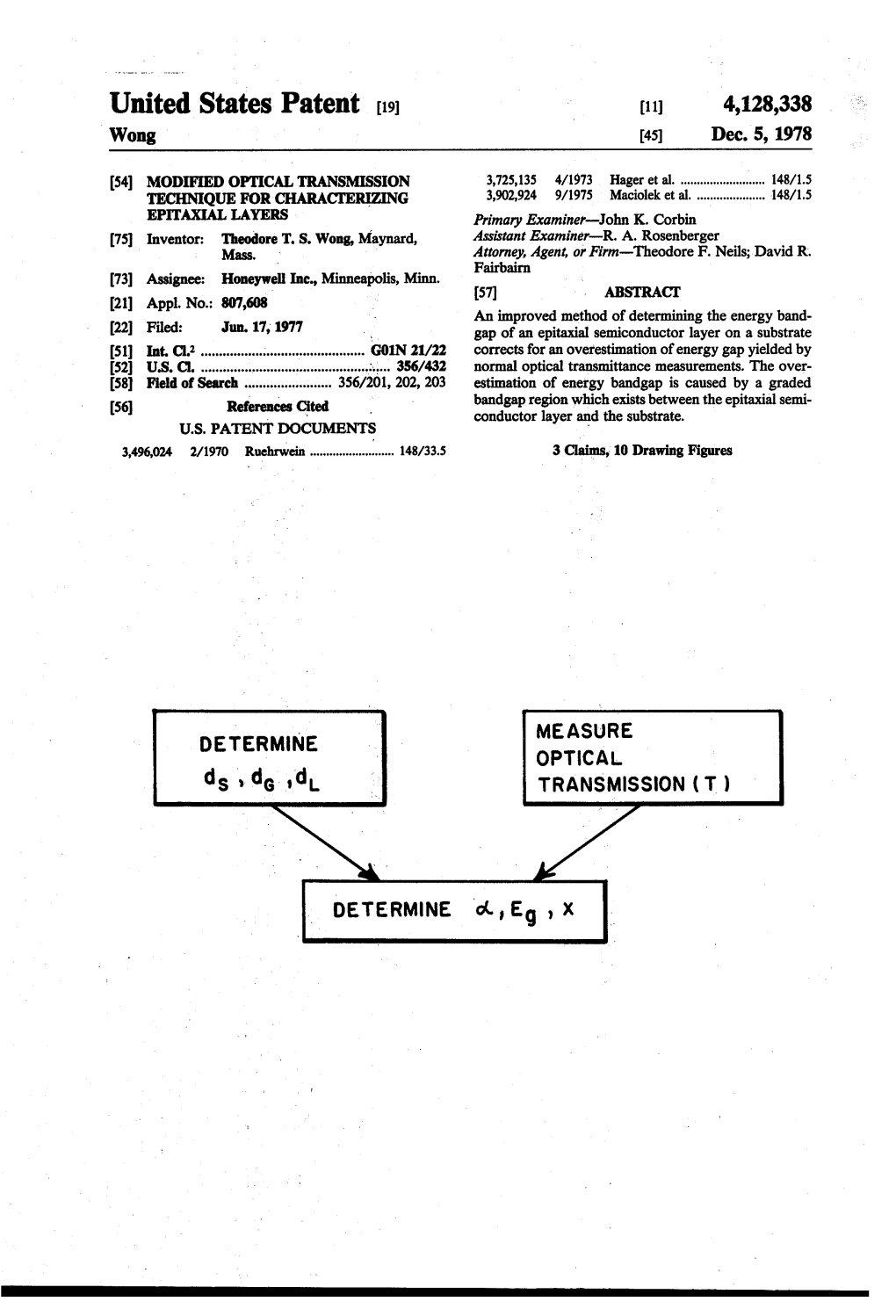

DETERMINE Ol. Eg., X U.S

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

19800021154.Pdf

NEW PbSnTe HETEROJLJNCTION LASER DIODE STRUCTURES WITH IMPROVEDPERFORMANCE* § C. G. Fonstad, D. Kasemset, H. H. Hsieh , and S. Rotter Departmentof Electrical Engineeringand Computer Science -andCenter for Materials Scienceand Engineering? MassachusettsInstitute of Technology Cambridge,Massachusetts 02139 INTRODUCTION In this article, we will summarize several ofour recent advances in the state-of-the-artof lead tin telluride double heterojunction laser diodes,ad- vanceswhich make significant strides in increasing the operating temperatures ofthese devices and in controlling the modal quality and tunability of their output. CW operationto 120°K andpulsed operation to 166°K withsingle, low- est ordertransverse mode emission to in excess of four times threshold at 80°K havebeen achieved in buried stripe lasers fabricated by liquidphase epitaxy inthe lattice-matched system, lead-tin telluride-lead telluride selenide [1,2]. At the same time, liquidphase epitaxy has been used to produce PbSnTe distri- butedfeedback lasers with much broadercontinuous single mode tuningranges than are availablefrom Fabry-Perot lasers [3]. The physicsand philosophy behind these advances is as important as the structuresand performance of the specific devices embodying the advances, par- ticularlysince structures are continually being evolved and the performance continuesto be improved. There is art in anyscience, but as we will demon- strate, there is a tremendous amount ofscience to be applied to Pb-salt tun- ablediode lasers, andwhere this is done,their performance can be predicted, tailored,and reproducibly controlled. Most importantly,their performance can bedramatically enhance<. HIGH TEMPERATUREOPERATION Achievinghigher temperature operation of laser diodesrequires both that thethreshold current density be reduced at highertemperatures, and that the totalthreshold current be reduced. -

Band Crossing Evidence in Pbsnte Observed by Optical Transmission

Brazilian Journal of Physics, vol. 29, no. 4, Decemb er, 1999 771 Band Crossing Evidence in PbSnTe Observed by Optical Transmission Measurements 1 2 2 2 2 S. O. Ferreira , E. Abramof ,P. Motisuke ,P. H. O. Rappl , H. Closs , 2 2 2 A. Y. Ueta , C. Boschetti , and I. N. Bandeira , 1: Dep. F sica, UniversidadeFederal de Vicosa, 36571-000, Vicosa, MG, Brazil 2: Instituto Nacional de Pesquisas Espaciais, C.P. 515 - 12201-970 S~ao Jos e dos Campos, SP, Brazil Received February 8, 1999 Using high quality epitaxial layers, wehave obtained direct evidence of the band inversion in the Pb Sn Te system. The samples, covering the whole comp osition range, were grown by 1x x molecular b eam