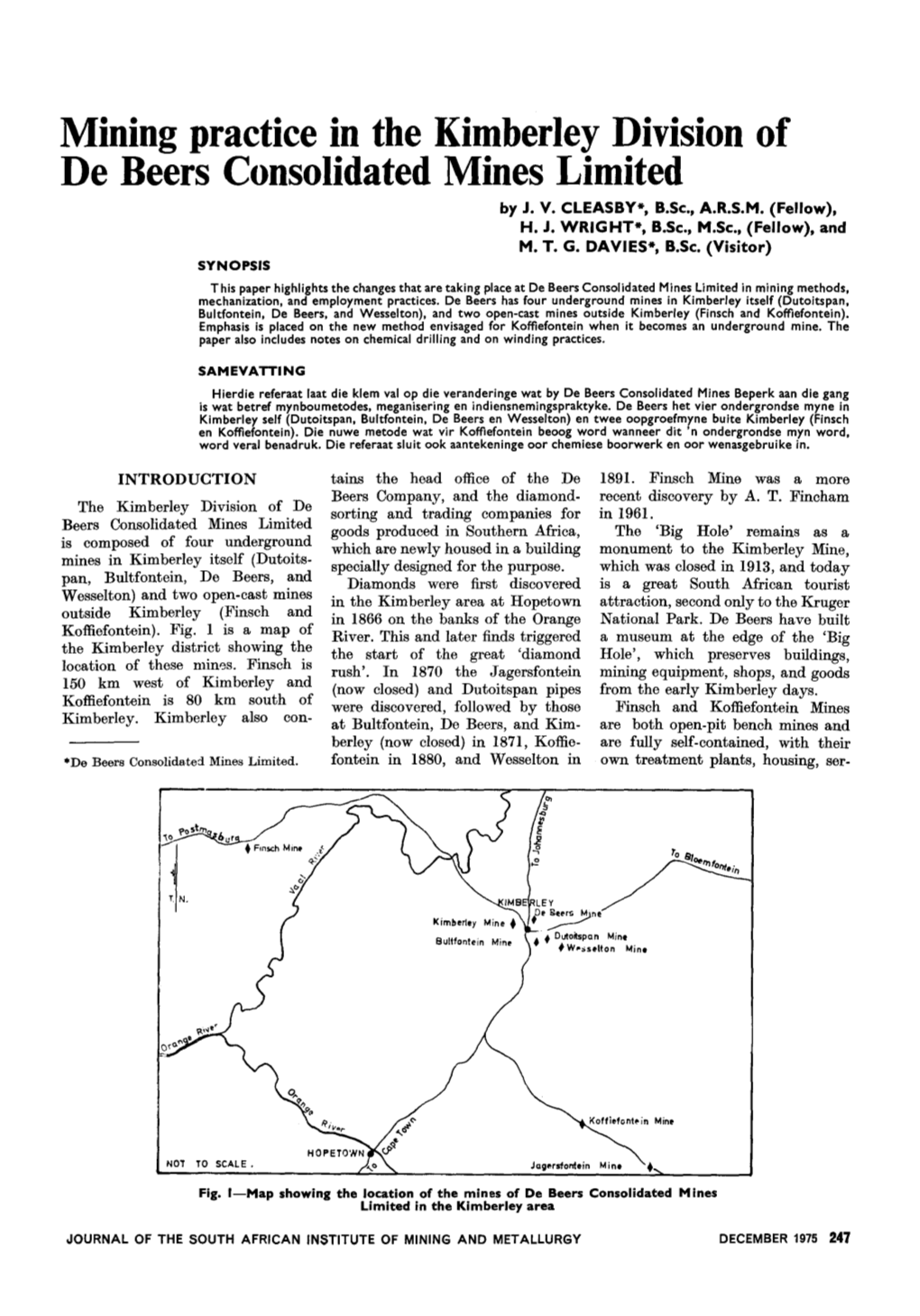

Mining Practice in the Kimberley Division of De Beers Consolidated Mines Limited by J

