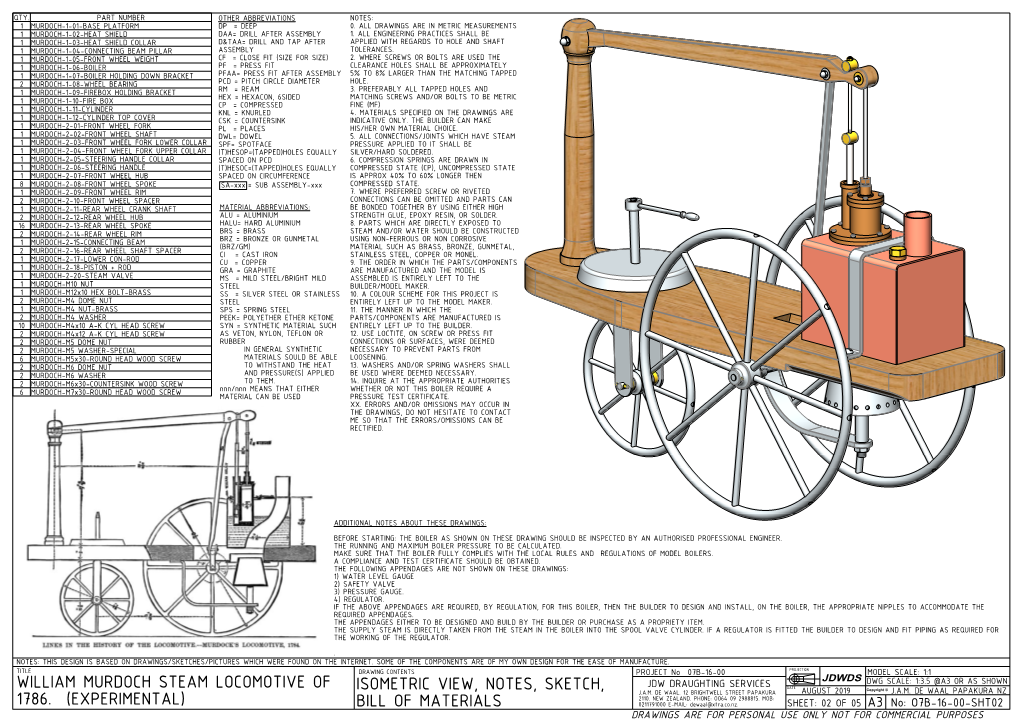

Isometric View, Notes, Sketch, Bill of Materials William

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

History of the Automobile

HISTORY OF THE AUTOMOBILE Worked by: Lara Mateus nº17 10º2 Laura Correia nº18 10º2 Leg1: the first car. THE EARLY HISTORY The early history of the automobile can be divided into a number of eras, based on the prevalent means of propulsion. Later periods were defined by trends in exterior styling, size, and utility preferences. In 1769 the first steam powered auto-mobile capable of human transportation was built by Nicolas-Joseph Cugnot. In 1807, François Isaac de Rivaz designed the first car powered by an internal combustion engine fueled by hydrogen. In 1886 the first petrol or gasoline powered automobile the Benz Patent-Motorwagen was invented by Karl Benz.This is also considered to be the first "production" vehicle as Benz made several identical copies. FERDINAND VERBIEST Ferdinand Verbiest, a member of a Jesuit mission in China, built the first steam-powered vehicle around 1672 as a toy for the Chinese Emperor. It was of small enough scale that it could not carry a driver but it was, quite possibly the first working steam-powered vehicle. Leg2: Ferdinand Verbiest NICOLAS-JOSEPH CUGNOT Steam-powered self-propelled vehicles large enough to transport people and cargo were first devised in the late 18th century. Nicolas-Joseph Cugnot demonstrated his fardier à vapeur ("steam dray"), an experimental steam-driven artillery tractor, in 1770 and 1771. As Cugnot's design proved to be impractical, his invention was not developed in his native France. The center of innovation shifted to Great Britain. NICOLAS-JOSEPH CUGNOT By 1784, William Murdoch had built a working model of a steam carriage in Redruth. -

