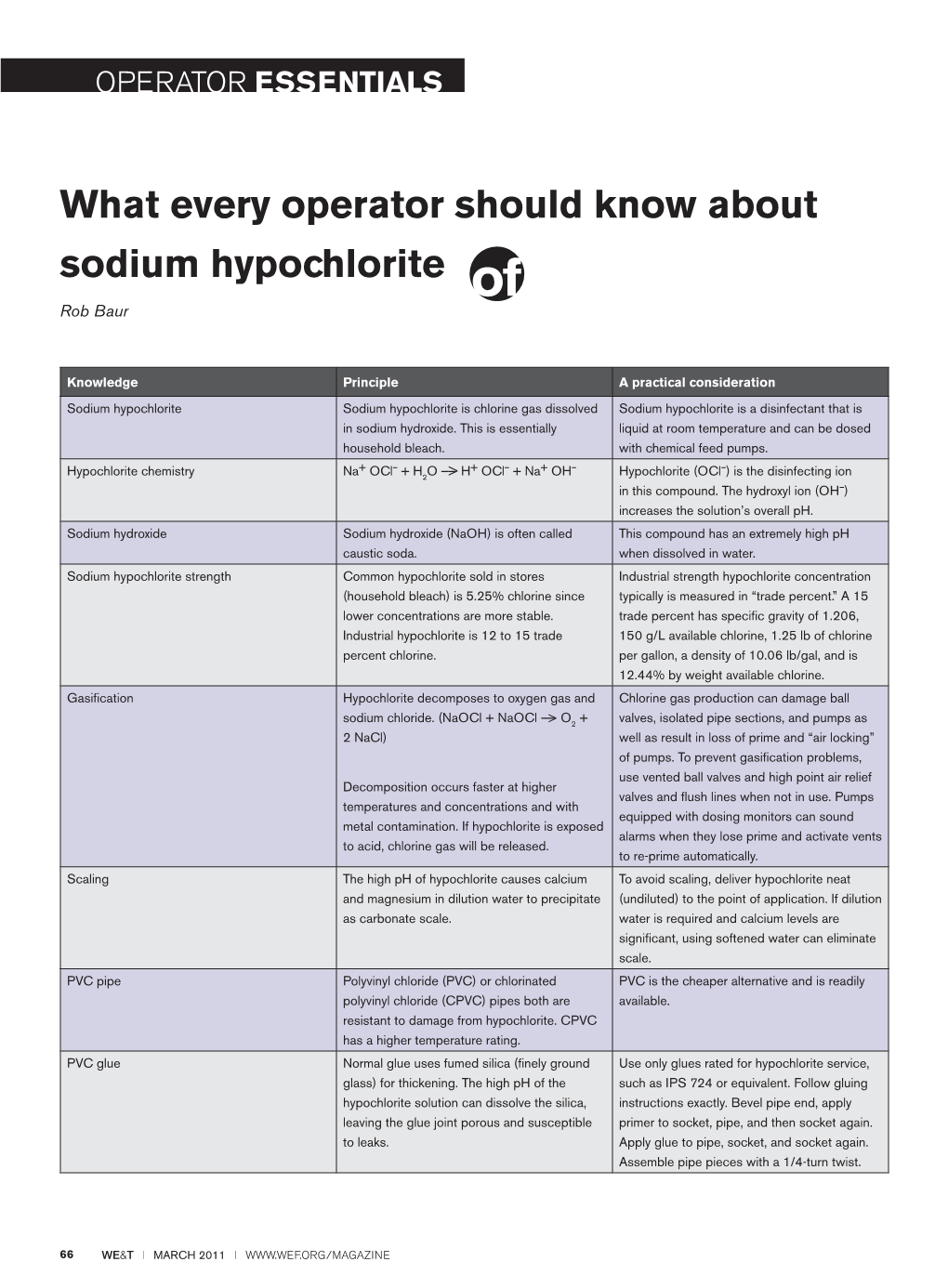

What Every Operator Should Know About Sodium Hypochlorite

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Chemical Disinfectants for Biohazardous Materials (3/21)

