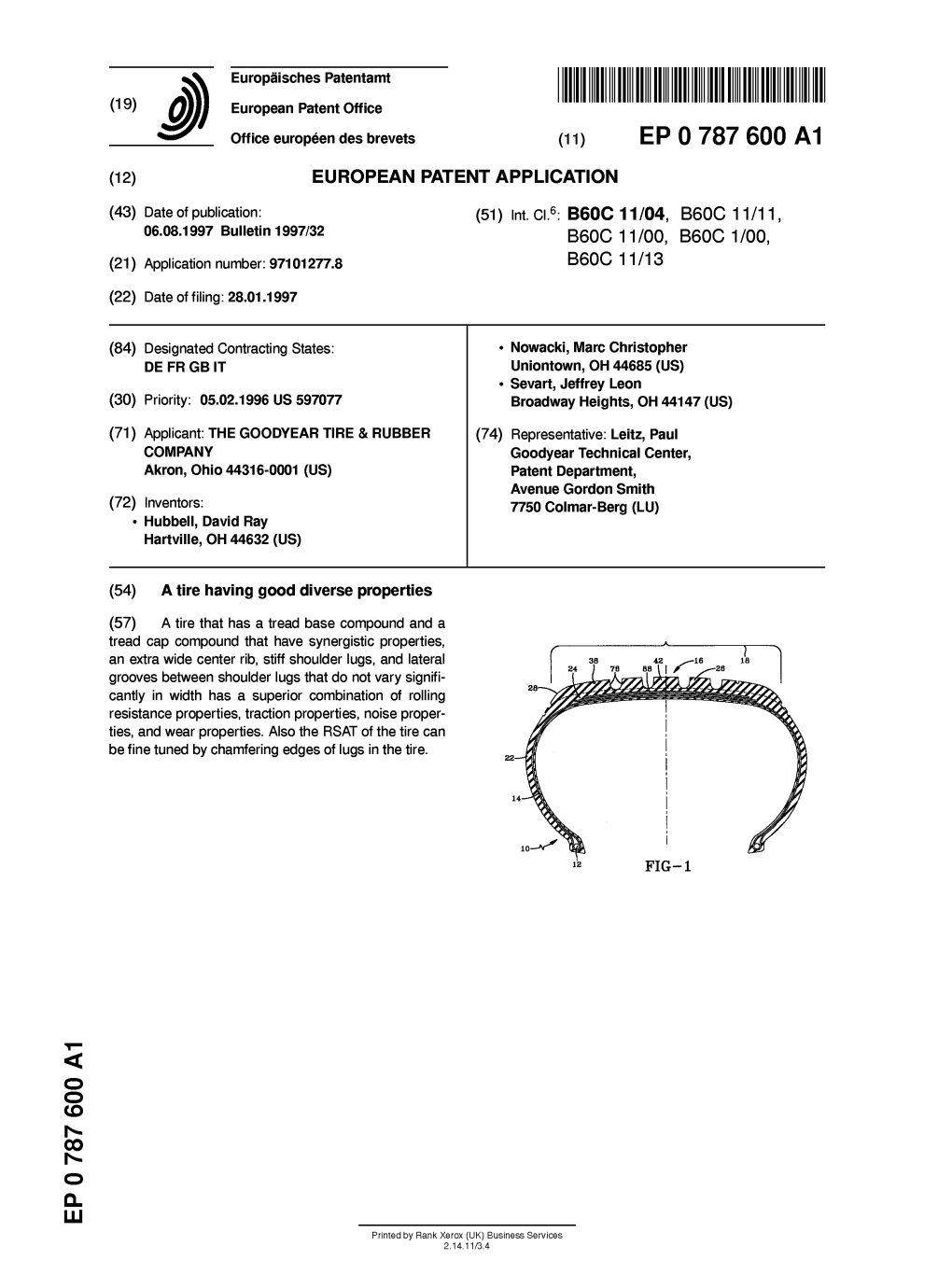

A Tire Having Good Diverse Properties

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Mechanics of Pneumatic Tires

