EMPIRE and OWNER's MANUAL Comfort Systems

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Catalogue Pilot Film & Television Productions Ltd

productions 2020 Catalogue Pilot Film & Television Productions Ltd. is a leading international television production company with an outstanding reputation for producing and distributing innovative factual entertainment, history and travel led programmes. The company was set up by Ian Cross in 1988; and it is now one of the longest established independent production companies under continuous ownership in the United Kingdom. Pilot has produced over 500 hours of multi-genre programming covering subjects as diverse as history, food and sport. Its award winning Globe Trekker series, broadcast in over 20 countries, has a global audience of over 20 million. Pilot Productions has offices in London and Los Angeles. CONTENTS Mission Statement 3 In Production 4 New 6 Tough Series 8 Travelling in the 1970’s 10 Specials 11 Empire Builders 12 Ottomans vs Christians 14 History Specials 18 Historic Walks 20 Metropolis 21 Adventure Golf 22 Great Railway Journeys of Europe 23 The Story Of... Food 24 Bazaar 26 Globe Trekker Seasons 1-5 28 Globe Trekker Seasons 6-11 30 Globe Trekker Seasons 12-17 32 Globe Trekker Specials 34 Globe Trekker Around The World 36 Pilot Globe Guides 38 Destination Guides 40 Other Programmes 41 Short Form Content 42 DVDs and music CDs 44 Study Guides 48 Digital 50 Books 51 Contacts 52 Presenters 53 2 PILOT PRODUCTIONS 2020 MISSION STATEMENT Pilot Productions seeks to inspire and educate its audience by creating powerful television programming. We take pride in respecting and promoting social, environmental and personal change, whilst encouraging others to travel and discover the world. Pilot’s programmes have won more than 50 international awards, including six American Cable Ace awards. -

Not for Publication United States Court of Appeals

NOT FOR PUBLICATION FILED AUG 28 2020 UNITED STATES COURT OF APPEALS MOLLY C. DWYER, CLERK FOR THE NINTH CIRCUIT U.S. COURT OF APPEALS EHM PRODUCTIONS, INC., DBA TMZ, a No. 19-55288 California corporation; WARNER BROS. ENTERTAINMENT INC., a Delaware D.C. No. corporation, 2:16-cv-02001-SJO-GJS Plaintiffs-Appellees, MEMORANDUM* v. STARLINE TOURS OF HOLLYWOOD, INC., a California corporation, Defendant-Appellant. Appeal from the United States District Court for the Central District of California S. James Otero, District Judge, Presiding Argued and Submitted August 10, 2020 Pasadena, California Before: WARDLAW and CLIFTON, Circuit Judges, and HILLMAN,** District Judge. Starline Tours of Hollywood, Inc. (Starline) appeals the district court’s * This disposition is not appropriate for publication and is not precedent except as provided by Ninth Circuit Rule 36-3. ** The Honorable Timothy Hillman, United States District Judge for the District of Massachusetts, sitting by designation. orders dismissing its First Amended Counterclaim (FACC) and denying its motion for leave to amend. We dismiss this appeal for lack of appellate jurisdiction. 1. Under 28 U.S.C. § 1291, the courts of appeals have jurisdiction over “final decisions of the district court.” Nat’l Distrib. Agency v. Nationwide Mut. Ins. Co., 117 F.3d 432, 433 (9th Cir. 1997). Generally, “a voluntary dismissal without prejudice is ordinarily not a final judgment from which the plaintiff may appeal.” Galaza v. Wolf, 954 F.3d 1267, 1270 (9th Cir. 2020) (cleaned up). A limited exception to this rule—which Starline seeks to invoke—permits an appeal “when a party that has suffered an adverse partial judgment subsequently dismisses its remaining claims without prejudice with the approval of the district court, and the record reveals no evidence of intent to manipulate our appellate jurisdiction.” James v. -

