AKEBONO REPORT 2012 Akebono Brake Industry Co., Ltd

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Typical Brake Disc and Brake Pad Damage Patterns and Their Root Causes

Typical brake disc and brake pad damage patterns and their root causes www.meyle.com Good brakes save lives! The consequences of choosing the wrong or low-grade brake parts can be dramatic. Only use the brake components specified for the given vehicle application. Brake system repairs may only be performed by skilled and trained personnel. Adhere to the vehicle or brake manufacturer‘s specifications at all times. MEYLE Platinum Disc: When installing new brake components, observe the All-new finish. No degreasing. following: Fit and go. > Always replace brake pads along with brake discs. > Always replace all brake discs and pads per axle. All MEYLE brake discs come as ready-to-mount assemblies, most of > Be careful to bed in new brake discs and pads properly. them featuring the locating screw. They do not require degreasing > Avoid unnecessary heavy braking on the first 200 kilometres. and are resistant to rim cleaners. Cutting-edge paint technology > Brake performance may be lower on the first 200 driven made in Germany provides MEYLE Platinum Discs with long-term kilometres. anti-corrosion protection while adding a brilliant appearance. Further refinement of the tried-and-tested MEYLE finish has led to Check for functional reliability after installation: environmentally-friendly production processes. > Pump brake pedal until it becomes stiff. > Pedal travel must not vary at constant pedal load after pedal has MEYLE Platinum Discs – the safety solution engineered by one been depressed several times. of the industry‘s leading experts in coated brake discs. > Check wheels for free rotation. > Check brake fluid level in expansion tank and top up, if required. -

11 an Top 100 FINAL Pages.Qxp

Global Cover-060712.qxp 6/7/2012 4:14 PM Page 1 Top 100 global OEM parts suppliers – Ranked on 2011 global OEM automotive parts sales Total global Total global OEM automotive OEM automotive Percent Percent parts sales parts sales North Percent Percent rest of 2011 (dollars in (dollars in America Europe Asia world 2010 rank Company Address Executive millions) 2011 millions) 2010 2011 2011 2011 2011 Products rank 1 Robert Bosch GmbH Postfach 106050 Franz Fehrenbach $39,753 e $34,565 e 14 54 26 6 Gasoline, diesel & steering systems, chassis system controls, electrical 1 (49) 711-811-0; bosch.com Stuttgart D-70049, Germany chairman drives, starter motors & generators, car multimedia & electronics, battery technology, exhaust gas turbochargers & treatment systems 2 Denso Corp. 1-1 Showo-cho Nobuaki Katoh 34,153 fe 32,850 fe 16 12 70 2 Thermal, powertrain control, electronic & electric systems; small 2 (81) 566-25-5511; globaldenso.com Kariya-Aichi 00448, Japan president & CEO motors, telecommunications 3 Continental AG Vahrenwalder Strasse 9 Elmar Degenhart 30,521 fe 24,819 fe 19 52 25 4 Electronic & foundation brakes, stability management systems, tires, 3 (49) 511-938-01; conti-online.com Hanover 30165, Germany CEO chassis systems, safety system electronics, telematics, powertrain electronics, interior modules, instrumentation, technical elastomers 4 Magna International Inc.† 337 Magna Drive Donald Walker 28,300 23,600 52 43 5 Complete vehicle engineering & assembly; body & chassis, 5 (905) 726-2462; magna.com Aurora, Ontario L4G7K1, Canada CEO closures, electronic, interior/exterior, powertrain, roof, seating, & vision systems; hybrid & electric vehicle systems 5 Aisin Seiki Co. -

Electric to Hydraulic Disc Brake Conversion Installation and Owner’S Manual (For Aftermarket Application)