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Ethical Product Havens in the Global Diamond Trade: Using the Wayback Machine to Evaluate Ethical Market Outcomes

University of South Florida Scholar Commons School of Geosciences Faculty and Staff Publications School of Geosciences 2021 Ethical Product Havens in the Global Diamond Trade: Using the Wayback Machine to Evaluate Ethical Market Outcomes Trina Hamilton State University of New York at Buffalo Seth Cavello University of South Florida, [email protected] Follow this and additional works at: https://scholarcommons.usf.edu/geo_facpub Part of the Earth Sciences Commons Scholar Commons Citation Hamilton, Trina and Cavello, Seth, "Ethical Product Havens in the Global Diamond Trade: Using the Wayback Machine to Evaluate Ethical Market Outcomes" (2021). School of Geosciences Faculty and Staff Publications. 2325. https://scholarcommons.usf.edu/geo_facpub/2325 This Article is brought to you for free and open access by the School of Geosciences at Scholar Commons. It has been accepted for inclusion in School of Geosciences Faculty and Staff Publications by an authorized administrator of Scholar Commons. For more information, please contact [email protected]. This is a pre-print version. The final article is available here: https://doi.org/10.1177%2F0308518X211029661 Citation: Hamilton, T. and S. Cavello. 2021. Ethical product havens in the global diamond trade: Using the Wayback Machine to evaluate ethical market outcomes. Environment and Planning A: Economy and Space. https://doi.org/10.1177%2F0308518X211029661 Ethical product havens in the global diamond trade: Using the Wayback Machine to evaluate ethical market outcomes Abstract Who benefits from ethical product markets? While most ethical products (e.g. fair trade and eco- certified products) are intended to benefit marginalized communities and vulnerable ecosystems, the reality is that the geographic preferences exhibited by so-called ethical markets may, in fact, reinforce global inequities rather than remedy them. -

Building Forever Our Journey

BUILDING FOREVER OUR JOURNEY VOLUME 1 NOVEMBER 2018 ABOUT THIS PUBLICATION Use of ‘our’ or ‘we’ in this report relates to De Beers Group and is used for both wholly-owned and joint venture business entities that De Beers Group has a significant shareholding in. Building Forever: Our Journey, Volume 1 has been prepared in accordance with the core option of the Global Reporting Initiative (GRI) Standards. Further information on the topics covered in this report, and a GRI Index, can be found at www.debeersgroup.com/buildingforever. 200,000 We maintain around 200,000 hectares for conservation – six hectares for every one impacted by mining. DISCLAIMER This publication has been prepared for general guidance on matters of interest only, and does not constitute professional advice. Readers should not act upon the information contained in this publication without obtaining specific professional advice. No representation or warranty (expressed or implied) is given as to the accuracy or completeness of the information contained in this report, and, to the extent permitted by law, the authors and distributors do not accept or assume any liability, responsibility or duty of care for any consequences the reader or anyone else may incur from acting, or refraining from acting, in reliance on the information contained in this publication or for any decision based on it. © De Beers UK Limited 2018. ™, Forevermark Tribute™, TRACR™ and SYNTHdetect™ are trade marks of De Beers Group. BUILDING FOREVER DESCRIBES HOW WE SEEK TO ENSURE THAT ALL OUR ACTIVITIES LEAVE A POSITIVE LASTING LEGACY. THIS IS MORE THAN THE RIGHT THING TO DO. -

