JCM ID F PDD Ver02.0 1 JCM Project Design Document Form A

Total Page:16

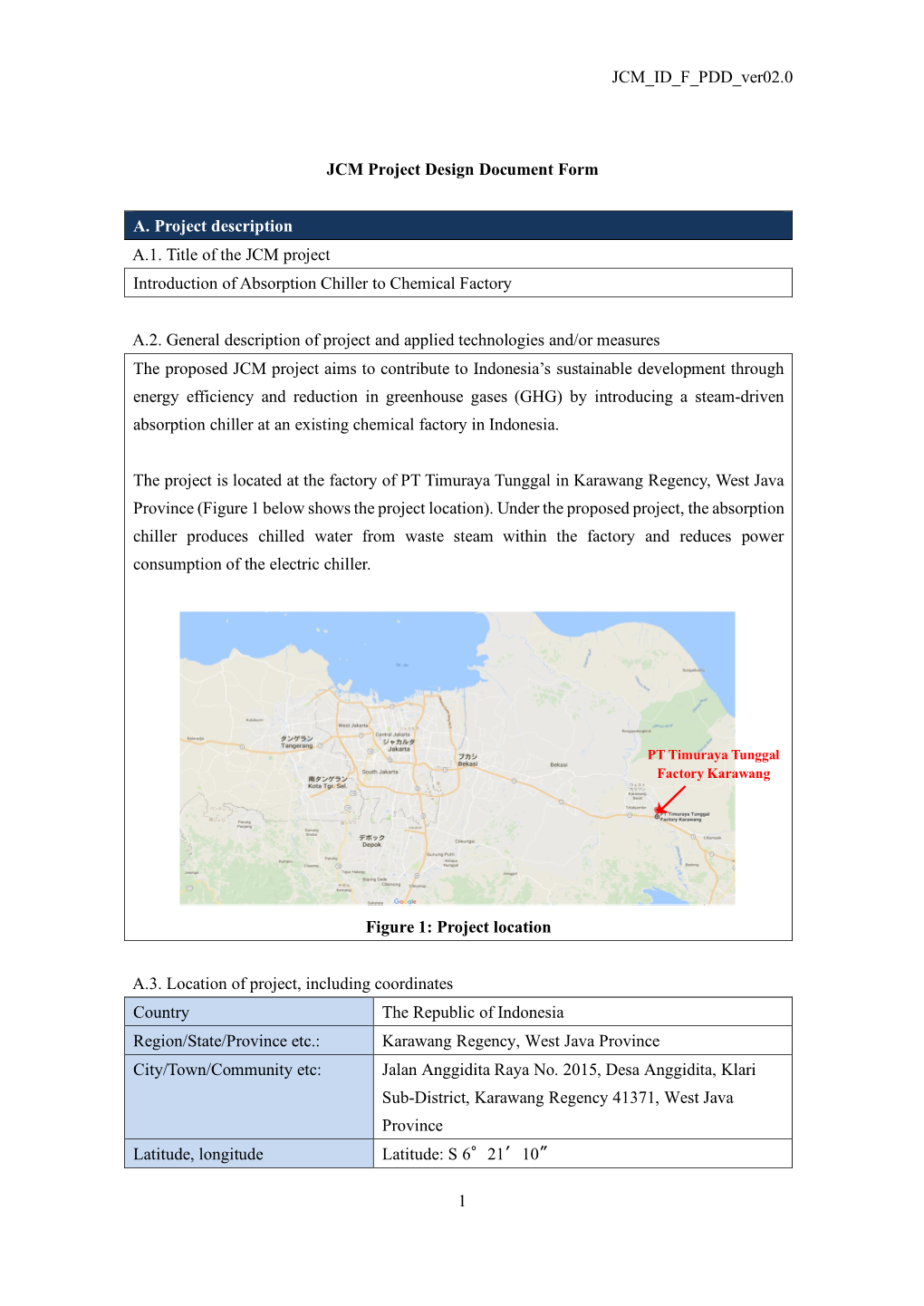

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Determining Strategies for Water, Energy, and Food-Related Sectors in Local Economic Development Aries Purwanto A,*, Janez Sušnik B, F.X

