Fact Sheet on Hydrated Lime for Masonry Purposes

Total Page:16

File Type:pdf, Size:1020Kb

Load more

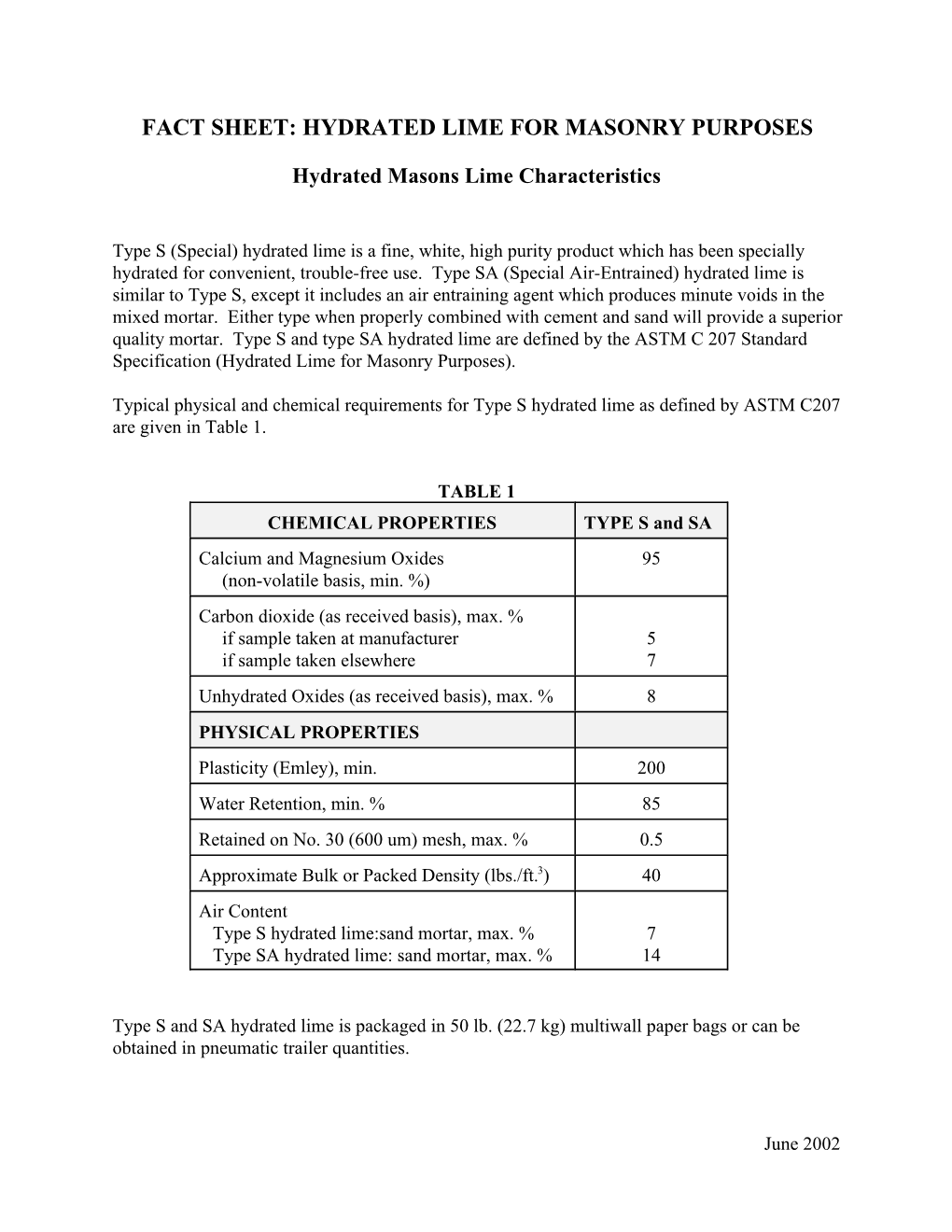

Recommended publications

-

SAFETY DATA SHEET Quicklime

Quicklime Conforms to HazCom 2012/United States SAFETY DATA SHEET Quicklime Section 1. Identification GHS product identifier : Quicklime Other means of identification : Snowbright Quicklime, Quicklime, High calcium quicklime, Pebble lime, Hi Cal, Unslaked lime, Calcium Oxide, CaO, Type S, Type N, Calcined limestone, Burnt lime, Chemical lime Identified uses : Water treatment, Caustic agent, pH adjustment, Neutralization, Acid gas absorption, Construction Supplier's details : Pete Lien & Sons, Inc. PO Box 440 Rapid City, SD 57702 Emergency telephone : (605) 342-7224 (Monday-Friday 8am-5pm) number (hours of operation) Section 2. Hazards identification Classification of the : SKIN IRRITATION - Category 2 substance or mixture EYE DAMAGE - Category 1 SPECIFIC TARGET ORGAN TOXICITY SINGLE EXPOSURE [Respiratory System] - Category 3 SPECIFIC TARGET ORGAN TOXICITY REPEAT EXPOSURE [Respiratory System] - Category 1 CARCINOGEN - Category 1A GHS label elements Hazard pictograms : Signal word : Danger Hazard statements : Causes skin irritation. Causes serious eye damage. May cause cancer through inhalation. May cause respiratory irritation. Reacts violently with water, releasing heat, which can ignite combustible material. Causes damage to lungs through prolonged and repeated exposure. Precautionary statements Prevention : Wear protective gloves/protective clothing/face protection /eye protection. Wash exposed skin thoroughly after handling. Use only outdoors or in a well-ventilated area. Obtain special instructions before use. Do not handle until all safety precautions have been read and understood. Do not breathe dust. Do not eat, drink or smoke when using this product. 1/7 Quicklime Response : IF ON SKIN: Wash exposed skin with plenty of water. If skin irritation occurs: Get medical attention. Take off contaminated clothing and wash it before reuse. -

