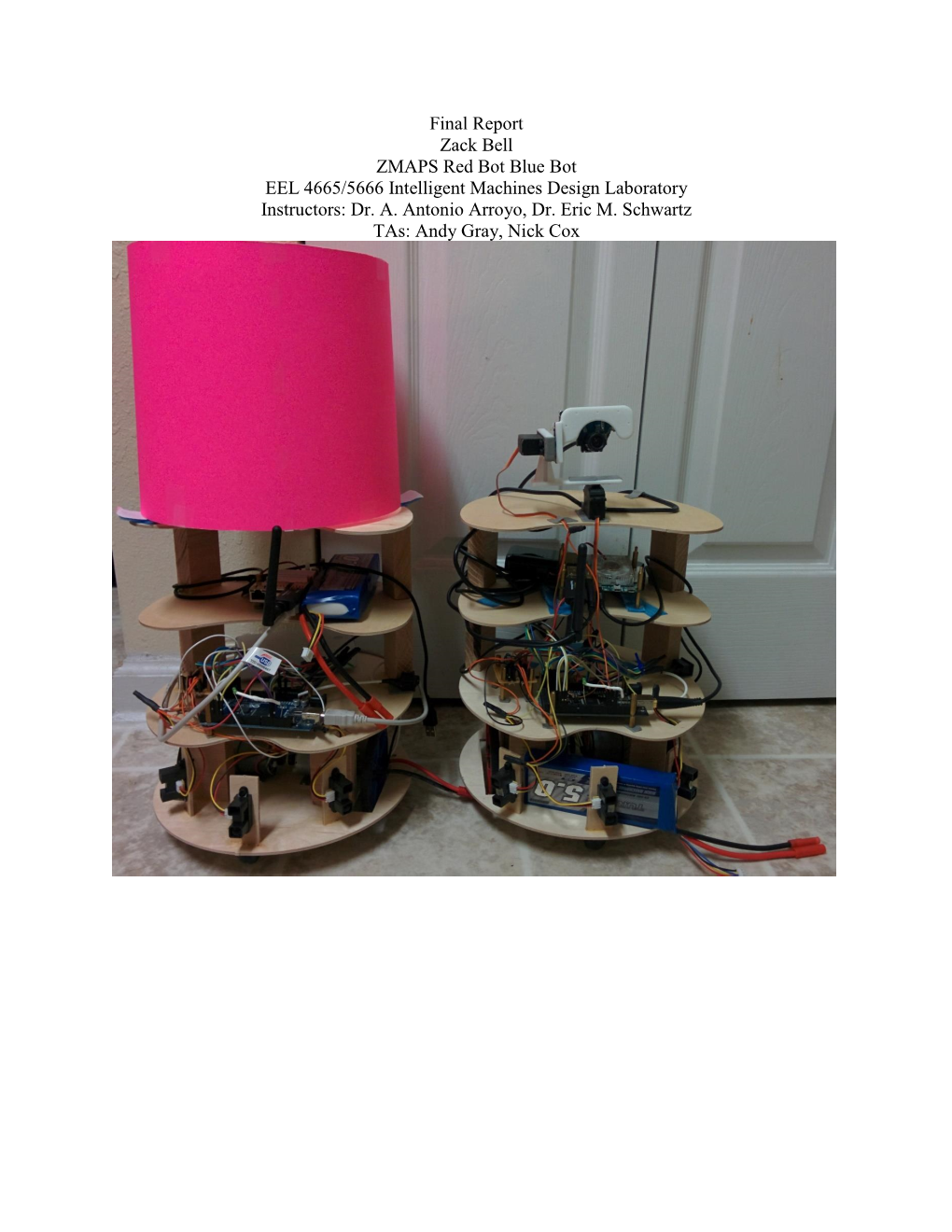

Final Report Zack Bell ZMAPS Red Bot Blue Bot EEL 4665/5666 Intelligent Machines Design Laboratory Instructors: Dr