DIAMONDS from the DEEP WINDOWS INTO SCIENTIFIC RESEARCH Karen V

DIAMONDS FROM THE DEEP WINDOWS INTO SCIENTIFIC RESEARCH Karen V. Smit and Steven B. Shirey Kimberlites: Earth’s Diamond Delivery System Diamonds are the most amazing of gems. Just as amazing, It took experiments and geochemical analysis to show however, is how natural diamonds reach Earth’s surface. that diamonds do not form as a result of kimberlite reac- Diamonds are formed 150 to 700 km deep in Earth, and are tion with shale. But it would take more than 100 years then carried upward in a rare volcanic eruption of a kim- after the discovery of kimberlite to prove that diamonds berlite magma. Man has never witnessed such an event, do not crystallize out of the kimberlite magma. and the eruption of this magma is thought to be the most The first step in our knowledge about the relationship rapid and violent type of volcanic eruption on Earth. Luck- between diamonds and kimberlites comes from early work ily, since diamond is the hardest mineral, it can usually on how diamond crystallizes. Experiments in the labora- survive such rough handling. This delivery system in the tory showed that the transformation of graphite to dia- form of volcanic transport only adds to the mystique and mond occurred at high pressure and temperature deep value of natural diamond. within the mantle, although we now know most diamond There are two main magma types that carry natural di- forms by other reactions (see Winter 2018 Diamonds from amonds to the surface. These magmas crystallize on cool- the Deep). Subsequently, geoscientists obtained pressure ing into volcanic rocks known as kimberlite and lamproite and temperature constraints for diamond formation (from (see box A). -

Marine Mining of Dimonds Off the West Coast of Southern Africa

By John J. Gurney, Alfred A. Levinson, and 11. Stuart Smith A vast resource of gem-qnality diamonds exists off the west coast of southern @ecausethe continued diamonds supply are the of heartfine ofdiamonds the jewelry from trade, the Africa. Over the course of millions of , - mines into the marketplace is of critical importance to years, many diamond-bearing kimberlite this industry. According to the Central selling Organi- pipes in the Orange River drainage basin sation, about one-eighth (approximately 13 million have been extensively eroded and the carats) of the diamonds now mined annually eventually released diamonds transported to the west coast. Raised marine deposits now end up in jewelry (figure 1). Yet for the largest producer on land have yielded almost 100 million of diamonds in 1990, the Argyle mine in Western carats of predominantly gem diamonds; Australia (36 million carats), fine gem-quality diamonds similar marine deposits and feeder represented only about 5% of the total yield. In addition, channels are now known to exist off- older deposits of gem-quality diamonds are gradually shore. Techniques for exploiting the off- being exhausted. For example, the total production at the shore resources have been proved on a Kimberley pool of mines was 1,173,042 ct in 1980 but small scale in shallow (<I5m) waters. only 574,188 ct in 1990 (De Beers Consolidated Mines New technological developments in Ltd., 1981, 1991). underwater mining systems have In the future, the steady supply of gem diamonds to progressed to the point where mining has the jewelry industry will depend on the discovery of commenced in deep (about 100 m) Namibian waters. -

Heritage Survey for De Beers Consolidated Mines, Koffiefontein Mine

HERITAGE SURVEY FOR DE BEERS CONSOLIDATED MINES, KOFFIEFONTEIN MINE Survey undertaken by Zoë Henderson Archaeologist, National Museum, Bloemfontein P.O. Box 266, Bloemfontein, 9300 Tel: 051 – 447 9609 Fax: 051 – 447 6273 e-mail: [email protected] Date: August/September 2004 CONTENTS Summary of findings…………………………………………………………………… 3 Introduction …………………………………………………………………………….. 3 Areas surveyed …….……..…………………………………………………………….. 4 Archaeological sites ………….………………………………………………………… 5 Industrial Historical Structures ………………………………………………………… 11 Military Sites ……………………………………………………………………………19 Domestic Historical Structures ………………………………………………………….23 Burial Grounds ………………………………………………………………………….26 Other remains on the property ..........................................................................................30 Conclusion ………………………………………………………………………………30 Acknowledgements ……………………………………………………………………..30 References used ………………………………………………………………………... 31 Qualifications of archaeologist ………………………………………………………… 33 Figures ...............................................................................................................................34 Appendix 1 - The black eagles nest ………………………………………………… 118 Appendix 2 - South African Heritage Resource Agency (SAHRA) details ………….. 120 Appendix 3 - Rock engravings ...................................................................................... 121 Appendix 4 - Leaving his mark, an otherwise invisible man ........................................ 123 Appendix 5 - A miner's graveyard at Koffiefontein -