Specialists Q & a on the Use of Lime Plastering

posed to much less water making it less reactive but retaining its dry nature as a powdered product so it Q To avoid shrinkage, should hair be added to never matures to become a good binder in its own the lime mix? form. Hydrate is used as a plasticiser for cement Hair is added to help lime mortars bind or hold mixes. Hydraulic lime is a powder and also burnt A but the limestone is not pure calcium carbonate onto laths but can still shrink and crack if cured too Specialists Q & A on the and contains impurities such as clays and silicates quickly. Hair is always used on lath and plaster work which change the reactive nature of the lime and but is not necessary on brickwork. use of lime plastering allow it to set chemically when exposed to water. Q How do l make a lime wash? Q What type of lime should be used for lime A Lime wash is simply lime putty, water and a mineral pig- plastering? Q What are the advantages of using lime plas- ment, and for external use a water repellent such as linseed or tallow is added. ter? A Lime plaster can be made with lime putty or hydraulic lime but hydrate is too weak. Putty is best Q Can lime plaster be applied to plasterboard? A They allow buildings to breathe which is essential for ceilings and lath work as it has better flexural for older buildings that have been constructed with strength and sticks well to laths. Hydraulic lime is A The only benefit to applying a lime plaster to lime fine as a hard wall plaster where there is no move- plasterboard is the aesthetic look, however this mortars and soft bricks or stone. -

