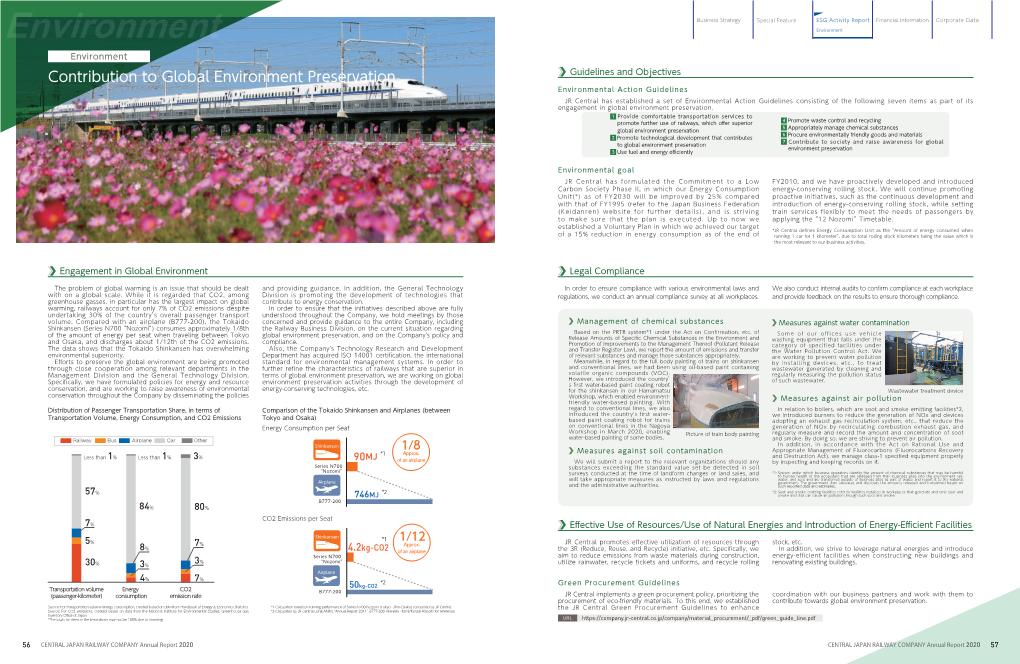

Contribution to Global Environment Preservation

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

About Suspension of Some Trains

About suspension of some trains Some trains will be suspended considering the transport of passengers due to the outbreak of the Novel Coronavirus. *Please note that further suspension may be subject to occur. 【Suspended Kyushu Shinkansen】 (May 11 – 31) ○Kumamoto for Kagoshima-Chūō ※Service between Kumamoto and Shin-Osaka is available. Name of train Kumamoto Kagoshima-Chūō Day of suspension SAKURA 545 10:34 11:20 May 11~31 SAKURA 555 15:23 16:10 May 11~31 SAKURA 409 12:18 13:15 May 11~31 ○Kagoshima-Chūō for Kumamoto ※Service between Kumamoto and Shin-Osaka is available. Name of train Kagoshima-Chūō Kumamoto Day of suspension SAKURA 554 11:34 12:20 May 11~31 SAKURA 562 14:35 15:20 May 11~31 SAKURA 568 17:18 18:03 May 11~31 MIZUHO 612 18:04 18:48 May 11~31 【Suspended Hokuriku Shinkansen】 (May 1 – 31) ○Tōkyō for Kanazawa Name of train Tōkyō Kanazawa Day of suspension KAGAYAKI 521 8:12 10:47 May 1~31 KAGAYAKI 523 10:08 12:43 May 2. 9. 16. 23. 30 KAGAYAKI 525 10:48 13:23 May 1~4. 9. 16. 23. 30 KAGAYAKI 527 11:48 14:25 May 2. 3. 5. 6 KAGAYAKI 529 12:48 15:26 May 2~6 KAGAYAKI 531 13:52 16:26 May 1. 3~6. 8. 15. 22. 29. 31 KAGAYAKI 533 14:52 17:26 May 1. 8~10. 15~17. 22~24. 29~31 KAGAYAKI 535 17:04 19:41 May 2~6 KAGAYAKI 539 19:56 22:30 May 1~6. -

