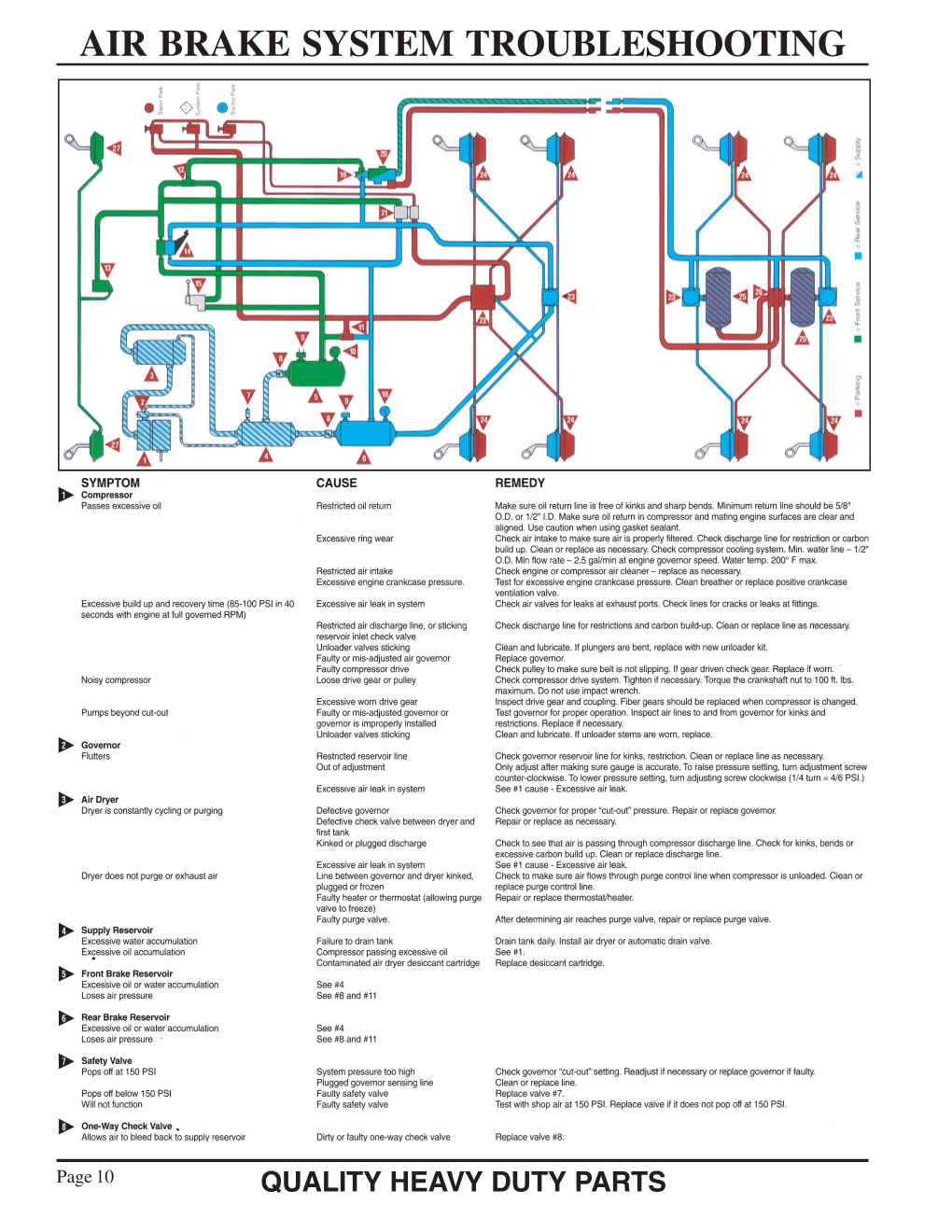

Air Brake System Troubleshooting

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Braking Systems in Railway Vehicles