Different Types of Building Limes

Different types of building limes Natural hydraulic limes are made from limestone that contains impurities such as clay or silicates. Unlike lime putty which is non-hydraulic lime, NHLs can set in damp conditions, indeed they require water for a minimum period of around 72 hours to gain maximum strength. They also have some free lime available for carbonation. There are three European classifications NHL 2, NHL3.5 and NHL5 based on the compressive strength of laboratory mortars after 28 days. These are often somewhat misleadingly termed feebly hydraulic, moderately hydraulic and eminently hydraulic. We generally recommend the use of NHLs where the need for breathability and lower strength is outweighed by the desire for an earlier and harder set such as working on bedding hard masonry, wall copings, chimneys and slate floors. In some circumstances hydraulic lime mortars can be used for rendering or plastering. The strength of a hydraulic lime mortar (HLM) varies depending on the manufacturer of the hydraulic lime as some NHL will be high in the band or low. HLM will also vary depending on the ratio of lime binder to aggregate and the type of aggregate or sand used. Natural Hydraulic Lime (NHL) NHL or Natural Hydraulic Lime, comes from limestone that has natural impurities of clay and other minerals, the amount of impurities within it determines how hard it will set. NHL works by setting in the presence of water, hence the term Hydraulic: Natural hydraulic lime powders come in 3 European grades: GRADE STRENGTH(MPa) EXAMPLES OF USE NHL2 >2 to <7 Pointing internally or with soft masonry, plastering NHL3.5 >3.5 to <10 Bedding, pointing NHL5 >5 to <15 Flooring, below DPC or chimney flaunchings NHL's can be used when speed is essential as it sets much quicker than a Lime Putty based mortar. -

The Effect of Linseed Oil on the Properties of Lime-Based Restoration Mortars

Allma Mater Studiiorum – Uniiversiità dii Bollogna DOTTORATO DI RICERCA Science for Conservation Ciclo XXII Settore/i scientifico disciplinari di afferenza: CHIM/12 TITOLO TESI THE EFFECT OF LINSEED OIL ON THE PROPERTIES OF LIME-BASED RESTORATION MORTARS Presentata da: Eva Čechová Coordinatore Dottorato Relatore Prof. Rocco Mazzeo Prof. Ioanna Papayianni Esame finale anno 2009 Abstract THE EFFECT OF LINSEED OIL ON THE PROPERTIES OF LIME-BASED RESTORATION MORTARS The traditional lime mortar is composed of hydrated lime, sand and water. Besides these constituents it may also contain additives aiming to modify fresh mortar´s properties and/or to improve hardened mortar´s strength and durability. Already in the first civilizations various additives were used to enhance mortar´s quality, among the organic additives, linseed oil was one of the most common. From literature we know that it was used already in Roman period to reduce water permeability of a mortar, but the mechanism and the technology, e.g. effects of different dosages, are not clearly explained. There are only few works studying the effect of oil experimentally. Knowing the function of oil in historical mortars is important for designing a new compatible repair mortar. Moreover, linseed oil addition could increase the sometimes insufficient durability of lime-based mortars used for reparation and it could be a natural alternative to synthetic additives. In the present study, the effect of linseed oil on the properties of six various lime- based mortars has been studied. Mortars´ compositions have been selected with respect to composition of historical mortars, but also mortars used in a modern restoration practise have been tested. -

Agricultural Lime Recommendations Based on Lime Quality E.L

University of Kentucky College of Agriculture, Food and Environment ID-163 Cooperative Extension Service Agricultural Lime Recommendations Based on Lime Quality E.L. Ritchey, L.W. Murdock, D. Ditsch, and J.M. McGrath, Plant and Soil Sciences; F.J. Sikora, Division of Regulatory Services oil acidity is one of the most important soil factors affect- Figure 1. Liming acid soils increases exchangeable Ca and Mg. Sing crop growth and ultimately, yield and profitability. It is determined by measuring the soil pH, which is a measure Acid Soil Limed Soil Ca2+ H+ H+ Ca2+ Ca2+ of the amount of hydrogen ions in the soil solution. As soil Lime Applied H+ H+ H+ H+ Ca2+ acidity increases, the soil pH decreases. Soils tend to be + + + 2+ + naturally acidic in areas where rainfall is sufficient to cause H H H Mg H substantial leaching of basic ions (such as calcium and mag- nesium), which are replaced by hydrogen ions. Most soils in Kentucky are naturally acidic because of our abundant rainfall. Nitrogen fertilization can also contribute to soil acid- The majority of the hydrogen ions are actually held on ity as the nitrification of ammonium increases the hydrogen cation exchange sites. To effectively neutralize soil acidity, ion concentration in the soil through the following reaction: hydrogen ions must be removed from both the soil solution and the exchange sites. While soil pH only measures the solu- + - - + NH4 + 2O2 --> NO3 = H2O + 2H tion hydrogen, the buffer pH is an indication of exchangeable acidity and how much ag lime is actually needed. It is possible Periodically, agricultural limestone (ag lime) is needed to for two soils to have the same water pH but different lime neutralize soil acidity and maintain crop productivity. -