SPC: 161 Model 5G pp. 1–14 (col. fig: NIL) Sustainable Production and Consumption xx (xxxx) xxx–xxx Contents lists available at ScienceDirect Sustainable Production and Consumption journal homepage: www.elsevier.com/locate/spc Determining strategies for water, energy, and food-related sectors in local economic development Aries Purwanto a,*, Janez Su²nik b, F.X. Suryadi a, Charlotte de Fraiture a a IHE Delft Institute for Water Education, Land & Water Development Department, P.O. Box 3015, 2601 DA, Delft, The Netherlands b IHE Delft Institute for Water Education, Integrated Water Systems & Governance Department, P.O. Box 3015, 2601 DA, Delft, The Netherlands article info a b s t r a c t Article history: Water, energy, and food (WEF) related sectors are important to support people's life in a region. Resource Received 14 May 2018 evaluation is one of the stages in resource management to ensure that the existence of those sectors is Received in revised form 3 August 2018 provided sustainably. The assessment of the agglomeration level and growth of each sector in economic Accepted 9 August 2018 development can give better insights for local stakeholders either government bodies or private firms Available online xxxx to improve sustainable management of these sectors. The objectives of this paper are to portray the Keywords: agglomeration level and recent growth of WEF related sectors in local regions in Indonesia, and to Location quotient determine possible sustainable development strategies. The location quotient (LQ) and competitive Competitive position position (CP) analysis methods are employed in this regard. By analysing Gross Regional Domestic Product Basic sector (GRDP) between 2000 and 2015, basic and non-basic sectors have been determined. -

Planning Guide for Area Business Continuity ~ Area BCM Toolkits ~

Planning Guide for Area Business Continuity ~ Area BCM Toolkits ~ Version 2 Supplemental Volume Tools for Area BCM March 2015 AHA CENTRE Japan International Cooperation Agency OYO International Corporation Mitsubishi Research Institute, Inc. CTI Engineering International Co., Ltd. Tool 1:Area BCPs Prepared for the Pilot Areas Area Business Continuity Plan (Area BCP), Version 2, Karawang and Bekasi, West Java, Indonesia Area Business Continuity Plan (Area BCP), Version 2, Cavite, Laguna and Metro Manila, The Philippines. Area Business Continuity Plan (Area BCP), Version 2, Hai Phong, Viet Nam Area BCP ver.2 Bekasi & Karawang, Indonesia- Area Business Continuity Plan(Area BCP) Version 2 -Karawang and Bekasi, West Java, Indonesia- November2014 Local Planning and Development Agency, Province of West Java ○This plan (version 2) was promoted by local Planning and Development Agency,Province of West Java, and was formulated with the participation of local government, public sectors and private sectors in Bekasi and Karawang under the cooperation of JICA Study Team. ○The stakeholdersin Bekasi and Karawang will be expected to continue the activities of Area BCM, and revise this plan. i Planning Guide for Area Business Continuity ~ Area BCM Tool Kits ~ Ver.2 Tool 1 Contents 1 Purpose of the Plan ---------------------- 1 1.1 Introduction to the Version 2 ---------------------- 1 1.2 Purpose of the Plan ---------------------- 1 2 Scope of the Plan ---------------------- 3 2.1 Organization ---------------------- 3 2.2 Area ---------------------- 4 -

Commentary on the Labour Cluster of the Omnibus Bill on Job Creation

AMNESTY INTERNATIONAL COMMENTARY ON THE LABOUR CLUSTER OF THE OMNIBUS BILL ON JOB CREATION (RUU CIPTA KERJA) Amnesty International is a global movement of more than 7 million people who campaign for a world where human rights are enjoyed by all. Our vision is for every person to enjoy all the rights enshrined in the Universal Declaration of Human Rights and other international human rights standards. We are independent of any government, political ideology, economic interest or religion and are funded mainly by our membership and public donations. © Amnesty International 2020 Except where otherwise noted, content in this document is licensed under a Creative Commons (attribution, non-commercial, no derivatives, international 4.0) licence. https://creativecommons.org/licenses/by-nc-nd/4.0/legalcode For more information please visit the permissions page on our website: www.amnesty.org Where material is attributed to a copyright owner other than Amnesty International this material is not subject to the Creative Commons licence. First published in 2020 by Amnesty International HDI Hive Menteng 3rd Floor Probolinggo No. 18 Central Jakarta 10350 Index: ASA 21/2879/2020 Original language: English amnesty.org - amnesty.id 3 CONTENTS I. INTRODUCTION ........................................................................................................................ 4 II. INTERNATIONAL HUMAN RIGHTS INSTRUMENTS ..................................................................... 6 III. PRINCIPLES OF NON-RETROGRESSION .................................................................................. -

