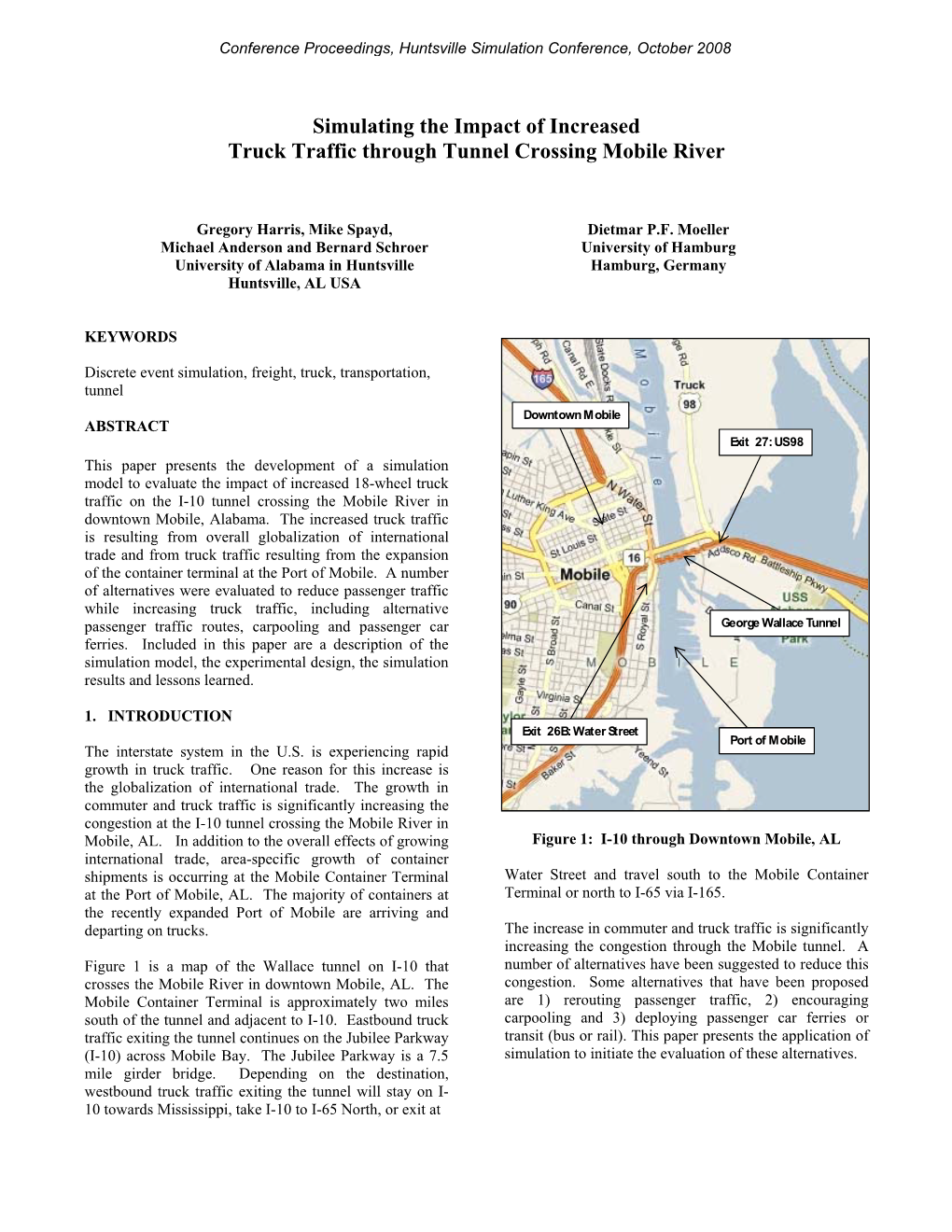

Simulating the Impact of Increased Truck Traffic Through Tunnel Crossing Mobile River

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Spanish Fort Town Center Cell: 251-591-3168 Cell: 251-975-8222 20000 Bass Pro Drive, Spanish Fort, AL [email protected] [email protected]