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 4 Issue01,January-2015 Braking Systems in Railway Vehicles Rakesh Chandmal Sharma1 , Manish Dhingra2, Rajeev Kumar Pathak3 1Department of Mechanical Engineering, M. M. University, Mullana (Ambala) INDIA, 2Department of Mechanical Engineering, T. M. University, Moradabad INDIA 3Department of Mechanical Engg, Rakshpal Bahahur College of Engg. and Tech., Bareilly INDIA Abstract— Brake is an essential feature in order to retard and Researchers in the past have investigated different stop the railway vehicle within minimum possible time. This aspects of braking of railway vehicle. Bureika & Mikaliunas paper presents a discussion about the different braking [1] provided the calculations for Vehicle Braking Force systems used in railway vehicles. This paper also considers Fitted with UIC Air Brake for Passenger Trains, Wagon electrodynamic and electromagnetic braking of trains, which is Braking Force Fitted with a UIC Air Brake for Freight of particular importance in high-speed trains. The calculation Trains Wagon, Braking Distance. Liudvinavicius & Lingaitis for stopping distance for railway vehicle is provided in this [2] studied different features and related mathematics of study. electrodynamic braking in high‐speed trains. Vernersson [3] developed a dimensional finite element model of block and Keywords— Air brake; Straight air brake system; Automatic air brake system; Braking distance; Brake cylinder; Brake pipe; Vacuum brake; wheel, which was coupled through a contact interface for the Brake delay time purpose of control of heat generation and also the heat partitioning at block-wheel surface through thermal contact I. INTRODUCTION resistances. Influence of temperature in wheels and brake The brakes are used on the coaches of railway trains to block at rail tread braking was analyzed under brake rig enable deceleration, control acceleration (downhill) or to conditions in the later part of study by Vernersson [4]. -

Design and Analysis of the Eddy Current Brake with the Winding Change

ISSN (Print) 1226-1750 ISSN (Online) 2233-6656 Journal of Magnetics 22(1), 23-28 (2017) https://doi.org/10.4283/JMAG.2017.22.1.023 Design and Analysis of the Eddy Current Brake with the Winding Change Sooyoung Cho1, Huai-Cong Liu1, Ju Lee1, Chang-Moo Lee2, Sung-Chul Go3, Sang-Hwan Ham4, Jong-Hyuk Woo1, and Hyung-Woo Lee5* 1Department of Electrical Engineering, Hanyang University, Seoul, 04763, Republic of Korea 2Korea Railroad Research Institute, Uiwang 16105, Republic of Korea 3Samsung Electronics Company, Ltd., Suwon, Gyeongi-do, 16677, Republic of Korea 4School of Electrical Engineering, Kyungil University, Gyeongsan, 38428, Republic of Korea 5Department of Railway Vehicle System Engineering, Korea National University of Transportation, Uiwang, 16106, Republic of Korea (Received 24 January 2017, Received in final form 16 February 2017, Accepted 21 February 2017) This paper is a study of the eddy current brake designed to replace the air brake of railway application. The eddy current brake has the advantage of being able to take a high current density compared to the other application because this brake is used for applying brakes to the rolling stock for a shorter amount of time. Also, this braking system has the merit of being able to take a high current density at low speed rather than at high speed, because the heat generated by the low speed operation is less than that of the high speed operation. This paper also presents a method of improving the output torque of the eddy current brake at low speed operation through a change of the winding as well as the basic design. -