epitaxy on 111BaF substrates. A minimum in the resistivity as a function 2 of temp erature was observed for all samples with Sn comp osition 0:35 x 0:70. In the same samples and at the same temp erature, temp erature dep endent optical transmission measurements have revealed a change in signal of the energy gap temp erature derivative, a direct evidence of the band inversion. However, the temp erature for which the inversion o ccurs is not the one exp ected by the band inversion mo del. This discrepancy is supp osed to b e due to the Burstein-Moss shift caused by the relatively high hole concentration observed in these samples. band edge states inverted, up to the SnT e value. The I Intro duction Sn comp osition for which the band inversion should Lead-tin telluride is a narrow gap semiconductor which o ccur varies from x 0:35 to x 0:70 as the tem- have b een investigated for manyyears and applied p erature increases from 4 to 300 K. -

United States Patent (19) 11) Patent Number: 4,722,087 Partin 45) Date of Patent: Jan

United States Patent (19) 11) Patent Number: 4,722,087 Partin 45) Date of Patent: Jan. 26, 1988 (54) LEAD-STRONTUM-CHALCOGENIDE Grown by Molecular Beam Epitaxy"; Journal of Elec DODE LASER tronic, vol. 13, No. 3, pp. 493-504, May 1984. (75 Inventor: Dale L. Partin, Sterling Heights, Primary Examiner-William L. Sikes Mich. Assistant Examiner-Bertha Randolph 73) Assignee: General Motors Corporation, Detroit, Attorney, Agent, or Firm-Randy M. Tung Mich. 57 ABSTRACT (21) Appl. No.: 895,286 A double heterojunction lead salt infrared diode laser 22) Filed: Aug. 11, 1986 having an active region layer of a lead salt semiconduc (51) Int. Cl."................................................ H01S 3/19 tor of a given lattice constant, energy band gap, and 52) U.S. C. ........................................ 372/44; 372/45; index of refraction. The active region layer is sand 357/16; 357/17; 357/61 wiched between two lead salt semiconductor layers (58) Field of Search ...................... 372/44, 45; 357/16, containing strontium and selenium that are mutually of 357/63, 17, 61 opposite conductivity type and have substantially the same lattice constant as the active region layer. In addi (56) References Cited tion, the two outside layers have an energy band gap U.S. PATENT DOCUMENTS greater than the active region layer and an index of 4,608,694 8/1986 Partin .................................... 372/44 refraction less than the active region layer. The result 4,612,644 9/1986 Partin .................................... 372/44 ing laser has lattice matching, as well as enhanced car OTHER PUBLICATIONS rier confinement and optical confinement. D. L. Partin; "Lead-Europium-Selenide-Telluride 3 Claims, 1 Drawing Figure on Junction sS.s U.S. -