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

18 Free Ways to Download Any Video Off the Internet Posted on October 2, 2007 by Aseem Kishore Ads by Google

http://www.makeuseof.com/tag/18-free-ways-to-download-any-video-off-the-internet/ 18 Free Ways To Download Any Video off the Internet posted on October 2, 2007 by Aseem Kishore Ads by Google Download Videos Now download.cnet.com Get RealPlayer® & Download Videos from the web. 100% Secure Download. Full Movies For Free www.YouTube.com/BoxOffice Watch Full Length Movies on YouTube Box Office. Absolutely Free! HD Video Players from US www.20north.com/ Coby, TV, WD live, TiVo and more. Shipped from US to India Video Downloading www.VideoScavenger.com 100s of Video Clips with 1 Toolbar. Download Video Scavenger Today! It seems like everyone these days is downloading, watching, and sharing videos from video-sharing sites like YouTube, Google Video, MetaCafe, DailyMotion, Veoh, Break, and a ton of other similar sites. Whether you want to watch the video on your iPod while working out, insert it into a PowerPoint presentation to add some spice, or simply download a video before it’s removed, it’s quite essential to know how to download, convert, and play these videos. There are basically two ways to download videos off the Internet and that’s how I’ll split up this post: either via a web app or via a desktop application. Personally, I like the web applications better simply because you don’t have to clutter up and slow down your computer with all kinds of software! UPDATE: MakeUseOf put together an excellent list of the best websites for watching movies, TV shows, documentaries and standups online. -

Primaria Digital. Aulas Digitales Móviles. Manual General Introductorio 1

ARGENTINA Primaria Digital. Aulas Digitales Móviles. Manual General Introductorio 1 Dirección de Gestión Educativa; Dirección de Educación Primaria Presenta los lineamientos del Plan Primaria Digital y cuenta con tres partes. En ellas se detallan la política de integración del país, sus objetivos, y una propuesta pedagógica para llevarla a cabo. También se trata la importancia de las Aulas Digitales móviles en la escuela primaria, sus ventajas e interacción, y se brinda una orientación para su uso. 01/08/2018 AULAS DIGITALES MÓVILES Instructivo técnico Equipo Técnico Jurisccional - Dirección Provincial de Tecnologías Educativas Ministerio de Educación Autoridades Presidente de la Nación Ing. Mauricio Macri Ministro de Educación y Deportes Lic. Esteban Bullrich Jefe de Gabinete Dr. Diego Sebastián Marías Secretario de Gestión Educativa Lic. Maximiliano Gulmanelli Secretaria de Innovación y Calidad Educativa Lic. María de las Mercedes Miguel Subsecretario de Coordinación Administrativa Sr. Félix Lacroze Gerente general Educ.ar S.E. Lic. Guillermo Fretes Directora de Educación Digital y Contenidos Multiplataforma Lic. María Florencia Ripani Director en Gestión de programas Ing. Mauro Iván Nunes Equipo Técnico Jurisccional - Dirección Provincial de Tecnologías Educativas Ministerio de Educación Argentina. Ministerio de Educación de la Nación Manual de primaria digital : instructivo técnico. - 1.a ed. - Ciudad Autónoma de Buenos Aires : Ministerio de Educación de la Nación, 2016. 39 p. : il. ; 28x20 cm. ISBN 978-950-00-1120-4 1. Formación -

How to Install and Configure Webcam Trust WB 3320X Live on Ubuntu /Debian Linux

Walking in Light with Christ - Faith, Computing, Diary Articles & tips and tricks on GNU/Linux, FreeBSD, Windows, mobile phone articles, religious related texts http://www.pc-freak.net/blog How to Install and configure webcam trust WB 3320X Live on Ubuntu /Debian Linux Author : admin I had to install WebCAM TRUST WB 3320X on one Xubuntu Linux install. Unfortunately by default the camera did not get detected (the Webcam vendor did not provide driver or specifications for Linux either). Thus I researched on the internet if and how this camera can be made work on Ubuntu Linux. I found some threads discussing the same issues as mine in Ubuntu Forums here . The threads even suggested a possible fix, which when followed literally did not work on this particular 32-bit Xubuntu 12.04.1 installation. I did 20 minutes research more but couldn't find much on how to make the Webcam working. I used Cheese and Skype to test if the webcamera can capture video, but in both of them all I see was just black screen. he camera was detected in lsusb displayed info as: # lsusb | grep -i webcam Bus 002 Device 002: ID 093a:2621 Pixart Imaging, Inc. PAC731x Trust Webcam After reading further a bit I found out some people online suggesting loading the gspca kernel module. I searched what kind of gspca*.kokernel modules are available using: 1 / 8 Walking in Light with Christ - Faith, Computing, Diary Articles & tips and tricks on GNU/Linux, FreeBSD, Windows, mobile phone articles, religious related texts http://www.pc-freak.net/blog locate gspca |grep -i .ko 1. -