Angela McArthur Jeff Barnes, CCIM Direct: 251-375-2481 Direct: 251-375-2496 Spanish Fort Town Center Cell: 251-591-3168 Cell: 251-975-8222 20000 Bass Pro Drive, Spanish Fort, AL [email protected] [email protected] Overview Site Plan Lease Plan Aerial Photos Signage Demos 447,748 SF Mixed Use Development For Lease on 230 Acres Bass Pro Anchored Property Description Prominently positioned along Interstate 10 in Spanish Fort, Alabama, Spanish Fort Town Center is a signature mixed-use development serving the Mobile / Pensacola MSA. Anchored by Bass Pro Shop, a regional destination tenant that draws customers from a 100 mile radius, Spanish Fort Town Center is poised to take advantage of being centrally located in the fastest growing county in Alabama. Attributes of the property include great exposure and access at the northeast corner of Interstate 10 and US Highway 98, views of Mobile Bay, established anchor tenants, direct proximity to a maturing trade area, restaurants, and over 1 million square feet of retail shopping. This 230 acre development includes retail space, restaurant sites, hotels, a multi-family component, and land for future commercial development. Available Traffic Counts ( ADT 2015) • 1,200 SF and Up • Highway 98: 33,650 • Interstate 10: 60,670 • Outparcels from .94 to 7.09 Acres with Built to Suit Opportunities Parking • 12:1 Parking Ratio Zoning • B-2 Property Highlights • Interstate Frontage • Easy Access • Prominent Sign Bands • High Traffic Counts Developed and Managed by: • Competitive Rates The foregoing is solely for information purposes and is subject to change without notice. Stirling Properties makes no representations or warranties regarding the properties or information herein including but not stirlingproperties.com limited to any and all images pertaining to these properties. -

GUIDE to MOBILE a Great Place to Live, Play Or Grow a Business

GUIDE TO MOBILE A great place to live, play or grow a business 1 Every day thousands of men and women come together to bring you the wonder © 2016 Alabama Power Company that is electricity, affordably and reliably, and with a belief that, in the right hands, this energy can do a whole lot more than make the lights come on. It can make an entire state shine. 2 P2 Alabama_BT Prototype_.indd 1 10/7/16 4:30 PM 2017 guide to mobile Mobile is a great place to live, play, raise a family and grow a business. Founded in 1702, this port city is one of America’s oldest. Known for its Southern hospitality, rich traditions and an enthusiastic spirit of fun and celebration, Mobile offers an unmatched quality of life. Our streets are lined with massive live oaks, colorful azaleas and historic neighborhoods. A vibrant downtown and quality healthcare and education are just some of the things that make our picturesque city great. Located at the mouth of the Mobile River at Mobile Bay, leading to the Gulf of Mexico, Mobile is only 30 minutes from the sandy white beaches of Dauphin Island, yet the mountains of northern Alabama are only a few hours away. Our diverse city offers an endless array of fun and enriching activities – from the Alabama Deep Sea Fishing Rodeo to freshwater fishing, baseball to football, museums to the modern IMAX Dome Theater, tee time on the course to tea time at a historic plantation home, world-renowned Bellingrath Gardens to the Battleship USS ALABAMA, Dauphin Island Sailboat Regatta to greyhound racing, Mardi Gras to the Christmas parade of boats along Dog River. -

Comprehensive Plan (PDF)

PREPARING DAPHNE FOR THE FUTURE A COMPREHENSIVE PLAN 2000-2020 ADOPTED JUNE 26, 2003 PREPARED BY: SOUTH ALABAMA REGIONAL PLANNING COMMISSION 651 CHURCH ST MOBILE AL 36603 Preparing Daphne for the Future A Comprehensive Plan 2000-2020 Prepared for: The City of Daphne, Alabama City Council Planning Commission E. Harry Brown, Mayor E Harry Brown, Mayor Bailey Yelding, Jr. District 1 Robert Segalla, Chairman Lon Johnston District 2 Kenneth Day John L. Lake District 3 Brian Dekle Greg W. Burnam District 4 Lon D. Johnston Nell R. Gustavson District 5 Ed Kirby R. L. Kehr District 6 Maria Bueche John H. Gwin District 7 Arnold Schwarz Warren West David L. Cohen, William H. Eady – City Clerk Planning Director Ross & Jordan – Legal Council Prepared by: South Alabama Regional Planning Commission 651 Church Street Mobile, AL 36602 251-433-6541 (Tel) 251-433-6009 (Fax) PREPARING DAPHNE FOR THE FUTURE A Comprehensive Plan 2000-2020 Purpose To be the preferred residential waterfront community in South Alabama for families, retirees and businesses. Vision To be a safe, healthy, caring and progressive City committed to a high quality of life, financial self-sufficiency, a spirit of civic cooperation, a strong sense of community, and a positive environment for educational, personal, cultural, religious, and business growth. Through comprehensive planning, the citizens of Daphne intend to manage and direct the City's growth, ensure the highest quality of living for each resident, stimulate economic growth, and attract quality industry. TABLE OF CONTENTS -