United States Patent [191 4,612,644

United States Patent [191 [11] Patent Number: 4,612,644 Partin [45] Date of Patent: Sep. 16, 1986 [54] LEAD-ALLOY-TELLURIDE by Molecular Beam Epitaxy”, Journal of Electronics HETEROJUNCI‘ION SEMICONDUCTOR Materials, vol. 13, No. 3, 1984. LASER Weber et al., “Waveguide and Luminescent Properties [75] Inventor: Dale L. Partin, Sterling Heights, of Thin Film Pb-Salt Injection Lasers”, Journal Applied Mich. Physics, vol. 44, No. 11, Nov. 1973, pp. 4991-5000. [73] Assignee: General Motors Corporation, Detroit, Primary Examiner-James W. Davie Mich. Assistant Examiner—-Georgia Y. Epps Attorney, Agent, or Firm—Randy W. Tung [21] Appl. No.: 754,171 [57] ABSTRACT [22] Filed: Jul. 12, 1985 A double heterojunction lead salt infrared diode laser [51] Int. Clx‘ ....................... .. H018 3/19; H01L 33/00 having an active region layer of a lead salt semiconduc [52] US. Cl. ...................................... .. 372/44; 357/16; tor of a given lattice constant, energy band gap, and 357/17; 357/61; 372/45 index of refraction. The active region layer is sand [58] Field of Search .................... .. 372/44, 45; 357/ 17, wiched between two lead salt semiconductor layers 357/61, 16 containing calcium and one element selected from the [56] References Cited group consisting of europium and strontium that are mutually of opposite conductivity type and have sub PUBLICATIONS stantially the same lattice constant as the active region Partin et al., “Wavelength coverage of Lead-Europi layer. In addition, the two outside layers have an energy um-Selenide-Telluride Diode Lasers”, Applied Physics band gap greater than the active region layer and an Letters, 45(3), Aug. -

Arxiv:1206.2088V1

Observation of topological crystalline insulator phase in the lead tin chalcogenide Pb1−xSnxTe material class Su-Yang Xu,1 Chang Liu,1 N. Alidoust,1 D. Qian,1, 2 M. Neupane,1 J. D. Denlinger,3 Y. J. Wang,4 H. Lin,4 L. A. Wray,1, 3 R. J. Cava,5 A. Marcinkova,6 E. Morosan,6 A. Bansil,4 and M. Z. Hasan1 1Joseph Henry Laboratory, Department of Physics, Princeton University, Princeton, New Jersey 08544, USA 2Key Laboratory of Artificial Structures and Quantum Control (Ministry of Education), Department of Physics, Shanghai Jiao Tong University, Shanghai 200240, China. 3Advanced Light Source, Lawrence Berkeley National Laboratory, Berkeley, California 94305, USA 4Department of Physics, Northeastern University, Boston, Massachusetts 02115, USA 5Department of Chemistry, Princeton University, Princeton, New Jersey 08544, USA 6Department of Physics and Astronomy, Rice University, Houston, Texas 77005, USA (Dated: September 19, 2018) We perform systematic angle-resolved photoemission spectroscopic measurements on the lead tin telluride Pb1−xSnxTe pseudobinary alloy system. We show that the (001) crystalline surface, which is a crystalline surface symmetric about the (110) mirror planes of the Pb1−xSnxTe crystal, pos- sesses four metallic surface states within its surface Brillouin zone. Our systematic Fermi surface and band topology measurements show that the observed Dirac-like surface states lie on the X¯ − Γ¯ − X¯ momentum-space cuts. We further show that upon going to higher electron binding energies, the surface states’ isoenergetic countours in close vicinity of each X¯ point are observed to hybridize with each other, leading to a Fermi surface fractionalization due to a Lifshitz transition. -