Nat'l Highway Traffic Safety Admin., DOT § 570.57

Nat’l Highway Traffic Safety Admin., DOT § 570.57 [(A ¥ B) / A] × 100 (c) Vacuum brake system integrity. (1) The vacuum brake system shall dem- The engine must be operating when onstrate integrity by meeting the fol- power-assisted brakes are checked. lowing requirements: (d) Brake hoses, master cylinder, tubes (i) The vacuum brake system shall and tube assemblies. Hydraulic brake provide vacuum reserve to permit one hoses shall not be mounted so as to service brake application with a brake contact the vehicle body or chassis. pedal force of 50 pounds after the en- Hoses shall not be cracked, chafed, or gine is turned off without actuating flattened. Brake tubes shall not be flat- the low vacuum indicator. tened or restricted. Brake hoses and tubes shall be attached or supported to (ii) Trailer vacuum brakes shall oper- prevent damage by vibration or abra- ate in conjunction with the truck or sion. Master cylinder shall not show truck tractor brake pedal. signs of leakage. Hose or tube protec- (2) Inspection procedure. (i) Check the tive rings or devices shall not be con- trailer vacuum system by coupling sidered part of the hose or tubing. trailer(s) to truck or truck tractor and (1) Inspection procedure. Examine vis- opening trailer shutoff valves. Start ually brake master cylinder, hoses and the engine and after allowing approxi- tubes, including front brake hoses, mately 1 minute to build up the vacu- through all wheel positions from full um, apply and release the brake pedal. left turn to full right turn for condi- In the case of trailer brakes equipped tions indicated. -

Brakes Andrelated Systems

BRAKES ALL MODELS Air Brake Modifications Certification Procedures For DOT FMVSS-121 The Federal Department of Transportation's Motor Vehicle Safety Standard 121 required that virtually all trucks equipped with air brakes and manufactured on or after March 1, 1975 must comply with a comprehensive set of design and performance parameters concerning the air brakes and related systems. Of the many requirements of FMVSS 121, two are of primary concern between the truck manufacturer and the body and allied equipment manufacturer. The first concern is the center of gravity location on a truck used for compliance testing and the second involves the tubing and air flow design of the brake system. Cautions - FMVSS-121 Air Brake System Modifications CAUTION: If wheelbase alterations are made to International vehicles with FMVSS-121 brakes: • DO NOT make alterations to air lines with hose, piping or fittings of sizes other than those currently in use on the truck. • DO NOT allow sharp bends or other constrictions in hosing. • DO NOT exceed the minimum or maximum wheelbase available from the factory for that model after lengthening or shortening the wheelbase. For wheelbases longer or shorter than those available from the factory, International will provide verbal opinion (through contacting your local International dealer). International will be available to provide certification testing and documentation of compliance or non-compliance with FMVSS-121 for the specific situation at an additional cost. dy Builder Diagrams (CT-471) 2010 October, CAUTION: Air reservoirs may be relocated providing these guidelines are followed: • DO NOT make alterations to air lines with hose, piping or fittings of sizes other than those currently in use on the truck. -

Design and Analysis of Electromagnetic Breaking System

ISSN(Online): 2319-8753 ISSN (Print): 2347-6710 International Journal of Innovative Research in Science, Engineering and Technology (A High Impact Factor, Monthly, Peer Reviewed Journal) Visit: www.ijirset.com Vol. 9, Issue 2, February 2020 Design and Analysis of Electromagnetic Breaking System A.Harris1, J.Joseph Ajith Kumar1, Jibin Sam Mathew1, T.Karthikeyan1, J.Y.Arthur Jebaraj2, I.Neethi Manickam2, S.Shiek Sulaiman2 Final year students, Department of Mechanical Engineering, Francis Xavier Engineering College, Tirunelveli, Tamil Nadu, India1. Professor, Department of Mechanical Engineering, Francis Xavier Engineering College, Tirunelveli, Tamil Nadu, India2 ABSTRACT: This project is a new technology in braking system. Electromagnetic braking system is used in light motor and heavy motor vehicle like buses, truck, etc. An Electromagnetic Braking system uses Magnetic force to engage the brake, but the power required for braking is transmitted manually. The electromagnetic braking systems are also called electro-mechanical brake .In Future we can use this braking system to avoid the accidents. An electromagnetic braking system uses a magnetic force to apply brake. The power source used in the electromagnetic break is electric current. The electric power applied to the magnetic coil developes the magnetic field in armature coil and attracts the electromagnet aluminum disc. Applying brake to stop the vehicle. I. INTRODUCTION A brake is a device which inhibits motion. Its opposite component is a clutch. Most commonly brakes use friction to convert kinetic energy into heat, though other methods of energy conversion may be employed. For example regenerative braking converts much of the energy to electrical energy, which may be stored for later use. -

