Precast Elements for the James-Simon Gallery in Berlin

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Obligatory Guidelines for Film & Photo Shootings

Film & Foto Shootings Obligatory Guidelines for film & photo shootings Information about the planning of film & photo shootings in The National Museums of Berlin In general We ask you to respect the dignity of the art objects, to observe the conservational requirements and not to change the character of the exhibition rooms. The Museum Island belongs to the UNESCO cultural heritage since 1999. The individual opening hours of the museums are basically from 10am – 6pm, on Thursdays 10am – 8pm. Most museums are closed on Mondays and some close earlier on Thursdays. Shootings and Filming are possible outside the regular opening hours. The places Alte Nationalgalerie Hamburger Bahnhof – Museum für Gegenwart – Neues Museum Berlin Altes Museum Kulturforum Bode-Museum Neue Nationalgalerie Pergamonmuseum Friedrichwerdersche Kirche Pergamonmuseum, das Panorama Museum Berggruen James-Simon-Galerie Sammlung Scharf-Gerstenberg Haus Bastian Schloss Köpenick Page 2 of 3 Guidelines for shootings & filming at National Museums of Berlin Basically 1. Absolutely smoking ban on the grounds of the National Museums in Berlin. 2. Candles, burner paste, fire paste or the like are not allowed anywhere in the museums. 3. Food and beverage are only allowed in the agreed areas. Taking food and beverage into the exhibition areas is not allowed. 4. All members of the crew must wear name badges during the stay in the museums, on set and during the shooting. Please send us an example two days in advance of the shooting at the latest. 5. The costs for the cleaning as well as the employment of a technician (if needed) will be paid by the user. -

Urban-River-Swimming As Spatial Appropriation in the Spree Canal in Central Berlin

Graduate Journal for the Study of Culture // No. 3 - 2nd Series // February 2021 Swimming in the City: Urban-River-Swimming as Spatial Appropriation in the Spree Canal in Central Berlin Caitlin Kraemer Center for Metropolitan Studies, Technical University Berlin. [email protected] doi: 10.34632/diffractions.2021.9733 Abstract What effect can urban-river-swimming, in particular along the Spree Canal in central Berlin, have? Michel de Certeau (1984) distinguishes between ‘voyeurs’, viewing the city at a distance from above, disconnecting the body from the city, and ‘walkers’, walking in the city and immersing their body into the urban ‘text’. Certeau describes “walking as a space of enunciation” (98), a form of expression, and as an art of appropriation. Inspired by this, the paper transfers and expands Certeau’s thoughts on spatial appropriation by analyzing ‘swimming in the city’ and introducing the figure of the ‘city swimmer’. The paper explores what insights architecture and urban design along the (not yet swimmable) Spree Canal in central Berlin give into the urban history and river-city-relationship. Also, the paper discusses how urban-river- swimming (in Berlin: Flussbad Berlin Project) can work as a practice of spatial appropriation, reclaiming urban nature and public liquid space, as well as enabling a post-industrial ‘re-writing’ of the urban experience. Creating, transforming and appropriating space by ‘swimming in the city’ raises awareness of and creates visibility for urban nature, its ecological condition and accessibility to humans and non-human life in the city, which is especially important in the light of the climate situation and corona virus crisis. -

