CNC and DNC Systems: a Future Approach

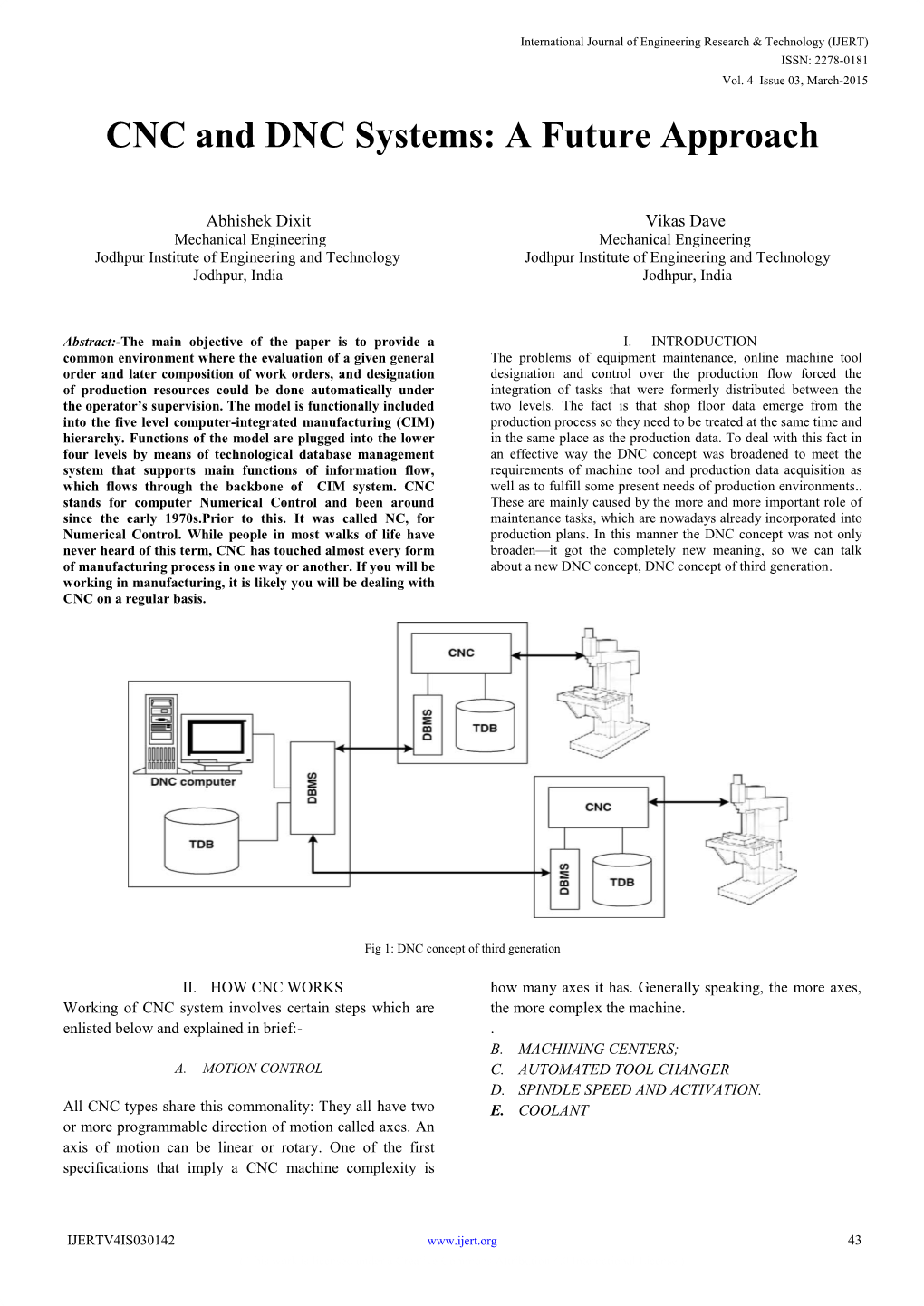

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Numerical Control (NC) Fundamentals