Safe Operating Procedure (Revised 3/21) CHEMICAL DISINFECTANTS FOR BIOHAZARDOUS MATERIALS ____________________________________________________________________________ Chemicals used for biohazardous decontamination are called sterilizers, disinfectants, sanitizers, antiseptics and germicides. These terms are sometimes equivalent, but not always, but for the purposes of this document all the chemicals described herein are disinfectants. The efficacy of every disinfectant is based on several factors: 1) organic load (the amount of dirt and other contaminants on the surface), 2) microbial load, 3) type of organism, 4) condition of surfaces to be disinfected (i.e., porous or nonporous), and 5) disinfectant concentration, pH, temperature, contact time and environmental humidity. These factors determine if the disinfectant is considered a high, intermediate or low-level disinfectant, in that order. Prior to selecting a specific disinfectant, consider the relative resistance of microorganisms. The following table provides information regarding chemical disinfectant resistance of various biological agents. Microbial Resistance to Chemical Disinfectants: Type of Microbe Examples Resistant Bovine spongiform encephalopathy (Mad Prions Cow) Creutzfeldt-Jakob disease Bacillus subtilis; Clostridium sporogenes, Bacterial Spores Clostridioides difficile Mycobacterium bovis, M. terrae, and other Mycobacteria Nontuberculous mycobacterium Poliovirus; Coxsackievirus; Rhinovirus; Non-enveloped or Small Viruses Adenovirus Trichophyton spp.; Cryptococcus sp.; -

EH&S COVID-19 Chemical Disinfectant Safety Information

COVID-19 CHEMICAL DISINFECTANT SAFETY INFORMATION Updated June 24, 2020 The COVID-19 pandemic has caused an increase in the number of disinfection products used throughout UW departments. This document provides general information about EPA-registered disinfectants, such as potential health hazards and personal protective equipment recommendations, for the commonly used disinfectants at the UW. Chemical Disinfectant Base / Category Products Potential Hazards Controls ● Ethyl alcohol Highly flammable and could form explosive Disposable nitrile gloves Alcohols ● ● vapor/air mixtures. ● Use in well-ventilated areas away from o Clorox 4 in One Disinfecting Spray Ready-to-Use ● May react violently with strong oxidants. ignition sources ● Alcohols may de-fat the skin and cause ● Wear long sleeve shirt and pants ● Isopropyl alcohol dermatitis. ● Closed toe shoes o Isopropyl Alcohol Antiseptic ● Inhalation of concentrated alcohol vapor 75% Topical Solution, MM may cause irritation of the respiratory tract (Ready to Use) and effects on the central nervous system. o Opti-Cide Surface Wipes o Powell PII Disinfectant Wipes o Super Sani Cloth Germicidal Wipe 201 Hall Health Center, Box 354400, Seattle, WA 98195-4400 206.543.7262 ᅵ fax 206.543.3351ᅵ www.ehs.washington.edu ● Formaldehyde Formaldehyde in gas form is extremely Disposable nitrile gloves for Aldehydes ● ● flammable. It forms explosive mixtures with concentrations 10% or less ● Paraformaldehyde air. ● Medium or heavyweight nitrile, neoprene, ● Glutaraldehyde ● It should only be used in well-ventilated natural rubber, or PVC gloves for ● Ortho-phthalaldehyde (OPA) areas. concentrated solutions ● The chemicals are irritating, toxic to humans ● Protective clothing to minimize skin upon contact or inhalation of high contact concentrations. -