RT Rondelle PDF Specimen

RAZZIATYPE RT Rondelle RAZZIATYPE RT RONDELLE FAMILY Thin Rondelle Thin Italic Rondelle Extralight Rondelle Extralight Italic Rondelle Light Rondelle Light Italic Rondelle Book Rondelle Book Italic Rondelle Regular Rondelle Regular Italic Rondelle Medium Rondelle Medium Italic Rondelle Bold Rondelle Bold Italic Rondelle Black Rondelle Black Italic Rondelle RAZZIATYPE TYPEFACE INFORMATION About RT Rondelle is the result of an exploration into public transport signage typefa- ces. While building on this foundation it incorporates the distinctive characteri- stics of a highly specialized genre to become a versatile grotesque family with a balanced geometrical touch. RT Rondelle embarks on a new life of its own, lea- ving behind the restrictions of its heritage to form a consistent and independent type family. Suited for a wide range of applications www.rt-rondelle.com Supported languages Afrikaans, Albanian, Basque, Bosnian, Breton, Catalan, Croatian, Czech, Danish, Dutch, English, Esperanto, Estonian, Faroese, Fijian, Finnish, Flemish, French, Frisian, German, Greenlandic, Hawaiian, Hungarian, Icelandic, Indonesian, Irish, Italian, Latin, Latvian, Lithuanian, Malay, Maltese, Maori, Moldavian, Norwegian, Polish, Portuguese, Provençal, Romanian, Romany, Sámi (Inari), Sámi (Luli), Sámi (Northern), Sámi (Southern), Samoan, Scottish Gaelic, Slovak, Slovenian, Sorbian, Spa- nish, Swahili, Swedish, Tagalog, Turkish, Welsh File formats Desktop: OTF Web: WOFF2, WOFF App: OTF Available licenses Desktop license Web license App license Further licensing -

Intimations 1800-1825

Intimations Extracted from the Watt Library index of family history notices as published in Inverclyde newspapers between 1800 and 1918. 1800-1825 This index covers birth, marriage and death notices that appeared in newspapers in the Greenock and Port Glasgow area from 1800 until 1825. It is provided to researchers as a reference resource to aid the searching of these historic publications which can be consulted on microfiche, preferably by prior appointment, at the Watt Library, 9 Union Street, Greenock. Records are indexed by type: birth, death and marriage, then by year in chronological order followed by surnames in alphabetical order. Marriage records are listed by year and the surnames, in alphabetical order, of the spouses. The copyright in this index is owned by Inverclyde Libraries, Museums and Archives to whom application should be made if you wish to use the index for any commercial purpose. It is made available for non- commercial use under the Creative Commons Attribution-Noncommercial-ShareAlike International License (CC BY-NC-SA 4.0 License). This document is also available in Open Document Format. 1800-1825 Record When Surname First Name Entry Type Birth 1794 CRAWFORD A daughter to Mr and Mrs Hugh Crawford junior, writer, born at Greenock on 3rd December 1794. (Advertiser and Courant 11.12.1794) Birth 1806 RAMSAY A daughter born 11th September 1806 to Major and Mrs Ramsay of Kelly. (Greenock Advertiser 17.9.1806) Birth 1808 GEILS A son born to Major and Mrs Geils of Geilstown, Dumbartonshire on 26th December 1808 at Greenock. (Greenock Advertiser 28.12.1808). -