Uredas, URGENT EARTHQUAKE DETECTION and ALARM SYSTEM, NOW and FUTURE

13th World Conference on Earthquake Engineering Vancouver, B.C., Canada August 1-6, 2004 Paper No. 908 UrEDAS, URGENT EARTHQUAKE DETECTION AND ALARM SYSTEM, NOW AND FUTURE Yutaka NAKAMURA 1 SUMMARY UrEDAS, Urgent Earthquake Detection and Alarm System, can realize the real-time early earthquake detection and alarm system in the world. There is a local government that has realized a tsunami warning system using real-time estimated earthquake parameters as magnitude and location, distributed by UrEDAS. On 26th May 2003, the Miyagiken-Oki Earthquake was occurred. It was so large that the maximum acceleration of about 600 Gal was observed along the Shinkansen line and 23 columns of the rigid frame viaducts (RC) were severely cracked. This earthquake occurred on the business hours of the Shinkansen. As expected, coastline “Compact UrEDAS” along the Shinkansen took out the early P-wave alarm before the destructive earthquake motion and the validity of this system was proved for the first time. INTRODUCTION UrEDAS is the only real time P-wave alarm system over the world on practical use. It is characterized to be able to process digitized waveform step by step without saving. Amount of procedure does not differs either earthquake occurs or not, so failure because of over load will not occur. The 2003 Miyagiken-Oki earthquake (Mj 7.1) occurred on 26th May, Compact UrEDAS worked as expected. It was for the first time that the validity of the early warning system was verified under circumstances of big earthquake such as rigid frame viaducts of Shinkansen were damaged. In this paper, the present condition of P-wave early detection system UrEDAS will be viewed referring to cases at work, also result of test observation where faults exists will be reported. -

About Suspension of Some Temporary Trains(Translation:PDF76KB)

About suspension of some temporary trains Some temporary trains will be suspended considering the transport of passengers due to the outbreak of the Novel Coronavirus. *Please note that further suspension may be subject to occur. 【Suspended Sanyo Shinkansen】 (April 1 – May 6) ○Tōkyō for Hakata Name of train Tōkyō Hakata Day of suspension NOZOMI 135 7:12 12:14 May 6 NOZOMI 137 7:21 12:19 May 3. 4 NOZOMI 139 8:12 13:14 May 3 NOZOMI 145 9:12 14:14 May 3. 6 NOZOMI 149 10:12 15:14 May 3 NOZOMI 151 10:42 15:47 May 2. 4 NOZOMI 155 11:42 16:47 May 3 NOZOMI 159 12:42 17:47 May 2 NOZOMI 163 13:42 18:47 May 2. 6 NOZOMI 169 14:42 19:47 May 4 NOZOMI 173 15:21 20:19 May 2. 3. 5. 6 NOZOMI 181 16:42 21:46 May 6 NOZOMI 183 17:12 22:14 May 1. 6 NOZOMI 185 17:21 22:19 May 4 NOZOMI 189 18:12 23:14 May 1. 5 ○Hakata for Tōkyō Name of train Hakata Tōkyō Day of suspension NOZOMI 136 7:58 13:03 May 3 NOZOMI 138 8:31 13:33 May 1 NOZOMI 140 8:58 14:03 May 2. 3. 5. 6 NOZOMI 144 9:58 15:03 May 2. 3. 5. 6 NOZOMI 150 11:31 16:33 May 2. 5 NOZOMI 152 11:58 17:03 May 4 NOZOMI 156 12:58 18:03 May 3 NOZOMI 160 13:31 18:33 May 4 NOZOMI 170 15:31 20:33 May 2. -