MX-19.2 Users Manual

MX-19.2 Users Manual v. 20200801 manual AT mxlinux DOT org Ctrl-F = Search this Manual Ctrl+Home = Return to top Table of Contents 1 Introduction...................................................................................................................................4 1.1 About MX Linux................................................................................................................4 1.2 About this Manual..............................................................................................................4 1.3 System requirements..........................................................................................................5 1.4 Support and EOL................................................................................................................6 1.5 Bugs, issues and requests...................................................................................................6 1.6 Migration............................................................................................................................7 1.7 Our positions......................................................................................................................8 1.8 Notes for Translators.............................................................................................................8 2 Installation...................................................................................................................................10 2.1 Introduction......................................................................................................................10 -

Pipenightdreams Osgcal-Doc Mumudvb Mpg123-Alsa Tbb

pipenightdreams osgcal-doc mumudvb mpg123-alsa tbb-examples libgammu4-dbg gcc-4.1-doc snort-rules-default davical cutmp3 libevolution5.0-cil aspell-am python-gobject-doc openoffice.org-l10n-mn libc6-xen xserver-xorg trophy-data t38modem pioneers-console libnb-platform10-java libgtkglext1-ruby libboost-wave1.39-dev drgenius bfbtester libchromexvmcpro1 isdnutils-xtools ubuntuone-client openoffice.org2-math openoffice.org-l10n-lt lsb-cxx-ia32 kdeartwork-emoticons-kde4 wmpuzzle trafshow python-plplot lx-gdb link-monitor-applet libscm-dev liblog-agent-logger-perl libccrtp-doc libclass-throwable-perl kde-i18n-csb jack-jconv hamradio-menus coinor-libvol-doc msx-emulator bitbake nabi language-pack-gnome-zh libpaperg popularity-contest xracer-tools xfont-nexus opendrim-lmp-baseserver libvorbisfile-ruby liblinebreak-doc libgfcui-2.0-0c2a-dbg libblacs-mpi-dev dict-freedict-spa-eng blender-ogrexml aspell-da x11-apps openoffice.org-l10n-lv openoffice.org-l10n-nl pnmtopng libodbcinstq1 libhsqldb-java-doc libmono-addins-gui0.2-cil sg3-utils linux-backports-modules-alsa-2.6.31-19-generic yorick-yeti-gsl python-pymssql plasma-widget-cpuload mcpp gpsim-lcd cl-csv libhtml-clean-perl asterisk-dbg apt-dater-dbg libgnome-mag1-dev language-pack-gnome-yo python-crypto svn-autoreleasedeb sugar-terminal-activity mii-diag maria-doc libplexus-component-api-java-doc libhugs-hgl-bundled libchipcard-libgwenhywfar47-plugins libghc6-random-dev freefem3d ezmlm cakephp-scripts aspell-ar ara-byte not+sparc openoffice.org-l10n-nn linux-backports-modules-karmic-generic-pae -

Computer Vision Using Simplecv and the Raspberry Pi 2

1 COMPUTER VISION USING SIMPLECV AND THE RASPBERRY PI Cuauhtemoc Carbajal ITESM CEM Reference: Practical Computer Vision with SimpleCV - Demaagd (2012) Enabling Computers To See 2 SimpleCV is an open source framework for building computer vision applications. With it, you get access to several high-powered computer vision libraries such as OpenCV – without having to first learn about bit depths, file formats, color spaces, buffer management, eigenvalues, or matrix versus bitmap storage. This is computer vision made easy. SimpleCV is an open source framework 3 It is a collection of libraries and software that you can use to develop vision applications. It lets you work with the images or video streams that come from webcams, Kinects, FireWire and IP cameras, or mobile phones. It’s helps you build software to make your various technologies not only see the world, but understand it too. SimpleCV is written in Python, and it's free to use. It runs on Mac, Windows, and Ubuntu Linux, and it's licensed under the BSD license. Features 4 Convenient "Superpack" installation for rapid deployment Feature detection and discrimination of Corners, Edges, Blobs, and Barcodes Filter and sort image features by their location, color, quality, and/or size An integrated iPython interactive shell makes developing code easy Image manipulation and format conversion Capture and process video streams from Kinect, Webcams, Firewire, IP Cams, or even mobile phones New (and only) book! 5 Learn how to build your own computer vision (CV) applications quickly and easily with SimpleCV. You can access the book online through the Safari collection of the ITESM CEM Digital Library. -

