Controlling the Organisation of Matter Using Thin Film Microfluidics

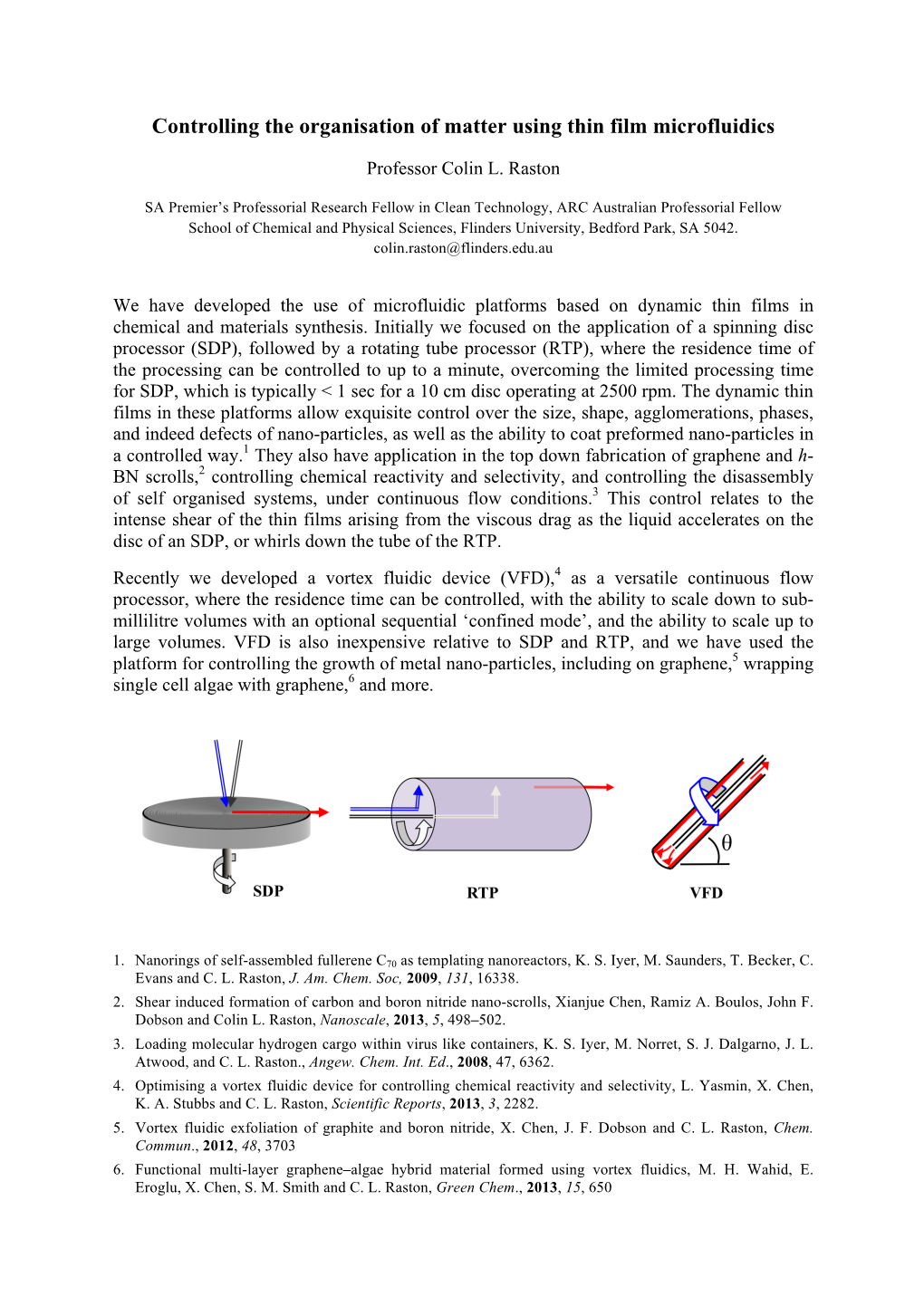

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Annual Report 2015 Scanning Electron Microscopy Samples Undergoing Preparation at the Centre for Microscopy and Microanalysis Facility at AIBN