For Peer Review Only - Page 1 of 27 BMJ Open

BMJ Open BMJ Open: first published as 10.1136/bmjopen-2015-010387 on 4 April 2016. Downloaded from FALSIFIED MEDICINES IN PERU: A Retrospective Review (1997-2014). ForJournal: peerBMJ Open review only Manuscript ID bmjopen-2015-010387 Article Type: Research Date Submitted by the Author: 27-Oct-2015 Complete List of Authors: Medina, Edwin; University of Barcelona - Faculty of Pharmacy, Department of Pharmacy and Pharmaceutical Technology Bel, Elvira; University of Barcelona - Faculty of Pharmacy, Department of Pharmacy and Pharmaceutical Technology Suñé, Josep María; University of Barcelona - Faculty of Pharmacy, Department of Pharmacy and Pharmaceutical Technology <b>Primary Subject Public health Heading</b>: Secondary Subject Heading: Global health, Epidemiology, Health policy, Health services research Keywords: Safety, Falsified, Medicines, Alerts, counterfeit, Drugs http://bmjopen.bmj.com/ on September 24, 2021 by guest. Protected copyright. For peer review only - http://bmjopen.bmj.com/site/about/guidelines.xhtml Page 1 of 27 BMJ Open BMJ Open: first published as 10.1136/bmjopen-2015-010387 on 4 April 2016. Downloaded from 1 2 3 FALSIFIED MEDICINES IN PERU: A Retrospective Review (1997-2014). 4 5 6 7 Authors: Edwin Medina1, Elvira Bel1, Josep María Suñé1 8 9 10 11 12 Affiliations: 13 14 15 1. DepartmentFor of peerPharmacy and review Pharmaceutical onlyTechnology, Faculty of 16 Pharmacy, University of Barcelona, Spain 17 18 19 20 Corresponding author: 21 22 Edwin Salvador Medina Vargas 23 24 Department of Pharmacy and Pharmaceutical Technology 25 Faculty of Pharmacy 26 University of Barcelona 27 Joan XXIII, s/n, 08028 Barcelona 28 29 Spain 30 Email: [email protected] 31 32 33 http://bmjopen.bmj.com/ 34 Keywords: Safety, Falsified, Medicines, Alerts, counterfeit, Drugs 35 36 37 38 39 Word Count 40 41 Abstract: 298 on September 24, 2021 by guest. -

Sodium Chloride (Halite, Common Salt Or Table Salt, Rock Salt)

71376, 71386 Sodium chloride (Halite, Common Salt or Table Salt, Rock Salt) CAS number: 7647-14-5 Product Description: Molecular formula: NaCl Appearance: white powder (crystalline) Molecular weight: 58.44 g/mol Density of large crystals: 2.17 g/ml1 Melting Point: 804°C1 Density: 1.186 g/ml (5 M in water)2 2 Solubility: 1 M in H2O, 20°C, complete, clear, colorless 2 pH: 5.0-8.0 (1 M in H2O, 25°C) Store at room temperature Sodium chloride is geologically stable. If kept dry, it will remain a free-flowing solid for years. Traces of magnesium or calcium chloride in commercial sodium chloride adsorb moisture, making it cake. The trace moisture does not harm the material chemically in any way. 71378 BioUltra 71386 BioUltra for molecular biology, 5 M Solution The products are suitable for different applications like purification, precipitation, crystallisation and other applications which require tight control of elemental content. Trace elemental analyses have been performed for all qualities. The molecular biology quality is also tested for absence of nucleases. The Certificate of Analysis provides lot-specific results. Much of the sodium chloride is mined from salts deposited from evaporation of brine of ancient oceans, or recovered from sea water by solar evaporation. Due to the presence of trace hygroscopic minerals, food-grade salt has a small amount of silicate added to prevent caking; as a result, concentrated solutions of "table salt" are usually slightly cloudy in appearance. 71376 and 71386 do not contain any anti-caking agent. Applications: Sodium chloride is a commonly used chemical found in nature and in all body tissue, and is considered an essential nutrient. -

Uncovering Evidence for Endocrine-Disrupting Chemicals That Elicit Differential Susceptibility Through Gene-Environment Interactions

toxics Review Uncovering Evidence for Endocrine-Disrupting Chemicals That Elicit Differential Susceptibility through Gene-Environment Interactions Dylan J. Wallis 1 , Lisa Truong 2 , Jane La Du 2, Robyn L. Tanguay 2 and David M. Reif 1,* 1 Department of Biological Sciences, North Carolina State University, Raleigh, NC 27695, USA; [email protected] 2 Department of Environmental and Molecular Toxicology, Oregon State University, Corvallis, OR 97331, USA; [email protected] (L.T.); [email protected] (J.L.D.); [email protected] (R.L.T.) * Correspondence: [email protected] Abstract: Exposure to endocrine-disrupting chemicals (EDCs) is linked to myriad disorders, charac- terized by the disruption of the complex endocrine signaling pathways that govern development, physiology, and even behavior across the entire body. The mechanisms of endocrine disruption in- volve a complex system of pathways that communicate across the body to stimulate specific receptors that bind DNA and regulate the expression of a suite of genes. These mechanisms, including gene regulation, DNA binding, and protein binding, can be tied to differences in individual susceptibility across a genetically diverse population. In this review, we posit that EDCs causing such differential responses may be identified by looking for a signal of population variability after exposure. We begin Citation: Wallis, D.J.; Truong, L.; La by summarizing how the biology of EDCs has implications for genetically diverse populations. We Du, J.; Tanguay, R.L.; Reif, D.M. then describe how gene-environment interactions (GxE) across the complex pathways of endocrine Uncovering Evidence for Endocrine- signaling could lead to differences in susceptibility. We survey examples in the literature of individual Disrupting Chemicals That Elicit susceptibility differences to EDCs, pointing to a need for research in this area, especially regarding Differential Susceptibility through the exceedingly complex thyroid pathway. -