Shinkansen Bullet Train

Jōetsu Shinkansen (333.9 km) Train Names: TOKI, TANIGAWA Max-TOKI, Max-TANIGAWA JAPAN RAIL PASS Can also be Used for Shinkansen Jōetsu Shinkansen "Max-TOKI"etc. “bullet train” Travel Akita Shinkansen "KOMACHI" Akita Shinkansen (662.6 km) Train Name: KOMACHI Akita Shin-Aomori Yamagata Shinkansen "TSUBASA" Hokuriku Shinkansen (450.5 km) Yamagata Shinkansen Train Names: KAGAYAKI, HAKUTAKA, (421.4 km) Shinjo¯ Morioka TSURUGI, ASAMA Train Name: TSUBASA Niigata Yamagata Sendai Kanazawa Toyama Nagano Hokuriku Shinkansen "KAGAYAKI"etc. Fukushima Takasaki Omiya¯ Sanyō & Kyūshū Shinkansen "SAKURA" Sanyō Shinkansen (622.3 km) Train Names: NOZOMI*, MIZUHO*, Tōhoku Shinkansen "HAYABUSA "etc. Tōkaidō & Sanyō Shinkansen "HIKARI" HIKARI (incl. HIKARI Rail Star), SAKURA, KODAMA Tōkaidō Shinkansen (552.6 km) (Tōkyō thru Hakata, 1,174.9km) Train Names: NOZOMI*, HIKARI, KODAMA Hakata Kokura Hiroshima Okayama Shin-Osaka¯ Kyōto Nagoya Shin-Yokohama Shinagawa Tokyo¯ ¯ * There are six types of train services, “NOZOMI,” “MIZUHO,” “HIKARI,” “SAKURA,” “KODAMA” and “TSUBAME” trains on the Tōkaidō, Sanyō and Kyūshū Shinkansen, and the stations at which trains stop vary with train types. The JAPAN RAIL PASS is only valid for “HIKARI,” “SAKURA,” “KODAMA” Tōhoku Shinkansen "HAYATE," "YAMABIKO,"etc. and “TSUBAME” trains, and not valid for any seats, reserved or non-reserved, on “NOZOMI” and “MIZUHO” trains. To travel on the Tōkaidō, Sanyō and Kyūshū Shinkansen, the pass holders must take Tōhoku Shinkansen (713.7 km) “HIKARI,” “SAKURA,” “KODAMA” or “TSUBAME” trains, or -

Case of High-Speed Ground Transportation Systems

MANAGING PROJECTS WITH STRONG TECHNOLOGICAL RUPTURE Case of High-Speed Ground Transportation Systems THESIS N° 2568 (2002) PRESENTED AT THE CIVIL ENGINEERING DEPARTMENT SWISS FEDERAL INSTITUTE OF TECHNOLOGY - LAUSANNE BY GUILLAUME DE TILIÈRE Civil Engineer, EPFL French nationality Approved by the proposition of the jury: Prof. F.L. Perret, thesis director Prof. M. Hirt, jury director Prof. D. Foray Prof. J.Ph. Deschamps Prof. M. Finger Prof. M. Bassand Lausanne, EPFL 2002 MANAGING PROJECTS WITH STRONG TECHNOLOGICAL RUPTURE Case of High-Speed Ground Transportation Systems THÈSE N° 2568 (2002) PRÉSENTÉE AU DÉPARTEMENT DE GÉNIE CIVIL ÉCOLE POLYTECHNIQUE FÉDÉRALE DE LAUSANNE PAR GUILLAUME DE TILIÈRE Ingénieur Génie-Civil diplômé EPFL de nationalité française acceptée sur proposition du jury : Prof. F.L. Perret, directeur de thèse Prof. M. Hirt, rapporteur Prof. D. Foray, corapporteur Prof. J.Ph. Deschamps, corapporteur Prof. M. Finger, corapporteur Prof. M. Bassand, corapporteur Document approuvé lors de l’examen oral le 19.04.2002 Abstract 2 ACKNOWLEDGEMENTS I would like to extend my deep gratitude to Prof. Francis-Luc Perret, my Supervisory Committee Chairman, as well as to Prof. Dominique Foray for their enthusiasm, encouragements and guidance. I also express my gratitude to the members of my Committee, Prof. Jean-Philippe Deschamps, Prof. Mathias Finger, Prof. Michel Bassand and Prof. Manfred Hirt for their comments and remarks. They have contributed to making this multidisciplinary approach more pertinent. I would also like to extend my gratitude to our Research Institute, the LEM, the support of which has been very helpful. Concerning the exchange program at ITS -Berkeley (2000-2001), I would like to acknowledge the support of the Swiss National Science Foundation. -