Engineering Assessments of Climate Change Impacts and Adaptation Measures

Impacts of Climate Change and Variability on Transportation Systems and Infrastructure: The Gulf Coast Study, Phase 2 Task 3.2: Engineering Assessments of Climate Change Impacts and Adaptation Measures U.S. Department of Transportation August 2014 Gulf Coast Study, Phase 2 FHWA-HEP-15-004 Gulf Coast Study, Phase 2—Task 3.2: Engineering Analysis and Assessment Impacts of Climate Change and Variability on Transportation Systems and Infrastructure The Gulf Coast Study, Phase 2 Engineering Analysis and Assessment Final Report, Task 3.2 Prepared for: The USDOT Center for Climate Change and Environmental Forecasting Project managed by: Office of Planning, Environment, and Realty Federal Highway Administration, USDOT Robert Hyman, Robert Kafalenos, Brian Beucler Prepared by: Parsons Brinckerhoff and ICF International With contributions from South Coast Engineers Date: August 2014 Contract No.: GS-10F-0124J Report No.: FHWA-HEP-15-004 U.S. Department of Transportation i August 2014 Gulf Coast Study, Phase 2—Task 3.2: Engineering Analysis and Assessment Acknowledgements The authors gratefully acknowledge the assistance from the following: The Mobile Metropolitan Planning Organization’s Climate Change Work Group The U.S. Department of Transportation’s Gulf Coast Phase 2 Technical Advisory Committee Local Experts on Highways: Kevin Harrison and Tom Piper of the South Alabama Regional Planning Commission; Lee Reach, Don Powell, David Ramsey of the Alabama Department of Transportation; Ricky Mitchell and Tina Sanchez, Mobile County; Nick Amberger -

Schedules Soul Caffeine Coffee House

Soul Caffeine Coffee House Coffee, community, missions, ministry Schedules Pastors Conference and state convention annual meeting Contents 07Spiritual retreat Coastal camps in Baldwin and Mobile counties offer 14Pride & dignity beach getaways. A donations-only restaurant in Brewton 12 serves more than food. Coastal ministry Opportunities to share Christ and serve others 04 abound in the resorts, Coffee, community, campgrounds and RV missions, ministry parks dotting Alabama’s Gulf Coast. Owners and employees at this Daphne coffee shop use tips to support missions, ministries and nonprofits in the area. 08Restaurants. Food. Beverages. Comprehensive list and select recommendations 15Pastors Conference of area restaurants. schedule A full day of music, messages, prayer and encouragement awaits those who attend this annual event. 2 | THEALABAMABAPTIST.ORG FRUITFUL A special publication of The Alabama Baptist for the 2019 Alabama Baptist Pastors Conference and Alabama Baptist 16Explore the State Convention, November 11–13, Eastern Shore 2019, at Eastern 22Sights on the Shore Baptist New to Mobile Bay’s Eastern Shore Church, Daphne. Eastern Shore? See what’s nearby as you plan your Have you ever heard of a JENNIFER DAVIS RASH schedule and maybe even jubilee? This rare coastal EDITOR-IN-CHIEF your next visit. event is just one of the Cynthia Watts Janet Erwin Executive Executive Editor many wonders of Mobile 29‘A cheerful heart is Assistant Carrie B. Bay and its shoreline good medicine’ Debbie Campbell McWhorter communities. Director of Content Editor Communications Chonda Pierce has used Lauren C. Grim Bill Gilmore Creative Services her brand of clean, honest Director of Sales comedy to speak truth Jessica Ingram Melanie Production to audiences around the McKinney Manager Advertising world for more than 26 Manager Grace Thornton years. -