CHAPTER 1 MECHANICS OF PNEUMATIC TIRES Aside from aerodynamic and gravitational forces, all other major forces and moments affecting the motion of a ground vehicle are applied through the running gear–ground contact. An understanding of the basic characteristics of the interaction between the running gear and the ground is, therefore, essential to the study of performance characteristics, ride quality, and handling behavior of ground vehicles. The running gear of a ground vehicle is generally required to fulfill the following functions: • to support the weight of the vehicle • to cushion the vehicle over surface irregularities • to provide sufficient traction for driving and braking • to provide adequate steering control and direction stability. Pneumatic tires can perform these functions effectively and efficiently; thus, they are universally used in road vehicles, and are also widely used in off-road vehicles. The study of the mechanics of pneumatic tires therefore is of fundamental importance to the understanding of the performance and char- acteristics of ground vehicles. Two basic types of problem in the mechanics of tires are of special interest to vehicle engineers. One is the mechanics of tires on hard surfaces, which is essential to the study of the characteristics of road vehicles. The other is the mechanics of tires on deformable surfaces (unprepared terrain), which is of prime importance to the study of off-road vehicle performance. 3 4 MECHANICS OF PNEUMATIC TIRES The mechanics of tires on hard surfaces is discussed in this chapter, whereas the behavior of tires over unprepared terrain will be discussed in Chapter 2. A pneumatic tire is a flexible structure of the shape of a toroid filled with compressed air. -

05(167-178) 120160093 조현석.Hwp

Transactions of KSAE, Vol. 25, No. 2, pp.167-178 (2017) Copyright Ⓒ 2017 KSAE / 147-05 pISSN 1225-6382 / eISSN 2234-0149 DOI https://doi.org/10.7467/KSAE.2017.25.2.167 Sensitivity Analysis of Steering Wheel Return-ability at Low Speed HyeonSeok Cho․ByungRim Lee*․SeHyun Chang․YoungDae Park․MinJun Kim․SangWoo Hwang Suspension and Steering Research Lab, Hyundai Motor Company, 150 Hyundaiyeonguso-ro, Hwaseong-si, Gyeonggi 18280, Korea (Received 26 September 2016 / Revised 13 December 2016 / Accepted 11 January 2017) Abstract : The steering wheel of a vehicle has a typical characteristic of automatically returning to its neutral state when the driver releases it. Steering returnability originated from the tire forces and kingpin moments. It is proportional to the reaction torque that is generated through the rack and column, which are dependent on suspension and steering geometry. It is also important to accurately predict and design it because steering returnability is related to steering performance. In this study, a detailed multibody dynamics model of a vehicle was designed by using ADAMS/Car and simulated for steering returnability. In addition, a tolerance analysis of the chassis system in terms of part dimension and properties has been performed in order to minimize the design parameters. The sensitivity of the selected design parameters was then analyzed via Design of Experiments(DOE). As a result, we were able to obtain the main parameters through a contribution analysis. It can be used to predict steering returnability and improve -

A Novel Chassis Concept for Power Steering Systems Driven by Wheel Individual Torque at the Front Axle M