In This Issue

Issue 537 October 2015 Worth £ 3/0/0 John Gotts’s steams his Ruston Proctor traction engine on to the arena for the first time after a 10 year restoration . Newsletter from the National Steam Centre In This Issue Tractors at National Rally Early Steam Engines Oct 2015 STEAM SUPREME 2 Club Cranes Part 2 Conquip 10 ton Crane By Rohan Lamb In this second part we look at the club’s 10 ton crane. This In 1958 tractor cranes were added to the product range. crane was built by Conquip Ltd., Auburn, NSW. It is a four wheel The first model was a 2¼ to 5 ton trailing-type crane based on a articulated crane with a non-telescopic boom, and rated to 10 tons. conventional tractor with an unrated front steering axle. The crane It was based around a Chamberlain Mk 3 industrial tractor (serial was mounted on a turntable at the rear of the tractor and trailed the no.2648) built in 19711, and fitted with a Perkins 4-270D 4 cylin- tractor during travel, but arched over the top when used for lifting. der diesel engine rated at 62 horsepower. Based on the date the tractor was made, the crane (serial no. A3367) was probably also built in 1971. Conquip was founded in 1947 by A. M. (Neil) Morison as a private business, and manufactured agricultural products such as farm graders, a hiball for land clearing, and blades and loaders for all types of crawler tractors. The company was publically listed in 1952. Early products were designed by the works manager, Bob Wallace who had previously worked as a designer at LeTourneau. -

The Steam Engine in England and France

Master’s Thesis 2016 30 ECTS School of Economics and Business The spark that ignited the Industrial Revolution An examination of the institutions surrounding the development of the steam engine in England and France Joshua Bragg Development and Natural Resource Economics Contents Preface and Acknowledgements ............................................................................................................. 1 Introduction ............................................................................................................................................. 3 Research Questions ............................................................................................................................. 5 Why did England dominate steam engine development and not France? ..................................... 6 Journey into Great Economic Mysteries ............................................................................................. 6 Background .............................................................................................................................................. 8 Energy Canyons ................................................................................................................................... 8 The Sources of Economic Growth ....................................................................................................... 8 The Mystery of Economic Growth ..................................................................................................... 10 Endogenous Growth -

William Murdoch (Edited from Wikipedia)

William Murdoch (Edited from Wikipedia) SUMMARY William Murdoch (sometimes spelled Murdock) (21 August 1754 – 15 November 1839) was a Scottish engineer and inventor. Murdoch was employed by the firm of Boulton and Watt and worked for them in Cornwall, as a steam engine erector for ten years, spending most of the rest of his life in Birmingham, England. Murdoch was the inventor of the oscillating cylinder steam engine, and gas lighting is attributed to him in the early 1790s, also the term "gasometer". Murdoch also made innovations to the steam engine, including the sun-and-planet gear. He invented the steam gun and the pneumatic tube message system, and worked on one of the first British paddle steamers to cross the English Channel. Murdoch built a prototype steam locomotive in 1784 and made a number of discoveries in chemistry. Murdoch remained an employee and later a partner of Boulton & Watt until the 1830s, and his reputation as an inventor has been obscured by the reputations of Boulton and Watt and the firm they founded. HISTORY William Murdoch was born in Lugar near Cumnock, East Ayrshire, Scotland, the third of seven children and the first son to survive beyond infancy. A son of John Murdoch, a former artillery gunner and a Millwright and tenant of Bello Mill, he was educated until the age of ten at the Old Cumnock Kirk (Church) School. He then began attending Auchinleck school under William Halbert, author of a highly regarded arithmetic textbook. Murdoch excelled in mathematics. Murdoch also learned the principles of mechanics, practical experimentation and working in metal and wood by assisting in his father's work. -

Two and Three Wheeler

UNIT I Lecture Hour 1: INTRODUCTION Heat engine is a machine for converting heat, developed by burning fuel into useful work. It can be said that heat engine is equipment which generates thermal energy and transforms it into mechanical energy. CLASSIFICATION OF HEAT ENGINES 1. Based on combustion of fuel: (i) External combustion engine (ii) Internal combustion engine. External combustion engine Here, the working medium, the steam, is generated in a boiler, located out side the engine and allowed in to the cylinder to operate the piston to do mechanical work. Internal combustion engine In internal combustion engine, the combustion of fuel takes place inside the engine cylinder and heat is generated within the cylinder. This heat is added to the air inside the cylinder and thus the pressure of the air is increased tremendously. This high pressure air moves the piston which rotates the crank shaft and thus mechanical work is done 2. Based on fuel used 1. Diesel engine 2. Petrol engine 3. Gas engine Diesel engine – Diesel is used as fuel Petrol engine – Petrol is used as fuel Gas engines – propane, butane or methane gases are used 3. Based ignition of fuel 1. Spark ignition engine (Carburetor type engines) 2. Compression ignition engine ( injector type engines) Spark ignition engine – a mixture of air and fuel is drawn in to the engine cylinder. Ignition of fuel is done by using a spark plug. The spark plug produces a spark and ignites the air- fuel mixture. Such combustion is called constant volume combustion (C.V.C.). Compression ignition engine – In compression ignition engines air is compressed in to the engine cylinder,. -