Air Brake & Train Handling Rules

Air Brake & Train Handling Rules Effective March 25, 2019 AIR BRAKE & TRAIN HANDLING RULES TABLE OF CONTENTS 100.0 Train Air Brake Tests and Inspections 5 100.1 Compliance with FRA and Transport Canada Regulations 5 100.2 Safety Inspection of Freight Cars 5 100.3 Coupling and Securing Air Hoses 6 100.4 Operative Brakes - US Only 6 100.5 Person in Charge of Air Brake Test 7 100.6 Standard Brake Pipe Pressures 7 100.7 Charging Air Brake System 7 100.8 Air Brake Tests Using End-of-Train Telemetry Devices (ETD) Continuity Tests 7 100.8.1 Air Brake Tests Using Handheld Gauges 8 100.9 Brake Pipe Leakage Test 8 100.10 Initial Terminal and Road Air Brake Test (Class 1 Air Brake Test) Canadian Class 1 Brake Test and Class 1-A Brake Tests 9 100.11 Transfer Train Movements Test – United States 12 100.12 Transfer Movements – Canada 13 100.13 Running Air Brake Test 13 100.14 Air Brake Test When Cutting Off and Recoupling 14 100.15 Application and Release Test (Class 3 Air Brake Test) United States and Canada 14 100.16 Air Brake Test When Adding Pre-Tested Cars 14 100.17 Inbound Train Inspection 14 100.18 Piston Travel Limits 15 100.19 Dynamic Brake Requirements 15 100.20 Inoperative Dynamic Brake on Lead, Controlling Locomotive 15 101.0 Locomotive Air Brake Tests and Inspections 16 101.1 General Requirements 16 101.2 Locomotive Daily Inspection 16 101.3 Defects Other Than Non-Complying Conditions 20 101.4 Non-Complying Condition Found En Route 21 101.5 Major Internal Defects Found En Route 21 101.6 Locomotive Air Brake Test 22 101.7 Standard Air Pressures -

The 26-L Brake Equipment

INSTRUCTION PAMPHLET No. 74 June 1964 THE 26-L BRAKE EQUIPMENT with 26-C BRAKE VALVE and 26-F CONTROL VALVE arranged for SAFETY CONTROL OVERSPEED CONTROL DYNAMIC INTERLOCK and MULTIPLE-UNIT CONTROL for LOCOMOTIVES THE 26-L BRAKE EQUIPMENT WITH 26-C BRAKE VALVE AND 26-F CONTROL VALVE ARRANGED FOR SAFETY CONTROL OVERSPEED CONTROL DYNAMIC INTERLOCK AND MULTIPLE-UNIT CONTROL FOR LOCOMOTIVES INSTRUCTION PAMPHLET NO. 74 JUNE 1964 (Supersedes Issue of September 1960) CONTENTS Paqe The Equipment .................................................................................................................................. 3 26-C Brake Valve .............................................................................................................................. 5 Automatic Brake Operation .................................................................................................... 9 Independent Brake Operation ................................................................................................. 11 26-F Control Valve ........................................................................................................................... 13 J-1 Relay Valve ................................................................................................................................. 20 MU-2-A Valve ................................................................................................................................... 23 F-1 Selector Valve ........................................................................................................................... -