Historic Baldwin People 2019-2020

big beautiful BALDWIN Historic Baldwin People 2019-2020 GulfCoastNewsToday.com HISTORIC BALDWIN PEOPLE • 2019-20 • Big Beautiful Baldwin 3 4 Big Beautiful Baldwin • 2019-20 • HISTORIC BALDWIN PEOPLE GulfCoastNewsToday.com BRENNY’S JEWELRY COMPANY 333 Fairhope Ave • Fairhope, AL 36532 (251) 928-3916 BRENNY’S TOO! 331 Fairhope Ave • Fairhope, AL 36532 BRENNY’S JEWELRY (251) 928-4011 Mon. - Fri. 9:30 - 5:00 • Sat. 10:00 - 5:00 An Eastern Shore Tradition Since 1986 COME BY AND VISIT OUR SHOP IN SHOPS Check out our specials and our local charms Luxury Your story is one of a kind, within reach make it your own! Free pair of earrings ($80 value) with $200 purchase! 20% OFF! 20% OFF! Natures Beauty, Nature’s Power One Step Ahead Of The Rest Created by Alamea from Hawaii Over 200 watches in stock to choose from! ½ off all Antique & Estate Jewelry ALEX AND ANI Designed and crafted in the USA Made With Love 20% off all Antique & Estate Jewelry TABLE OF CONTENTS For those who grow most Introduction: 10 OUTDOOR 31 Parks 46 Pet Friendly Places 77 Our Heritage ACTIVITIES Beach Access 50 Agriculture 78 Water Sports 32 of their own groceries. THE REGION 13 Boat Launches 33 ENTERTAINMENT 55 NEED TO KNOW 81 The Kubota L3301 and L3901 compact tractors make caring for your land comfortable North Baldwin 14 Fishing 34 Live Music 56 Hurricane Readiness 82 Eastern Shore 16 Camping 36 Annual Events 60 Driver License Info 82 and easy. With performance-matched front loaders and backhoes, they simplify the Central Baldwin 18 Hunting 37 Fine Arts 66 Utility Info 83 toughest tasks with outstanding durability. -

Introduction to Transportation Analysis, Modeling and Simulation

Simulation Foundations, Methods and Applications Dietmar P.F. Möller Introduction to Transportation Analysis, Modeling and Simulation Computational Foundations and Multimodal Applications Simulation Foundations, Methods and Applications Series Editor: Louis G. Birta, University of Ottawa, Canada Advisory Board: Roy E. Crosbie, California State University, Chico, USA Tony Jakeman, Australian National University, Australia Axel Lehmann, Universita¨t der Bundeswehr Mu¨nchen, Germany Stewart Robinson, Loughborough University, UK Andreas Tolk, Old Dominion University, USA Bernard P. Zeigler, George Mason University, USA More information about this series at http://www.springer.com/series/10128 Dietmar P.F. Mo¨ller With a Chapter Contribution together with Prof. Dr. Bernard Schroer Introduction to Transportation Analysis, Modeling and Simulation Computational Foundations and Multimodal Applications Dietmar P.F. Mo¨ller Clausthal University of Technology Clausthal-Zellerfeld, Germany ISSN 2195-2817 ISSN 2195-2825 (electronic) ISBN 978-1-4471-5636-9 ISBN 978-1-4471-5637-6 (eBook) DOI 10.1007/978-1-4471-5637-6 Springer London Heidelberg New York Dordrecht Library of Congress Control Number: 2014952305 # Springer-Verlag London 2014 This work is subject to copyright. All rights are reserved by the Publisher, whether the whole or part of the material is concerned, specifically the rights of translation, reprinting, reuse of illustrations, recitation, broadcasting, reproduction on microfilms or in any other physical way, and transmission or information storage and retrieval, electronic adaptation, computer software, or by similar or dissimilar methodology now known or hereafter developed. Exempted from this legal reservation are brief excerpts in connection with reviews or scholarly analysis or material supplied specifically for the purpose of being entered and executed on a computer system, for exclusive use by the purchaser of the work. -