Electric to Hydraulic Disc Brake Conversion Installation and Owner’s Manual (For Aftermarket Application) Electric to Hydraulic Disc Brake Conversion Installation and Owner’s Manual (For Aftermarket Applications) Table of Contents Introduction Introduction �������������������������������������������� 1 Document Information ................................. 1 Document Information Trailer Axle Brake Inspection .......................... 1 The hydraulic disc brake assembly and kits are an Safety Information ..................................... 2 additional option for replacement brakes or the installation Resources Required ................................... 2 of current industry standards in braking. Parts List ................................................ 3 Trailer Axle Brake Inspection Installation .............................................. 3 In general, based on normal activity, trailer brakes should Mount Hydraulic Brake Actuator ....................... 3 be checked annually or every 36,000 miles, whichever Electric Brake Hubs Removal .......................... 4 comes first. If above normal trailer activity is experienced, Brake Hub Removal ................................... 4 then more frequent brake component inspections are Hydraulic Disc Brake Preparation ...................... 6 Disc Brake Assembly Installation ...................... 6 recommended. In the event the braking system encounters Inner Bearing Cone and Grease Seal Installation ..... 7 symptoms of improper application or failure, immediate New Seal Installation -

Royal-Enfield-Classic

about seventy on freeways…at least you won’t be getting any speeding tickets. Weighing in at 425 lbs. with a 3.56 gal- lon tank and claimed 75 mpg, the Classic 500 puts others to shame in the mileage depart- ment. Anyone looking for the fastest, most comfortable, best handling, best braking motor- cycle should look elsewhere, that’s not what the Classic or Bullet is about. Riding the wave of ‘new vintage’ motor- cycles, Royal Enfield hits the mark dead center. This is a commuter bike that not only gets the job done respectably, it will steal the attention from motorcycles three times its price. Gawkers commented on the impec- cable restoration job or que- ried its history and lineage. Royal Enfield’s reek retro cool without the stench of costly maintenance and exorbitant prices of actual vintage. At $5,499.00 what’s not to like! I just bought a vintage Bullet on eBay that will be prominently displayed in my living room. Royal Enfield also revealed an all new Interceptor 650 and the Continental GT 650 will be released this year. Both bikes share the same steel tube chassis and an all-new air- cooled 650cc parallel making them more highway-friendly By Koz Mraz malayan Roadrunners. They are the and faster. The 2018 Royal Photos by Koz & Gabrielle Romanello very first company to offer such trips Enfield Interceptor 650 is a ENGINE: thirty years ago. See “Motorcycling standard bike with an upright Type: Single Cylinder, 4-Stroke, Spark Ignition, Air-Cooled, Fuel Injection Rebirthing classic styling is very the Himalayas” in this issue. -

Akebono Report 2017

AKEBONO REPORT 2017 AKEBONO REPORT AKEBONO REPORT 2017 AKEBONO REPORT 2017 Issued August 2017 Corporate Communications Office 19-5 Nihonbashi Koami-cho, Chuo-ku, Tokyo 103-8534, Japan TEL +81 (0) 3-3668-5183 FAX +81 (0) 3-5695-7391 Akebono Brake Industry Co., Ltd. URL http://www.akebono-brake.com/english/ E-mail [email protected] Please send your opinions and impressions to the above office. This report was printed on Forest Stewardship Council-certified paper, sourced from well-managed forests and other controlled sources. In addition, the printing involved no volatile organic compounds (VOCs). akebono’s Through “Friction and Vibration, their Control and Analysis,” Corporate Mission we are determined to protect, grow and support every individual life We will continue to create value long into the 21st century as we pursue our Corporate Mission. We declare that we will: akebono’s Declaration for the 1. Recognize the real value of what we create and provide. 21st Century 2. Assure our own indispensability by continuously creating new value. 3. Accomplish our tasks with speed and the courage of our convictions without fear of failure. 4. Achieve our aspirations through the pride of each and every individual. 1. Customer needs first Corporate Goals 2. Technology realignment 3. Establishing a global network Brand Slogan Brand Statement Since 1929, akebono has brought assurance and peace of mind to our customers and end-users everywhere as a global industry leader in brake design and production. We take pride in our history of achieving safety without compromise, and continue to pursue new standards of perfection with Absolute safety; Unparalleled control innovation. -

Ceramic Disc Brake Were Developed and Tested by Porsche for Their Model Porsche 911Turbo in 1990