统信软件技术有限公司 Uniontech Software Technology Co., Ltd

统信软件技术有限公司 Uniontech Software Technology Co., Ltd. 网址:www.uniontech.com 地址:北京经济技术开发区科谷一街 10 号院 12 号楼 电话:400-8588-488 北京·上海·广州·武汉·成都·西安·太原·重庆·南京·无锡·云浮·金华 更强生态 更加友好 更易操作 www.uniontech.com 态 生 新 创 统 系 作 操 造 打 统信软件是以“打造中国操作系统创新生态”为使命 的中国基础软件公司,由国内领先的操作系统厂家于 2019 年联合成立。公司专注于操作系统等基础软件的 研发与服务,致力于为不同行业的用户提供安全稳定、 智能易用的操作系统产品与解决方案。统信软件总部设 立在北京,同时在武汉、上海、广州、南京等地设立了 运营中心、研发中心和通用软硬件适配认证中心。 作为国内领先的操作系统研发团队,统信软件拥有操作 系统研发、行业定制、国际化、迁移和适配、交互设计、 咨询服务等多方面专业人才,能够满足不同用户和应用 场景对操作系统产品的广泛需求。基于国产芯片架构的 操作系统产品已经和龙芯、飞腾、申威、鲲鹏、兆芯、 海光等芯片厂商开展了广泛和深入的合作,与国内各主 流整机厂商,以及数百家国内外软件厂商展开了全方位 的兼容性适配工作。 统信软件正努力发展和建设以中国软硬件产品为核心 的创新生态,同时不断加强产品与技术研发创新。统信 软件将立足中国、面向国际,争取在十年内成为全球主 要的基础软件供应商。 打造操作系统创新生态 统一 统一 统一 统一 统一 统一 版本 支撑平台 软件商店 开发接口 标准规范 文档 三大产品 统信桌面操作系统 统信专用设备操作系统 统信服务器操作系统 三大解决方案 统信应用商店 终端域管平台 统信云打印 合作伙伴及镜像获取:https://www.chinauos.com 产 品 统信桌面操作系统 一 智能协同 · 美观易用 统信桌面操作系统将全球领先的技术和创新带入政府信息化建设和企业级信息技术基础架构,是当今国内增 长最快的操作系统之一。许多政府和企业用户由于其易用性和可扩展性而选择统信操作系统,信息部门和运 维部门则更重视统信操作系统提供给桌面终端的稳定性、安全性和灵活性。因为完全开放源代码和自下而上 的自主研发,统信操作系统可以快速、轻松的增强和定制,而无需依赖国外厂家的产品维护周期。面向安全 可靠环境和开放环境,帮助希望拥有安全、稳定和易用的桌面操作系统的用户,及想通过开源解决方案提升 生产力的用户,提供了一种高效的操作系统替换方案。 特点与优势 自主应用 文件管理器 设备管理器 截图录屏 影院 终端 软件商店 音乐 语音备忘录 相册 文档查看器 光盘刻录器 生态应用 Skype 企业微信 QQ 钉钉 搜狗输入法 科大讯飞输入法 百度输入法 金蝶天燕云 百度网盘 Seafile Google Chrome 360 红莲花 阿里云 360 安全云盘 和信云桌面 安全浏览器 安全浏览器 WPS 泛微 OA 坚果云 中望 CAD 金山词霸 360 压缩 360 安全卫士 京东 网易云音乐 Tower 协作 雷鸟邮件 ·自主研发 : 国内自主研发的 DDE 桌面环境 ·美观友好 : 简单易用、时尚便捷的交互界面 ·多平台支持: 龙芯、申威、鲲鹏、飞腾、海光、兆芯等硬件及虚拟化平台,并适用于私有云与公有云平台 产 品 统信服务器操作系统 二 安全稳定 · 使用高效 · 广泛支撑 统信服务器操作系统是统信软件技术有限公司(简称“统信软件”)发布的基于 Linux 内核的 服务器操作系统产品,它广泛兼容国内外各种数据库和中间件,支持企业级的应用软件和开发 环境,并提供丰富、高效的管理工具。统信操作系统服务器版软件能为裸机、虚拟环境、容器、 -