MOULDINGS | STAIR PARTS | BOARDS | EXTERIOR MILLWORK MIDWEST CHICAGO DISTRIBUTION CENTER Our Our STORY FAMILY DEEP ROOTS

MOULDINGS | STAIR PARTS | BOARDS | EXTERIOR MILLWORK MIDWEST CHICAGO DISTRIBUTION CENTER our our STORY FAMILY DEEP ROOTS. HIGH STANDARDS. BRIGHT FUTURE. EMPIRE IS NOW A PART OF THE NOVO FAMILY. Founded in 1946 Empire has grown into With a geographic footprint that touches Novo Building Products is the industry door shops, retail home centers, and one of the largest millwork distribution the majority of the eastern half of the leading manufacturer and distributor of millwork manufacturing partners and manufacturing companies in the United States, Empire is positioned for mouldings, stair parts, doors, and specialty throughout the United States and parts United States. continued expansion. building products. We are proud to serve of Canada and Mexico. LJ Smith building material dealers (lumberyards), Puyallup, WA L.J. Smith Learn more at . Salem, NH novobp.com Empire Zeeland, MI L.J. Smith Empire A llentown, PA Empire Bowerston, OH Channahon, IL L.J. Smith West Valley City, UT Empire REFRESH. Ornamental Mouldings Empire Archdale, NC Dallas, TX L.J. Smith Ball Ground, GA L.J. Smith Corona, CA Southwest Dallas, TX REVIVE. L.J. Smith Empire Houston, TX Lakeland, FL RENEW. 2 empireco.com | 800.253.9000 empireco.com | 800.253.9000 3 Style is individual, personal, and unique. Make your room a reflection of you... DISCOVER YOUR STYLE HERE Achieve a similar look using: P 450 Chair Rail | 041 Crown | 5030 Architrave | 312 Casing | L 163E Base Colonial, Ranch, Traditional, Midwestern, Early American, Inviting and Timeless... The new and improved Empireco.com. Explore our comprehensive collections of mouldings, Classic Classic Mouldings enhance any home style from Midwestern to stair parts, boards, and exterior millwork as well Early American, and blend perfectly with the classic style furnishing as find inspiration for every room in the home. -

Boardwalk Empire

BOARDWALK EMPIRE "Pilot" Written by Terence Winter FIRST DRAFT April 16, 2008 EXT. ATLANTIC OCEAN - NIGHT With a buoy softly clanging in the distance, a 90-foot fishing schooner, the Tomoka, rocks lazily on the open ocean, waves gently lapping at its hull. ON DECK BILL MCCOY, pensive, 40, checks his pocket watch, then spits tobacco juice as he peers into the darkness. In the distance, WE SEE flickering lights, then HEAR the rumble of motorboats approaching, twenty in all. Their engines idle as the first pulls up and moors alongside. BILL MCCOY (calling down) Sittin' goddarnn duck out here. DANNY MURDOCH, tough, 30s, looks up from the motorboat, where he's accompanied by a YOUNG HOOD, 18. MURDOCH So move it then, c'mon. ON DECK McCoy yankS a canvas tarp off a mountainous stack of netted cargo -- hundreds of crates marked 'Canadian Club Whiskey·. With workmanlike precision, he and .. three CREWMAN hoist the first load of two dozen crates up and over the side, lowering it down on a pulley. As the net reaches the motorboat: MURDOCH (CONT'D) (to the Young Hood) Liquid gold, boyo. They finish setting the load in place, then Murdoch guns the motorboat and heads off. Another boat putters in to take his slot as the next cargo net is lowered. TRACK WITH MURDOCH'S MOTORBOAT as it heads inland through the darkness over the water. Slowly, a KINGDOM OF LIGHTS appears on the horizon, with grand hotels, massive neon signs, carnival rides and giant lighted piers lining its shore. As we draw closer, WE HEAR faint music which grows louder and LOUDER -- circus calliope mixed with raucous Dixieland jazz. -