AIBNAustralian Institute for Bioengineering and Nanotechnology Annual Report 2015 Scanning electron microscopy samples undergoing preparation at the Centre for Microscopy and Microanalysis facility at AIBN. 2 - AIBN Annual Report 2015 AIBN Annual Report 2015 Vice-Chancellor and President’s Message 2 Discoveries and collaborations 28 MERS antibody building on Hendra virus work 30 Director’s Message 3 Cheaper, cleaner production of carbon fibre 31 AIBN Board 4 Getting biomarkers out of the skin Scientific Advisory Committee 5 with Micropatches 32 AIBN Research 6 High performance cluster boosts Alexandrov Group research capabilities 33 Synthetic biology drives diagnostic care 8 Self-assembled nanocapsules deliver results 34 Bernhardt Group Using theoretical and computational science Fast, cheap and easy to use for nanomaterials and fluids 9 tuberculosis screening 35 Cooper-White Group IAP removes barriers between academia Biomaterials development and discovery for and industry 36 regenerative medicine 10 AIBN Early-/Mid-Career Support Program 37 Gray Group Funding and recognition 38 Mammalian cell expression and bulk stem cell Australian Research Council funding 40 cultivation 11 National Health and Medical Research Council 41 Halley Group Biopolymers and starch for a Fellowships fuel research opportunities 42 cheaper, cleaner future 12 Awards highlight scientific excellence 43 Kendall Group Newly awarded research funding Gene and drug delivery and diagnostics commencing in 2015 44 through the skin 13 Facilities and infrastructure 46 Mahler -

Prof. Colin Raston

Colin Raston, Ph.D ([email protected]) Professor Clean Technology, College of Science and Engineering Flinders University Adelaide, Australia Colin Raston is a Professor in Clean Technology, at Flinders University. He completed a PhD at the University of Western Australia, and after postdoctoral studies at the University of Sussex he was appointed a lecturer at The University of Western Australia (1981) then to positions as Professor of Chemistry at Griffith University (1988), Monash University (1995), The University of Leeds (2001), and The University of Western Australia (2003). He is a former President, Queensland Branch President, and Chair of the Inorganic Division, of the Royal Australian Chemical Institute (RACI). He has received the RACI’s Green Chemistry Challenge Award, the H.G. Smith Award for the most distinguished contribution to research in chemistry in Australia in the previous ten years, the Burrows Award for distinguished research in inorganic chemistry, and the Leighton Memorial Award for outstanding contributions to the profession. In 2015 he shared the Ig Nobel Prize in Chemistry with colleagues at the University of California, Irvine and the University of Western Australia, in 2016 he was Appointed an Officer in of the Order of Australia, and 2018 he was elected Fellow of the Australian Academy of Science. Prof Raston is former recipient of an Australian Research Council Special Investigator Award, two Senior Research Fellowships and two Australian Professorial Fellowships. His current research covers clean technology and green chemistry, nanotechnology and self-assembly, and is currently on the editorial advisory board of the international journals Green Chemistry, Crystal Growth and Design and Nature’s Scientific Reports. -

Technical Programme

Technical Programme International Conference on Materials for Advanced Technologies 2009 ICMAT 2009 AND IONAL U ERNAT NION INT OF International Union of Materials Research Societies- M A S TE TIE RIA CIE LS RESEARCH SO International Conference in Asia 2009 IUMRS - ICA 2009 28 June - 3 July 2009, Singapore Suntec Singapore International Convention & Exhibition Centre www.mrs.org.sg Conference Organisation Principal Advisor SHIH Choon Fong, King Abdulla University of Science and Technology, Saudi Arabia Chairman B. V. R. CHOWDARI, National University of Singapore, Singapore Co-Chairmen LIM Seh Chun, National University of Singapore, Singapore Freddy BOEY, Nanyang Technological University, Singapore Secretary CHIA Ching Kean, Institute of Materials Research and Engineering, Singapore Technical Chair FENG Yuan Ping, National University of Singapore, Singapore Treasurer DING Jun, National University of Singapore, Singapore Joint Treasurer Gregory GOH, Institute of Materials Research and Engineering, Singapore Materials Research Society of Singapore Institute of Materials Research and Engineering 3 Research Link, Singapore 117602 Tel: (65) 6874 1975 Fax: (65) 6777 2393 Email: [email protected] ICMAT 2009 and IUMRS - ICA 2009 Technical Programme Preface ICMAT 2009 is the 5th in the series of the “International Conference on Materials for Advanced Technologies” organized by the Materials Research Society of Singapore (MRS-S). It is held together with the International Union of Materials Research Societies’ (IUMRS) International Conference in Asia (IUMRS – ICA 2009). Similar to the previous four conferences in this series, this conference is also organized in association with the National University of Singapore (NUS), Nanyang Technological University (NTU), and the Institute of Materials Research and Engineering (IMRE), with the support of A*STAR and many other national and international organizations. -