Download This PDF File

THE INTERNATIONAL JOURNAL OF BUSINESS REVIEW (THE JOBS REVIEW), 2 (2), 2019, 107-120 Regional Typology Approach in Education Quality in West Java Based on Agricultural and Non-Agricultural Economic Structure Nenny Hendajany1, Deden Rizal2 1Program Studi Manajemen, Universitas Sangga Buana, Bandung, Indonesia 2Program Studi Keuangan Perbankan, Universitas Sangga Buana, Bandung, Indonesia Abstract. West Java is the province in Indonesia with the highest population and has a location close to the capital. However, the condition of education in West Java is generally still low. This is estimated because there are imbalances between districts / cities. The research objective is to get a clear picture of the condition of education in West Java by using secondary data issued by the Central Statistics Agency. The research method uses descriptive analysis, with analysis tools of regional typology. The division of regional typologies from the two indicators produces four regional terms, namely developed regions, developed regions constrained, potential areas to develop, and disadvantaged areas. Based on the indicators of education quality and life expectancy in 2017, from 27 municipal districts in West Java there were 33.3% in developed regions, 18.52% in developed regions were constrained, 7.4% in potential developing regions, and 40.74 % in disadvantaged areas. Bandung and Bekasi regencies are included in developed regions. While the cities of Banjar and Tasikmalaya include potential developing regions. Regional division with three indicators, namely the average length of school, Location Quation, and life expectancy. This division produces three filled quadrants. Quadrant I has 29.6%, quadrant III has 18.5%, and the remaining 51.9% is in quadrant IV. -

Download Article (PDF)

Advances in Engineering Research, volume 198 International Seminar of Science and Applied Technology (ISSAT 2020) Study of Hydraulic Models in the Compilation of Alternative Management of Purbaleunyi Toll Road Inundation (+ STA 131) Ahmad Salim Muttaqin1, Djuwadi2,* and Bambang S. Budianto2 1Applied Infrastructure Post Graduate Program, Politeknik Negeri Bandung, Indonesia 2Department of Civil Engineering, Politeknik Negeri Bandung, Indonesia *Corresponding author. Email: [email protected] ABSTRACT Toll roads are currently one of the supporting factors for economic growth. So that if the function is slightly disturbed, obstacles will arise, which will hamper vehicle's journey using the toll road. Many factors hinder this toll road. One of the traffic obstacles is a flood disaster. Floods are also one of the biggest natural disasters in Indonesia. This study aims to calculate and assess the extent of flooding, which will impact toll roads. So that it can determine the impact and how to handle it. Applying the ten years returned rainfall periods, HEC_RAS simulation shows that the flood inundation area is 176.636,69 m2, including toll road areas. The hydraulic simulation also indicates that the flood inundation area can be reduced by adding two 3.5 x 4 meter Box Culvert, while to minimize the traffic disturbance during the construction period, it is recommended to apply microtunneling method. Keywords: Flood, Toll Road, HEC-RAS, Microtunnel. 1. INTRODUCTION decrease. Meanwhile, floods are also one of the most common natural disasters in Indonesia. Transportation is economic support for a region [1]. The road is one of the supports for the smooth operation Floods on toll roads also occur frequently in of land transportation. -