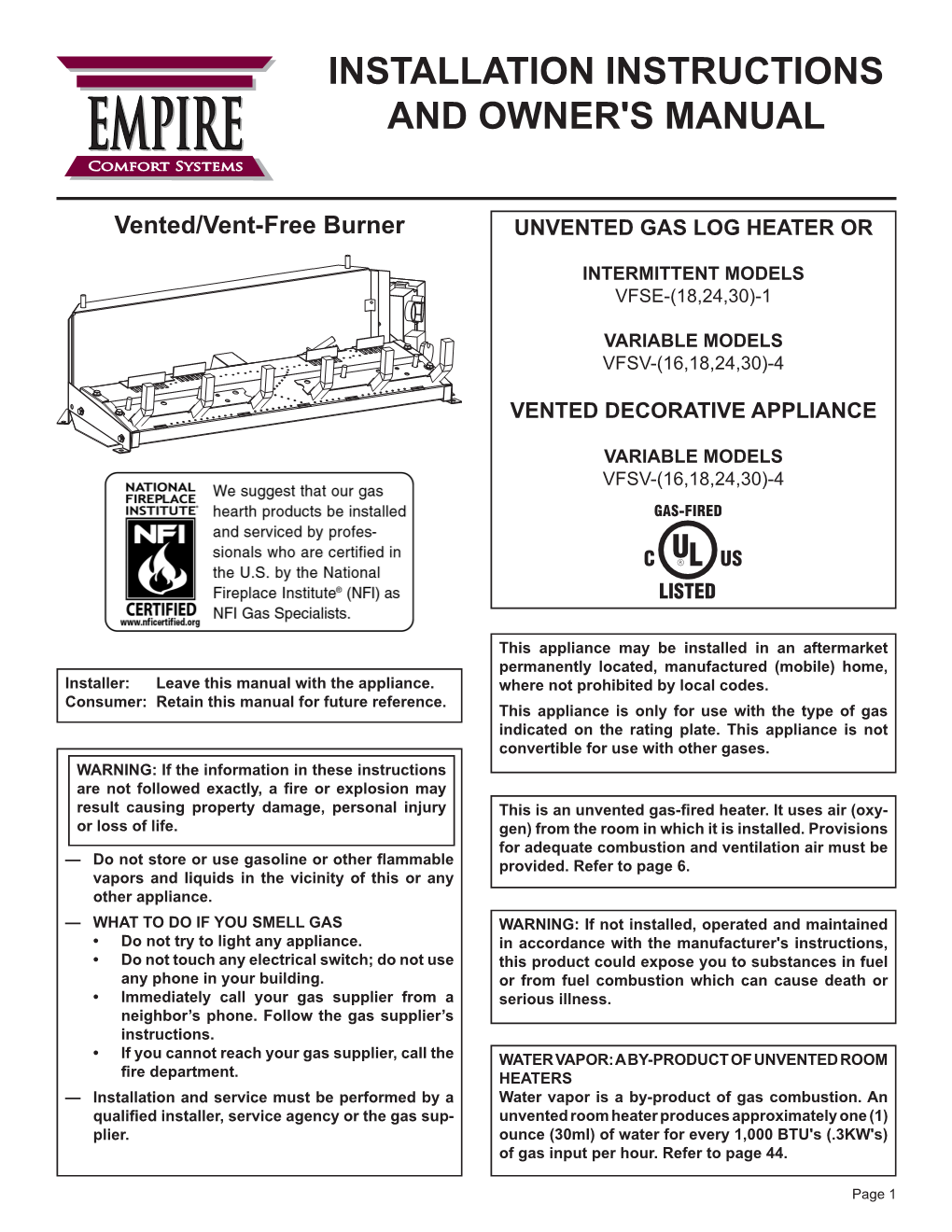

Installation INSTRUCTIONS and OWNER's MANUAL

Installation INSTRUCTIONS AND OWNER'S MANUAL UNVENTED ROOM HEATER MODELS SR-10TW-1 SR-18TW-1 SR-30TW-1 WARNING SR-30TW SHOWN If not installed, operated and maintained in accordance with the manufacturer’s INSTALLER: instructions, this product could expose you Leave this manual with the appliance. to substances in fuel or from fuel combustion CONSUMER: which can cause death or serious illness. Retain this manual for future reference. WARNING “FIRE, EXPLOSION, AND ASPHYXIATION HAZARD WARNING Improper adjustment, alteration, service, FIRE OR EXPLOSION HAZARD maintenance, or installation of this heater or Failure to follow safety warnings exactly its controls can cause death or serious injury. could result in serious injury, death or Read and follow instructions and precautions property damage. in User’s Information Manual provided with — Do not store or use gasoline or other this heater.” flammable vapors and liquids in the This is an unvented gas-fired heater. It vicinity of this or any other appliance. uses air (oxygen) from the room in which — WHAT TO DO IF YOU SMELL GAS it is installed. Provisions for adequate • Do not try to light any appliance. combustion and ventilation air must be • Do not touch any electrical switch; do provided. Refer to page 6. not use any phone in your building. • Leave the building immediately. WATER VAPOR: A BY-PRODUCT OF UNVENTED • Immediately call your gas supplier ROOM HEATERS from a neighbor’s phone. Follow the Water vapor is a by-product of gas combustion. gas supplier’s instructions. An unvented room heater produces approximately • If you cannot reach your gas supplier, one (1) ounce (30ml) of water for every 1,000 BTU’s call the fire department. -