Parcel a & Pad J

SPANISH FORT TOWN CENTER DEVELOPMENT OPPORTUNITY FOR SALE 20000 Bass Pro Drive, Spanish Fort, Alabama OVERVIEW PROJECT OVERVIEW PARCEL A & PAD J PARCEL C & F1 AERIAL DEMOGRAPHICS 1.63 Acres Description 3.14 Acres Available Available Prominently positioned along Interstate 10 in Spanish Pending Fort, Alabama, Spanish Fort Town Center is a signature * 5,000 SF mixed-use development serving the Mobile / Pensacola 1.04 Acres Available Existing Multi-Family Available 216 Units * MSA. Anchored by Bass Pro Shop, a regional destination * 13,000 SF tenant that draws customers from a 100 mile radius, .96 Acres Available Available Spanish Fort Town Center is poised to take advantage 10,000 SF 11,970 SF of being centrally located in the fastest growing county Available Available Park with Restaurant Pad 3.51 Acres in Alabama. Attributes of the property include great 2.26 Acres 15,253 SF +/- 25.17 Acres Available Available Available exposure and access at the northeast corner of Interstate 5,600 SF 10 and US Highway 98, views of Mobile Bay, established Available Available for Future anchor tenants, direct proximity to a maturing trade 1 Acre 7.09 Acres Development area, restaurants, and over 1 million square feet of retail Available 1 Acre 1 Acre Available Available Available 1.95 Acres shopping. This 230 acre development includes retail space, 13,589 SF .97 Acres Available Available restaurant sites, hotels, a multi-family component, and land for future commercial development. 52,890 17,570 SF (ADT 2012) Available 42 Interstate 10 Available Property Highlights 28,820 (ADT 2012) 10 Outparcels from 1.95 to Interstate Frontage 25.17 Acres For Sale Easy Access U. -

GUIDE to MOBILE a Great Place to Live, Play and Grow a Business

GUIDE TO MOBILE A great place to live, play and grow a business. GUIDE TO MOBILE 1 2021 GUIDE TO MOBILE Mobile is a great place to live, play, raise a family and grow a business. Founded in 1702, this port city is one of America’s oldest. Known for its Southern hospitality, rich traditions and CONTENTS an enthusiastic spirit of fun and celebration, Mobile offers an unmatched quality of life. Our streets are lined with massive live Interesting Mobile Facts ...........................................4 oaks, colorful azaleas and historic neighborhoods. A vibrant Mobile by the Numbers ............................................5 downtown and quality healthcare and education are just Business ................................................................. 6-8 some of the things that make our city so livable. Located at the mouth of the Mobile River at Mobile Bay, leading to the Gulf of Mobile’s Largest Employers .....................................9 Mexico, Mobile is only 30 minutes from the sandy white beaches Transportation ...................................................10-11 of Dauphin Island, yet the mountains of northern Alabama are Health Care .........................................................12-13 only a few hours away. Our diverse city offers an endless array of fun and enriching activities – from the Alabama Deep Sea Real Estate ...............................................................14 Fishing Rodeo to freshwater fishing, museums to the modern Education ............................................................15-16 -

Impacts of Climate Change and Variability on Transportation Systems and Infrastructure: the Gulf Coast Study, Phase 2

Impacts of Climate Change and Variability on Transportation Systems and Infrastructure: The Gulf Coast Study, Phase 2 Task 3.2: Engineering Assessments of Climate Change Impacts and Adaptation Measures U.S. Department of Transportation August 2014 Gulf Coast Study, Phase 2 FHWA-HEP-15-004 Gulf Coast Study, Phase 2—Task 3.2: Engineering Analysis and Assessment Impacts of Climate Change and Variability on Transportation Systems and Infrastructure The Gulf Coast Study, Phase 2 Engineering Analysis and Assessment Final Report, Task 3.2 Prepared for: The USDOT Center for Climate Change and Environmental Forecasting Project managed by: Office of Planning, Environment, and Realty Federal Highway Administration, USDOT Robert Hyman, Robert Kafalenos, Brian Beucler Prepared by: Parsons Brinckerhoff and ICF International With contributions from South Coast Engineers Date: August 2014 Contract No.: GS-10F-0124J Report No.: FHWA-HEP-15-004 U.S. Department of Transportation i August 2014 Gulf Coast Study, Phase 2—Task 3.2: Engineering Analysis and Assessment Acknowledgements The authors gratefully acknowledge the assistance from the following: The Mobile Metropolitan Planning Organization’s Climate Change Work Group The U.S. Department of Transportation’s Gulf Coast Phase 2 Technical Advisory Committee Local Experts on Highways: Kevin Harrison and Tom Piper of the South Alabama Regional Planning Commission; Lee Reach, Don Powell, David Ramsey of the Alabama Department of Transportation; Ricky Mitchell and Tina Sanchez, Mobile County; Nick Amberger -