Lab Sheet for CNC Laboratory Department of Production Engineering and Metallurgy Prepared by: Dr. Laith Abdullah Mohammed Production Engineering – CNC Lab Lab Sheet Numerical Control (NC) Fundamentals What is Numerical Control (NC)? Form of programmable automation in which the processing equipment (e.g., machine tool) is controlled by coded instructions using numbers, letter and symbols - Numbers form a set of instructions (or NC program) designed for a particular part. - Allows new programs on same machined for different parts. - Most important function of an NC system is positioning (tool and/or work piece). When is it appropriate to use NC? 1. Parts from similar raw material, in variety of sizes, and/or complex geometries. 2. Low-to-medium part quantity production. 3. Similar processing operations & sequences among work pieces. 4. Frequent changeover of machine for different part numbers. 5. Meet tight tolerance requirements (compared to similar conventional machine tools). Advantages of NC over conventional systems: Flexibility with accuracy, repeatability, reduced scrap, high production rates, good quality. Reduced tooling costs. Easy machine adjustments. More operations per setup, less lead time, accommodate design change, reduced inventory. Rapid programming and program recall, less paperwork. Faster prototype production. Less-skilled operator, multi-work possible. Limitations of NC: · Relatively high initial cost of equipment. · Need for part programming. · Special maintenance requirements. · More costly breakdowns. Advantages -

MCIS Direct Numerical Control for NX CAM

MCIS Direct Numerical Control for NX CAM Connect NX CAM output directly to CNC machines Benefits Summary • Reduce NC data NX™ CAM software uses direct numerical control (DNC) connections from management costs for the Siemens’ Motion Control Information System (MCIS) to provide CNC file shop floor control to the shop floor. By directly linking CNC machines to NX CAM files, • Leverage user-friendly DNC enables NC programmers, shop floor managers, and machine tool interface to manage NC operators to easily organize, manage and transfer the correct NC programs to programs specified machines. • Reduce setup times • Automate NC program transfer to the machine tool • Keep NC data safe and backed up • Use Siemens’ SINUMERIK controllers without any additional hardware • Scalable to production requirements Connecting NX CAM data to the shop floor DNC system for transfer to CNC machines. NX machining and manufacturing solutions combine to ensure that parts are manufactured on-time and to specification by helping planning and production departments to work together more efficiently with the right data. The MCIS-DNC system can be configured to automatically transfer NC program files posted directly from NX CAM to the proper machine tools on the network. This gaurantees that the right NC program is always loaded on the right machine. Automatically route NX CAM data to the shop floor Using MCIS-DNC Explorer to manage You can generate enhanced NC programs from NX CAM that include special NC programs and related files on the instructions the DNC system can use to automatically route programs to shop floor. specified machines and operators on the shop floor. -

ME 440: Numerically Controlled Machine Tools Outline

Outline – Introduction ME 440: Numerically Controlled Machine Tools • Basic Definitions – Machine Tools – Precision Engineering Introduction • Historical Developments • Numerical Control Assistant Prof. Melik Dölen • Direct Numerical Control Department of Mechanical Engineering • CtNilCtlComputer Numerical Control • Distributed Numerical Control Middle East Technical University – Flexible Manufacturing Systems Chapter 1 ME 440 2 Definition of Machine Tool Conventional Machine Tools • Milling Mac hine • A machine used for sculpturing metal and • Lathe other substances to the desired form. • Drilling/Boring Machine • A machine system utilized for producing • Shaper/Planer machine par ts an d e lemen ts. • Grinding Machine •A machine tool is a powered mechanical • Filing Machines device, typically used to fabricate metal • Sawing Machines comppyonents of machines by the selective removal of metal. Chapter 1 ME 440 3 Chapter 1 ME 440 4 Non-traditional Machine Tools Machining Accuracy • Electro-Discharge Machine • Wire EDM • Plasma Cutter • Electron Beam Machine • Laser Beam Machine Chapter 1 ME 440 5 Chapter 1 ME 440 6 Ultraprecision Machining History of Machine Tools Processes • 1770: Simple production machines • Single-point diamond and mechanization – at the turning and CBN beggginning of the industrial cutting revolution. • 1920: Fixed automatic mechanisms • Abrasive/erosion and transfer lines for mass processes (fixed and production. free) • 1945: Machine tools with simple automatic control, such as plug • Chemical/corrosion board controllers. processes (etch- • 1952: Invention of numerical control machining) (NC). Chapter 1 ME 440 7 Chapter 1 ME 440 8 History of Machine Tools (Cont’ d) History of Machine Tools (Cont’d) • 1961: First commercial Industrial robot. • 1972: First CNCs introduced. • 1978: Flexible manufacturing system (FMS); contains CNCs, robots, material transfer system. -