From Disney to Disaster: the Disney Corporation’S Involvement in the Creation of Celebrity Trainwrecks

From Disney to Disaster: The Disney Corporation’s Involvement in the Creation of Celebrity Trainwrecks BY Kelsey N. Reese Spring 2021 WMNST 492W: Senior Capstone Seminar Dr. Jill Wood Reese 2 INTRODUCTION The popularized phrase “celebrity trainwreck” has taken off in the last ten years, and the phrase actively evokes specified images (Doyle, 2017). These images usually depict young women hounded by paparazzi cameras that are most likely drunk or high and half naked after a wild night of partying (Doyle, 2017). These girls then become the emblem of celebrity, bad girl femininity (Doyle, 2017; Kiefer, 2016). The trainwreck is always a woman and is usually subject to extra attention in the limelight (Doyle, 2017). Trainwrecks are in demand; almost everything they do becomes front page news, especially if their actions are seen as scandalous, defamatory, or insane. The exponential growth of the internet in the early 2000s created new avenues of interest in celebrity life, including that of social media, gossip blogs, online tabloids, and collections of paparazzi snapshots (Hamad & Taylor, 2015; Mercer, 2013). What resulted was 24/7 media access into the trainwreck’s life and their long line of outrageous, commiserable actions (Doyle, 2017). Kristy Fairclough coined the term trainwreck in 2008 as a way to describe young, wild female celebrities who exemplify the ‘good girl gone bad’ image (Fairclough, 2008; Goodin-Smith, 2014). While the coining of the term is rather recent, the trainwreck image itself is not; in their book titled Trainwreck, Jude Ellison Doyle postulates that the trainwreck classification dates back to feminism’s first wave with Mary Wollstonecraft (Anand, 2018; Doyle, 2017). -

Lee Daniels on Empire: the Show Has Already Changed Homophobes' Minds

8/15/2018 Empire on Fox: Lee Daniels on his Show's Effect on Homophobia | Time Lee Daniels on Empire: The Show Has Already Changed Homophobes' Minds Lee Daniels on Dec. 1, 2014 in New York City. Theo Warg—Getty Images / IFP By LILY ROTHMAN January 7, 2015 Lee Daniels is best known as the lmmaker behind gritty independent lms like Precious, but his new project is the slick primetime drama Empire, premiering Jan. 7 on Fox, which he co-created with Danny Strong. Daniels recently spoke to TIME about the show, and how — despite not being independently made — http://time.com/3656583/lee-daniels-empire/ 1/3 8/15/2018 Empire on Fox: Lee Daniels on his Show's Effect on Homophobia | Time it’s a personal story. The Shakespeare-inected tale of record mogul Lucious Lyon (Terrence Howard), his ex-wife Cookie (Taraji P. Henson) and their sons Andre, Jamal and Hakeem, often draws on stories from his own life. And, he tells TIME, the show is already making a difference toward his larger aim of increasing tolerance among its audience: TIME: You’ve told a story about trying on your mother’s shoes as a child. There’s a scene in the Empire pilot that sounds very similar to that episode, where Lucious reacts to seeing his young son do just that… Lee Daniels: I was terried of that scene. My sister was an extra — she’s in the scene — and when the kid put the shoes on, having him walk in front of his father, I had a meltdown. -