Bendix® Adb22x™ Air Disc Brake Recall Repair Kit

BENDIX® ADB22X™ AIR DISC BRAKE RECALL REPAIR KIT 4 Spring Brake Label Location Chamber 4 2 3 2 Carrier Caliper Bendix ADB22X Air Disc Brake Carrier 1 Vertical Style Bendix® ADB22X™ Air Disc Brake Axial Style Kits are vehicle/application specific. Do not install this kit unless it is for the intended application. Kit Contents Item Recall Kit Part Numbers No. Description Qty. Part No. Application 1 Caliper/Carrier Assembly 1 K191727 Axial Caliper Kit, Blue Bird® 2 Mounting Bolts 6 K191735SC Axial Caliper Kit, Navistar® 3 Washers (Axial Style Only) 6 K191738 Axial Caliper Kit, Thomas Built® 4 Chamber Mounting Nuts 2 K191740 Vertical Caliper Kit, Thomas Built Figure 1 – Bendix® ADB22X™ Air Disc Brake Recall Repair Kit GENERAL This instruction sheet is intended to provide the necessary are installed on the left (driver’s side) rear axle of a school information to service the Bendix® ADB22X™ Air Disc Brake bus. This kit contains the components shown in Figure caliper/carrier assembly in connection with recall campaign 1. All of the kit contents must be used for the installation. number 19E030. This campaign applies only to ADB22X Do not reuse the removed hardware (Items 2 through 4). brake assemblies that were manufactured between January 01, 2009 and November 27, 2018, inclusive and 1 GENERAL SAFETY GUIDELINES WARNING! PLEASE READ AND FOLLOW THESE INSTRUCTIONS TO AVOID PERSONAL INJURY OR DEATH: When working on or around a vehicle, the following guidelines should be observed AT ALL TIMES: ▲P ark the vehicle on a level surface, apply the parking brakes and always block the wheels. -

Emergency Brakes. After Every Working Day. to Keep from Fouling the Air Compressor Oil. Water Can Freeze in Cold Weather And

1. Modern air brake systems combines three different systems. They are the service brakes, the parking brakes and the: a. S-S-cam brakes.cam brakes. b. Drum brakes. c. Foot brakes. d. Emergency brakes. 2. Oil and water usually collect in compressed air tanks. If you do not have an automatic tank drain, when should you drain the air tanks? a. After every working day. b. After every four hours of service. c. Once a week. d. Every other week. 3. Why drain water from the compressed air tanks? a. To keep from fouling the air compressor oil. b. Water can freeze in cold weather and cause brake failure. c. The low boiling point of water reduces braking power. d. Water over cools the compressor. 4. Air brake equipped vehicles must have: a. A supply pressure gauge. b. An air use gauge. c. At least two brake heaters. d. A backup hydraulic system. 5. What can legally hold a parking or emergency brake in position for a truck, truck tractor or bus? a. Fluid pressure b. Air pressure c. Spring pressure d. Any of the above 6 Air loss in a straight truck or bus should not be more than ____ with the engine off and the brakes on. a. 1 psi in 30 seconds b. 1 psi in one minute c. 2 psi in 45 seconds d. 3 psi in one minute 7 To make an emergency stop with air brakes, using the stab braking method, you should: a. Pump the brake pedal rapidly and lightly. b. Brake hard until the wheels lock, and then get off the brakes for as much time as the wheels were locked. -

Design and Development on Electro Magnetic and Automatic Breaking System

DESIGN AND DEVELOPMENT ON ELECTRO MAGNETIC AND AUTOMATIC BREAKING SYSTEM GUIDED BY :- PROF. MANOJ P . RAJPARA PREPARED BY: GROUP NO:-27 RAJPUT VIPUL 11ME64 PARAJAPATI NIKUL 12ME02 MODI SAGAR 12ME17 DARJI MILAN 12 ME18 CONTENT Introduction Project Principal Literature Review Types of brake Component Component design Construction Future Scope Advantage Disadvantage Application Work Planning Reference INTRODUCTION In this project we have designed and establishment and Electromagnetic disk braking system so as to have a future alternative to traditional breaking systems. Electromagnetic disk braking system slows an objects by creating an eddy current through electromagnetic induction which create resistance. When electromagnetic are used, control of the breaking action is made possible by varying the strength of the magnetic field of the electromagnets creates eddy currents in the discs. These eddy currents generate an opposing magnetic field (Lenz's law), which then resists the rotation of the discs, providing braking force. The net result is to convert the motion of the rotors into heat in the rotors. Electro magnetic and auto breaking system designed to develop a new system that can solve this problem where drivers may not brake manually but the vehicles can stop automatically due to obstacles. This project is about a system that can control braking system for safety. Using ultrasonic as a ranging sensor, its function based on ultrasonic wave. After transmit by transmitter, the wave can reflect when obstacle detected and receive by receiver. The main target for this project is, car cans automatically braking due to obstacles when the sensor senses the obstacles. The braking circuit function is to brake the car automatically after received signal from the sensor. -