Night Thoughts About Dawn Over the Beloved Country Truman Schwartz Macalester College, [email protected]

Macalester International Volume 9 After Apartheid: South Africa in the New Article 23 Century Fall 12-31-2000 Night Thoughts about Dawn over the Beloved Country Truman Schwartz Macalester College, [email protected] Follow this and additional works at: http://digitalcommons.macalester.edu/macintl Recommended Citation Schwartz, Truman (2000) "Night Thoughts about Dawn over the Beloved Country," Macalester International: Vol. 9, Article 23. Available at: http://digitalcommons.macalester.edu/macintl/vol9/iss1/23 This Article is brought to you for free and open access by the Institute for Global Citizenship at DigitalCommons@Macalester College. It has been accepted for inclusion in Macalester International by an authorized administrator of DigitalCommons@Macalester College. For more information, please contact [email protected]. Night Thoughts about Dawn Over the Beloved Country Truman Schwartz But when that dawn will come, of our emancipation, from the fear of bondage and the bondage of fear, why, that is a secret. For some inexplicable reason, I had never read Alan Paton’s 1948 classic Cry, The Beloved Country before I got to South Africa. When I fin- ished the last lines of the book, at midnight on my last night in Cape Town, I knew I had found an epigraph for this essay. I am afraid that the five weeks I spent in southern Africa, in December 1999 and Janu- ary 2000, did not reveal to me the secret Paton pondered. Perhaps the dawn has already come, in the lifting of restrictions and the end of apartheid in 1990, or in the first free and democratic elections in 1994. -

Geological Survey of Canada, 601 Booth Street

KIMBERLITE DIAMOND DEPOSITS B.A. KJARSGAARD Geological Survey of Canada, 601 Booth Street, Ottawa, Ontario, K1A 0E8 Corresponding author’s email: [email protected] Abstract Diamonds have formed over a significant period of the Earth’s history, from ca. 3.57 Ga to 88 Ma, and probably to present day. Macrodiamonds are interpreted to crystallize from low-density fluids, or carbon- and water-rich melts at pressures >~4.0 GPa and temperatures <~1350°C. These P–T conditions are met within thick, old lithospheric mantle roots that have low paleogeothermal gradients, and these roots lie under ancient continental nuclei. Kimberlite-hosted diamond mines occur in these cratonic shield regions that are older than 2.5 Ga. Macrodiamonds are transported as xenocrysts from the mantle to the surface by kimberlite magmas. The initiation of kimberlite magmatism is at depth in the asthenospheric mantle (>150 km), although the initiation and generation of kimberlite magma is poorly understood. Kimberlites magmas generate a range of rocks that form a wide variety of landforms and intrusions, in many aspects similar to that generated by small-volume alkali basaltic volcanic systems. Kimberlite bodies typically form from mul- tiple intrusive and/or extrusive events; these discrete events form distinct kimberlite phases. These individual kimberlite phases are characterized by differing textures, mineralogy and geochemistry, and diamond grade, size populations and morphology, and value. Résumé Des diamants se sont formés pendant une longue période de l’histoire de la Terre, de 3,57 Ga à 88 Ma environ, et se forment probablement encore de nos jours. Selon diverses interprétations, les macrodiamants se formeraient par cristallisation à partir de fluides de faible densité ou encore de bains magmatiques riches en carbone et en eau à des pressions supérieures à environ 4,0 GPa et à des températures inférieures à environ 1350 oC. -

Kimberley Ex-Pats Newsletter #34 – Milchig and Fleishig Compiled by Geraldine Auerbach MBE, London, 5 February 2021