ADDIS ABABA UNIVERSITY the Effect of Egg and Lime on The

ADDIS ABABA UNIVERSITY ADDIS ABABA INSTITUTE OF TECHNOLOGY SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING The Effect of Egg and Lime on the Compressive Strength of Mortar By: - Neima Yesuf Advisor: - Dr. Esayas G/Yohannes A thesis submitted as a Partial Fulfillment of the Requirements for the degree of Masters of Science in Structural Engineering August 2014 1 Acknowledgment First of all I would like to thank Addis Ababa institute of Technology for giving me this opportunity to conduct this interesting research. And I would like to thank Dr Esayas G/yohannes for giving me great advices during this research. And I would like to give my gratitude for W/t Yewubdar Eshetu, Ato Daniel Kibret, Ato Getachew Asrat, Ato Sirahbizu W/senbet, Ato Wubale, my family and close friends and all those that contributed in different ways in making this research happen. 2 ABSTRACT The Effect of Egg and Lime on the Compressive strength of Mortar Neima Yesuf Addis Ababa University, 2014 In Ethiopia there is a saying that tells buildings like Fasiledes castle of Gondar were built from materials that did not include cement. This saying describes the buildings as made from stones using lime mortar, consisting of sand, lime and egg parts, as a binder. This saying gave a motivation for this research to investigate the effect of egg parts on the compressive strength of mortar. This research concentrates on the effect of egg albumin and egg shell on the compressive strength of mortar since there is already good known material on lime and the effect of the egg albumin and egg shell with regards to cement can be studied on mortar without the addition of aggregates. -

A Study of Lime and Fly Ash with Regard to Soil Stabilization

COMMONWEALTH OF KENTUCKY DEPARTMENT OF HIGHWAYS FRANKFORT April 28, 1958 ADDRESS REPLY TO DEPARTMENT OF HIGHWAYS MATERIALS RESEARCH LABORATORY 132 GRAHAM AVENUE LEXINGTON 29, KENTUCKY C.Z. 7. D.l. 7. MEMO TO: D. V. Terrell Director of Research The attached report, "A Study of the Use of a Local Fly Ash in Concrete Mixes", by Frank D. Whitney, represents two approaches to the addition of fly ash to portland cement concrete. Certain percentages of cement were replaced with the fly ash for one series of inve sti.gations and for the other the cement content wa.s kept constant and the fly ash was used to replace sand. It was found that 25% of the cement could be replaced with the fly ash without detrimental losses, to the 28- and 60-day compressive strengths.· The 7-day strengths were lowered for the cement replacement tests. This report outlines procedures that are required to obtain durable concrete while replacing either 25% of the sand or 25% of the cement with fly ash, depending upon the particular economic situation or shortage of materiaL The findings here reported may be of considerable value to the department, especially if materia\ shortages should develop. Respectfully submitted, W. B. Drake Associate Director of Research WBD:dl Enc. cc: Resea):"ch Committee Members Bureau of Public Roads (3) COMMONWEALTH OF KENTUCKY DEPARTMENT OF HIGHWAYS FRANKFORT April 23, 1958 ADDRESS REPLY TO DEPARTMENT OF HIGHWAYS MATERIALS RESEARCH LABORATORY 132 GRAHAM AVENUE LEXINGTON 29, KENTUCKY D.l. 7. B. 3. 6. MEMO TO: D. V. Terrell Director of Research There are two large hydrated lime stockpiles in Kentucky. -