Shakespeare Unlimited: How King Lear Inspired Empire

Shakespeare Unlimited: How King Lear Inspired Empire Ilene Chaiken, Executive Producer Interviewed by Barbara Bogaev A Folger Shakespeare Library Podcast March 22, 2017 ---------------------------- MICHAEL WITMORE: Shakespeare can turn up almost anywhere. [A series of clips from Empire.] —How long you been plannin’ to kick my dad off the phone? —Since the day he banished me. I could die a thousand times… just please… From here on out, this is about to be the biggest, baddest company in hip-hop culture. Ladies and gentlemen, make some noise for the new era of Hakeem Lyon, y’all… MICHAEL: From the Folger Shakespeare Library, this is Shakespeare Unlimited. I‟m Michael Witmore, the Folger‟s director. This podcast is called “The World in Empire.” That clip you heard a second ago was from the Fox TV series Empire. The story of an aging ruler— in this case, the head of a hip-hop music dynasty—who sets his three children against each other. Sound familiar? As you will hear, from its very beginning, Empire has fashioned itself on the plot of King Lear. And that‟s not the only Shakespeare connection to the program. To explain all this, we brought in Empire’s showrunner, the woman who makes everything happen on time and on budget, Ilene Chaiken. She was interviewed by Barbara Bogaev. ---------------------------- BARBARA BOGAEV: Well, Empire seems as if its elevator pitch was a hip-hop King Lear. Was that the idea from the start? ILENE CHAIKEN: Yes, as I understand it, now I didn‟t create Empire— BOGAEV: Right, because you‟re the showrunner, and first there‟s a pilot, and then the series gets picked up, and then they pick the showrunner. -

Boardwalk Empire’ Comes to Harlem

ENTERTAINMENT ‘Boardwalk Empire’ Comes to Harlem By Ericka Blount Danois on September 9, 2013 “One looks down in secret and sees many things,” Dr. Valentin Narcisse (Jeffrey Wright) deadpans, speaking to Chalky White (Michael K. Williams). “You know what I saw? A servant trying to be a king.” And so begins a dance of power, politics and personality between two of the most electrifying, enigmatic actors on the television screen today. Each time the two are on screen—together or apart—they breathed new life into tonight’s premiere episode of Boardwalk Empire season four, with dark humor, slight smiles, powerful glances, smart clothes and killer lines. Entitled “New York Sour,” the episode opened with bombast, unlike the slow boil of previous seasons. Set in 1924, we’re introduced to the tasteful opulence of Chalky White’s new club, The Onyx, decorated with sconces custom-made in Paris and shimmering, shapely dancing girls. Chalky earned an ally, and eventually a partnership to be able to open the club, with former political boss and gangster Nucky Thompson (Steve Buscemi) by saving Nucky’s life last season. This sister club to the legendary Cotton Club in Harlem is Whites-only, but features Black acts. There are some cringe-worthy moments when Chalky, normally proud and infallible, has to deal with racism and bends over to appease his White clientele. But more often, Chalky—a Texas- born force to be reckoned with—breathes an insistent dose of much needed humor into what sometimes devolves into cheap shoot ’em up thrills this season. The meeting of the minds between Narcisse and Chalky takes root in the aftermath of a mistake by Chalky’s right hand man, Dunn Purnsley (Erik LaRay Harvey), who engages in an illicit interracial tryst that turns out to be a dramatic, racially-charged sex game gone horribly wrong. -

Redalyc.SUGAR, EMPIRE, and REVOLUTION in EASTERN CUBA

Caribbean Studies ISSN: 0008-6533 [email protected] Instituto de Estudios del Caribe Puerto Rico Casey, Matthew SUGAR, EMPIRE, AND REVOLUTION IN EASTERN CUBA: THE GUANTÁNAMO SUGAR COMPANY RECORDS IN THE CUBAN HERITAGE COLLECTION Caribbean Studies, vol. 42, núm. 2, julio-diciembre, 2014, pp. 219-233 Instituto de Estudios del Caribe San Juan, Puerto Rico Available in: http://www.redalyc.org/articulo.oa?id=39240402008 How to cite Complete issue Scientific Information System More information about this article Network of Scientific Journals from Latin America, the Caribbean, Spain and Portugal Journal's homepage in redalyc.org Non-profit academic project, developed under the open access initiative SUGAR, EMPIRE, AND REVOLUTION IN EASTERN CUBA... 219 SUgAR, EMPIRE, AND REVOLUTION IN EASTERN CUBA: ThE gUANTáNAMO SUgAR COMPANy RECORDS IN ThE CUBAN hERITAgE COLLECTION Matthew Casey ABSTRACT The Guantánamo Sugar Company Records in the Cuban Heritage Col- lection at the University of Miami represent some of the only accessible plantation documents for the province of Guantánamo in republican Cuba. Few scholars have researched in the collection and there have not been any publications to draw from it. Such a rich collection allows scholars to tie the province’s local political, economic, and social dynamics with larger national, regional, and global processes. This is consistent with ongoing scholarly efforts to understand local and global interactions and to pay more attention to regional differences within Cuba. This research note uses the records to explore local issues of land, labor, and politics in republican-era Guantánamo in the context of larger national and international processes. -