25th Aachen Colloquium Automobile and Engine Technology 2016 1 A Novel Chassis Concept For Power Steering Systems Driven By Wheel Individual Torque At The Front Axle M. Sc. Philipp Kautzmann Karlsruhe Institute of Technology, Institute of Vehicle System Technology, Karlsruhe, Germany M. Sc. Jürgen Römer Schaeffler Technologies AG & Co. KG, Karlsruhe, Germany Dr.-Ing. Michael Frey Karlsruhe Institute of Technology, Institute of Vehicle System Technology, Karlsruhe, Germany Dr.-Ing. Marcel Ph. Mayer Schaeffler Technologies AG & Co. KG, Karlsruhe, Germany Summary The project "Intelligent Assisted Steering System with Optimum Energy Efficiency for Electric Vehicles (e²-Lenk)" focuses on a novel assisted steering concept for electric vehicles. We analysed different suspensions to use with this innovative power steering concept driven by wheel individual drive torque at the front axle. Our investigations show the potential even for conventional suspensions but reveal the limitations of standard chassis design. Optimized suspension parameters are needed to generate steering torque efficiently. Requirements arise from emergency braking, electronic stability control systems and the potential of the suspension for the use with our steering system. In lever arm design a trade-off between disturbing and utilizable forces occurs. We present a new design space for a novel chassis layout and discuss a first suspension design proposal with inboard motors, a small scrub radius and a big disturbance force lever arm. 1 Introduction Electric vehicles are a promising opportunity to reduce local greenhouse gas emissions in transport and increase overall energy efficiency, as electric drivetrain vehicles operate more efficiently compared to conventionally motorized vehicles. The internal combustion engine of common vehicles not only accelerates the vehicle, but also supplies energy to on-board auxiliary systems, such as power-assisted steering, which reduces the driver’s effort at the steering wheel. -

Kristian Lee Lardner

Prediction of the Off-Road Rigid-Ring Model Parameters for Truck Tire and Soft Soil Interactions By Kristian Lee Lardner A Thesis Presented in Partial Fulfillment of the Requirements for the Degree of Master of Applied Science in Automotive Engineering Faculty of Engineering and Applied Science University of Ontario Institute of Technology Oshawa, Ontario, Canada July 2017 © 2017 Kristian Lardner ABSTRACT Significant time and cost savings can be realized through the use of virtual simulation of testing procedures across diverse areas of research and development. Fully detailed virtual truck models using the simplified off-road rigid-ring model parameters may further increase these economical savings within the automotive industry. The determination of the off-road rigid-ring parameters is meant to facilitate the simulation of full vehicle models developed by Volvo Group Trucks Technology. This works features new FEA (Finite Element Analysis) tire and SPH (Smoothed Particle Hydrodynamics) soil interaction modeling techniques. The in-plane and out-of-plane off-road rigid-ring parameters are predicted for an RHD (Regional Haul Drive) truck tire at varying operating conditions. The tire model is validated through static and dynamic virtual tests that are compared to previously published literature. Both the in-plane and out-of-plane off-road rigid-ring RHD parameters were successfully predicted. The majority of the in-plane parameters are strongly influenced by the inflation pressure of the tire because the in-plane parameters are derived with respect to the mode of vibration of the tire. The total equivalent vertical stiffness on a dry sand is not as heavily influenced by the inflation pressure compared to predictions on a hard surface. -

Study on Cornering Stability Control Based on Pneumatic Trail Estimation by Using Dual Pitman Arm Type Steer-By-Wire on Electric Vehicle

Study on Cornering Stability Control Based on Pneumatic Trail Estimation by Using Dual Pitman Arm Type Steer-By-Wire on Electric Vehicle Ryo Minaki Yoichi Hori The University of Tokyo The University of Tokyo Department of Electrical Engineering Graduate School of Frontier Sciences Hongo, Bunkyo-ku, Japan Kashiwa, Chiba, Japan [email protected] [email protected] Abstract—This paper proposes novel high accuracy road margin). In addition, we propose a novel cornering stability condition estimation called Tire Grip Margin (TGM), and TGM control technique based on the tire grip margin with active is estimated by using dual pitman arm type steer-by-wire and front steering and in-wheel motor on electric vehicle. Finally, lateral force sensor and estimator. In addition, we propose we verify the technique by the vehicle dynamics simulator cornering stability control technique based on the TGM. It can CarSim. help driver and vehicle before unstable state. We verify our proposed system achieves robust vehicle dynamics control on the low friction road by CarSim. CarSim is simulator for the vehicle II. TIRE GRIP MARGIN (TGM) dynamics. A. Ground Contact Length of Tire and Lateral Keywords-active front steering; electric power steering; electric Displacement of Tire Tread Rubber vehicle; in-wheel motor; pitman arm; pneumatic trail; steer-by- A Tire has ground contact length caused by vehicle load, wire; tire grip margin; deflection because tire is made of hollow rubber. It is about 15- 20 [cm]. When a tire is rolled ground contact is started. After a I. INTRODUCTION few second, it is ended. -