Manufacturing Glossary

MANUFACTURING GLOSSARY Aging – A change in the properties of certain metals and alloys that occurs at ambient or moderately elevated temperatures after a hot-working operation or a heat-treatment (quench aging in ferrous alloys, natural or artificial aging in ferrous and nonferrous alloys) or after a cold-working operation (strain aging). The change in properties is often, but not always, due to a phase change (precipitation), but never involves a change in chemical composition of the metal or alloy. Abrasive – Garnet, emery, carborundum, aluminum oxide, silicon carbide, diamond, cubic boron nitride, or other material in various grit sizes used for grinding, lapping, polishing, honing, pressure blasting, and other operations. Each abrasive particle acts like a tiny, single-point tool that cuts a small chip; with hundreds of thousands of points doing so, high metal-removal rates are possible while providing a good finish. Abrasive Band – Diamond- or other abrasive-coated endless band fitted to a special band machine for machining hard-to-cut materials. Abrasive Belt – Abrasive-coated belt used for production finishing, deburring, and similar functions.See coated abrasive. Abrasive Cutoff Disc – Blade-like disc with abrasive particles that parts stock in a slicing motion. Abrasive Cutoff Machine, Saw – Machine that uses blade-like discs impregnated with abrasive particles to cut/part stock. See saw, sawing machine. Abrasive Flow Machining – Finishing operation for holes, inaccessible areas, or restricted passages. Done by clamping the part in a fixture, then extruding semisolid abrasive media through the passage. Often, multiple parts are loaded into a single fixture and finished simultaneously. Abrasive Machining – Various grinding, honing, lapping, and polishing operations that utilize abrasive particles to impart new shapes, improve finishes, and part stock by removing metal or other material.See grinding. -

COMPUTER INTEGRATED MANUFACTURING TECHNOLOGIES Course Objectives

COURSE MATERIAL III Year B. Tech I- Semester MECHANICAL ENGINEERING COMPUTER INTEGRATED MANUFUCTING TECHNOLOGIES R18A0312 MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY DEPARTMENT OF MECHANICAL ENGINEERING (Autonomous Institution-UGC, Govt. of India) Secunderabad-500100, Telangana State, India. www.mrcet.ac.in MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY (Autonomous Institution – UGC, Govt. of India) DEPARTMENT OF MECHANICAL ENGINEERING CONTENTS 1. Vision, Mission & Quality Policy 2. Pos, PSOs & PEOs 3. Blooms Taxonomy 4. Course Syllabus 5. Lecture Notes (Unit wise) a. Objectives and outcomes b. Notes c. Presentation Material (PPT Slides/ Videos) d. Industry applications relevant to the concepts covered e. Question Bank for Assignments f. Tutorial Questions 6. Previous Question Papers www.mrcet.ac.in MALLA REDDY COLLEGE OF ENGINEERING & TECHNOLOGY (Autonomous Institution – UGC, Govt. of India) VISION To establish a pedestal for the integral innovation, team spirit, originality and competence in the students, expose them to face the global challenges and become technology leaders of Indian vision of modern society. MISSION To become a model institution in the fields of Engineering, Technology and Management. To impart holistic education to the students to render them as industry ready engineers. To ensure synchronization of MRCET ideologies with challenging demands of International Pioneering Organizations. QUALITY POLICY To implement best practices in Teaching and Learning process for both UG and PG courses meticulously. To provide state of art infrastructure and expertise to impart quality education. To groom the students to become intellectually creative and professionally competitive. To channelize the activities and tune them in heights of commitment and sincerity, the requisites to claim the never - ending ladder of SUCCESS year after year. -