VIRGINIA's LIME INDUSTRY Palmer C.Sweet

Vol. 32 November 1986 No. 4 VIRGINIA'S LIME INDUSTRY Palmer C.Sweet Lime production in Virginia continued on the materials that contain at least 97 percent com- increase in 1985 after a four-year decline from bined calcium and magnesium carbonate content 1980-1983. Production tonnages and values are are considered necessary for salable lime. indicated in the Table; 1985 production was 605,000 short tons at a value of $26.4 million. PROCESSING Virginia's highest ranking in production oc- curred in 1915 when Virginia was third behind For calcining (burning) of the limestone, sev- Pennsylvania and Ohio with 267,000 short tons eral types of kilns are utilized depending on from 40 plants (Wood, 1958, p. 6). High produc- capacity of operation, fuel costs, market require- tion also occurred during the early 1940's with ments, and air pollution regulations. Increasingly the increased use in the steel furnaces at that important is the amount and cost of fuel required time. The year of most lime production was 1969, to convert each ton of limestone to lime. when Virginia ranked fifth behind Ohio, Penn- Vertical (shaft) kilns are elliptical or circular sylvania, Texas, and Michigan with 1,072,000 and may be of stone, reinzorced concrete, or boiler short tons ($13.6 million). Lime production of plate construction. The kilns are lined, usually 824,000 short tons in 1981 yielded a record value with two layers of refractory brick, and are of almost 36 million dollars. divided into three sections: preheating, calcining, Lime (calcium oxide), marketed as quicklime and cooling. -

Stabil-Mix Brochure

FLY ASH Stabil-Mix Improved Soil Stabilization with Construction Cost Savings FLYASH.COM FLY ASH Stabil-Mix Improved Soil Stabilization with Construction Cost Savings STABIL-MIX CUSTOM BLENDS FOR A SINGLE APPLICATION Contractors have long utilized roadbed stabilization Stabil-Mix can be custom blended for optimal results in techniques using chemicals such as lime or portland cement varying soil conditions and is delivered to the job site in to strengthen pavement subgrades. Lime has traditionally high-volume trailers. Thoroughly blended, Stabil-Mix reduces been used in cohesive clay soils, while portland cement the time normally required for separate lime and fly ash has been used more for granular soils. Increasingly, public applications and often does not require a waiting period and private sector engineers are interested in stabilizing for remix or processing. Generally, a single application of silty, clayey soils that do not match the classic definitions Stabil-Mix will properly stabilize subgrades. Waiting time is for either lime or cement. Historically, lime and fly ash have effectively reduced or eliminated. been used together to stabilize those soils. However, the application of each of the products separately has been time COST SAVINGS consuming and difficult. In addition to the savings from a single-product application, Stabil-Mix material savings can be as much as 50% when Now, thanks to a unique alliance between Boral Resources, compared to cement stabilization. And, depending on local the nation’s largest marketer of coal combustion products, conditions, Stabil-Mix may enable designers to reduce and Chemical Lime, a major international lime producer, the thickness of subsequent pavement layers—further a product is available to bridge the gap between lime and reducing material costs. -