Experience The

28—29 MAY 2020 #COMMSSUMMIT RADIALSYSTEM BERLIN FOR LEADERS AND NEW TALENTS IN PR PLUS SEE PAGE 12 FOR DETAILS EXPERIENCE THE TRANSFORM TRANSFORM TRANSFORM TRANSFORM WORK ORGANISATIONS LEADERSHIP THE WORLD FULL PROGRAMME AND TICKETS: WWW.COMMUNICATION-SUMMIT.EU CORPORATE ACTIVISM INTERNAL COMMS STORYTELLING CEO POSITIONING FAKE NEWS REPUTATION SOCIAL MEDIA CLIMATE CHANGE CRISIS MANAGEMENT ARTIFICIAL INTELLIGENCE EXPERIENCE THE GLOBAL COMMUNICATION 28—29 MAY 2020 RADIALSYSTEM BERLIN MENTORSHIP SKILLS DEVELOPMENT CYBER SECURITY DATA & ANALYTICS CSR POPULISM AGILE C SUITE MANAGEMENT MARKETING WELCOME TO 28—29 MAY 2020 THE GLOBAL RADIALSYSTEM BERLIN COMMUNICATION SUMMIT 2020 A changing world demands new approaches to politics, business, trade and work – and to the role and profile of communications professionals. Recent headlines – from protests in Hong Kong to the bushfire inferno in Australia, impeachment in the White House and tensions in the EU – drive home the message that ‘business as usual’ no longer cuts it. It’s up to all of us – from senior communications leaders to new talents at the start of their careers – to hear and respond to new global dynamics. At the Global Communication Summit, the annual flagship event for international communication and PR professionals, communications is the thread that helps us navigate an uncertain world. To explore this idea more fully, the Global Communication Summit 2020 features four parallel tracks: • TRANSFORM WORK: How are new tools and trends changing the way communicators work on a daily -

Berlin Divided Berlin United

COMPANION GUIDE BEGLEITBUCH BERLIN DIVIDED BERLIN GETEILT BERLIN UNITED BERLIN VEREINT Copyright © 2019 Bibi LeBlanc Culture To Color, LLC All Rights Reserved No part of this book may be used or reproduced or transmitted in any form or by any means without the express written permission of the author. First Edition Cover Design & Interior by Bibi LeBlanc CultureToColor.com To Order in Bulk Contact Publisher: CultureToColor.com For more information visit: CultureToColor.com COMPANION GUIDE Discover the sights of Berlin with the photography and links to background information for destinations, people, and events. BEGLEITBUCH Entdecken Sie die Sehenswürdigkeiten Berlins mit Fotografien und Links zu Hintergrundinformationen der Orte, Persönlichkeiten und Ereignisse. WELCOME TO BERLIN WILLKOMMEN IN BERLIN GETEILTES DEUTSCHLAND GERMANY DIVIDED KAISER WILHELM MEMORIAL CHURCH PHOTO CREDIT: Bibi LeBlanc Photography RESOURCES: https://www.visitberlin.de/en/kaiser-wilhelm- memorial-church SIEGESSÄULE VICTORY COLUMN PHOTO CREDIT: Bibi LeBlanc Photography RESOURCES: https://www.berlin.de/en/attractions-and- sights/3560160-3104052-victory-column.en.html - BERLINER MAUER BERLIN WALL PHOTO CREDIT: LEFT: Bibi LeBlanc Photography RIGHT: https://en.wikipedia.org/wiki/Berlin_Wall RESOURCES: https://www.history.com/topics/cold-war/berlin-wall ALEXANDERPLATZ, WELTZEITUHR & FERNSENTURM ALEXANDERPLATZ, WORLD CLOCK & TV TOWER PHOTO CREDIT: BIBI LEBLANC RESOURCES: • https://theculturetrip.com/europe/germany/articles/the-history-of- the-world-clock-in-1-minute • -

Neues Museum

Neues Museum Museum Island Berlin, Germany 1997–2009 Development of Museumsinsel (Museum Island), previously known as the Spreeinsel (Spree Island), began in the sixteenth century as a pleasure garden for the Stadtschloss (City Palace). The Altes Museum (Old Museum) by Karl Friedrich Schinkel was completed in 1828, and then in 1841 King Friedrich Wilhelm IV of Prussia ordered his court architect, Friedrich August Stüler, to draw up a plan to develop the land behind the Altes Museum – hitherto used for commercial purposes – and create a ‘sanctuary for the arts and sciences’. Designed by Stüler, the Neues Museum (New Museum) became the first component of this visionary haven, and was erected between 1841 and 1859. The Neues Museum was the first three-storey museum ever built and was organised as a solitaire construction executed according to a simple ground plan that enclosed two courtyards and replaced the central rotunda and cupola used in the Altes Museum with a rectangular stair hall that rose through all floors and occupied the full width of the building. Extensive bombing during World War II left the building in ruins with some sections severely damaged and others completely destroyed. Few attempts at repair were made after the war, and the wreck was left exposed with only a minimum of consolidation and protection undertaken during the GDR period. After David Chipperfield Architects’ appointment to the project in 1997–98, the building and restoration took nearly eleven years to complete, and the entire Museum Island was added to the UNESCO World Cultural Heritage list in 1999. The project was unique given that no earlier reconstruction attempt had been fully realised over a relatively long period of quiescence. -