Distributed Numerical Control System: an Advancement in CNC/DNC System

International Journal of Science and Research (IJSR) ISSN (Online): 2319-7064 Index Copernicus Value (2016): 79.57 | Impact Factor (2015): 6.391 Distributed Numerical Control System: An Advancement in CNC/DNC System Anshul Mathur1, Shraddha Arya2, Tushar Sharma3 Abstract: In the today’s manufacturing environment, every kind of system is integrating with the computerization systems. This computerized system is already involved in the manufacturing environment. This manufacturing system is controlled by numbers, letters & symbols, called Numerical Control System (NC System). This system gets advancement by the role of computers & efficient system created, called Computer Numerical Control System (CNC System) and again improved by central computer system, called Direct Numerical Control System (DNC System). Now, for get a highly efficient numerical control system with precision and accuracy beyond human ability, a new system introduces, called Distributed Numerical Control System, which is the advancement in CNC/ DNC System. Thus, this paper presents the advancements of Distributed Numerical Control System over CNC/DNC System. Keywords: Advancement, Manufacturing Systems, NC, CNC, DNC, CAPP, CAD, CAM, CIM 1. Introduction The systems aspects of manufacturing are more important than ever today. The word manufacturing was originally derived from two Latin words, Manus (hand) and Factus (make), so that the combination means made by hand. In 1567 this type of manufacturing system was used and product verities were very simple to construct. This system is improved and makes efficient with the control of numbers, letters and symbols, called Numerical Control System (NC System). For the manufacturing, a set of programs were used Figure 1: Components of an NC System to control the processes. -

Numerical Control Fabrication: Its Nature and Application

MICHAEL L. HAGLER NUMERICAL CONTROL FABRICATION: ITS NATURE AND APPLICATION Numerical control is a tool that frees the craftsman from the mechanical control of equipment in much the same way that the calculator and computer freed the engineer from the burden of manual calcula tions. This article presents background information that describes the nature of numerical control and highlights several applications of numerical control fabrication at APL. INTRODUCTION machine's motions and functions needed to fabricate a In order to understand the application of numerical workpiece contained in the numerical control program. control and computer numerical control fabrication, it It is important to understand that numerical control is valuable to review the nature of these processes that is a concept of machine control, not a manufacturing have become so commonplace in metalworking facilities. method. While it is important to understand what nu Numerical control is the operation of a machine by merical control is, it is equally critical to understand what a series of coded instructions comprised of alphanumeric it is not. Numerical control is not an electronic brain; characters. The instructions are translated into electri not even computer numerical control at the current state cal pulses or other output signals that activate motors of technology can approach the capabilities of the hu and other devices to control a machine. For machine man brain. Numerical control cannot think, evaluate, tools, numerical control commands range from positive judge, discern, or show any true adaptability. It is pos positioning of the spindle in relation to the workpiece, sible, with advanced computer numerical control, to have to auxiliary functions such as selecting a tool station or predetermined logic trees or alternatives that allow in a turret, or controlling the speed and direction of spin correct instructions or unplanned occurrences such as dle rotation. -

VOWS AGENCY Office of Vocational and Adult Education (ED), Washington, DC

DOCUMENT RESUME ED 222 772 CE 034 312 AUTWOR Jaffe, J. A., Ed.; And Others TIT1E Technologies of the '80s: Their Impact on Trade and Industrial Occupations. INSTITUTION Conserve, Inc., Raleigh, N.C. VOWS AGENCY Office of Vocational and Adult Education (ED), Washington, DC. PUB DATE Sep 82 CONTRACT 300-81-0352 NOTE 85p.; For related documents, see ED 219 527, ED 219 586, and CE 034 303-313. PUB TYPE Viewpoints (120) -- Reports -,Descriptive (141) EDRS PRICE MF01/PC04 Plus Postage. DESCRIPTORS Automation; Blue Collar Occupations; *Diffusion (Communication); *Industrial Personnel; Job Skills; Machine Tools; Microcomputers; Postsecondary Education; Secondary Education; Semiskilled Occupations; Service Occupations; *Skilled Occupations; Technical Occupations; *Technological Advancement; *Trade and Industrial Education; *Vocational Education; Welding IDENTIFIERS Computer Assisted Design; Computer Assisted Manufacturing; *Impact; Microelectronics; Optical Data Transmission; Robotics ABSTRACT This report is one of seven that identify major new and emerging technological advances expected toinfluence major vocational education program areas and todescribe the programmatic implications in terms of skill-knowledge requirements,occupations most directly affected, and theanticipated diffusion rate. Chapter 1 considers technology as process, the relation oftechnology and productivity, and technology as the arbitrator of work.The first of Chree sections in chapter 2 presents the proceduresused to identify and clarify the most innovative, new, andemerging technologies with implications for vocational education. Briefdescriptions of the technologies expected to affect trade andindustrial occupations are included in section 2. Section 3 contains eight essaysdescribing Chese new and emerging technologies withimplications for trade and industrial occupations: process control,microelectronic monitors and controls, computer-based design and manufacture,robotics, machining, welding, optical data transmission, andmicrocomputers and microprocessors. -