The Relevance of Skills to Innovation During the British Industrial Revolution, 1651-1851

The Relevance of Skills to Innovation during the British Industrial Revolution, 1651-1851 WORKING PAPER (NB: the final sample will be double the size, and extended back to 1551) Anton Howes [email protected] Brown University August 2016 What role did skills and education have in causing the rate of innovation to accelerate during the British Industrial Revolution? I present new evidence on the educational and professional backgrounds of 677 people who innovated in Britain between 1651 and 1851. Almost a third of innovators improved at least one industry or process for which they had no prior professional experience or training. And a fifth of innovators had professional experience irrelevant to all of their innovations. Yet common to almost all innovators was that they had prior contact with other innovators, suggesting the spread of an improving mentality. Where people lacked the skills to realise their envisioned improvements, they engaged in self-education. Even of the majority of innovators who improved familiar industries, it was not the skills training itself that influenced their decisions to become innovators, but that they were trained by other innovators. Skills and education often influenced what people chose to improve – people tended to stick to what they knew best – but not their decisions to become innovators. 1 Introduction In the two centuries between the end of the English Civil War in 1651 and the Great Exhibition of 1851, Britain became the world’s technological leader.1 The Great Exhibition was symbolic of the transformation from war-torn country to innovation superpower. Between May and October of 1851 over six million people, equivalent to a fifth of the country’s population, flocked to a glass hall, a Crystal Palace, purpose-built to celebrate the latest innovations.2 The transformation – an Industrial Revolution – was brought about by an unprecedented acceleration in the rate of innovation. -

The World's First Steam Train

The world's first steam train Richard Trevithick was a mining engineer from Cornwall who had grand ideas. In the early 1800s, he experimented with steam power. People already used steam to power machines, but nobody until Trevithick had thought of putting the engine on wheels. He did just this, and then watched as the steam powered the wheels, and the engine moved. Trevithick had invented the locomotive! Trevithick's manager saw what he had done, and was impressed. He decided to place a bet with another manager. He bet 500 guineas that Trevithick's locomotive could pull ten tons of iron along ten miles of track. The bet was accepted. Trevithick tested his locomotive on 21st February 1804 in front of a curious public audience. The heavy iron locomotive was ready at one end. Five wagons loaded with iron were attached, and the engine boiler filled with water. The locomotive was fired into action. The wheels started to turn, spinning against the iron rails until they gripped. Then, almost imperceptibly, the train began to move. It went slowly at first, but then sped up, chuffing all the way. The crowd cheered, and pointed at the train, which was unlike anything they had seen before. It was only going at five miles per hour, but it was moving all the same. After a few miles, the train came to a low bridge. "Watch out!" cried one of the spectators. But it was too late. The top of the engine's chimney hit the bridge and crashed to the ground. Men quickly rushed to replace the chimney, and it was soon up and running again. -

Industry Profile

Industry profile History The history of the automobile begins as early as 1769, with the creation of steam engine automobiles capable of human transport. In 1806, the first cars powered by an internal combustion engine running on fuel gas appeared, which led to the introduction in 1885 of the ubiquitous modern gasoline- or petrol-fueled internal combustion engine. Cars powered by electric power briefly appeared at the turn of the 20th century, but largely disappeared from use until the turn of the 21st century. The need to reduce the amount of air pollution generated by transportation has raised new interest in electric and hybrid vehicles. The early history of the automobile can be divided into a number of eras, based on the prevalent method of automotive propulsion during that time. Later periods were defined by trends in exterior styling, and size and utility preferences. The design of the Cugnot Steam Trolley (Jonathan Holguinisburg) (1769) Eras of invention Pioneer inventors German engineer Karl Benz, the inventor of numerous car-related technologies, is generally regarded as the inventor of the modern automobile, and received a German patent in 1886. The American George B. Selden filed for a patent on May 8, 1879. His application included not only the engine but its use in a 4-wheeled car. Mr. Selden filed a series of amendments to his application which stretched out the legal process, resulting in a delay of 16 years before the US 549160 was granted on November 5, 1895. The four-stroke petrol (gasoline) internal combustion engine that constitutes the most prevalent form of modern automotive propulsion is a creation of Page 1 German inventor Nikolaus Otto. -