1.1 INTRODUCTION One of the most important control systems of an automobile is Brake system. They are required to stop the vehicle within the smallest possible distance and it is done by converting kinetic energy of the vehicle into heat energy which is dissipated into atmosphere. The main requirements of brakes are given below:- The brakes must be strong enough to stop the vehicle within the minimum possible distance in an emergency. But this should also be consistent with safety. The driver must have a proper control over the vehicle during emergency braking and the vehicle must not skid. The brakes must have good antifade characteristics and their effectiveness should not decrease with constant prolonged application. The actual stopping distance of vehicle while braking depends on the following factors:- 1. Vehicle speed 2. Condition of the road surface 3. Condition of tyre 4. Coefficient of friction between the tyre and the road surface 5. Coefficient of friction between the brake drum/disc and brake lining pad 6. Braking force applied by the driver 1.2 HISTORY Disc-style brakes development and use began in England in the 1890s. The first caliper-type automobile disc brake was patented by Frederick William Lanchester in his Birmingham, UK factory in 1902 and used successfully on Lanchester cars. However, the limited choice of metals in this period meant that it had to use copper as the braking medium acting on the disc. The poor state of the roads at this time, no more than dusty, rough tracks, meant that the copper wore quickly making the disc brake system non- viable. -

Akebono Report 2018

AKEBONO REPORT 2018 AKEBONO REPORT AKEBONO REPORT 2018 AKEBONO REPORT 2018 Issued August 2018 Corporate Planning Division, Corporate Communications Office 19-5 Nihonbashi Koami-cho, Chuo-ku, Tokyo 103-8534, Japan Akebono Brake Industry Co., Ltd. TEL +81 (0) 3-3668-5183 FAX +81 (0) 3-5695-7391 URL http://www.akebono-brake.com/english/ Please send your opinions and impressions to the above office. This report was printed on Forest Stewardship Council-certified paper, sourced from well-managed forests and other controlled sources. In addition, the printing involved no volatile organic compounds (VOCs). Contents Message Top Message ................................................................................................................... 03 Akebono’s Journey .......................................................................................................... 05 akebono’s Through “Friction and Vibration, their Control and Analysis,” Akebono 2018 ................................................................................................................. 07 we are determined to protect, grow and support every individual life About Akebono Product Introduction ........................................................................................................ 09 Corporate Mission Basic Principles of Brakes ............................................................................................... 11 Established 1999 Global Expansion ............................................................................................................ -

Developing Material Requirements for Automotive Brake Disc

ISSN: 2692-5397 DOI: 10.33552/MCMS.2020.02.000531 Modern Concepts in Material Science Mini Review Copyright © All rights are reserved by Samuel A Awe Developing Material Requirements for Automotive Brake Disc Samuel A Awe* R & D Department, Automotive Components Floby AB, Sweden *Corresponding author: Samuel A Awe, R&D Department, Automotive Components Received Date: November 12, 2019 Floby AB, Aspenäsgatan 2, SE-521 51 Floby, Sweden. Published Date: November 15, 2019 Abstract As electric vehicles are becoming more popular in society and several regulations concerning vehicle safety and performance as well as particulate matter emissions reduction are progressively becoming stringent, the author opines that these determinants would shape future automotive brake discs development. This mini-review highlights some of the essential parameters that would contribute to the next brake disc design and development and discusses how these factors will govern the choice of brake disc material in the coming years. Keywords: Automotive vehicle; Brake system; Brake discs; Particle emissions; Lightweight; Regulations; Corrosion; Electric cars Introduction weak corrosion resistance, heavyweight and weak wear resistance The automotive vehicle has transformed and will continue to are some of the drawbacks of grey cast iron as brake disc material. change human’s mobility in the future. To ensure the safety of lives Nonetheless, the functional requirements for automotive brake and properties, the braking system, which is a crucial component discs nowadays are becoming stricter, prompted by the stringent of an automobile plays an essential role in the safe drive of a car. regulations to reduce vehicle emissions, the emergence of electric The primary function of automotive friction brakes is to generate vehicles, demands to improve vehicle safety and performance, and a braking torque that decelerates the vehicle’s wheel and therefore the desire to enhance the driving experience of cars. -