High Shear Spheroidal Topological Fluid Flow Induced Coating of Polystyrene Beads with C60 Cite This: Chem

ChemComm View Article Online COMMUNICATION View Journal | View Issue High shear spheroidal topological fluid flow induced coating of polystyrene beads with C60 Cite this: Chem. Commun., 2021, 57, 5638 spicules† Received 29th October 2020, Accepted 16th March 2021 Matt Jellicoe, Kasturi Vimalanathan, Jason R. Gascooke, Xuan Luo and Colin L. Raston * DOI: 10.1039/d0cc07165j rsc.li/chemcomm Spheroidal spicular like topological fluid flow in an angled vortex fluidic surface of the tube, and the so called signature of a liquid.7 The device (VFD) housing a 20 mm diameter tube with a hemispherical base latteristhesumoftheeffectsofthechangeintemperature,film rotating at 4k rpm and tilted at 458 is effective in reducing the thickness and mixing time as a function of rotational speed, o.7 thermodynamic equilibrium concentration of fullerene C60 in toluene, These collective studies established three different types of topo- Creative Commons Attribution-NonCommercial 3.0 Unported Licence. with the formation of spicules of the material under continuous flow logical fluid flow in the VFD for a 20 mm OD (17.5 mm ID) quartz processing. Under the same operational conditions in the presence of tube with a hemispherical base (and similarly for a 10 mm OD polystyrene beads 2 to 6 lm in diameter, spicules of C60 ca. 150 nm in tube), Fig. 1(a), namely (i) Coriolis circular flow (diameter = dC) length grow on their surfaces. This establishes that the spheroidal from the hemispherical base of the tube, (ii) double helical flow topological fluid flow in the VFD prevails while enveloping spheroidal (diameter = dDH) arising from eddies generated by the Faraday like particles of such size. -

Accurate Potential Energy Surfaces and Beyond: Chemical Reactivity, Binding, Long-Range Interactions, and Spectroscopy

Advances in Physical Chemistry Accurate Potential Energy Surfaces and Beyond: Chemical Reactivity, Binding, Long-Range Interactions, and Spectroscopy Guest Editors: Laimutis Bytautas, Joel M. Bowman, Xinchuan Huang, and António J. C. Varandas Accurate Potential Energy Surfaces and Beyond: Chemical Reactivity, Binding, Long-Range Interactions, and Spectroscopy Advances in Physical Chemistry Accurate Potential Energy Surfaces and Beyond: Chemical Reactivity, Binding, Long-Range Interactions, and Spectroscopy Guest Editors: Laimutis Bytautas, Joel M. Bowman, Xinchuan Huang, and Antonio´ J. C. Varandas Copyright © 2012 Hindawi Publishing Corporation. All rights reserved. This is a special issue published in “Advances in Physical Chemistry.” All articles are open access articles distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Editorial Board Janos´ G. Angy´ an,´ France F. Illas, Spain Eli Ruckenstein, USA M. Sabry Abdel-Mottaleb, Egypt KwangS.Kim,RepublicofKorea Gnther Rupprechter, Austria Taicheng An, China Bernard Kirtman, USA Kenneth Ruud, Norway J. A. Anderson, UK Lowell D. Kispert, USA Viktor A. Safonov, Russia Panos Argyrakis, Greece Marc Koper, The Netherlands Dennis Salahub, Canada Ricardo Aroca, Canada Alexei A. Kornyshev, UK Anunay Samanta, USA Stephen H. Ashworth, UK Yuan Kou, China Dipankar Das Sarma, India Biman Bagchi, India David Logan, UK Joop Schoonman, The Netherlands Hans Bettermann, Germany Clare M. McCabe, USA Stefan Seeger, Switzerland Vasudevanpillai Biju, Japan James K. McCusker, USA Tamar Seideman, USA Joel Bowman, USA MichaelL.McKee,USA Hiroshi Sekiya, Japan Wybren J. Buma, The Netherlands Robert M. Metzger, USA Luis Serrano-Andres,´ Spain Sylvio Canuto, Brazil Michael V. -