List of Semiconductor Materials - Wikipedia, the Free Encyclopedia Page 1 of 4

List of semiconductor materials - Wikipedia, the free encyclopedia Page 1 of 4 List of semiconductor materials From Wikipedia, the free encyclopedia Semiconductor materials are insulators at absolute zero temperature that conduct electricity in a limited way at room temperature. The defining property of a semiconductor material is that it can be doped with impurities that alter its electronic properties in a controllable way. Because of their application in devices like transistors (and therefore computers) and lasers, the search for new semiconductor materials and the improvement of existing materials is an important field of study in materials science. The most commonly used semiconductor materials are crystalline inorganic solids. These materials can be classified according to the periodic table groups from which their constituent atoms come. Semiconductor materials are differing by their properties. Compound semiconductors have advantages and disadvantages in comparison with silicon. For example gallium arsenide has six times higher electron mobility than silicon, which allows faster operation; wider band gap, which allows operation of power devices at higher temperatures, and gives lower thermal noise to low power devices at room temperature; its direct band gap gives it more favorable optoelectronic properties than the indirect band gap of silicon; it can be alloyed to ternary and quaternary compositions, with adjustable band gap width, allowing light emission at chosen wavelengths, and allowing e.g. matching to wavelengths with lowest losses in optical fibers. GaAs can be also grown in a semiinsulating form, which is suitable as a lattice-matching insulating substrate for GaAs devices. Conversely, silicon is robust, cheap, and easy to process, while GaAs is brittle, expensive, and insulation layers can not be created by just growing an oxide layer; GaAs is therefore used only where silicon is not sufficient.[1] Some materials can be prepared with tunable properties, e.g. -

LONG WAVELENGTH Pbsnte LASERS with CW OPERATION ABOVE 77K

LONG WAVELENGTH PbSnTe LASERS WITH CW OPERATION ABOVE 77K Koji Shinohara, Mitsuo Yoshikawa, Michiharu Ito and Ryuiti Ueda Kansai Research Center Fujitsu Laboratories Ltd.,JAPAN SUMMARY Lead tin telluride diode lasers with emission wavelengths6 to of9 pm easily operate continuously at temperatures above 77K. These lasers have the Pb Sn Te/Pbl-xSnxTE/Pb Sn Te/PbTe (substrate), (x > y) double 1-Y Y 1-Y Y heterostructure. To prepare this structure LPE,by the growth temperature must be below 600°C to suppress diffusion of the tin during the epitaxial growth. In this paper, the mechanism by which the heterojunction boundaries become irregular is cleared anda new LPEmethod which prevents the irregularity is explained. The lasers prepared from the wafers grown by the new method have demonstratedCW operation at wavelengths longer than10 urn above liquid nitrogen temperature. INTRODUCTION Lead tin telluride diode lasers are well known as excellent radiation sources in the wavelengths longer than6 pm"). The diode lasers should be of double heterostructures to reduce the threshold current densities or to operate at temperatures above77K(2). Lasers with wavelengths from 6 to 10 ~IUoperate easily above 77K and they in are practical use. On the otherhand, it is very difficult for the lasers to operateCW on with wavelengths over10 urn above liquid nitrogen temperature. The reason for this is the difficulty of preparing flat heterojunctions for the lasers with wavelengths over 10 pm. The heterojunction boundaries become irregular if the junctions are made by the usualLPE method. A new LPEmethod has been developed which overcomes the problem of irregular heterojunction boundaries. -