Shinkansen - Wikipedia 7/3/20, 10�48 AM

Shinkansen - Wikipedia 7/3/20, 10)48 AM Shinkansen The Shinkansen (Japanese: 新幹線, pronounced [ɕiŋkaꜜɰ̃ seɴ], lit. ''new trunk line''), colloquially known in English as the bullet train, is a network of high-speed railway lines in Japan. Initially, it was built to connect distant Japanese regions with Tokyo, the capital, in order to aid economic growth and development. Beyond long-distance travel, some sections around the largest metropolitan areas are used as a commuter rail network.[1][2] It is operated by five Japan Railways Group companies. A lineup of JR East Shinkansen trains in October Over the Shinkansen's 50-plus year history, carrying 2012 over 10 billion passengers, there has been not a single passenger fatality or injury due to train accidents.[3] Starting with the Tōkaidō Shinkansen (515.4 km, 320.3 mi) in 1964,[4] the network has expanded to currently consist of 2,764.6 km (1,717.8 mi) of lines with maximum speeds of 240–320 km/h (150– 200 mph), 283.5 km (176.2 mi) of Mini-Shinkansen lines with a maximum speed of 130 km/h (80 mph), and 10.3 km (6.4 mi) of spur lines with Shinkansen services.[5] The network presently links most major A lineup of JR West Shinkansen trains in October cities on the islands of Honshu and Kyushu, and 2008 Hakodate on northern island of Hokkaido, with an extension to Sapporo under construction and scheduled to commence in March 2031.[6] The maximum operating speed is 320 km/h (200 mph) (on a 387.5 km section of the Tōhoku Shinkansen).[7] Test runs have reached 443 km/h (275 mph) for conventional rail in 1996, and up to a world record 603 km/h (375 mph) for SCMaglev trains in April 2015.[8] The original Tōkaidō Shinkansen, connecting Tokyo, Nagoya and Osaka, three of Japan's largest cities, is one of the world's busiest high-speed rail lines. -

Central Japan Railway Company (JR Central)

20 Years After JNR Privatization Vol. 2 Central Japan Railway Company (JR Central) Company Foundation and Business During the last 20 years we have also made great efforts to strengthen our financial position; long-term liabilities Trends of ¥5.5 trillion inherited after the dissolution of the JR Central was established in April 1987 when Japanese Shinkansen Lease System in October 1991 have been National Railways (JNR) was broken up and privatized. paid down to ¥3.5 trillion at the end of FY2005. JR Central A principal role of the new company is to maintain and was listed on the Tokyo Stock Exchange in October 1997 develop the Tokaido Shinkansen, the main transport artery and the government sold all its remaining shares in the linking Tokyo, Nagoya and Osaka, as well as to provide company in April 2006. local transportation in the urban areas around Nagoya and Shizuoka. In the following 20 years, we have done Safe and Stable Transport our utmost to ensure customer satisfaction by providing Ensuring safe and stable transport is the fundamental convenient and comfortable services based on an principle of all JR Central operations. Based on the integrated approach to the railway business, and with recognition that safety is the most important duty of a safety and provision of a stable transport service as our transport business, we have improved and strengthened top priority. We have also worked to achieve efficient our safety facilities by consolidating and investing in our operations across all our business activities and to safety systems and taking systematic safety measures every maintain a healthy relationship between management year. -