Air Brake Systems

Table of Contents Introduction .................................................................................... 1 Air Brake Systems ......................................................................... 2 Important Points about Air Brake Systems .................................... 4 Anti-Lock Braking Systems (ABS) ................................................. 5 ABS Based Safety Technologies ................................................... 8 A Typical Scenario With/Without Traction Control .......................... 9 Important Points about ABS and Related Technologies ............... 11 Safe Use of Cruise Control .......................................................... 12 Retarders...................................................................................... 13 Important Points about Retarders ............................................... 16 Brake Fade ................................................................................... 17 Important Points about Brake Fade ............................................. 20 Driving Tips and Cautions ........................................................... 21 Where to Go For Additional Information ...................................... 22 Introduction This booklet provides information and guidance to motorcoach drivers who have the challenge of understanding and properly handling complex mechanical devices, technologies, and safety related systems. Each section of this booklet concludes with important summary points. Always refer to the manufacturer’s operating -

Air Brake Hose Assemblies 02/25/2019

Order ™ NLINE www.midwestwheel.com 06 Order ™ NLINE www.midwestwheel.com CATALOG NUMBER CATALOG Air Brake Hose Assemblies DUAL LIFESwivel™ HOSE ASSEMBLIES Also available in red and blue BLACK HOSE DUAL LIFESwivel™ HOSE ASSEMBLIES ▪ LIFESwivel™ - a live swivel design Length 1/2” Hose x 3/8” Fittings featuring all brass construction to 18" TC 681866 eliminate corrosion (Patent Pending) 20" TC 682066 ▪ LIFESwivel™ ends allow for movement 22” TC 682266 without binding 24" TC 682466 ▪ Double O-ring leak free “life” design 26" TC 682666 ▪ Barbed hose inserts on both ends 28" TC 682866 provide added durability when crimped 30" TC 683066 ▪ Quick & easy single wrench installs 32" TC 683266 34” TC 683466 ▪ Wide selection of lengths & custom sizes available 36" TC 683666 38” TC 683866 ▪ Meets or exceeds SAE J1402 - Type 40" TC 684066 A - DOT FMVSS - No. 106 Brake Hoses, 49 CFR 571.10 42” TC 684266 44” TC 684466 46” TC 684666 48" TC 684866 50” TC 685066 52” TC 685266 60” TC 686066 Single Swivel End Part Number Fittings Nominal Hose I.D Length TC 16120 1/4" Fixed - 1/4" Swivel 3/8" 20" Air Brake Hose TC 16124 1/4" Fixed - 1/4" Swivel 3/8" 24" TC 16128 1/4" Fixed - 1/4" Swivel 3/8" 28" Assemblies TC 16130 1/4" Fixed - 1/4" Swivel 3/8" 30" TC 16132 1/4" Fixed - 1/4" Swivel 3/8" 32" TC 16134 1/4" Fixed - 1/4" Swivel 3/8" 34" TC 16136 1/4" Fixed - 1/4" Swivel 3/8" 36" ▪ Factory tested to ensure quality TC 18124 3/8" Fixed - 3/8" Swivel 1/2" 24" TC 18126 3/8" Fixed - 3/8" Swivel 1/2" 26" Meets or exceeds SAE J1402 - Type A ▪ TC 18128 3/8" Fixed - 3/8" Swivel 1/2" 28" ▪ Meets or exceeds DOT FMVSS No.