The AV Linux Manual

AV LINUX 6.0 USER MANUAL A Guide to Get Acquainted with AV Linux Prepared by Glen MacArthur, August 14/2012 Legal Disclaimer: Debian/GNU Linux comes with no guarantee so neither does AV Linux. I accept no responsibility for any hardware/software malfunctions or data loss resulting from it's use. It is important to note that the AV Linux ISO contains software that is non- free and is distributed under a special licensing arrangement with the original developers, re-distributing the AV Linux ISO with the non-free content included is a violation of these licenses. AV Linux also contains Multimedia Codecs that may be under patent in certain countries, it is the users responsibility to know the law as it applies to their own respective country before downloading or installing. TABLE OF CONTENTS: • Page 3. - PREFACE – NEW TO LINUX? • Page 4. - THE AV LINUX STORY • Page 5. - CREDITS & CONTACT • Page 6. - RUNNING AV LINUX LIVE • Page 9. - AV LINUX BASIC BOOTING BIBLE • Page 10. - INSTALLING AV LINUX • Page 11. - GETTING AROUND IN AV LINUX • Page 19. - SliM LOGIN MANAGER • Page 20. - MOUSE CURSOR THEMES • Page 21. - PERFORMANCE SETTINGS • Page 23. - PROPRIETARY VIDEO DRIVERS IN AV LINUX • Page 25. - COMPIZ WINDOW MANAGER • Page 26. - AV LINUX KERNELS • Page 27. - KERNEL CHEATCODES • Page 28. - AV LINUX SOFTWARE • Page 30. - INSTALLING SOFTWARE IN AV LINUX • Page 33. - NETWORKING WITH AV LINUX • Page 36. - PRINTING WITH AV LINUX • Page 37. - USING JACK • Page 39. - USING THE ALOOP DAEMON • Page 40. - SUPPORTED PRO HARDWARE IN AV LINUX • Page 48. - M-AUDIO 1010LT PCM_MULTI WITH AV LINUX • Page 51. -

C4C Lubuntu 16.04.4 Respin User Guide & Manual

C4C Lubuntu 16.04.4 ReSpin User Guide & Manual C4C Lubuntu 16.04.4 ReSpin User Guide & Manual About Your Christian Operating System The C4C Lubuntu 16.04.4 ReSpin User Guide & Manual is Copyright © 2018 Computers4Christians. Computers4Christians accepts no responsibility for the accuracy, or use, of the information presented in the guide for any purpose and makes no commitment as to support for the computers, computer equipment and/or software, files or data it gives away. Only the Bible is infallible. TABLE OF CONTENTS C4C Lubuntu 16.04.4 ReSpin User Guide & Manual Table of Contents ABOUT , C4C, Statement of Faith, Disclaimer/Copyright Information.............................................3 Artistic License 2.0.................................................................................................................... 4 Christian Purpose [and Objectives], Secular Purpose, Linux, Chapters......................................6 Biblical Purpose, Why Free, Witness..........................................................................................7 C4C Lubuntu ReSpin................................................................................................................. 8 BEGIN........................................................................................................................................... 9 Update (Apt, Software Updater, Apt-url, GDebi, LSC, Snap, Synaptic).....................................13 Deleting Files (Empty Trash, Shift+Delete)..............................................................................18 -