Two-Armed Silicon

NEWS & VIEWS RESEARCH INORGANIC CHEMISTRY (109.7°), perhaps implying that their silylene is more reactive than Rekken and colleagues’ compound. Both silylenes exhibit striking thermal Two-armed silicon stability for divalent silicon compounds: Rekken and colleagues’ compound is stable up Compounds of transition metals are often used to activate small molecules for to 146 oC, whereas Protchenko and colleagues’ chemical reactions. The discovery of unusual silicon-containing compounds compound is stable up to 130 oC. The stability raises the prospect of metal-free activators. of the new silylenes must be due largely to steric protection of the reactive silicon atoms by the attached groups (in other words, the bulky ROBERT WEST from a starting material that was structurally groups shield the silicon atoms from attack identical to the silylene product, but in which by other molecules). The bulky groups might ny chemist will tell you that silicon two bromine atoms were also attached to the also stabilize the compounds by donating atoms are tetravalent — that is, they silicon atom. They removed the two bromine electrons to the silicon atom. have four electrons available for atoms using a magnesium-containing reduc- Further insight into the chemical bonding Achemical bonding, and therefore usually form ing agent. in the two silylenes was obtained by looking at four single bonds to other atoms. But two In the second paper2, Protchenko and col- the signals (the chemical shifts) of silicon-29 papers1,2 published in the Journal of the Am leagues’ silylene (Fig. 1b) has a more complex nuclei in the nuclear magnetic resonance eri can Chemical Society report some remark- structure than Rekken and colleagues’ com- spectra for the molecules. -

Royal Australian Chemical Institute Awards 2018

Angewandte News Chemie Royal Australian Chemical Institute institution for his PhD (completed in 1969). After Awards 2018 postdoctoral work with Hans Dahn (Universit de Awarded … Lausanne), William M. Jones (University of Flor- The Royal Australian Chemical Institute (RACI) ida), and Maitland Jones Jr. (Princeton University), presented its national awards in November 2018. he held academic positions at the Universit de We congratulate all the awardees and feature those Lausanne and a professorship at the University of who are associated with Angewandte Chemie and Marburg (1976–1985). He was made Professor of its sister journals as authors, referees, and board Organic Chemistry the University of Queensland in members. 1985, and is currently emeritus professor there. Amanda Ellis (University of Melbourne) Wentrups research involves experimental and received the Margaret Sheil Leadership Award. theoretical investigations of reactive intermediates Ellis studied at the Auckland University of Tech- using flash vacuum pyrolysis, matrix isolation, and nology and the University of Technology, Sydney, matrix photochemistry. He has reported in Chemis- and completed her PhD (supervised by Mick try—A European Journal on the photolysis of Wilson) at the latter institution in 2003. She trimethylsilyl azide to generate the triplet ground subsequently carried out postdoctoral research state trimethylsilylnitrene.[3] Wentrup was on the with Ganpati Ramanath at the Rensselaer Poly- Founding Editorial Board of Chemistry—A Euro- technic Institute (2002–2003) and Shay Curran at pean Journal. New Mexico State University (2003–2004), and was Katrina Jolliffe (The University of Sydney) won a research fellow with Jeff Tallon at Industrial the H. G. Smith Memorial Award, which is pre- Research Ltd (now Callaghan Innovations). -

Metal–Organic Calixarene Capsules: the Evolution of Controlled Assembly Cite This: Crystengcomm,2014,16, 3655 Piotr P