Matthew J. Blevins, Vice President, Empire Stock Transfer Inc

\JHf Empire Stock Transfer Inc. 1859 Whitney Mesa Dr. Henderson, NV 89014 KECEIVED January 15,2014 JAN 16 2014 Elizabeth M. Murphy OFFICbOHHESFrpcTi.gg Secretary U.S. Securities and Exchange Commission 100 F Street, NE Washington, DC 20549 Dear Ms. Murphy: Today I am responding on behalf of Empire Stock Transfer Inc. with respect to the Securities and Exchange Commission's Crowdfunding rule proposal, Release Nos. 33-9470; 34-70741; File No. S7-09-13. " The Securities and Exchange Commission, the "Commission", is proposing for comment new Regulation Crowdfunding under the Securities Act of 1933 and the Securities Exchange Act of 1934 to implement the requirements of Title III of the Jumpstart Our Business Startups Act. Regulation Crowdfunding would prescribe rules governing the offer and sale of securities under new Section 4(a)(6) ofthe Securities Act of 1933. The proposal also would provide a framework for the regulation of registered funding portals and brokers that issuers are required to use as intermediaries in the offer and sale of securities in reliance on Section 4(a)(6). In addition, the proposal would exempt securities sold pursuant to Section 4(a)(6) from the registration requirements ofSection 12(g) of the Securities Exchange Act of 1934. Empire Stock Transfer Inc., "Empire", is a stock transfer agent with operations in the United States. Our clients, whom are primarily small-cap issuers, are located throughout the world. Empire assists private startups as well as publicly-traded companies in their efforts to maintain a compliant and healthy shareholder relationship. How does the Commission view a transfer agent? http://www.sec.gov/divisions/marketreg/mrtransfer.shtml Transfer agents record changes of ownership, maintain the issuer's security holder records, cancel and issue certificates, and distribute dividends. -

BT TM-15 Manual.Pdf

BT_TM-15_Manual.qxp 6/17/09 5:23 PM Page C OWNER’S MANUAL BTPAINTBALL.COM BT_TM-15_Manual.qxp 6/17/09 5:23 PM Page D CONTENTS Page 1. Rules for Safe Marker Handling 1 2. Introduction and Specifications 1 3. Battery Replacement and Life Indicator 1 4. Compressed Air/Nitrogen Supply 2 5. Basic Operation 2 6. Firing the TM-15 4 7. Break Beam Eyes Operation 4 8. Unloading the TM-15 5 9. Regulator and Velocity Adjustments 5 10. Programming 6 11. Setting Functions 7 12. Trigger Adjustments 9 13. General Maintenance 10 14. Assembly/Disassembly Instructions 11 15. Storage and Transportation 14 16. Troubleshooting Guide 14 For manuals and warranty details, go to: 17. Diagrams and Parts List 17 paintballsolutions.com WARRANTY (Inside Back Cover) For manuals in other languages, (where appli- cable), go to:paintballsolutions.com ©2009 BT Paintball Designs, Inc. The BT Shield, “Battle Tested” and “TM-15” are trademarks of NEITHER BT PAINTBALL DESIGNS, INC. NOR ANY OF ITS PRODUCTS ARE AFFILIATED WITH TIPPMANN SPORTS, LLC. BT Paintball Designs, Inc. All rights reserved. BTPAINTBALL.COM BT_TM-15_Manual.qxp 6/17/09 5:23 PM Page 1 1. Rules for Safe Marker Handling nology. The TM-15 is precision engineered from magnesium alloy, aircraft- IMPORTANT: Never carry your TM-15 uncased when not on a playing grade aluminum, and composite materials. We expect you to play hard and field. The non-playing public and law enforcement personnel may not be play frequently and the TM-15 was built with this in mind. able to distinguish between a paintball marker and firearm.