Official Berlin City Pass Berlin Cityguide 2020

OFFICIAL BERLIN CITY PASS BERLIN CITYGUIDE 2020 berlin-welcomecard.de AKTUELLER HINWEIS CURRENT NOTE Liebe Gäste, Dear guests, vielen Dank, dass Sie sich für die Berlin WelcomeCard entschieden thank you for choosing the Berlin WelcomeCard. haben. Wir freuen uns über Ihren Besuch in der Hauptstadt! We look forward to your visit to the capital! Bitte beachten Sie: Please note: die vorliegende Ausgabe des CityGuide + Stadtplan 2020 this edition of the CityGuide + City Map 2020 is intended as a guide dient der Orientierung für Touren und bietet einen allgemeinen for tours and provides a general overview of our partners. Überblick zu den Partnern. Due to the dynamic situation, you can get the latest information Auf Grund der dynamischen Situation erhalten Sie die aktuellsten about the participating discount partners, opening hours, possibilities Informationen zu den beteiligten Rabattpartnern, Öffnungszeiten, for ticket purchase etc. at Möglichkeiten für den Ticketerwerb usw. unter berlin-welcomecard.de berlin-welcomecard.de as well as from our colleagues at the Berlin Tourist Info. sowie bei unseren Kolleginnen und Kollegen in den Berlin Tourist Infos. Further details will also be published on the partner websites named Weitere Details werden auch auf den im CityGuide benannten in the CityGuide. Websites der Partner veröffentlicht. We thank you for your understanding Wir bedanken uns für Ihr Verständnis and wish you a pleasant stay in Berlin! und wünschen Ihnen schöne Tage in Berlin! Your visitBerlin Team Ihr visitBerlin-Team 1 BERLIN TOURIST -