Analysisofhumanresourc

GSJ: Volume 7, Issue 12, December 2019 ISSN 2320-9186 202 GSJ: Volume 7, Issue 12, December 2019, Online: ISSN 2320-9186 www.globalscientificjournal.com ANALYSIS OF HUMAN RESOURCES COMPETITIVENESS OF MINAPADI AQUACULTURE FISHERIES IN WEST JAVA PROVINCE Rosidah**, Annes Ilyas *, Asep. A.H. Suryana **, Atikah Nurhayati** *) Bachelor of Fisheries and Marine Sciences Faculty, University of Padjadjaran **) Lecturer of Fisheries and Marine Sciences Faculty, University of Padjadjaran Email : [email protected] ABSTRACT The fisheries sector is an important sector for the people of Indonesia and can be used as a prime mover of the national economy. Minapadi cultivation is a fisheries sector with a system of rice and fish cultivation which is cultivated together in a paddy field. West Java Province as one of the biggest producing regions of Minapadi fisheries in Indonesia, and is considered as a potential area for Minapadi cultivation. The potential of human resources affects the efforts of business entities in achieving maximum mineral production. Minapadi aquaculture competitiveness can be used as a benchmark for regional development, regional mapping, and regional development planning. This study has the objective to analysis of human resources competitiveness of Minapadi aquaculture in West Java Province. The method used in this study is the litelature survey method to determine the competitiveness of minapadi cultivation in 18 regencys and nine cities in West Java Province. After all data has been processed, the data will be analyzed descriptively. The technique used to retrieve primary data in this study in the from of expert judgment. Whereas secondary data was obtained from statistical data of the Office of Maritime Affairs and Fisheries of West Java Province. -

Migration Pattern of Industrial Workers in Bekasi Regency

Migration Pattern of Industrial Workers in Bekasi Regency Sony Nugratama Hijrawadia,1, Adriana a Department of Geography Education Universitas Islam 45 Bekasi, Indonesia 1 [email protected] Informasi Artikel A B S T R A K Sejarah artikel Kabupaten Bekasi yang terletak di pheryphery kota Jakarta dan Bekasi, Diterima : 12 Agustus 2019 telah mengalami perkembangan wilayah yang signifikan. Sebagai Revisi : 10 September 2019 kawasan industri, Kabupaten Bekasi sangat menarik bagi calon pekerja. Dipublikasikan : 3 Oktober 2019 Masalah kependudukan yang perlu diperhatikan adalah masalah Kata kunci: ketenagakerjaan. Seiring dengan meningkatnya populasi, jumlah pekerja Tenaga Kerja juga meningkat. Tujuan dari penelitian ini adalah untuk mengidentifikasi Migrasi Musiman secara geografis daerah asal tenaga kerja industri di Kabupaten Bekasi Industri yang paling dominan, untuk mengetahui karakteristik tenaga kerja sektor Kabupaten Bekasi industri berdasarkan tingkat pendidikan dan kompetensi. Penelitian ini menggunakan metode deskriptif kuantitatif dengan pendekatan survei, dan juga melakukan wawancara kepada pemangku kepentingan yaitu pemerintah daerah Kabupaten Bekasi. A B S T R A C T Keywords: Bekasi Regency, which is located in the periphery cities of Jakarta and Labor Bekasi, has experienced significant regional development. As an industrial Seasonal Migration area, Bekasi Regency is very attractive to prospective workers. The Industry population problem that needs attention is the employment issue. As the Bekasi Regency population increases, the number of workers also increases. The purpose of this study is to geographically identify the area of origin of industrial labor in the Bekasi District which is the most dominant, to find out the characteristics of the industrial sector workforce based on their level of education and competence. -

Indication of Source in West Java Province: the First Government's Certification on Local Products in Indonesia