Scottish Eccentrics

SCOTTISH ECCENTRICS by HUGH MacDIARMID SCOTTISH ECCENTRICS The distinguished Scottish poet and literary critic who writes this book recalls how Bernard Shaw in On The Rocks ironically declares that the massacres after the Battle of Culloden were not "mur- der" but simply "liquidation," since the slain Scots in question were "incompatible with British civilization." He then surveys the whole field of Scottish biography, and shows how true this has proved of an amazing number of distinguished Scots, no matter how successfully the bulk of the Scottish people have been assim- ilated to English standards since the Union. The facts are irresist- ible and bring out the "eccen- tricity" of Scottish genius in an extraordinary fashion. The author gives full-length studies often outstanding Scottish eccentrics, including Lord George Gordon of the "Gordon Riots"; Sir Thomas Urquhart, the trans- lator of Rabelais', "Christopher North"; "Ossian" (James Mac- pherson, M.P.); James Hogg, the Ettrick Shepherd; and William McGonagall, perhaps the world's best "bad poet". But he supports these leading cases with apt material drawn from the lives of hundreds of Scots of every period in history and every walk of life, and in this way builds up a bril- liant panoramic picture of Scottish psychology through the ages, singularly at variance with all generally accepted views of the national character. 15 S. net By the Same Author Poetry Sangschaw Penny Wheep To Circumjack Cencrastus First Hymn to Lenin, and other Poems A Drunk Man looks at the Thistle Stony Limits, and other Poems Fiction Annals of the Five Senses Translations The Handmaid of the Lord (novel, from the Spanish of Ramon Maria de Tenreiro) Birlinn Chlann-Rhagnaill (poem, from the Scots Gaelic of Alasdair Mac- Mhaighstir Alasdair) Criticism Contemporary Scottish Studies Albyn: or Scotland and the Future Scottish Scene (in collaboration with Lewis Grassic Gibbon) At the Sign of the Thistle etc. -

Abstract Godfrey Iii, Edward Eugene

ABSTRACT GODFREY III, EDWARD EUGENE. Gas-Insulated Gasifier for Biomass Derived Producer Gas. (Under the direction of Dr. Mari S. Chinn). This work focused on designing and fabricating a novel downdraft gasifier for biomass derived producer gas. Biomass offers itself up as a viable alternative energy source that can be sustained anywhere that agricultural and forestry commodities are grown. Gasification technology provides a means to manage and add value to normally underutilized agricultural and forestry crops and residues. Gasification can produce energy-rich gases while consuming fuel sources high in lignocellulose, offering an advantage over other bio-energy generation methods that cannot effectively use or convert lignin and hemicellulose. The objectives of this project were to 1) examine and describe the theory behind downdraft gasification; 2) design and fabricate a novel downdraft gasifier capable of generating producer gas from readily available fuels; and 3) investigate the effects of solid fuel physical characteristics (charcoal and sweet sorghum) and gasifying agent (air) flow rates 25.48 m3 h-1 (15 ft3 min-1) and 50.97 m3 h-1 (30 ft3 min-1) on gasification effectiveness. A research scale gas-insulated downdraft gasifier was designed using figures derived from published data in the field of biomass gasification. Design criteria for the gasifier included research-scale (e.g. quick run time and change over between testing events), mobility, modularity, gas conditioning (e.g. cooling and cleaning), and data acquisition with automated control capabilities. The gasifier was assembled from four major components (e.g. inner chamber, superstructure, outer panels, and ash collection), and mounted on caster wheels for mobility.