Computer Numerical Control CNC Is Used to Distinguish This Type of NC from Its Technological Predecessors That Were Based Entirely on a Hard-Wired Electronics

CAD/CAM CHAPTER FOUR COMPUTER NUMERIC CONTROL (CNC) Dr. Ibrahim Al-Naimi 1 Numerical Control Definition and Applications Introduction The subject of this lecture is the interface between CAD and the manufacturing processes actually used to make the parts, and how to extract the data from the CAD model for the purpose of controlling a manufacturing process. Getting geometric information from the CAD model is of particular relevance to the manufacture of parts directly by machining (i.e. by material removal), and to the manufacture of tooling for forming and molding processes by machining. The use of numerical information for the control of such machining processes is predominantly through the numerical control NC of machines. 2 Numerical Control Definition and Applications Fundamentals of numerical control Today numerically controlled devices are used in all manner of industries. Milling machines manufacture the molds and dies for polymer products. Flame cutting and plasma arc machines cut shapes from large steel plates. Lasers are manipulated to cut tiny cooling holes in gas turbine parts. Electronic components are inserted into printed circuit boards by NC insertion machines. 3 Numerical Control Definition and Applications Numerical Control NC is a form of programmable automation in which the mechanical actions of a machine tool or other equipment are controlled by a program containing coded alphanumerical data. Numerical control NC is any machining process in which the operations are executed automatically in sequences as specified by the program that contains the information for the tool movements. The alphanumerical data represent relative positions between a workhead and a workpart as well as other instructions needed to operate the machine. -

Me6402 Manufacturing Technology-Ii

M.I.E.T. ENGINEERING COLLEGE/ DEPT. of Mechanical Engineering M.I.E.T. ENGINEERING COLLEGE (Approved by AICTE and Affiliated to Anna University Chennai) TRICHY – PUDUKKOTTAI ROAD, TIRUCHIRAPPALLI – 620 007 DEPARTMENT OF MECHANICAL ENGINEERING COURSE MATERIAL ME6402 - MANUFACTURING TECHNOLOGY-II II YEAR - IV SEMESTER M.I.E.T. /Mech. / II /MFT-II M.I.E.T. ENGINEERING COLLEGE/ DEPT. of Mechanical Engineering M.I.E.T. ENGINEERING COLLEGE (Approved by AICTE and Affiliated to Anna University Chennai) TRICHY – PUDUKKOTTAI ROAD, TIRUCHIRAPPALLI – 620 007 DEPARTMENT OF MECHANICAL ENGINEERING SYLLABUS (THEORY) Sub. Code : ME6402 Branch / Year / Sem : MECH/II/A Sub.Name :MANUFACTURING TECHNOLOGY-II Staff Name :DHAMODARAN.K L T P C 3 0 0 3 UNIT I THEORY OF METAL CUTTING 9 Mechanics of chip formation, single point cutting tool, forces in machining, Types of chip, cutting tools– nomenclature, orthogonal metal cutting, thermal aspects, cutting tool materials, tool wear, tool life, surface finish, cutting fluids and Machinability. UNIT II TURNING MACHINES 9 Centre lathe, constructional features, specification, operations – taper turning methods, thread cutting methods, special attachments, machining time and power estimation. Capstan and turret lathes- tool layout – automatic lathes: semi automatic – single spindle : Swiss type, automatic screw type – multi spindle: UNIT III SHAPER, MILLING AND GEAR CUTTING MACHINES 9 Shaper – Types of operations. Drilling ,reaming, boring, Tapping. Milling operations-types of milling cutter. Gear cutting – forming and -