Indication of Source in West Java Province: the First Government's Certification on Local Products in Indonesia Miranda Risang Ayu Palar, S.H., LL.M., Ph.D. Head of Intellectual Property Centre for Regulation and Application Studies, Department of Law on Information Technology and Intellectual Property, Faculty of Law, Universitas Padjadjaran, West Java, Indonesia Intellectual Property Rights Exclusive Rights Communal IPR Inclusive Rights Intellectual Property Rights Individual IPR Exclusive Rights Communal Intellectual Property Rights Exclusive Rights Lisbon System Paris Convention System EU System TRIPS Agreement Trade Names Controlled Appellations of Origin Geographical Collective Marks Indications Protected Designations of Certification Origin Marks Traditional Indications Specialized of Source Guarrantee Communal Intellectual Property Rights Inclusive Rights Moral Rights Economic & Moral Rights Traditional Intangible Traditional Genetic Indications Cultural Cultural Knowledge Resources of Source Heritage Expression IS, GI, AO in International Legal Instruments Indications of Source (IS) . Paris Convention for the Protection of Industrial Property of 1883 and the 1911 Revision . Madrid Agreement of 1891 for the Repression of False or Deceptive Indications of Source on Goods Geographical Indications (GIs) . Agreement on the Establishment of the World Trade Organization – Agreement on the Trade Related Aspects of Intellectual Property Rights 1994 IS, GIs, AO in International Legal Instruments Appellations of Origin . Lisbon Agreement of 1958 for the Protection of Appellations of Origin and their Registration (rev. 1967, amn. 1979) . Administrative Instructions for the Application of the Lisbon Agreement 2010 . International Convention of 1951 on the Use of Appellations of Origin and Denominations of Cheeses (Stresa Convention) Appellations of Origin & Geographical Indications . Geneva Act of the Lisbon Agreement on Appellations of Origin and Geographical Indications 2015 . -

Environmental and Occupational Risk Factors Associated with Chronic Kidney Disease of Unknown Etiology in West Javanese Rice Farmers, Indonesia

International Journal of Environmental Research and Public Health Article Environmental and Occupational Risk Factors Associated with Chronic Kidney Disease of Unknown Etiology in West Javanese Rice Farmers, Indonesia Laila Fitria 1,*, Nurhayati Adnan Prihartono 2 , Doni Hikmat Ramdhan 3, Tri Yunis Miko Wahyono 2, Pornpimol Kongtip 4 and Susan Woskie 5 1 Department of Environmental Health, Faculty of Public Health, University of Indonesia, Depok 16424, Indonesia 2 Department of Epidemiology, Faculty of Public Health, University of Indonesia, Depok 16424, Indonesia; [email protected] (N.A.P.); [email protected] (T.Y.M.W.) 3 Department of Occupational Health and Safety, Faculty of Public Health, University of Indonesia, Depok 16424, Indonesia; [email protected] 4 Department of Occupational Health and Safety, Faculty of Public Health, Mahidol University, 420/1 Rajvidhi Road, Bangkok 10400, Thailand; [email protected] 5 Department of Public Health, University of Massachusetts Lowell, One University Ave, Lowell, MA 01854-2867, USA; [email protected] * Correspondence: lfi[email protected] Received: 4 June 2020; Accepted: 20 June 2020; Published: 23 June 2020 Abstract: Chronic kidney disease of unknown etiology (CKDu) in agricultural population is an increasing issue. This study aims to obtain a prevalence estimate of CKDu in male rice farmers in West Java, Indonesia; and analyze the relationship between CKDu and environmental and occupational factors. The study design was cross-sectional. This study included 354 healthy male farmers in two rice agriculture areas in West Java with different altitudes (low altitude and high-altitude location). This research included blood and urine sampling from the farmers for serum creatinine (SCr) level and proteinuria; questionnaire on demographic information, occupational factors and other risk factors for CKDu. -

An Assessment of Economic and Financial Impacts of Jakarta-Bandung High-Speed Railway Project

PISSN-26852004 An Assessment of Economic and Financial Impacts of Jakarta-Bandung High-Speed Railway Project An Assessment of Economic and Financial Impacts of Jakarta-Bandung High-Speed Railway Project Siddhartha Nath and Gusti Raganata1 1(University of Tokyo, Japan) *corresponding author : [email protected] Abstract In this paper, we assess the economic and financial impacts of the proposed Jakarta-Bandung high speed railway project. Our assessment following Zou et. al. (2018) suggests that, over the long run, the project may increase the combined income of Jakarta, the neighbouring province Karawang and the country’s major industrial centre Bandung, by an estimated 12-18%, by increasing ‘market access’, by the firms in the region, under several assumptions. We estimated that the project will increase Indonesian real GDP by almost 0.4%, mostly during its construction phase, with certain assumptions on the returns to capital. On the other hand, although the project is expected to generate over 40,000 jobs in Indonesia, according to several sources, the project may entail an immediate loss of over 2,000 traditional jobs around the track. In addition, Transit Oriented Development plans, such as tourist spot in Walini, residential complex around the project site etc. are likely to affect community farming and water supply in the region. Therefore, we assessed that, the success of the project is subjected to several legal and institutional barriers including ongoing issues related to the land acquisition. The sluggish progress of the project exerts financial risk to the stakeholders, especially since the project has no ‘guarantee’ from the Indonesian government. -