Japan's High-Speed Rail System Between Osaka

MTI Report MSTM 00-4 Japan’s High-Speed Rail System Between Osaka and Tokyo and Commitment to Maglev Technology: A Comparative Analysis with California’s High Speed Rail Proposal Between San Jose/San Francisco Bay Area and Los Angeles Metropolitan Area March 2000 Robert Kagiyama a publication of the Norman Y. Mineta International Institute for Surface Transportation Policy Studies IISTPS Created by Congress in 1991 Technical Report Documentation Page 1. Report No. 2. Government Accession No. 3. Recipients Catalog No. 4. Title and Subtitle 5. Report Date Japan’s High-Speed Rail System between Osaka and Tokyo and March 2000 Commitment to Maglev Technology: A Comparative Analysis with California’s High-Speed Rail Proposal between San Jose/San Francisco bay Area and Los Angeles Metropolitan Area 6. Performing Organization Code 7. Author 8. Performing Organization Report No. Robert Kagiyama MSTM 00-4 9. Performing Organization Name and Address 10. Work Unit No. Norman Y. Mineta International Institute for Surface Transportation Policy Studies College of Business—BT550 San José State University San Jose, CA 95192-0219 11. Contract or Grant No. 65W136 12. Sponsoring Agency Name and Address 13. Type of Report and Period Covered California Department of Transportation U.S. Department of Transportation MTM 290 March 2000 Office of Research—MS42 Research & Special Programs Administration P.O. Box 942873 400 7th Street, SW Sacramento, CA 94273-0001 Washington, D.C. 20590-0001 14. Sponsoring Agency Code 15. Supplementary Notes This capstone project was submitted to San José State University, College of Business, Master of Science Transportation Management Program as partially fulfillment for graduation. -

Sanyo Shinkansen “Nozomi” Fares & Surcharges(¥)

TOKAIDO/SANYO SHINKANSEN “NOZOMI” FARES & SURCHARGES(¥) Notes:1. The special surcharge for non‐reserved seats on “NOZOMI” is a special rate, equivalent to rates for non‐reserved seats on HIKARI and KODAMA trains. 2. When you want to change your seat on “NOZOMI” from non‐reserved to reserved, you must pay the difference for the reserved‐seat super‐express surcharge (minus ¥ 200 at off‐ peak season, and plus ¥ 200 at peak season). 3. When riding “MIZUHO” between Shin‐Osaka and Hakata, the basic fare and the super‐ express surcharge are the same as those for the “NOZOMI” (they are also the same if you transfer between the “MIZUHO” and “NOZOMI” ). 4. A ¥ 200 discount during the off‐peak season and a ¥ 200 surcharge during the peak season are applicable. 5. When a Green Car is used, an additional surcharge is applicable. 6. Fares for children aged from 6 to 11 years are half of the adult fare; Green Car charges are the same for children as for adults. Children aged 5 years or younger may travel with an adult without charge if they do not use a separate seat. 7. Japan Rail Pass is not valid for “Nozomi” and “Mizuho” trains(including non‐reserved seats). To travel on Tokaido & Sanyo Shinkansen lines, Japan Rail Pass holders have to take “Hikari” trains, “Kodama” trains or “Sakura” trains(see the next page). Sta ons Tokyo 東京 170 Shinagawa 品川 2,500 Shinagawa 870 510 420 Shin-Yokohama 新横浜 2,500 2,500 Shin-Yokohama 870 870 6,380 6,380 5,720 4,920 4,920 4,920 Nagoya Nagoya 名古屋 4,180 4,180 4,180 8,360 8,360 8,030 2,640 Kyoto 京都 5,810 5,810 5,470 3,270 -

The Asia-Pacific Journal: Japan Focus In-Depth Critical Analysis of the Forces Shaping the Asia-Pacific...And the World