Automating the Future a History of the Automated Manufacturing Research Facility 1980-1995

A History of the I Automated ' Automdtinci I the Manufacturing Future Research QC 100 .U57 N0.967 I Institute of Standards and Te Administration, U.S. Department of Commerce 2001 jy c. 3. AUTOMATING THE FUTURE A HISTORY OF THE AUTOMATED MANUFACTURING RESEARCH FACILITY 1980-1995 NIST Special Publication 967 Joan M. Zenzen Manufacturing Engineering Laboratory National Institute of Standards and Technology Gaithersburg, Maryland 20899-8200 March 2001 U.S. DEPARTMENT OF COMMERCE Donald L. Evans, Secretary Technology Administration Karen H. Brown, Acting Under Secretary for Technology National Institute of Standards and Technology Karen H. Brown, Acting Director Disclaimer Statement Commercial equipment and materials are identified in order to specify adequately certain procedures and/or research. In no case does such identification imply recommendation or endorsement by the NIST, nor does it imply that the materials or equipment identified are necessarily the best available for the purpose. National Institute of Standards and Technology Special Publication 967 Natl. Inst. Stand. Technol. Spec. Publ. 967, 104 pages (March 2001) CODEN: NSPUE2 U.S. GOVERNMENT PRINTING OFFICE - WASHINGTON: 2001 For sale by the Superintendent of Documents, U.S. Government Printing Office Internet: bookstore.gpo.gov — Phone: (202) 512-1800 — Fax: (202) 512-2250 Mail: Stop SSOP, Washington, DC 20402-0001 CONTENTS List of Figures iv Foreword v Acknowledgments vi Chapters 1 Measuring for Manufacturing 1 2 Envisioning a Future with Automation 9 3 Magical Manufacturing 25 4 Graduation 49 5 Legacy 73 Appendixes 1 Acronyms 83 2 Awards 84 3 Standards 85 4 Donations 86 5 Industrial Research Associates 88 6 Patents 89 7 Products 90 8 Thesis Research 91 9 Academic Connections 92 10 Personal Interviews 93 Bibliography 94 About the Author 98 Automated Manufacturing Research Facility iii FIGURES 1 The robot arm of the Turning Workstation 1 2 Robert J. -

Slotting Machine/Slotter

MODULE 2 LATHE WORKING PRINCIPLE OF LATHE THREADING DRILLING MACHINE MILLING MACHINE SHAPING MACHINE/SHAPER PLANER MACHINE SLOTTING MACHINE/SLOTTER Slotting machine is a reciprocating machine tool in which, the ram holding the tool reciprocates in a vertical axis and the cutting action of the tool is only during the downward stroke. Construction: The slotter can be considered as a vertical shaper and its main parts are: 1. Base, column and table 2. Ram and tool head assembly 3. Saddle and cross slide 4. Ram drive mechanism and feed mechanism. • Base of the slotting machine is rigidly built to take up all the cutting forces. • Front face of the vertical column has guide ways for Tool the reciprocating ram. • Ram supports the tool head to which the tool is attached. • Workpiece is mounted on the table which can be given longitudinal, cross and rotary feed motion. Slotting machine is used for cutting grooves, keys and slotes of various shapes making regular and irregular surfaces both internal and external cutting internal and external gears and profiles. Slotter machine can be used on any type of work where vertical tool movement is considered essential and advantageous. Different types of slotting machines are: 1. Punch slotter: a heavy duty rigid machine designed for removing large amount of metal from large forgings or castings 2. Tool room slotter: a heavy machine which is designed to operate at high speeds. This machine takes light cuts and gives accurate finishing. 3. Production slotter: a heavy duty slotter consisting of heavy cast base and heavy frame, and is generally made in two parts.