Logitech Cam Linux Driver

Logitech cam linux driver Are you trying to install the webcam on Ubuntu? Have you tried plugging it in and just trying to use it? Ubuntu contains lots of drivers out of the. This site hosts the Linux driver for the QuickCam Express and other Dexxa Webcam; Labtec Webcam (old model); LegoCam; Logitech QuickCam Express (old Supported Cameras · Installation. logitech webcam linux driver free download. Creative WebCam PD Linux driver This is linux driver for webcams based on the Endpoints EP image. Webcam drivers are usually available one of three ways: within the kernel, as a .. Some Logitech camera models are supported by the Philips driver in Section. Hi guys, Can anone tell me how to install my logitech webcam? Again, im very new to linux so instruction must be grandpa noobie:)[ubuntu] Logitech C webcam install. Welcome to the USB Video Class Linux device driver home. The goal of . dc7, Logitech Quickcam OEM Cisco VT Camera II, Logitech, [1,2]. dc9. ? gmdl&keyword=logitech+cam+driver+linux Logitech cam driver linux I suppose that was a logical fallacy on my part. Introduction to. Here is how you set up your webcam with Linux, capture videos and images, do VoIP .com/linux-driver-for-quickcam-usb-cameras-logitech-quickcam- fusion/. Linux Webcam drivers are provided by several different projects. Although the Linux UVC project covers many devices. Reason: Several drivers in this article are available as built-in kernel modules, linux-uvc. Genius iLook ; Logitech C Pro Stream Webcam; Logitech. How I got my Logitech web cam working with Linux. -

1. Variation of Camera Modules 2.Hardware Requirement

1. Variation of Camera Modules Flat cable type for example, the Physical Computing Lab Camera Module USB Cable type USB connected WEB camera . 2.Hardware Requirement When the camera module is connected to the Tinker Board, the following equipment are required. (1) Camera module board (2) Tinker Board / Tinker Board S (3) Micro SD card (4) 5 V 2.5 A Power supply or more (5) HDMI cable (6) LAN cable (7) HDMI display (8) Mouse (9) Keyboard (2) - (6), you can purchase "Tinker Board Complete Starter Kit". Please use it by all means. 3. Preparation of OS Target and assembly of equipment Let's explain how to use above equipment with Tinker OS. To use flat cable type camera, v2.0.4 or later Tinker OS required. ①OS Installation When using the Complete Starter Kit, installation process is needless, because the micro SD card with latest OS is included. From the ASUS site, download the new image file of Tinker OS Debian and write it into micro SD card. ASUS Website https://www.asus.com/us/Single-Board-Computer/Tinker-Board/ ② Insertion of the micro SD card Please insert OS written microSD card into the Tinker Board. ③ Connection of necessary equipment Connect the mouse, keyboard, LAN cable (when using wireless it’s not necessary), HDMI cable and power supply. ④ Camera Connection Before turning on the power, connect the camera. Please follow the procedure described as below. 4. About the connection method of the camera. 4.1 In the case of flat type cable camera module A flat cable like the one shown below. -

Mechanical Design of a Photogrammetry Imaging Platform for Prototype Meshing

TREBALL FI DE GRAU Grau en Enginyeria Mecànica MECHANICAL DESIGN OF A PHOTOGRAMMETRY IMAGING PLATFORM FOR PROTOTYPE MESHING Volume I (of III) Report Author: Carlos Gómez Gaibar Director: Pedro Ortiz Morón Call: June 2017 Mechanical design and manufacturing of a photogrammetry imaging platform for prototype meshing TABLE OF CONTENTS 1. OBJECTIVE, BACKGROUND AND MOTIVATION .......................................................................................... 1 2. PHOTOGRAPHY AND PHOTOGRAMMETRY: A BRIEF DESCRIPTION .......................................................... 2 2.1. Photography ....................................................................................................................................... 2 2.2. Photogrammetry ................................................................................................................................ 2 3. WORKING PRINCIPLES AND APPLICATIONS OF PHOTOGRAMMETRY ....................................................... 4 4. PATH TOWARDS THE CHOICE OF A SPECIFIC APPROACH .......................................................................... 6 4.1. Laser reconstruction and Surface from Motion (SFM) ....................................................................... 6 4.1.1. The use of laser in 3-D reconstruction operations ..................................................................... 6 4.1.2. Direct, realistic results ................................................................................................................ 6 4.2. Turntable vs orbiting