Somerset Geology-A Good Rock Guide

SOMERSET GEOLOGY-A GOOD ROCK GUIDE Hugh Prudden The great unconformity figured by De la Beche WELCOME TO SOMERSET Welcome to green fields, wild flower meadows, farm cider, Cheddar cheese, picturesque villages, wild moorland, peat moors, a spectacular coastline, quiet country lanes…… To which we can add a wealth of geological features. The gorge and caves at Cheddar are well-known. Further east near Frome there are Silurian volcanics, Carboniferous Limestone outcrops, Variscan thrust tectonics, Permo-Triassic conglomerates, sediment-filled fissures, a classic unconformity, Jurassic clays and limestones, Cretaceous Greensand and Chalk topped with Tertiary remnants including sarsen stones-a veritable geological park! Elsewhere in Mendip are reminders of coal and lead mining both in the field and museums. Today the Mendips are a major source of aggregates. The Mesozoic formations curve in an arc through southwest and southeast Somerset creating vales and escarpments that define the landscape and clearly have influenced the patterns of soils, land use and settlement as at Porlock. The church building stones mark the outcrops. Wilder country can be found in the Quantocks, Brendon Hills and Exmoor which are underlain by rocks of Devonian age and within which lie sunken blocks (half-grabens) containing Permo-Triassic sediments. The coastline contains exposures of Devonian sediments and tectonics west of Minehead adjoining the classic exposures of Mesozoic sediments and structural features which extend eastward to the Parrett estuary. The predominance of wave energy from the west and the large tidal range of the Bristol Channel has resulted in rapid cliff erosion and longshore drift to the east where there is a full suite of accretionary landforms: sandy beaches, storm ridges, salt marsh, and sand dunes popular with summer visitors. -

Characterisation and Consolidation of Historical Lime Mortars in Cultural Heritage Buildings and Associated Structures in East Africa

Characterisation and Consolidation of Historical Lime Mortars in Cultural Heritage Buildings and Associated Structures in East Africa Athuman M. K. Ngoma TRIKA-BKN. Bulletin 101, 2009 ISSN 1103-4270 ISRN KTH/BKN/B--101--SE Doctoral Thesis The Artichoke At first glance it seems unappetizing, even forbidding, with the meagre edible matter in its hard exterior. The reward, however, comes in taking it apart, devouring it leaf by leaf. Its leaves slowly become more tender and tastier, until you arrive at the succulent heart. ii ABSTRACT ...........................................................................................................................viii PREFACE ................................................................................................................................ix ACKNOWLEDGEMENTS..................................................................................................... x CHAPTER ONE: INTRODUCTION .................................................................................... 1 1.1 Background and Problem Identification .................................................................... 1 1.2 Restoration of Historical Structure............................................................................. 3 1.3 Objectives, Limitations and Method .......................................................................... 3 CHAPTER TWO: MORTAR AND MORTAR DAMAGE................................................. 5 2.1 Introduction ............................................................................................................... -

NHL Lime Plaster

NHL Lime Plaster St Astier Limes and Mortars telephone: 0800 783 9014 Lime Plaster using St Astier NHL Using St. Astier NHL plastering mortars instead of non hydraulic putty mortars reduces the working time by about 50%. NHL mortars offer similar vapour exchange qualities as putty mortars but are more robust, can be sprayed and used for decorative plasterwork without the addition of gypsum. Requiring less after care than putty, it can be applied in 2 coats on good level backgrounds. Mortar. Plastering in hydraulic lime mortar normally consists of two or three-coat work. Lime plaster made with feebly or moderately hydraulic lime and sand is the basis for this guide. This type of lime sets and hardens predominantly by an hydraulic set and re-absorption of Carbon Dioxide from the air. By its nature the drying and absorption process is slower than gypsum plasters, therefore lime plaster curing should not be hurried allowing approximately 3-5 days per coat depending on the hydraulic lime used. Background. When applying Lime Plaster on the hard, the background will normally be brick or stone. The surface should be clean, free from dust and any organic materials such as lichens etc. Test the surface of masonry backgrounds for dust by applying a piece of masking tape to the background and immediately remove, examine the sticky side for traces materials that may affect the bond between the plaster and the wall. Internal walls can be uneven and rough, often with areas that have been altered. Different background conditions are therefore common and this needs to be addressed before plastering.