Development of a Two-Dimensional Model of a Pneumatic Tire Timothy Lewis Clemson University, [email protected]

Clemson University TigerPrints All Theses Theses 12-2012 Development of a Two-dimensional Model of a Pneumatic Tire Timothy Lewis Clemson University, [email protected] Follow this and additional works at: https://tigerprints.clemson.edu/all_theses Part of the Mechanical Engineering Commons Recommended Citation Lewis, Timothy, "Development of a Two-dimensional Model of a Pneumatic Tire" (2012). All Theses. 1539. https://tigerprints.clemson.edu/all_theses/1539 This Thesis is brought to you for free and open access by the Theses at TigerPrints. It has been accepted for inclusion in All Theses by an authorized administrator of TigerPrints. For more information, please contact [email protected]. DEVELOPMENT OF A TWO-DIMENSIONAL MODEL OF A PNEUMATIC TIRE A Thesis Presented to the Graduate School of Clemson University In Partial Fulfillment of the Requirements for the Degree Master of Science Mechanical Engineering by Timothy R. Lewis December 2012 Accepted by: Dr. Paul F. Joseph, Committee Chair Dr. Timothy B. Rhyne Dr. Gang Li ABSTRACT The pneumatic tire has been studied extensively since its invention in 1888. With the advent of high-powered computers and the use of the finite element method, the understanding of the tire's complex non-linear behavior has grown tremendously. However, one weakness of finite element models is that parameter studies are difficult and time consuming to perform. In contrast, an analytical model can quickly and easily perform extensive parameter studies. To the knowledge of the author, all existing analytical models of the tire make assumptions concerning the tire's behavior and construction that while useful for obtaining some of the first-order characteristics, are limited since they cannot relate tire behavior such as force-deflection to individual tire stiffnesses. -

Tire - Wikipedia, the Free Encyclopedia

Tire - Wikipedia, the free encyclopedia http://en.wikipedia.org/wiki/Tire Tire From Wikipedia, the free encyclopedia A tire (or tyre ) is a ring-shaped covering that fits around a wheel's rim to protect it and enable better vehicle performance. Most tires, such as those for automobiles and bicycles, provide traction between the vehicle and the road while providing a flexible cushion that absorbs shock. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed air. Before rubber was developed, the first versions of tires were simply bands of metal that fitted around wooden wheels to prevent wear and tear. Early rubber tires were solid (not pneumatic). Today, the majority of tires are pneumatic inflatable structures, comprising a doughnut-shaped body of cords and wires encased in rubber and generally filled with compressed air to form an inflatable cushion. Pneumatic tires are used on many types of vehicles, including cars, bicycles, motorcycles, trucks, earthmovers, and aircraft. Metal tires are still used on locomotives and railcars, and solid rubber (or Stacked and standing car tires other polymer) tires are still used in various non-automotive applications, such as some casters, carts, lawnmowers, and wheelbarrows. Contents 1 Etymology and spelling 2 History 3 Manufacturing 4 Components 5 Associated components 6 Construction types 7 Specifications 8 Performance characteristics 9 Markings 10 Vehicle applications 11 Sound and vibration characteristics 12 Regulatory bodies 13 Safety 14 Asymmetric tire 15 Other uses 16 See also 17 References 18 External links Etymology and spelling Historically, the proper spelling is "tire" and is of French origin, coming from the word tirer, to pull. -