Kimberley Ex-Pats Newsletter #34 – Milchig and Fleishig Compiled by Geraldine Auerbach MBE, London, 5 February 2021 Showing the connections between De Beers Consolidated Mining Company (Stockdale St Headquarters below) and the Jewish farmers surrounding Kimberley in the early 1900s. Diamonds We have seen that diamonds have been a Jewish preserve for centuries. From the time of the discovery of these precious stones in Griqualand West, Jews flocked to the area – as diggers, brokers and then setting up their little tent offices to buy the stones and send them to Europe. Soon the volume and quality of stones became so great that the European merchants set up their own offices and employed representatives in Kimberley like Julius Wernher and Alfred Beit from Germany (who were representing the French Jewish diamond magnate, Jules Porgès). By the mid-1870s there was a large and growing cohort of sophisticated Western European Jewish diamond entrepreneurs in Kimberley from Germany and France. There were also some clever Jewish boys from London’s East End of like David Harris and his cousins the Barnatos, who arrived barely out of their teens, learned fast and climbed the ladder. Even the heads of the diamond firms like Jules Porgès himself, one of the most successful jewellers and entrepreneurs, dropped his plush mansion life in Paris, to rush out and live for a while in a tent in the windswept, smelly, mining community of the Northern Cape to see for himself what was going on. He also saw to it, that it was worth his while - as he was one of the main (unsung) winners and organisers of the diamond – and gold industries. -

Pretoria to Cape Town

J O U R N E Y I N F O R M A T I O N Pretoria to Cape Town 2018 & 2019 Itinerary The Journey Distance Chart Journey Map The Most Luxurious Train in the World PRETORIA TO CAPE TOWN DAY 1 15h00 The Pride of Africa departs from Rovos Rail Station in Pretoria and travels south via Johannesburg and Germiston towards the goldfields of the Witwatersrand. Guests may freshen up in their suites before joining fellow travellers in the midway lounge car or observation car at the rear of the train. 19h30 Dinner is served in the dining cars. Overnight on the train. DAY 2 07h00 Breakfast is served in the dining cars until 09h45. 09h30 Ten minutes before arriving in Kimberley a shallow lake appears on the right-hand side of the train where, on most occasions, there are spectacular flocks of Lesser Flamingos (approximately 23 000). 09h45 Arrive at the atmospheric railway station of Kimberley. Disembark and proceed via coach/combi for a tour of the renowned city, the Diamond Mine Museum and the extraordinary Big Hole. 12h30 Depart Kimberley and continue on overnight through the Karoo via Beaufort West to Matjiesfontein. 13h00 Lunch is served in the dining cars. 16h30 Tea in the midway lounge car or observation car at the rear of the train. 19h30 Dinner is served in the dining cars. Overnight on the train. DAY 3 07h00 Breakfast is served in the dining cars until 10h00. 08h00 There is a chance for guests to disembark the train at Whitehill Siding and walk the five kilometres into Matjiesfontein. -

Reprocessing Kimberlite Tailings: a Square Contaminant Source in a Big Hole?

REPROCESSING KIMBERLITE TAILINGS: A SQUARE CONTAMINANT SOURCE IN A BIG HOLE? T. HARCK1, M. PETERS2, G. HUBERT1, L. BURGER1, L. OCHIENG’1 1 and T. GERMISHUYSE 1Golder Associates Africa (Pty) Ltd Johannesburg, Gauteng, South Africa; E-mail: [email protected] 2De Beers Kimberley Mines Kimberley, Northern Cape, South Africa; E-mail: [email protected] ABSTRACT The mining town of Kimberley has had a tumultuous and colourful history. The first recorded diamond find was in 1866. Since then the hillock known as Colesberg Kopje has become the famous Big Hole. Five other kimberlite pipes have subsequently been mined out. Remnant piles of mine waste, known as tailings, are scattered throughout the town. In recent times, a finer-grained waste (slimes) has been deposited to the southeast. The groundwater impact of these wastes is the focus of considerable attention by Kimberley Mines. In the past, common belief held that the tailings and slimes were inert and that seepage from these wastes was not of concern. It has been suspected that tailings and slimes may have significant sulphide contents and exposure to rain and oxygen for more than a century may have led to the generation of acid seepage. However, neutralisation potential in the wastes and the arid environment has prevented direct observation of AMD. Diamond recovery at Kimberley has shifted from kimberlite mining to reprocessing of the old tailings. It has been proposed that the reprocessed tailings be returned to the open pits of the mined out kimberlite pipes. The implications of this proposal on groundwater quality over the long-term are not clear. -