Decontamination of Rooms, Medical Equipment and Ambulances Using an Aerosol of Hydrogen Peroxide Disinfectant B.M

Journal of Hospital Infection (2006) 62, 149–155 www.elsevierhealth.com/journals/jhin Decontamination of rooms, medical equipment and ambulances using an aerosol of hydrogen peroxide disinfectant B.M. Andersena,*, M. Rascha, K. Hochlina, F.-H. Jensenb, P. Wismarc, J.-E. Fredriksend aDepartment of Hospital Infection, Ulleva˚l University Hospital, Oslo, Norway bDivision of Pre-hospital Care, Ulleva˚l University Hospital, Oslo, Norway cDepartment of Medical Equipment, Ulleva˚l University Hospital, Oslo, Norway dHealth and Environment AS, Oslo, Norway Received 17 November 2004; accepted 1 July 2005 KEYWORDS Summary A programmable device (Sterinis, Gloster Sante Europe) Room decontamina- providing a dry fume of 5% hydrogen peroxide (H2O2) disinfectant was tion; Ambulance tested for decontamination of rooms, ambulances and different types of decontamination; medical equipment. Pre-set concentrations were used according to the Medical equipment decontamination; volumes of the rooms and garages. Three cycles were performed with Hydrogen peroxide increasing contact times. Repetitive experiments were performed using fume decontamina- Bacillus atrophaeus (formerly Bacillus subtilis) Raven 1162282 spores to tion; Spore test control the effect of decontamination; after a sampling plan, spore strips were placed in various positions in rooms, ambulances, and inside and outside the items of medical equipment. Decontamination was effective in 87% of 146 spore tests in closed test rooms and in 100% of 48 tests in a surgical department when using three cycles. One or two cycles had no effect. The sporicidal effect on internal parts of the medical equipment was only 62.3% (220 tests). When the devices were run and ventilated during decontamination, 100% (57/57) of spore strips placed inside were decontaminated. -

Calcium Chloride CAS N°:10043-52-4

OECD SIDS CALCIUM CHLORIDE FOREWORD INTRODUCTION Calcium chloride CAS N°:10043-52-4 UNEP PUBLICATIONS 1 OECD SIDS CALCIUM CHLORIDE SIDS Initial Assessment Report For SIAM 15 Boston, USA 22-25th October 2002 1. Chemical Name: Calcium chloride 2. CAS Number: 10043-52-4 3. Sponsor Country: Japan National SIDS Contact Point in Sponsor Country: Mr. Yasuhisa Kawamura Director Second Organization Div. Ministry of Foreign Affairs 2-2-1 Kasumigaseki, Chiyoda-ku Tokyo 100 4. Shared Partnership with: 5. Roles/Responsibilities of the Partners: • Name of industry sponsor Tokuyama Corporation /consortium Mr. Shigeru Moriyama, E-mail: [email protected] Mr. Norikazu Hattori, E-mail: [email protected] • Process used 6. Sponsorship History • How was the chemical or This substance is sponsored by Japan under ICCA Initiative and category brought into the is submitted for first discussion at SIAM 15. OECD HPV Chemicals Programme ? 7. Review Process Prior to The industry consortium collected new data and prepared the the SIAM: updated IUCLID, and draft versions of the SIAR and SIAP. Japanese government peer-reviewed the documents, audited selected studies. 8. Quality check process: 9. Date of Submission: 10. Date of last Update: 2 UNEP PUBLICATIONS OECD SIDS CALCIUM CHLORIDE 11. Comments: No testing (X) Testing ( ) The CaCl2-HPV Consortium members: (Japan) Asahi Glass Co., Ltd. Central Glass Co., Ltd. Sanuki Kasei Co., Ltd. Tokuyama Corporation [a global leader of the CaCl2-HPV Consortium] Tosoh Corporation (Europe) Brunner Mond (UK) Ltd. Solvay S.A. (North America) The Dow Chemical Company General Chemical Industrial Products Inc. Tetra Technologies, Inc. -