Religious Travel to Sheikh Quro's Tomb, Karawang, West Java

International Journal of Religious Tourism and Pilgrimage Volume 9 Issue 1 Islamic Tourism Article 3 2021 Religious Travel to Sheikh Quro’s Tomb, Karawang, West Java Diah Sri Rejeki University of Padjadjaran, [email protected] M. Sapari Dwi Hadian University of Padjadjaran, [email protected] Evi Novianti Universitas Padjajaran, [email protected] See next page for additional authors Follow this and additional works at: https://arrow.tudublin.ie/ijrtp Part of the Tourism and Travel Commons Recommended Citation Rejeki, Diah Sri; Hadian, M. Sapari Dwi; Novianti, Evi; and Agustin, Herlina (2021) "Religious Travel to Sheikh Quro’s Tomb, Karawang, West Java," International Journal of Religious Tourism and Pilgrimage: Vol. 9: Iss. 1, Article 3. doi:https://doi.org/10.21427/retc-3p66 Available at: https://arrow.tudublin.ie/ijrtp/vol9/iss1/3 Creative Commons License This work is licensed under a Creative Commons Attribution-Noncommercial-Share Alike 4.0 License. Religious Travel to Sheikh Quro’s Tomb, Karawang, West Java Authors Diah Sri Rejeki, M. Sapari Dwi Hadian, Evi Novianti, and Herlina Agustin This academic paper is available in International Journal of Religious Tourism and Pilgrimage: https://arrow.tudublin.ie/ijrtp/vol9/iss1/3 © International Journal of Religious Tourism and Pilgrimage ISSN : 2009-7379 Available at: http://arrow.tudublin.ie/ijrtp/ Volume 9(i) 2021 Religious Travel to Sheikh Quro’s Tomb, Karawang, West Java Diah Sri Rejeki University of Padjadjaran, Indonesia [email protected] M. Sapari Dwi Hadian University of Padjadjaran, Indonesia [email protected] Evi Novianti Universitas Padjajaran, Indonesia [email protected] Herlina Agustin Faculty of communication, Padjadjaran University, Indonesia [email protected] The tomb of Sheikh Quro Karawang attracts many visitors for religious tourism. -

Re-Enactment Share Understanding in the Process of Agricultural Food Management in Karawang Regency

Available online at https://journal.rescollacomm.com/index.php/ijbesd/index e-ISSN 2722-1156 International Journal of Business, Economics and p-ISSN27722-1164 Social Development Vol. 2, No. 1, pp. 18-23, 2021 Collaborative Governance: Re-Enactment Share Understanding in the Process of Agricultural Food Management in Karawang Regency Marvin Angelo Gracino*, Evi Priyanti and Dewi Noor Azijah Governmental Science Study Program, Universitas Singaperbangsa Karawang, Indonesia. *Corresponding author email: [email protected] Abstract Sustainable Food Agricultural Land Protection is a system and process in planning, developing, utilizing, controlling, and monitoring agricultural land that is determined to be consistently protected in order to produce staple food for national food security. Currently, food agriculture land in Karawang Regency is increasingly under threat along with the rapid development of the industrial sector in the area and threats from the surrounding area. Not only because of the conversion into industrial land, but the existence of factories around it also threatens soil fertility and water quality due to the factory waste itself. The focus in this paper is how the Karawang Regency Government carries out Collaborative Governance in protecting sustainable food agricultural land. In this study, the authors used a qualitative method with a phenomenological approach. The purpose of this research is to explain how to study and analyze the implementation of policies on the protection of sustainable agricultural land with one of the stages of collaborative governance from Ansell and Gash, namely share understanding. The results showed that the Government of Karawang Regency has succeeded in conducting share understanding in collaborative governance well because it has the same goal, namely to create national food security.