Autodesk W Branży Motoryzacyjnej

Autodesk w Branży Motoryzacyjnej Name Surname Job Title Image courtesy of Local Motors Inc. Idea Koncepcja Wizualizacja Ergonomia Konstrukcja i optymalizacja Symulacja Organizacja procesu produkcyjnego Marketing 14 GENERAL MOTORS CORPORATION EXEDY CORPORATION IMABARI SHIPBUILDING CO.,LTD. WERNER BAIER UND GERHARD MEY TOYOTA MOTOR CORPORATION TSUNEISHI SHIPBUILDING COMPANY CENTRAL JAPAN RAILWAY COMPANY AMSTED INDUSTRIES INCORPORATED HONDA MOTOR CO., LTD. MAZDA MOTOR CORPORATION LINAMAR CORPORATION MITSUBISHI MOTORS AUSTRALIA LIMITED MITSUBISHI HEAVY INDUSTRIES, LTD. GENERAL ELECTRIC COMPANY CHINA SHIPBUILDING INDUSTRY CORPORATION CHINA STATE SHIPBUILDING CORPORATION MICHELIN ET CIE GM DAEWOO AUTO & TECHNOLOGY COMPANY NAMURA SHIPBUILDING CO.,LTD. KEIHIN CORPORATION NORTHROP GRUMMAN CORPORATION SIEMENS AG AUSTAL USA, LLC AKEBONO BRAKE INDUSTRY CO., LTD. FORD MOTOR COMPANY VALEO MAG IAS HOLDINGS, INC. COOPER-STANDARD HOLDINGS, INC. HYUNDAI HEAVY INDUSTRIES CO., LTD. L-3 COMMUNICATIONS HOLDINGS, INC. KOREA DELPHI AUTOMOTIVE SYSTEMS CENTRAL MOTOR CO.,LTD. ROBERT BOSCH GMBH DANA HOLDING CORPORATION STELLA VERM?GENSVERWALTUNGS GMBH L?RSSEN MARITIME BETEILIGUNGEN GMBH. VOLKSWAGEN AG SUZUKI MOTOR CORPORATION REPUBBLICA ITALIANA CHINA COMMUNICATIONS CONSTRUCTION KUBOTA CORPORATION SEMBCORP INDUSTRIES LTD THAI SUMMIT AUTOPARTS INDUSTRY COMPANY PARKER -HANNIFIN CORPORATION FIAT SPA ROLLS-ROYCE GROUP PLC NAVISTAR INTERNATIONAL CORPORATION DCNS MAGNA INTERNATIONAL INC AB VOLVO PRESCO, Y.K. JUNGHEINRICH AG BRIDGESTONE CORPORATION CKD CORPORATION UNITED TECHNOLOGIES CORPORATION MITSUBA CORPORATION CONTINENTAL AG NIENPAL EMPREENDIMENTOS E PARTICIPACOES YAZAKI CORPORATION YOKOHAMA RUBBER COMPANY, LIMITED, THE DAIMLER AG FUJI HEAVY INDUSTRIES LTD. BENTELER AG MUSASHI SEIMITSU INDUSTRY CO., LTD. STX OFFSHORE & SHIPBUILDING CO., LTD. SHANGHAI AUTOMOTIVE INDUSTRY CORP ABEKING & RASMUSSEN SCHIFFS- UND ALLISON TRANSMISSION, INC. NISSAN MOTOR CO., LTD. BROSE FAHRZEUGTEILE GMBH & CO. KG ODIM ASA STICHTING ADMINISTRATIEKANTOOR HUISMAN MITSUBISHI MOTORS CORPORATION HARLEY-DAVIDSON, INC. -

ASIAN AUTOMOTIVE NEWSLETTER ISSUE 16, December 1999 a Bimonthly Newsletter of Developments in the Auto and Auto Components Markets