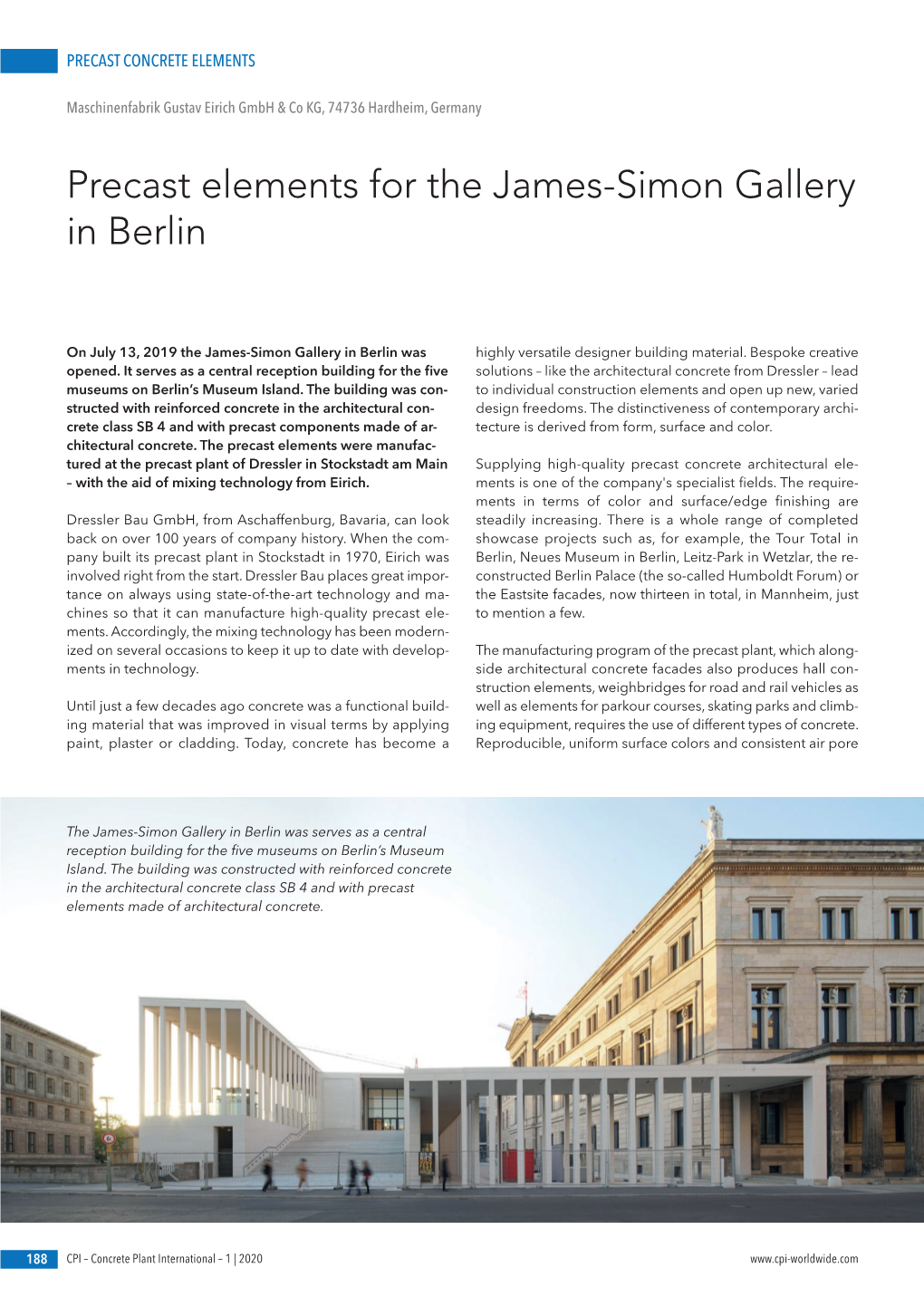

Precast Parts Made of Architectural Concrete

Press Release Hardheim, September 2019 Precast parts for the James-Simon Gallery in Berlin – a masterpiece from the Dressler precast component factory, achieved with the aid of mixing technology from EIRICH On July 13, 2019 the James-Simon Gallery in Berlin was opened. It serves as a central reception building for the five museums on Berlin’s Museum Island. The building was constructed with reinforced concrete in the architectural concrete class SB 4 and with precast components made of architectural concrete. The precast parts were manufactured at the precast component factory of Dressler in Stockstadt am Main – with the aid of mixing technology from EIRICH. Dressler Bau GmbH, from Aschaffenburg, Bavaria, can look back on over 100 years of company history. When the company built its precast component factory in Stockstadt in 1970, EIRICH was involved right from the start. Dressler Bau places great importance on always using state-of-the-art technology and machines so that it can manufacture high-quality precast components. Accordingly, the mixing technology has been modernized on several occasions to keep it up to date with developments in technology. Until just a few decades ago concrete was a functional building material that was improved in visual terms by applying paint, plaster or cladding. Today, concrete has become a highly versatile designer building material. Bespoke creative solutions – like the architectural concrete from Dressler – lead to individual construction elements and open up new, varied design freedoms. The distinctiveness of contemporary architecture is derived from form, surface and color. Supplying high-quality precast concrete architectural components is one of the company's specialist fields. -