Kimberlite-Hosted Diamond Deposits of Southern Africa: a Review Ore

Ore Geology Reviews 34 (2008) 33–75 Contents lists available at ScienceDirect Ore Geology Reviews journal homepage: www.elsevier.com/locate/oregeorev Kimberlite-hosted diamond deposits of southern Africa: A review Matthew Field a,⁎, Johann Stiefenhofer b, Jock Robey c, Stephan Kurszlaukis d a DiaKim Consulting Limited, Mayfield, Wells Road, Wookey Hole Wells, Somerset, BA5 1DN, United Kingdom b De Beers Group Services (Pty) Limited, Mineral Resource Management, P.O. Box 82851, Southdale, 2135, South Africa c De Beers Group Services, PO Box 47, Kimberley, South Africa d De Beers Canada Inc. 65 Overlea Boulevard, Toronto, Ontario, Canada ARTICLE INFO ABSTRACT Article history: Following the discovery of diamonds in river deposits in central South Africa in the mid nineteenth century, it Received 21 November 2006 was at Kimberley where the volcanic origin of diamonds was first recognized. These volcanic rocks, that were Accepted 4 November 2007 named “kimberlite”, were to become the corner stone of the economic and industrial development of Available online 22 April 2008 southern Africa. Following the discoveries at Kimberley, even more valuable deposits were discovered in South Africa and Botswana in particular, but also in Lesotho, Swaziland and Zimbabwe. Keywords: A century of study of kimberlites, and the diamonds and other mantle-derived rocks they contain, has Diamond Kimberlite furthered the understanding of the processes that occurred within the sub-continental lithosphere and in Diatreme particular the formation of diamonds. The formation of kimberlite-hosted diamond deposits is a long-lived Pipe and complex series of processes that first involved the growth of diamonds in the mantle, and later their Dyke removal and transport to the earth's surface by kimberlite magmas. -

Estimating Erosion of Cretaceous-Aged

ESTIMATING EROSION OF CRETACEOUS-AGED KIMBERLITES IN THE REPUBLIC OF SOUTH AFRICA THROUGH THE EXAMINATION OF UPPER-CRUSTAL XENOLITHS A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF MASTERS OF SCIENCE AT RHODES UNIVERSITY BY EMILY KATE HANSON JANUARY 2007 ABSTRACT The estimation of post-emplacement kimberlite erosion in South Africa through the study of upper-crustal xenoliths is relatively unexplored; however the presence of these xenoliths has been recognized for well over 100 years. Post-emplacement erosion levels of a small number of South African kimberlite pipes have been inferred through the study of the degree of country-rock diagenesis, the depth of sill formation, the depth of the initiation of the diatreme and fission track studies. Through these studies, several estimates were proposed for the Group I Kimberley kimberlites. Although the 1400 m estimate of erosion remains widely accepted today, this estimate relies on the presence of Karoo-like basalt xenoliths in the Group I Kimberley kimberlites, as their presence proves that basalt existed in the Kimberley area when the kimberlites were emplaced. Basaltic xenoliths were described during the early stages of mining in Kimberley, though only one of these descriptions suggests that the ‘basaltic’ boulders correlate with the Karoo basalts. Because of the discrepancy between these early documentations of upper-crustal xenoliths and because the occurrence of Karoo-like basalt xenoliths in the Group I Kimberley kimberlites is under question, a re-investigation of the erosion levels and the upper crustal xenolith suites in South African, Cretaceous-aged kimberlites, including Melton Wold, Voorspoed, Roberts Victor, West End, Record Stone Quarry, Finsch, Markt, Frank Smith, Pampoenpoort, Uintjiesberg, Koffiefontein / Ebenheuyser, Monastery, Kimberley (Big Hole), Kamfersdam , Jagersfontein, Kaal Vallei, De Beers, Bultfontein, Lushof, Britstown Cluster, Hebron and Lovedale, was conducted.