CrystEngComm View Article Online HIGHLIGHT View Journal | View Issue Metal–organic calixarene capsules: the evolution of controlled assembly Cite this: CrystEngComm,2014,16, 3655 Piotr P. Cholewa and Scott J. Dalgarno* Calixarenes are versatile cyclic host molecules that have been utilised widely across supramolecular chemistry for a variety of reasons. As the title suggests, the main thrust of this Highlight is the metal- directed assembly of calixarene (as well as other related host) capsules. As an introduction for the non- Received 25th October 2013, specialist, this article first describes some design strategies that have been successfully employed in the Accepted 11th February 2014 target synthesis of porous materials. The conformational features of calixarenes are then introduced prior to some developments in their (and other cyclic host) functionalisation. Finally we describe the applica- DOI: 10.1039/c3ce42169d tion of the aforementioned design strategies in metal-directed assembly to afford target capsules, www.rsc.org/crystengcomm highlighting recent developments in the field with p-carboxylatocalix[4 and 5]arenes. Creative Commons Attribution 3.0 Unported Licence. Introduction: common assembly of porous materials (PMs). Ever since zeolites found applica- tion in industry (due to their porosity and thermal stability) strategies for the targeted formation there has been a constant pursuit of the design and further of porous materials improvement of PMs.1 The volume of publications focusing on the design and modification of PMs grows larger each The past few decades have witnessed rapid technology year, with a number reporting on the application of these development that has moved hand-in-hand with new materials in chemistry (e.g. -

Shear-Stress-Mediated Refolding of Proteins from Aggregates and Inclusion Bodies

See discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/271226779 Shear-Stress-Mediated Refolding of Proteins from Aggregates and Inclusion Bodies ARTICLE in CHEMBIOCHEM · JANUARY 2015 Impact Factor: 3.09 · DOI: 10.1002/cbic.201402427 CITATIONS READS 2 399 11 AUTHORS, INCLUDING: Tom Z Yuan Kaitlin M Pugliese Agensys University of California, Irvine 4 PUBLICATIONS 25 CITATIONS 5 PUBLICATIONS 15 CITATIONS SEE PROFILE SEE PROFILE Tivoli Olsen Colin Raston University of California, Irvine Flinders University 14 PUBLICATIONS 39 CITATIONS 273 PUBLICATIONS 2,772 CITATIONS SEE PROFILE SEE PROFILE Available from: Colin Raston Retrieved on: 30 October 2015 DOI: 10.1002/cbic.201402427 Communications Shear-Stress-Mediated Refolding of Proteins from Aggregates and Inclusion Bodies Tom Z. Yuan,[a] Callum F. G. Ormonde,[b] Stephan T. Kudlacek,[c] Sameeran Kunche,[d] Joshua N. Smith,[a] William A. Brown,[c] Kaitlin M. Pugliese,[c] Tivoli J. Olsen,[c] Mariam Iftikhar,[a] Colin L. Raston,*[e] and Gregory A. Weiss*[a, c] Recombinant protein overexpression of large proteins in bacte- ies or GPCRs for structural biology) require extensively opti- ria often results in insoluble and misfolded proteins directed to mized mammalian or insect cell lines, media, and bioreactor inclusion bodies. We report the application of shear stress in conditions.[10–12] Recovery of correctly folded proteins from ag- micrometer-wide, thin fluid films to refold boiled hen egg gregates is inefficient and challenging for large-scale industrial white lysozyme, recombinant hen egg white lysozyme, and processes. Mechanical methods to solve this problem have recombinant caveolin-1. Furthermore, the approach allowed been reported. -

Honours Projects 2012

FACULTY OF LIFE AND PHYSICAL SCIENCES Honours Projects 2012 CHEMISTRY AND BIOCHEMISTRY Chemistry and Forensic Biochemistry and Genetics and Nanotechnology Science Molecular Biology Biomedical Science Biochemistry & Chemistry 2012 Honours If you are interested in undertaking Honours at UWA, you may be already asking about the exciting prospects available within each of the Disciplines and sub-disciplines comprising the School. These include Biochemistry and Molecular Biology, Biomedical Science, Chemistry, Forensic Chemistry, Nanotechnology, Genetics, and Structural Biology. This Honours Project book and the associated School Honours Expo are intended to help you explore the possibilities for 2012. If you intend to enrol in Honours in 2012, this booklet will provide you with a comprehensive overview of the interests of our research groups as well as outlining specific Honours projects that are available. The Honours Expo is designed to showcase the depth and diversity of research being undertaken in the School and will enable you to discuss particular projects or even discuss the design of new ones. We hope that you will enjoy our Expo and that it will serve as a good introduction to the range of Honours projects available in the School for next year. Professor M Spackman Head of School Honours Co-ordinators Biochemistry and Molecular Biology Chemistry Winthrop Professor Alice Vrielink Assoc Professor Sam Saunders Phone: 6488 3162 Phone: 6488 3153 [email protected] [email protected] Genetics Forensic Chemistry Winthrop -