BDA Business Development Asia ASIA IS A BUSINESS IMPERATIVE NOW MORE THAN EVER ASIAN AUTOMOTIVE NEWSLETTER ISSUE 16, December 1999 A bimonthly newsletter of developments in the auto and auto components markets CONTENTS CHINA/HK INTRODUCTION .............................................. 1 Ami Doduco, a unit of Technitrol Company of CHINA / HONG KONG ................................. 1 the US and a global leader in electrical contacts, has INDIA ..................................................................... 2 agreed to acquire Tianjin Electrical Metal Works INDONESIA ........................................................ 2 (TEM), an electrical contacts business based in JAPAN ..................................................................... 3 Tianjin, from Tianjin XinHao Investment Devel- KOREA ................................................................... 3 opment Company. Ami Doduco has established a MALAYSIA ............................................................ 4 wholly-owned enterprise in Tianjin City and obtained SINGAPORE ........................................................ 5 all approvals necessary to manufacture and sell sil- THAILAND .......................................................... 5 ver-based electrical contact products used in the ap- VIETNAM ............................................................. 5 pliance, automotive and construction industries. (No- FOCUS: Fast Fit Market in Asia ....................... 6 vember 10, 1999) Daewoo Motor Co has opened three car component JV plants -

SAE 2009 Brake Colloquium and Exhibition Technical Session Schedule As of 10/17/2009 07:40 Pm

SAE 2009 Brake Colloquium and Exhibition Technical Session Schedule As of 10/17/2009 07:40 pm Sunday, October 11 Environmental Issues Session Code: BC109 Room Ballroom A/B Session Time: 3:30 p.m. The session provides the status and issues with the various worldwide environmental regulatory and legislative actions (i.e., REACH, ELV, IMDS, California Copper, Green Chemistry Initiative..) as well as the latest studies in wear debris analysis. Organizers - Stephen Brown, Samarium LLC; Kwangjin M. Lee, Delphi Corp. Time Paper No. Title 3:30 p.m. 2009-01-3005 Wear Mechanisms in Automotive Brake Materials Plus Characterization and Potential Environmental Impact of Wear Debris ORAL ONLY Jana Kukutschova, VSB Technical University Ostrava; Peter Filip, Southern Illinois Univ at Carbondale; Vaclav Roubicek , VSB - Technical University Ostrava; Donald MacCrimmon, Southern Illinois Univ 3:55 p.m. ORAL ONLY European Enviornmental Regulations in Friction Materials Nanty Hautus, Lapinus Fibres BV 4:20 p.m. ORAL ONLY California Copper SB346 Update William P. Hilbrandt, Akebono Corp. 4:40 p.m. ORAL ONLY Green Chemistry Initiative (written presentation will be made available by the California Dept. of Toxic Substances Control) Stephen Brown, Samarium LLC 4:45 p.m. ORAL ONLY Suppliers Partnership for the Environment (SP) - Material Assessment Strategy Pat Beattie, Arcalis Scientific, Suppliers Partnership for Environment Monday, October 12 OEM Brake Management Panel Discussion Session Code: BC200 Room Ballroom A/B Session Time: 8:00 a.m. Join the key leaders of the Brake activities within the major OEM¿s to learn what to expect for the future in terms of business activities and technical issues which will be encountered as we move forward. -