Factors Influencing Tire Force, Moment Characteristics

www.rubbernews.com Rubber & Plastics News • August 20, 2018 19 Technical Factors influencing tire force, moment characteristics By Prasenjit Ghosh and Rabindra Mukhopadhyay Hari Shankar Singhania Elastomer and Tyre Research Institute Executive summary Tires largely influence the vehicle performance with respect to In an automobile, tires play a crucial role in ensuring dynamic stability of the vehicle, which includes handling, stability, ride comfort and fuel economy. Tire developers cornering, traction, braking, driving and steering, providing lateral and directional stability. are constantly working for improving the respective tire performance All these criteria are satisfied by lateral and longitudinal properties of the tire. The vehicle handling characteristics to keep pace with the emerging requirements from behavior and thus stability largely depends on tire force and moment (F&M) characteristics. With the de- the automobile industry. Very often, it is expected that tires must velopment of computational techniques, tire F&M properties have become the key input for multi-body achieve many of these mutually conflicting properties simultaneous- simulation, which is the integral part of any new vehicle development process. There are multiple parameters related to design as well as operational conditions that influence tire force TECHNICAL NOTEBOOK and moment characteristics. The present work aims to study the influence of design and operational pa- Edited by John Dick rameters on F&M properties of passenger car tires. The major design parameters like belt angle, belt ma- terial and tread material were varied. For operational parameters, load, inflation pressure, fitment rim ly, which is a daunting task for tire designers. Further, the linkages width and camber were used as variables. -

Test Methods of Rubber Materials and Products

TEST METHODS OF RUBBER MATERIALS AND PRODUCTS MATADOR RUBBER S.R.O. Summary Chapter “Rubber Raw Material Testing” describes chemical analyses of raw materials used in the rubber and tyre-making industry. This part is dedicated to a principal explanation of basic determinants in raw material analysis. Such analyses are used primarily to determine basic chemical and physical-chemical constants that are directly related to purity of the used raw materials. The second part describes chemical analyses of vulcanizates. More complex procedures are used and instrumental analytical methods are applied in chemical analyses of vulcanizates. This part explains principles of instrumental analyses used in rubber-making practice. Chapter “Rubber Compound and Vulcanizate Testing” is related to the chapter on “Rubber Raw Material Testing” and provides a comprehensive description of the system of testing rubber compounds, materials and vulcanizates, starting from sampling and testing vessels up to evaluation of test results according to specific standards. The chapter is divided into four parts as follows: • Rubber Compound Testing (determining viscosity, scorching, vulcanization characteristics) • Testing Rheologic Properties of Compounds (rheologic properties of elastomer systems, liquid classification, factors affecting polymer viscosity, rheometry) • Vulcanizate Testing (determining stress-strain properties, hardness, rebound resilience, tear strength, resistance to abrasion, aging test, dynamic tests, adhesion tests) • Dynamical-Mechanical-Thermal Analysis of Vulcanizates Chapter “Laboratory Tyre Testing” discusses measuring and testing tyres in laboratory conditions. Laboratory tests are divided according to two criteria – into specific categories of vehicles (passenger, utility, agricultural and special vehicles) depending on their intended use and into dynamic and static tests depending on the condition of the tyre to be tested. -

Advance Vehicle Technology

Advanced Vehicle Technology To my long-suffering wife, who has provided sup- port and understanding throughout the preparation of this book. Advanced Vehicle Technology Second edition Heinz Heisler MSc., BSc., F.I.M.I., M.S.O.E., M.I.R.T.E., M.C.I.T., M.I.L.T. Formerly Principal Lecturer and Head of Transport Studies, College of North West London, Willesden Centre, London, UK OXFORD AMSTERDAM BOSTON LONDON NEW YORK PARIS SAN DIEGO SAN FRANCISCO SINGAPORE SYDNEY TOKYO Butterworth-Heinemann An imprint of Elsevier Science Linacre House, Jordan Hill, Oxford OX2 8DP 225 Wildwood Avenue, Woburn, MA 01801-2041 First published by Edward Arnold 1989 Reprinted by Reed Educational and Professional Publishing Ltd 2001 Second edition 2002 Copyright # 1989, 2002 Heinz Heisler. All rights reserved The right of Heinz Heisler to be identified as the author of this work has been asserted in accordance with the Copyright, Designs and Patents Act 1988 No part of this publication may be reproduced in any material form (including photocopying or storing in any medium by electronic means and whether or not transiently or incidentally to some other use of this publication) without the written permission of the copyright holder except in accordance with the provisions of the Copyright, Designs and Patents Act 1988 or under the terms of a license issued by the Copyright Licensing Agency Ltd, 90 Tottenham Court Road, London, England W1T 4LP. Applications for the copyright holder's written permission to reproduce any part of this publication should be addressed to the publishers Whilst the advice and information in this book are believed to be true and accurate at the date of going to press, neither the authors nor the publisher can accept any legal responsibility or liability for any errors or omissions that may be made. -