Suppression Mechanisms of Alkali Metal Compounds

SUPPRESSION MECHANISMS OF ALKALI METAL COMPOUNDS Bradley A. Williams and James W. Fleming Chemistry Division, Code 61x5 US Naval Research Lnhoratory Washington, DC 20375-5342, USA INTRODUCTION Alkali metal compounds, particularly those of sodium and potassium, are widely used as fire suppressants. Of particular note is that small NuHCOi particles have been found to be 2-4 times more effective by mass than Halon 1301 in extinguishing both eountertlow flames [ I] and cup- burner flames [?]. Furthermore, studies in our laboratory have found that potassium bicarbonate is some 2.5 times more efficient by weight at suppression than sodium bicarhonatc. The primary limitation associated with the use of alkali metal compounds is dispersal. since all known compounds have very low volatility and must he delivered to the fire either as powders or in (usually aqueous) solution. Although powders based on alkali metals have been used for many years, their mode of effective- ness has not generally been agreed upon. Thermal effects [3],namely, the vaporization of the particles as well as radiative energy transfer out of the flame. and both homogeneous (gas phase) and heterogeneous (surface) chemistry have been postulated as mechanisms by which alkali metals suppress fires [4]. Complicating these issues is the fact that for powders, particle size and morphology have been found to affect the suppression properties significantly [I]. In addition to sodium and potassium, other alkali metals have been studied, albeit to a consider- ably lesser extent. The general finding is that the suppression effectiveness increases with atomic weight: potassium is more effective than sodium, which is in turn more effective than lithium [4]. -

Evaluating Disinfectants for Use Against the COVID-19 Virus

When it comes to choosing a disinfectant to combat the COVID-19 virus, research and health authorities suggest not all disinfectants are equally effective. The difference is in their active ingredient(s). HEALTH CANADA AND U.S. EPA ASSESSMENTS The work to evaluate disinfectants perhaps best starts with lists of approved disinfectants compiled by government health authorities. Health Canada has compiled a list of 85 hard surface disinfectant products (as of March 20, 2020) that meet their requirements for disinfection of emerging pathogens, including the virus that causes COVID-19. It can be accessed here. You can wade through the entire list. But if you locate the Drug Identification Number (DIN) on the disinfectant product label or the safety data sheet (SDS), then you can use the search function to quickly see if the product meets Health Canada requirements. A second list, updated on March 19, 2020, provides 287 products that meet the U.S. Environmental Protection Agency’s (EPA) criteria for use against SARS-CoV-2, the novel coronavirus that causes the disease COVID-19. This list can be found here. Like the Health Canada list, you can wade through this one too. However, to best use this list, you should locate the U.S. EPA registration number on the product label or SDS, and use that number to search the list. The U.S. EPA registration number of a product consists of two sets of numbers separated by a hyphen. The first set of numbers refers to the company identification number, and the second set of numbers following the hyphen represents the product number. -

Self-Diffusion of Sodium, Chloride and Iodide Ions in Methanol-Water Mixture

Self-Diffusion of Sodium, Chloride and Iodide Ions in Methanol-Water Mixture E. Hawlicka* Institute of Applied Radiation Chemistry, Technical University, Wroblewskiego 15, 93-590, Lodz, Poland Z. Naturforsch. 41 a, 939-943 (1986); received April 25, 1986 The self-diffusion coefficients of Na+, C l- and I- in methanol-water solutions at 35 ± 0.01 °C have been measured in their dependence on the salt molarity in the range 1 • 10-4— 1 • 10-2 mol dm -3. The ionic self-diffusion coefficients in infinitely diluted solutions have been computed. The influence of the solvent composition on the solvation of the ions is discussed. A preferential hydration of Na+, Cl - and I “ ions in water-methanol mixtures has been found. In spite of the great interest in the porperties of aqueous solution with a Nal(Tl) scintillation crystal water-organic solvent electrolyte solutions, data on of the well-type (2 x 2"). the ionic mobilities in such systems are scarce. For the self-diffusion measurements the open-end Usually the ionic mobility is calculated from the capillary method was used. The details of the equivalent conductance and the transference num experimental procedure have been described in [6], ber. Ionic transference numbers have been reported The labelling of the sodium ions with 22Na or for water and 17 organic solvents [1], but only for a 24Na and the iodide ions with i25I or 1311, respective few water-organic solvents mixtures. ly, did not make any difference in the results. Similar information can be obtained from the ionic self-diffusion coefficients, which have been reported for a few water-organic solvent systems Results [2-5], The aim of the present work was to determine the All self-diffusion experiments have been carried self-diffusion coefficients of sodium, chloride and out at 25.0 ± 0.05 °C. -