Transit Bus Air Disc Brake Wheels-Off Inspection and Reline

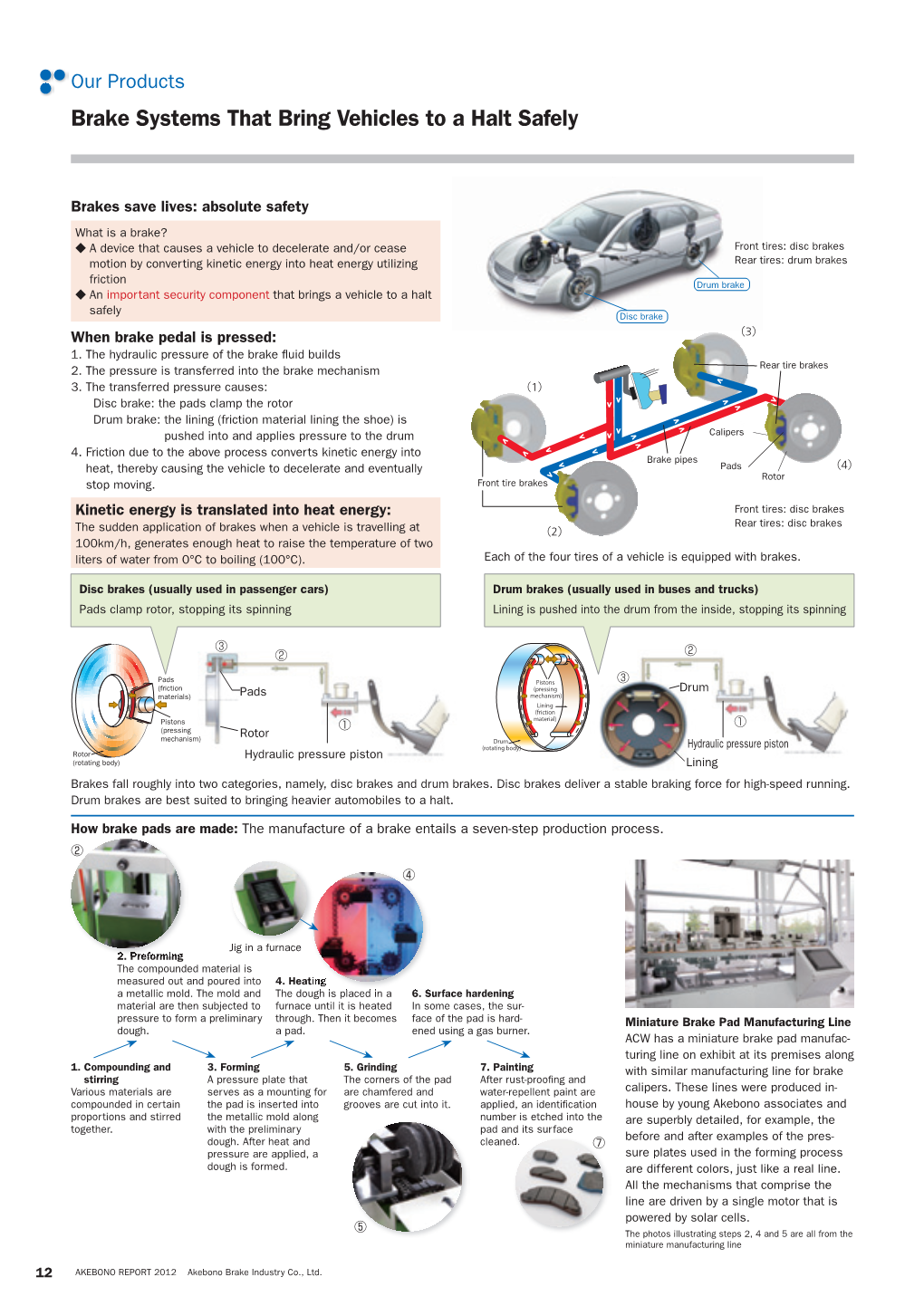

APTA STANDARDS DEVEL OPMENT PROGRAM APTA BTS-BC-RP-007-17 RECOMMENDED PRACTICE Published: January 26, 2017 American Public Transportation Association APTA Bus Brake Working Group 1300 I Street, NW, Suite 1200 East, Washington, DC 20006 Transit Bus Air Disc Brake Wheels-Off Inspection and Reline Abstract: This Recommended Practice provides guidelines for performing complete brake maintenance on a bus with disc brakes. It includes disassembly, cleaning, inspection and assembly. This document is to be used in conjunction with the manufacturer’s service manual. It is recommended that all components be replaced equally on both wheel ends of the axle. Failure to do so may affect braking performance. Keywords: ABS tone ring, boot, bridge, bushing, caliper, carrier, disc, disc brake maintenance, hub, pads, pin, potentiometers, retaining strap, rotor, seal, slide pins, spring clips, torque plate, wear indicator, wear sensors, wheel seals Summary: This document establishes a recommended practice for transit bus front/rear axle disc brake inspection and reline. Individual operating agencies should modify these guidelines to accommodate their specific equipment and mode of operation. The recommended practices and guidelines in this document assume that the end users have sufficient skills and knowledge to repair and maintain the related systems at a journeyman level. This must include a fluent understanding of safe shop working practices, not only for the agency but also OSHA/CCOHS/provincial/federal/state and local safety standards. A familiarity with applicable industries, component/system suppliers and vehicle manufacturers is also assumed. Scope and purpose: This Recommended Practice provides guidelines for disassembly, preparation, inspection and reassembly of the typical heavy-duty transit bus disc brake.