Robust Estimation of Road Friction Coefficient for Vehicle Active Safety Systems

Robust Estimation of Road Friction Coefficient for Vehicle Active Safety Systems by Chang Sun Ahn A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy (Mechanical Engineering) in The University of Michigan 2011 Doctoral Committee: Professor Huei Peng, Chair Professor Timothy J. Gordon Professor Jeffrey L. Stein Assistant Professor Ryan M. Eustice © Chang Sun Ahn 2011 ACKNOWLEDGEMENTS First and foremost I would like to express my gratitude to my advisor, Huei Peng, for his guidance, support, and motivation throughout my doctoral study. Without his encouragement, this dissertation and my doctoral study would not have been possible. I would also like to thank my committee members: Professor Timothy J. Gordon, Professor Jeffrey L. Stein, and Professor Ryan M. Eustice. Their advice and comments were greatly helpful to complete this dissertation. I gratefully acknowledge the support from Ford Motor Company through the Ford-University of Michigan Innovation Alliance Project program. Particularly, my gratitude goes to Dr. H. Eric Tseng for his guidance, insights into vehicle dynamics, and care for my personal development. In addition, I would like to thank Mitch McConnell at Ford Motor Company for his assistance in the vehicle winter test. My colleagues at the University of Michigan’s Vehicle Dynamics Lab (VDL) have been crucial part of my life at Ann Arbor. Many thanks for the unforgettable years to my friends: Chiao-Ting Li, Sean Yang, Jongwha Yoon, Youseok Kou, William Smith, Shenbo Li, Byung-Joo Kim, and Tianyou Guo. Finally, I would like to express my loving appreciation to my wife, Yeon Kim, and my mother. -

Systematic Review of Tyre Technology 1 Yasuhiro Ishikawa

Systematic Review of Tyre Technology 1 Yasuhiro Ishikawa ■ Abstract The history of the tyre starts with the use of the wheel, using a log or its x-section. Tyres then came into common use on the wheels of carts or horse carts. The pneumatic tyre was originally invented by R.W. Thomson in the middle of 19th century. Then at the end of 19th century, a pneumatic tyre for automobiles was invented. The history of the Japanese rubber industry also starts around this time: the latter half of 19th century, out of which the tyre industry then developed. The history of the Japanese tyre industry is divided into the three following stages: Stage 1: Dawn of the Industry The Japanese tyre industry began in the Meiji era (1868-1912) with the initial development of the Japanese rubber industry. The foundation of Tsuchiya Rubber Factory in 1886 (Meiji 19) is generally taken to herald the start of the Japanese rubber industry, approximately fifty years after the invention of vulcanization by C. Goodyear in 1839. Stage 2: Age of Growth This period from the beginning of the Taisho era (1912-1926) to the end of World War II saw the introduction to Japan of rubber technology from foreign countries, when domestic industry as a whole was developing with the importation of various technologies. The founding of domestic tyre manufacture dates from this period. Domestically-developed tyre technology showed dramatic growth during the War and played an important role in military supplies. Stage 3: Maturity This stage covers the time from the end of the War II to the present.