2.1. Royal Ontario Museum

The Icing on the Cake: Large-Scale Museum Extensions to Historic Buildings AR 597: Dissertation Kent School of Architecture University of Kent March 2015 IOANNIS MEXIS Supervisors: Dr. Manolo Guerci, Dr Timothy Brittain- Catlin. Word Count: 8789 ACKNOWLEGMENTS I would like to express my gratitude to Dr. Manolo Guerci and Dr. Timothy Brittain- Catlin for the valuable assistance in writing this essay. ABSTRACT This dissertation investigates how historic buildings are conserved and revitalized by extension projects. More specifically, it is about large scale contemporary museum extensions to historic compositions. The investigation of the topic is achieved through a series of case studies based on three different types of extension projects: “Juxtaposing free- standing extensions”, “Weaving extensions” and “Homogenous free-standing extensions”. Through the first category we will investigate: the Royal Ontario Museum by Daniel Libeskind (2007), MAXXI Museum by Zaha Hadid (2010) and Stedelijk Museum by Benthem Crouwel Architects (2012). All three of these extensions, are examples of bold interventions that contrasts both the historic building and their context and have become landmarks in the cities they are located in. In the second category, we will examine: the Neues Museum by David Chipperfield (2009) and Tate Modern by Herzog and de Meuron (2000). Both extensions are in direct relation with the existing building. The architects’ interventions are respectful towards the existing composites, giving the existing building a refreshed appearance. In the last category we will explore: the second extension project to Tate Modern by Herzog and de Meuron (2016) and the James Simon Gallery by David Chipperfield (2017). Both of these free standing extensions are cases of interventions that respect the existing building and their context but still manage to stand out of their context on a deferential manner. -

Berlin Museum Island Masterplan World Heritage

BERLIN MUSEUM ISLAND MASTERPLAN WORLD HERITAGE INSCRIPTION Caroline DEPEYRE Mathilde SCHAAL 18/05/2017 Contents : Introduction 3 I. QUICK HISTORY OF THE PROGRAM 4 II. PROGRAM 7 1. Complete Renovation and Modernization 9 2. Welcome and Guidance for Visitors 10 3. Creation of Connections 11 a. The Archaeological Promenade : b. Ancient Architectures Tour 4. Relocation of Museum-Related Internal Functions 13 5. Creation of Outside Spaces 14 a. Colonnade Courtyard b. Pergamonmuseum Spree side c. The Pergamonmuseum’s court of Honor d. New countryard e. Small curiosities and illuminated places III. UNESCO & BERLIN MUSEUM ISLAND 19 1. Who’s UNESCO ? 20 2. Relation between UNESCO and museums : 21 3. How Berlin Museum Island has been included to Unesco’s World Heritage. 22 4. Why did UNESCO choose Berlin Museum Island ? 22 a. The outstanding univeral valure b. Integrity and Autenticity c. Requirements for protection and Managment IV. OPENING AND CONCLUSION 26 Bibliographie 30 Liste of figures 31 Berlin Museum Island, World Heritage Inscritipon, Masterplan - Museology coursework 2 Mathilde Schaal, Caroline Depeyre - 18/05/2017 Introduction For foreigners, the Museum Island is a basis in the touristic tour of Berlin. It is situated ideally in the center of Berlin, in the axes between the Brandenburger Tor and Alexanderplatz, two main touristic monument of the city. Even during the construction of the new buildings, the island was full everydays of tourists and curious looking for all tresures exposed there. The Museum Island also tells the story of the power, the culure and the curiosity of Germany. At first, it brings together tresures coming from all over te world, antiquities and rare objects. -