Founding Families of Baldwin County 2020-2021

big beautiful BALDWIN Founding Families of Baldwin County 2020-2021 Gulf Coast Media GulfCoastNewsToday.com TABLE OF CONTENTS Introduction: 6 Heritage Families NATURE 41 Mardi Gras 64 Our Heritage of Baldwin County 24 Nature Trails 42 Pet Friendly Places 65 Parks 46 Agriculture 66 THE REGION 9 OUTDOOR Beach Access 51 North Baldwin 10 ACTIVITIES 28 NEED TO KNOW 69 Eastern Shore 12 Water Sports 30 ENTERTAINMENT 53 Hurricane Readiness 70 Central Baldwin 14 Boat Launches 31 Live Music 54 Driver License Info 70 South Baldwin 16 Fishing 32 Fine Arts 55 Utility Info 71 Camping 34 Splash Pads 56 Elected Officials 72 THE HISTORY 19 Hunting 35 Public Schools 73 Historical Attractions 20 Golf 36 CULTURE 59 City Info 76 Museums 21 Tennis 36 Seafood 60 Veteran’s Services 79 National Register Disc Golf & Skate Parks 38 41 Dishes to Try Church Directory 80 of Historic Places 23 Before You Die 62 Advertiser Index 84 PUBLISHER GRAPHIC DESIGN Parks Rogers Paige Marmolejo Many of the events listed in this book are waiting for COVID-19 restrictions to be lifted before they can be scheduled. Therefore many dates are not listed in our entertainment EDITOR PHOTOGRAPHY Allison Marlow Allison Marlow, section. Please visit the event’s online Facebook page or website for updates. CONTRIBUTING John Underwood and EDITORS/WRITERS Jessica Vaughn Guy Busby, ADVERTISING ABOUT THE COVER In 2019 Baldwin County celebrated the Melanie LeCroy, REPRESENTATIVES families whose ancestors built our first towns, elected our first big beautiful John Underwood, Frank Kustura, BALDWIN Founding Families of Baldwin County mayors and began a legacy that continues to thrive today. -

A State of Knowledge of the Natural, Cultural, and Economic Resources

National Park Service U.S. Department of the Interior Natural Resource Stewardship and Science A State of Knowledge of the Natural, Cultural, and Economic Resources of the Greater Mobile-Tensaw River Area Natural Resource Report NPS/NRSS/BRD/NRR—2016/1243 ON THIS PAGE Photograph of Ibis, Mobile Bay, Alabama. Photograph courtesy of Hunter Nichols (http://www.hnproductions.com) ON THE COVER Photograph of Bald Cypress, Mobile-Tensaw Delta, Alabama. Photograph courtesy Hunter Nichols (http://www.hnproductions.com). A State of Knowledge of the Natural, Cultural, and Economic Resources of the Greater Mobile-Tensaw River Area Natural Resource Report NPS/NRSS/BRD/NRR—2016/1243 Edited by: Gregory A. Waselkov1, C. Fred Andrus2, Glenn E. Plumb3 1Professor of Anthropology, Director Center for Archaeological Studies University of South Alabama 6052 USA Drive South Mobile, AL 36688 2Associate Professor of Geology, Chair Department of Geological Sciences University of Alabama Tuscaloosa, AL 35487 3Chief Wildlife Biologist National Park Service Biological Resources Division, Wildlife Conservation Branch 1201 Oak Ridge Drive, Suite 200 Fort Collins, CO 80525 Design by: Tani Hubbard National Park Service 12661 E. Broadway, Blvd. Tucson, AZ 85748 July 2016 U.S. Department of the Interior National Park Service Natural Resource Stewardship and Science Fort Collins, Colorado The National Park Service, Natural Resource Stewardship and Science office in Fort Collins, Colorado, publishes a range of reports that address natural resource topics. These reports are of interest and applicability to a broad audience in the National Park Service and others in natural resource management, including scientists, conserva- tion and environmental constituencies, and the public.