historical articles on the Napier company while NAP 4/2 includes a review Men and Machines: a history of D Napier & Son, Engineers Ltd 1808-1958 * by C H Wilson & W Reader (1958). Other historical background material is in NAP 5/3 and 5/4. Contents 1 1902-1958 Advertising and publicity booklets, brochures, press articles etc 2 - Instruction books 3 1929 Napier Aero Engines (booklet) 4 1955-1959 Periodicals 5 1921-1961 Napier family, personal history 6 1906-1936 Trade advertisements 7 1942-1943 Ministry of Aircraft Production 8 - Lists of photographs 9 1905-1931 Miscellaneous 10 1933-1947 John Cobb 11 1927-1932 Malcolm Campbell 12 1918 Silk calendar 13 1899-195- Photographs 14 1922-1930 Testimonials 15 1900-1904 Design notebooks 16 1949-1961 Engineering notebooks 17 1899-1955 Drawings 18 1913-1931 Photograph albums 1 Advertising and publicity booklets, brochures press articles etc. 1/1 (1907) Napier 1/2 (1923) Napier. -

Name of Plan Wing Span Details Sour Ce Area Price

WING SOUR NAME OF PLAN DETAILS AREA PRICE AMA POND RC FF CL OT SCALE GAS RUBBER ELECTRIC OTHER GLIDER 3 VIEW ENGINE RED. OT SPAN CE V 1 BUZZ BOMB NIGEL HAWES 40 12 $15 33689 77E7 X X X DOODLEBUG JACK VARTANIAN 1935 V B 2 96 18 $21 25536 48G1 X X X V B 2 $0 35127 RD552 X V B 41A $0 35128 RD553 X G BUSEK 1941, CZECHOSLOVAKIA V B 41A STRIBRNA 52 7 $9 33207 7E3 X X X G BUSEK 1941, CZECHOSLOVAKIA V B 43 BETA MINOR 52 12 $15 32967 57E5 X X X G BUSEK, CZECHOSLOVAKIA 1941 V B 45 KONDOR 57 12 $15 25076 45A5 X X V B 48 $0 35129 RD554 X G BUSEK, CZECHOSLOVAKIA 1941 V B 48 OSTRIZ 50 10 $13 25079 45A6 X X V B 601 $0 35130 RD555 X G BUSEK, CZECKOSLOVAKIA V B 602 REJNOK 50 12 $15 29605 72E3 X X JIROTKA, POLAND V J 6 44 6 $8 26680 57E7 X X VILLAGE MODEL SHOP 1940 V M S GAMMA 44 4 $5 23535 32G5 X X X V M S GAMMA $0 35133 RD558 X FLYING MODELS 2/55, PALANEK V T O 14 3 $4 30087 76F3 X X X JASCO 1937 YEARBOOK, LOWE V TAIL SWALLOW 84 22 $24 25540 48G3 X X X BERKELEY KIT PLAN V-16 13 4 $5 20801 10F3 X X NATIONAL GLIDER 1/32 VACUPLANE MODEL 9 20 $22 31193 81G1 X X AEROMODELLER PLAN, MARCH VAE VICTIS 42 1988 3 $4 14239 X X EAGLE MODEL AIRCRAFT CO. -

Comparative Costs of British Cross-Channel Airlines, 1918-1924 Robin Higham

Journal of Air Law and Commerce Volume 28 | Issue 2 Article 3 1962 Estimates and Actuality: Comparative Costs of British Cross-Channel Airlines, 1918-1924 Robin Higham Follow this and additional works at: https://scholar.smu.edu/jalc Recommended Citation Robin Higham, Estimates and Actuality: Comparative Costs of British Cross-Channel Airlines, 1918-1924, 28 J. Air L. & Com. 137 (1962) https://scholar.smu.edu/jalc/vol28/iss2/3 This Article is brought to you for free and open access by the Law Journals at SMU Scholar. It has been accepted for inclusion in Journal of Air Law and Commerce by an authorized administrator of SMU Scholar. For more information, please visit http://digitalrepository.smu.edu. ESTIMATES AND ACTUALITY: COMPARATIVE COSTS OF BRITISH CROSS-CHANNEL AIRLINES, 1918-1924 ROBIN HIGHAMt The two articles that follow are published as an illus- tration of the tremendous strides that have been made in air transportation in the past forty-odd years. Contrast, if you will, the absence of concrete data and the extent of speculation detailed in Dr. Hig- ham's article on the problems of the fledgling British airlines' cross-channel operations, with the statistical detail available to air carriers engaged in international operations today as they plan for supersonic oper- ations. T IS not possible to be definitive about the costs of establishing British overseas airlines for the simple reason that most of the early statistics simply do not exist. Many were allowed to go by default, some companies' accounts are not available or have been lost, and at least one company's rec- ords were destroyed during World War II air raids. -

B&W Real.Xlsx

NO REGN TYPE OWNER YEAR ‐‐‐‐‐‐ ‐‐‐‐‐‐‐‐‐‐ ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐ ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐ ‐‐‐‐‐‐‐‐‐‐‐‐‐‐ X00001 Albatros L‐68C X00002 Albatros L‐68D X00003 Albatros L‐69 X00004 Albatros L‐72C Hamburg Fremdenblatt X00005 Albatros L‐72C striped c/s X00006 D‐961 Albatros L‐73 Lufthansa X00007 Aviatik B.II German AF X00008 B.558/15 Aviatik B.II German AF X00009 Aviatik PG.20/2 X00010 C.1952 Aviatik C.I German AF X00011 Aviatik C.III German AF X00012 6306 Aviatik C.IX German AF X00013 Aviatik D.II nose view X00014 Aviatik D.III German AF X00015 Aviatik D.III nose view X00016 Aviatik D.VII German AF X00017 Aviatik D.VII nose view X00018 Arado J.1 X00019 D‐1707 Arado L.1 Ostseebad Warnemunde X00020 Arado L.II X00021 D‐1874 Arado L.II X00022 D‐817 Arado S.I DVL X00023 Arado S.IA nose view X00024 Arado S.I modified X00025 D‐1204 Arado SC.I X00026 D‐1192 Arado SC.I X00027 Arado SC.Ii X00028 Arado SC.II nose view X00029 D‐1984 Arado SC.II X00030 Arado SD.1 floatplane @ (poor) X00031 Arado SD.II X00032 Arado SD.III X00033 D‐1905 Arado SSD.I X00034 D‐1905 Arado SSD.I nose view X00035 Arado SSD.I on floats X00036 Arado V.I X00037 D‐1412 Arado W.2 X00038 D‐2994 Arado Ar.66 X00039 D‐IGAX Arado AR.66 Air to Air X00040 D‐IZOF Arado Ar.66C X00041 Arado Ar.68E Luftwaffe X00042 D‐ITEP Arado Ar.68E X00043 Arado Ar.68E nose view X00044 D‐IKIN Arado Ar.68F X00045 D‐2822 Arado Ar.69A X00046 D‐2827 Arado Ar.69B X00047 D‐EPYT Arado Ar.69B X00048 D‐IRAS Arado Ar.76 X00049 D‐ Arado Ar.77 @ X00050 D‐ Arado Ar.77 X00051 D‐EDCG Arado Ar.79 Air to Air X00052 D‐EHCR