Lead Telluride Bonding and Segmentation Study

d Semiannual Phase Report No. 1 LEAD TELLURIDE BONDING AND SEGMENTATION STUDY Covering period August 1, 1967 - January 31, 1968 Contract No. NAS 5-9149 Prepared by Tyco laboratories, Inc. Bear Hill Waltham, Massachusetts 02154 for , National Aeronautics and Space Administration Goddard Space Flight Center Greenbelt, Maryland 20771 Tyco Laboratories, Inc. Bear Hill Waltham, Massachusetts 02154 Lead Telluride Bonding and Segmentation Study Semiannual Phase Report No. 1 Covering period August 1, 1967 - January 31, 1968 Contract No, NAS 5-9149 H. Bates F. Wald M. Weinstein for National Aeronautics and Space Administration Goddard Space Flight Center Greenbelt, Maryland 2077 1 SUMMARY I. Constitutional Studies A. Tin-Telluride-Metal-Systems Accurate lattice constant determinations on SnTe as in- ? corporated in SnTe-Metal alloys revealed changes in the original lattice constant of the starting Sn. 492Te,508 composition. " From these findings it has to be concluded that PbTe-SnTe thermoelectric alloys in contact with metals might change their composition and therefore their electrical properties over long periods of time. Since such conditions could be important for the mechanism of aging of tungsten contacts to 3P material, a more thorough in- vestigation of similar changes in the W-PbTe-SnTe system is indicated. B. Silicon -Germanium -Metal-A lloys Investigations of the interaction of Si-Ge solid solution alloys withTi, Zr, V, Nb, Ta, Cr, Mo, W, Mn, ReandCohaverevealed two basic types of constitution. The first is one in which equilibria between Si-Ge solid solutions and solid s olutions of metal silicides and germanides exist. The elements Ti, Zr, Ta, and Co apparently belong to this category. -

MBE-Grown Lead Tin Telluride Infrared Devices

befSci J. Vol39. NO. January 1989. pp43-51 MBE-Grown Lead Tin Telluride Infrared Devices T. Srinivasan and J. Sobhanadri Indian Institute of Technology, Madras400 036 ABSTRACT An attempt was made to examine the performance of the Pb,.aFo,,bTe films grown by Molecular Beam Epitaxy (MBE) technique as infrared (IR) band pass filter and photoconductive IR detector. Films of required thickness for these purposes were precalculated and were grown by controlling the growth time. The fabricated band-pass filters were with Full Width at Half Maximum (FWHM) of 20-25 per ent centred at 6.5, 8 and 10 microns. The measured detectivity of the film was of the order of 10' cm HZ'~W-I for 500 K black body temperature with 800 Hz chopping frequency and 10 per cent electrical bandwidth at 77 K. All these films were grown on freshly cleaved KC1 (100) substrates. 1. INTRODUCTION Infrared imaging and monitering systems have gained strategic importance in recent years both for civilian and military applications. In these systems the main components are IR source, IR detector and IR band-pass filter which are apart from the optical components required for focussing and directing the beam;. Even though. IR wavelengths were varying from 7110th of micron to several microns, the atmospl~ere which contain different kinds of molecules, allow only a few narrow regmils for IR transmission. These are technically known as 'atmospheric windows1.. Among them 8-14 micron range window is given importance for IR communications because of its relatively broad nature. It is with transmittance more than 80 per cent (Fig. -

July 16, 1968 G

July 16, 1968 G. SONNENSCHEN 3,392,439 METHOD AND MATER ALS FCR OBTAINING LOW-RESISTANCE BONDS TO TELLURIDE THERMOELECTRIC BODIES Fied Oct. 28, 1963 9 29 INVENTOR. GEORGE SONNENSCHEIN ATTORNEY 3,392,439 United States Patent Office Patented July 16, 1968 2 3,392,439 METHOD AND MATERALS FOR OBTAINING the joining of thermoelectric semi-conductor elements LOW-RESISTANCE BONDS TO TELLURIDE into arrays of Suitable voltage and power output. This THERMOELECTRICBODES difficulty has been particularly pronounced in forming a George Sonnenschein, Los Angeles, Calif., assignor to satisfactory bond between the thermoelectric element and North American Rockwell Corporation, a corporation the conductive material at the hot junction, particularly of Delaware where this hot junction is operated at an elevated tem Filed Oct 28, 1963, Ser. No. 319,301 perature Such as found in a nuclear reactor. The conduc 7 Claims. (CI. 29-573) tive material to be bonded to the semiconductor material This invention relates to improved thermoelectric de must satisfy a varied set of stringent requirements, namely, vices and to methods of fabricating such devices. More 0. low electrical resistivity, high thermal conductivity, particularly, the invention relates to improved materials thermal expansivity closely matching that of the semi and methods for obtaining mechanically strong, thermally conductor, low vapor pressure, melting point well above stable, low-resistance contacts to thermoelectric bodies. the maximum operating temperature of the device, and, Still more particularly, -