The Asia-Pacific Journal: Japan Focus In-depth critical analysis of the forces shaping the Asia-Pacific...and the world. T he Asia-Pacif ic Jo urnal, Vo l. 12, Issue 4 7, No . 1, Dec. 1, 20 14 . Fift y Years o f t he Shinkansen Vaclav Smil Japan o f 20 14 is clearly a tro ubled natio n -– and I will remind the reader abo ut o nly a few key co mpo nents o f its peculiar s ituatio n. The co untry is s till rich by any glo bal s tandard but its natio nal debt is far higher than that in any o ther affluent co untry, and ris ing, and in 20 14 its eco no my has been chro nically clo s e to , o r actually in, a deflatio nary reces s io n. Japan is s till the wo rld’s third larges t eco no my, but after decades o f huge trade s urplus es it is no w running s ubs tantial trade deficits . The caus e o f thes e deficits go es beyo nd the po s t-Fukus hima need fo r higher impo rts o f o il and gas : o ffs ho ring o f Japan’s manufacturing has s een wides pread lo s s o f capacities and jo bs , and many jo bs have beco me part-time and tempo rary. Japan is s till ho me to famo us glo bal brands (To yo ta, Ho nda, Niko n) but perfo rmance o f s o me o f thes e co mpanies has been tainted by po o r quality pro ducts and co rpo rate s candals (financial fraud by Olympus , mas s ive recalls o f To yo ta cars , Takata’s deficient airbags ins talled in millio ns o f vehicles ) and s o me firms that were previo us ly pio neers o f widely admired technical advances and the envy o f co rpo rate managers (So ny, Panas o nic, Fujits u) no w face chro nic difficulties , if they are no t nearly bankrupt. -

Growth Strategy for Japan's Airline and Rail Industries:Tokyo Olympics to Trigger a Leap

No. 199 February 1, 2015 Growth Strategy for Japan’s Airline and Rail Industries: Tokyo Olympics to Trigger a Leap Keisuke SANO and Kotaro SHINTANI NRI Papers No. 199 February 1, 2015 Growth Strategy for Japan’s Airline and Rail Industries: Tokyo Olympics to Trigger a Leap Keisuke SANO and Kotaro SHINTANI I Vision for the Airline and Rail Markets as They Reach a Turning Point II Japan’s Stagnant and Shrinking Domestic Airline Market III Higher Demand in West Japan and Lower Demand in East Japan for Low Cost Carriers (LCCs) IV Success in the Market of Foreign Visitors to Japan is Key to Sustainable Growth V Approaching a Time Where Railway Company’s Business Model May No Longer Be Relevant VI Strengthening Cooperation between Companies to Spur Growth of Railway Business VII The Challenge of New Ways to Increase Revenues VIII The 2020 Tokyo Olympics Would Be an Ideal Showcase for Introducing Japan iven Japan’s shrinking population, in order for infrastructure businesses such as airlines and G railways to attain sustainable growth, it is vital that they both uncover latent demand in the domestic market and tap into overseas markets with a particular emphasis on emerging markets. Traditionally, transport service products have been designed for the working-age population as a major user base. However, in the future, increased attention must be paid to the senior market. Because people travel less as they age, transport companies must develop new services such as those that encourage senior citizens to travel as well as those related to nursing care. -

JRTR No.64 Feature 50 Years of High-Speed Railways

50 Years of High-Speed Railways 50 Years of Tokaido Shinkansen History Yoshiki Suyama Introduction regular service in the base timetable and arranging extra trains when necessary. The Tokaido Shinkansen commenced operation on October When the Tokaido Shinkansen commenced operation, 1, 1964 and is about to reach its 50th anniversary. The there were 60 departures per day in a “1-1” hourly timetable Tokaido Shinkansen, which takes on the role of Japan’s with one Hikari, stopping only at major stations, and one main transportation artery, has served 5.6 billion passengers Kodama, stopping at each station. The travel time of Hikari since its start and propped up Japan’s economy. Ever since between Tokyo and Shin-Osaka was 4 hours. the operation commenced, the Tokaido Shinkansen has Subsequently, the number of train departures was maintained a flawless record of no train accidents resulting increased time and again with the “2-2” and “3-3” hourly in fatalities or injuries of passengers onboard, and has timetables. Revisions were made almost annually to demonstrated stable and precise operation with an annual accommodate the rapid surge in transportation volume average delay of 0.9 minutes per operating train (FY2013). during Japan’s high-growth period. Transport capacity was The maximum speed in service has risen significantly boosted until the number of daily trains reached 240 in the from 210 km/h, when the line initially went into operation, year after the extension to Hakata was completed in 1975. to 270 km/h at present. Next spring, the maximum speed When Japanese National Railways (JNR) was privatized in is scheduled to be increased to 285 km/h.