Isuf 2020: Cities in the Twenty-First Century

ISUF 2020: CITIES IN THE TWENTY-FIRST CENTURY RESEARCH ON THE WEAVING STRATEGY FOR THE RENEWAL OF HISTORICAL BLOCKS Wenke Wu, College of Architecture and Urban Planning, Tongji University, China ABSTRACT The historical block is a symbol of city civilization. Changes of the times and rapid development of economy have caused great changes in the form and space of historical blocks, and also their decay in different degrees. How to solve the contradiction between the decline of historical blocks and the development of urban modernization has become the key. The weaving design, originated from western urban planning, is widely used in the revitalization of historical cities. It inherits the context of the original block, restore the form and activates its potential by gradually embedding new elements in the space required for transformation, so as to adapt historical blocks to modern cities. This paper explores the strategy of weaving design in the renewal of historical blocks. Taking some contemporary renewal projects of historical blocks in Europe and China as main objects, the study analyzes and summarizes the weaving methods and strategies from three aspects of urban, architecture and tectonic, trying to make contributions to the renewal and development of historical cities in the future. This paper is subsidized by NSFC project which is named as <Research on Time and Space Elements and Expression System of “Sharing Architecture”>, NO.51978468. Keywords: historic block, urban renewal, weaving strategy, modern and tradition INTRODUCTION With the advent of the information age and the development of economic globalization, the contradiction between the decline of historical blocks around the world and the development of urban modernization has gradually intensified. -

Tour Programme 2019

TOUR PROGRAMME 2019 TICKET B - experience architecture Thomas Michael Krüger · Architekt BDA Frankfurter Tor 1, 10243 Berlin Fon +49(0)30 420269620, Fax +49(0)30 420269629 Mail: [email protected], Internet: www.ticket-b.de Network: www.guiding-architects.net Index TICKET B – Experience architecture 3 Overview of our Tours 4 Classic Tours Parliamentary District 5 The New Museum Island 6 A cut through the inner city 7 Central East / City West 8 Karl-Marx-Allee / Hansaviertel 9 Europacity 10 Extra Tours Berlin Overview 11 Embassies and State Representations 12 20ies Berlin 13 Modernist Housing Estates 14 Science and Research 15 Contemporary residential buildings n° 1 - Prenzlauer Berg 16 Contemporary residential buildings n° 2 - Kreuzberg 17 Green City - Berlins open spaces by bike 18 Boat cruises 19 The new Potsdam 20 Premium Tours 21 Interior Visits 22 SideSteps 23 Events/Conferences/Presentations/Trips 24 Publications 25 Selection of References 1996–2018 26 What our clients say ... 27 TICKET B · Thomas Michael Krüger · Architect BDA · Frankfurter Tor 1, 10243 Berlin · Fon +49(0)30 420269620, Fax +49(0)30 420269629 · Mail: [email protected] · Internet: www.ticket-b.de · Network: www.guiding-architects. net © Marnie Schäfer TICKET B – Experience architecture Our highly qualified team of graduated architects, professors, lecturers and specialist authors present you with an exciting and authentic insight into the development of contemporary architecture in Berlin. Apart from looking at current construction projects and technology, the tours also focus on historical and social aspects. Years of experience and a far-reaching network of specialists enable us to offer you exclusive access to sites and buildings usually not open to the public. -

29697890 Lese 1.Pdf

MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:36 Uhr Seite 1 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:36 Uhr Seite 2 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 3 Pergamon Museum Berlin Collection of Classical Antiquities Museum of the Ancient Near East Museum of Islamic Art PRESTEL Munich · London · New York MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 4 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 5 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 6 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 7 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 8 Contents The Pergamon Museum – a long building history 10 Collection of Classical Antiquities 24 The history of the collection 28 Hall of Hellenistic Architecture 36 The Pergamon Altar 44 The Telephus Frieze 52 Hall of Roman Architecture (Miletus Hall) 58 Museum of the Ancient Near East 66 The history of the collection 70 Southern Mesopotamia and neighbouring Iran 74 Northern Mesopotamia and neighbouring Urartu 96 Northern Syria and Anatolia 114 Writing 122 MF_Pergamon_4241_engl.qxd:AEGYPT_2008 27.07.2011 16:37 Uhr Seite 9 Museum of Islamic Art 128 The history of the collection 132 The Umayyads (661–750) 136 The Abbasids and Samarra (750–1258) 140 The Mediterranean world at the time of the Fatimids (909–1171) 144 Iran and Central Asia in the 9th–13th centuries 148 The Rum Seljuks (1071–1307) and their capital, Konya 152 The Ayyubids and Mamluks in Syria and Egypt (1171–1517)