Rapid Protein Immobilization for Thin Film Continuous Flow Biocatalysis† Cite This: Chem

ChemComm View Article Online COMMUNICATION View Journal | View Issue Rapid protein immobilization for thin film continuous flow biocatalysis† Cite this: Chem. Commun., 2016, 52, 10159 Joshua Britton,ab Colin L. Raston*b and Gregory A. Weiss*a Received 19th May 2016, Accepted 18th July 2016 DOI: 10.1039/c6cc04210d www.rsc.org/chemcomm A versatile enzyme immobilization strategy for thin film continuous avoiding hazardous solvents and toxic metals. Combining the flow processing is reported. Here, non-covalent and glutaraldehyde benefits of continuous flow and biocatalysis offers numerous bioconjugation are used to immobilize enzymes on the surfaces of advantages such as processing with immobilized enzymes and borosilicate reactors. This approach requires only ng of protein per rapid scale-up. Continuous flow biocatalysis has thus increas- Creative Commons Attribution 3.0 Unported Licence. reactor tube, with the stock protein solution readily recycled to ingly become a focus of many laboratories, as shown in a few sequentially coat 410 reactors. Confining reagents to thin films examples.21–24 during immobilization reduced the amount of protein, piranha- Immobilizing enzymes can increase their industrial viability cleaning solution, and other reagents by B96%. Through this by creating reusable biocatalysts with potentially improved technique, there was no loss of catalytic activity over 10 h processing. reactivity, purity, specificity, selectivity, thermal stability and The results reported here combines the benefits of thin film flow pH tolerance.25–30 Given this importance, many immobilization processing with the mild conditions of biocatalysis. strategies have been described, including attachment to magnetic nanoparticles and nanomaterials,31,32 supports through antibody- Nature builds diverse and complex natural products through specific epitopes and crosslinking,33 and also entrapment within This article is licensed under a assembly line biosynthesis. -

International Workshop on Green Chemistry and Engineering: Global Collaborations

& TECH R.I.C NAT'L INS"! OF STAND HIST PUBLICATIONS A 11 10 5 652^15 NISTIR 6337 PROCEEDINGS International Workshop on Green Chemistry and Engineering: Global Collaborations Washington, D.C. July 1998 Held in Conjunction with the Second Annual Green Chemistry and Engineering Conference ... an environmentally interdependent global community ... QC United States Department of Commerce 100 Technology Administration .U56 National Institute of Standards and Technology NO. 6337 1999 NISTIR 6337 PROCEEDINGS International Workshop on Green Chemistry and Engineering: Global Collaborations Ellyn S. Beary, Editor Chemical Science and Technology Laboratory National Institute of Standards and Technology May 1999 U. S. DEPARTMENT OF COMMERCE William M. Daley, Secretary TECHNOLOGY ADMINISTRATION Gary R. Bachula, Acting Under Secretary for Technology NATIONAL INSTITUTE OF STANDARDS AND TECHNOLOGY Raymond G. Kammer, Director The Workshop was held in Washington DC on July 2, 1998 in nd conjunction with the 2 Annual Green Chemistry and Engineering Conference Co-sponsored by: American Chemical Society American Institute of Chemical Engineers Chemical Manufacturers Association Council for Chemical Research Green Chemistry Institute National Institute of Standards and Technology National Research Council National Science Foundation Organization for Economic Cooperation and Development U.S. Department of Energy U.S. Environmental Protection Agency For information contact NIST/CSTL, Ellyn S. Beary Telephone: 301-975-4138 Facsimile: 301-975-3845 E-Mail: [email protected]