N/ a National Aeronautics and Spaceadministration Langley Researchcenter Hampton,Virginia 23665

NASA Technical Memorandum 85698 NASA-TM-85698 19830027950 If EXPERIMENT REQUIREMENTS AND IMPLEMENTATION PLAN (ERIP) FOR SEMICONDUCTOR MATERIALS GROWTH IN LOW-G ENVIRONMENT Roger K. Crouch, Archibald L. Fripp, William J. Debnam, and Ivan O. Clark SEPTEMBER 1983 [.IOT TO LE ":,;.;i-.,; i ,. 2-_,:i:,L2, if?31", .",T c) z_ :m '". _1 LANGLEYL;SRARY,I_ES___,NASRCI-IAcEl'4 [El,_ H.-":.:3TOI1,VIt_S!H:A : N/ A National Aeronautics and SpaceAdministration Langley ResearchCenter Hampton,Virginia 23665 . TABLE OF CONTENTS Page TABLE OF CONTENTS ..................... i LIST OF FIGURES ...................... ii SUMMARY ......................... I • INTRODUCTION ....................... 2 LIST OF SYMBOLS ...................... 3 THE VALUE OF PROCESSING IN SPACE ............. 4 FLIGHT EXPERIMENT DEFINITION ............... 6 EXPERIMENT DEVELOPMENT .................. 6 FURNACE REQUIREMENTS FOR MEA EXPERIMENTS ......... 9 DESCRIPTION OF EXPERIMENT SPECIMENS ............ II SAFETY CONSIDERATIONS ................... 19 FUTURE EFFORT ....................... 19 MILESTONES ........................ 20 REFERENCES ........................ 21 TABLE I.- Anticipated furnace performance of the MEA-A furnace for the growth of PbSnTe .......... i0 ± LIST OF FIGURES Figure i. Compositional profile of Earth-grown PbSnTe crystal. 2 Loaded flight cartridge. 3. Instrumented boron nitride rod. 4. Temperature profiles in test rod. 5. Calculated compositional profile in MEA-A sampJe. 6. Plot of calculated 890 ° C isotherm. il SUMMARY The purpose of this experiment is to use the MEA-2 A facility to test the effect of the low gravity environment on suppressing convective mixing in the growth of Pbl_xSnxTe crystals. This document describes the need to eliminate convection, the furnace characteristics and operation that will be required for successful experimental implementation, and to the level that is presently known, the measured physical properties of the Pb I xSnxTe system. -

Thermoelectric Property Studies on Lead Chalcogenides, Double-Filled Cobalt Tri-Antimonide and Rare Earth

Thermoelectric Property Studies on Lead Chalcogenides, Double-filled Cobalt Tri-Antimonide and Rare Earth- Ruthenium-Germanium by Huijun Kong A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy (Physics) in The University of Michigan 2008 Doctoral Committee: Professor Ctirad Uher, Chair Professor Massoud Kaviany Professor Bradford G . Orr Professor Leonard M. Sander Associate Professor Cagliyan Kurdak © Huijun Kong All Rights Reserved 2008 Dedicated to my parents ii Acknowledgments I first wish to thank Professor Ctirad Uher, my committee chair and research advisor. Throughout the past four years, Professor Uher has supported me in completing this dissertation. He has taught me the work ethics as an experimental physicist by example. I am very grateful for his kindness, patience and encouragements, and for allowing me the freedom to work at my own pace. My committee members deserve thanks for serving on my doctoral committee and for their insightful comments. Special thanks are due to my collaborators, Professor Donald Morelli, Dr. Xun Shi, Professor Mercouri G. Kanatzidis, Dr. Pierre F. P. Poudeu, Dr. John Androulakis, Dr. Chia-Her Lin and Joseph Sootsman. The research presented in this dissertation would not have been possible without their contributions. My current labmates, Dr. Yi-Jiunn Chien, Dr. Changpeng Li, my junior Lynn Endicott also merit special acknowledgement for helping and assisting me in the lab on a daily basis. I would like to thank Dr. Carl Henderson at EMAL for helping me with EPMA measurement. I greatly appreciate his assistance. My parents have always been supporting me wholeheartedly. They provide me many opportunities in life.