Sodium Aluminium Silicate (Tentative)

SODIUM ALUMINIUM SILICATE (TENTATIVE) th Prepared at the 80 JECFA and published in FAO JECFA Monographs 17 (2015), superseding tentative specifications prepared at the 77th JECFA (2013) and published in FAO JECFA Monographs 14 (2013). An ADI 'not specified' for silicon dioxide and certain silicates was established at the 29th JECFA (1985). A PTWI of 2 mg/kg bw for total aluminium was established at the 74th JECFA (2011). The PTWI applies to all aluminium compounds in food, including food additives. Information required: Functional uses other than anticaking agent, if any, and information on the types of products in which it is used and the use levels in these products Data on solubility using the procedure documented in the “Compendium of Food Additives Specifications, Vol. 4, Analytical methods” Data on the impurities soluble in 0.5 M hydrochloric acid, from a minimum of five batches. If a different extraction and determination method is used, provide data along with details of method and QC data. Suitability of the analytical method for the determination of aluminium, silicon and sodium using the proposed “Method of assay” along with data, from a minimum of five batches, using the proposed method. If a different method is used, provide data along with details of the method and QC data. SYNONYMS Sodium silicoaluminate; sodium aluminosilicate; aluminium sodium silicate; silicic acid, aluminium sodium salt; INS No. 554 DEFINITION Sodium aluminium silicate is a series of amorphous hydrated sodium aluminium silicates with varying proportions of Na2O, Al2O3 and SiO2. It is manufactured by, precipitation process, reacting aluminium sulphate and sodium silicate. -

SODIUM HYDROXIDE @Lye, Limewater, Lyewater@

Oregon Department of Human Services Office of Environmental Public Health (503) 731-4030 Emergency 800 NE Oregon Street #604 (971) 673-0405 Portland, OR 97232-2162 (971) 673-0457 FAX (971) 673-0372 TTY-Nonvoice TECHNICAL BULLETIN HEALTH EFFECTS INFORMATION Prepared by: ENVIRONMENTAL TOXICOLOGY SECTION OCTOBER, 1998 SODIUM HYDROXIDE @Lye, limewater, lyewater@ For More Information Contact: Environmental Toxicology Section (971) 673-0440 Drinking Water Section (971) 673-0405 Technical Bulletin - Health Effects Information Sodium Hydroxide Page 2 SYNONYMS: Caustic soda, sodium hydrate, soda lye, lye, natrium hydroxide CHEMICAL AND PHYSICAL PROPERTIES: - Molecular Formula: NaOH - White solid, crystals or powder, will draw moisture from the air and become damp on exposure - Odorless, flat, sweetish flavor - Pure solid material or concentrated solutions are extremely caustic, immediately injurious to skin, eyes and respiratory system WHERE DOES IT COME FROM? Sodium hydroxide is extracted from seawater or other brines by industrial processes. WHAT ARE THE PRINCIPLE USES OF SODIUM HYDROXIDE? Sodium hydroxide is an ingredient of many household products used for cleaning and disinfecting, in many cosmetic products such as mouth washes, tooth paste and lotions, and in food and beverage production for adjustment of pH and as a stabilizer. In its concentrated form (lye) it is used as a household drain cleaner because of its ability to dissolve organic solids. It is also used in many industries including glassmaking, paper manufacturing and mining. It is used widely in medications, for regulation of acidity. Sodium hydroxide may be used to counteract acidity in swimming pool water, or in drinking water. IS SODIUM HYDROXIDE NATURALLY PRESENT IN DRINKING WATER? Yes, because sodium and hydroxide ions are common natural mineral substances, they are present in many natural soils, in groundwater, in plants and in animal tissues.