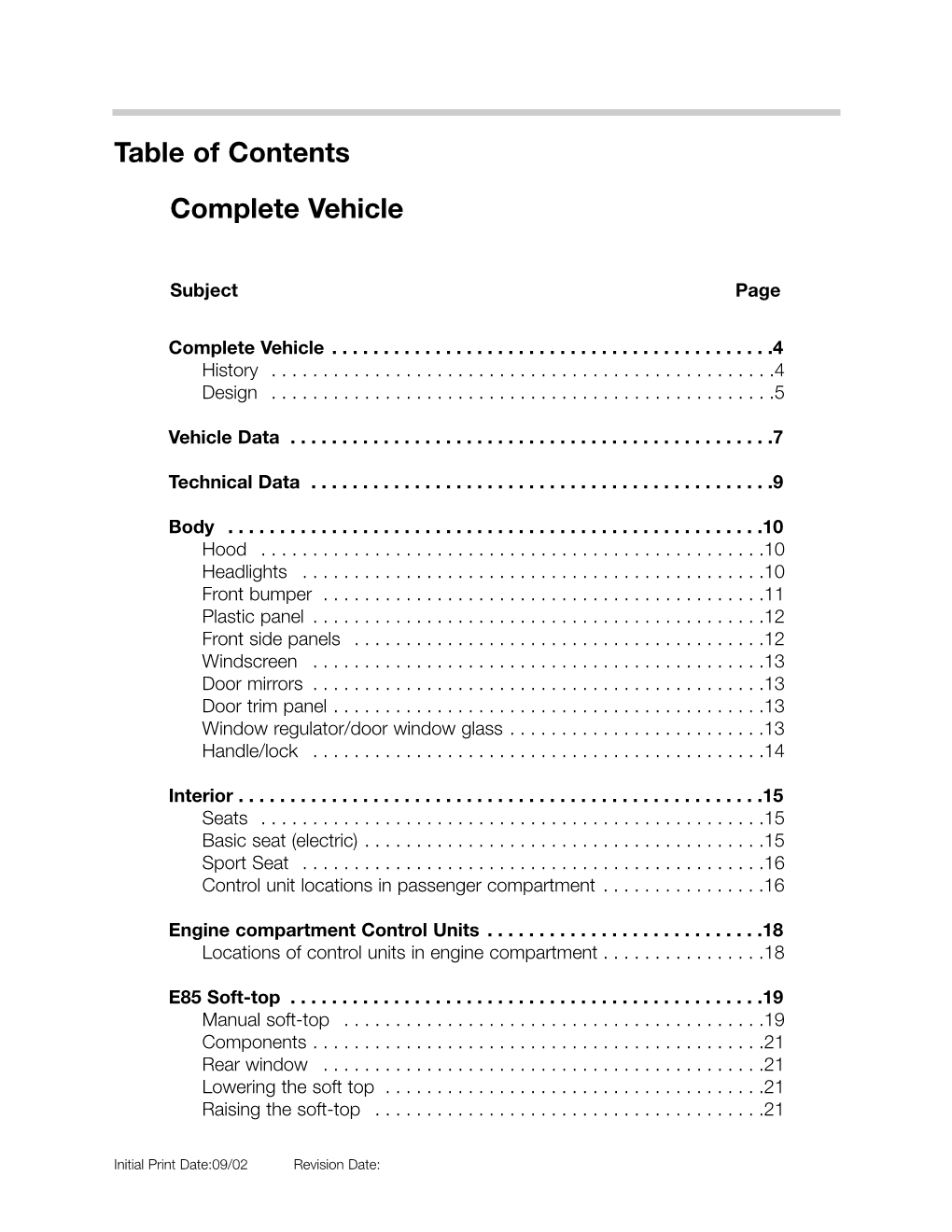

Table of Contents Complete Vehicle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

E226744 BMW Z4 E89 LCI.Indd

The BMW Z4 The Ultimate www.bmw.co.uk Driving Machine THE BMW Z4. PRICE LIST. FROM JANUARY 2014. 1 Contents CONTENTS. Page 1 Contents Page 2 The BMW Z4 Introduction Page 3 Standard Equipment Highlights – sDrive18i / 20i / 28i 35i / M Sport Page 4 Standard Equipment Highlights – sDrive 35is / Pure Traction Design and Pure Balance Design packages Page 5 Technical Information Page 6 Pricing Information Page 7 BMW EfficientDynamics / Paintwork / Upholsteries Page 8 Packages Page 9 Interior Trims / Transmissions / Steering and Chassis / Safety and Technology / Seats Page 10 Exterior Equipment / Interior Equipment / Steering Wheels Page 11 Light Alloy Wheels Page 12 Audio and Communication / Supplementary Options Page 13 Code Glossary Page 14 BMW ConnectedDrive Services BMW sDrive18i BMW sDrive20i BMW sDrive28i www.bmw.co.uk Introduction 2 THE BMW Z4. DRIVEN BY THE HEART. While we use our heads to make important decisions, the most emotive decisions are made by our hearts. Choosing the BMW Z4 is an excellent example. The efficiency of its engines is a convincing rational argument – but one look at its irresistible lines is enough to awaken roadster love in the heart of the observer. BMW EFFICIENT DYNAMICS. EfficientDynamics is BMW’s award-winning programme of technologies designed to reduce CO2 emissions and improve fuel economy, without compromising on performance or driving dynamics. These technologies are standard on every new BMW and could lower your fuel and tax costs, as well as ensure a lower benefit in kind tax rating for company car drivers. You can find out more about the benefits of BMW EfficientDynamics, as well as compare your own vehicle against any BMW Z4 model at www.bmw.co.uk/EfficientDynamics Auto Brake Energy Electric Power Lightweight Optimum Shift Reduced Rolling Start-Stop Regeneration Steering Engineering Indicator Resistance Tyres 0kg 4 3 Standard Equipment Highlights – sDrive18i / 20i / 28i 35i / M Sport STANDARD EQUIPMENT HIGHLIGHTS. -

Council News | Year 6 | Issue 01 | April 2008

www.bmw-clubs-international.com | Council News | Year 6 | Issue 01 | April 2008 Council News 1/08 Newsletter of the International Council of BMW Clubs BMW 524td and 525e, which constituted the start of a 25-year-old tradition of energy-efficient BMW models, at the Techno Classica 2008 Techno Classica 2008 Highlights of this issue: To put my impressions of this its entirety for the use of the year’s Techno Classica in Essen clubs. According to the press, • Report: Techno Classica 2008 into words is no easy matter, sim- the majority of the resources ply because it was so complete- in 2008 were reserved for the • Current Events: The BMW Welt – an attraction ly different to last year’s event. museum. Or was it that the men for all the senses So, inspired by Mary Chase, in Munich wanted to send out a • Report: A fantastic BMW Z4 weekend the BMW Clubs now have their message to their colleagues in very own Pooka, by the name of Stuttgart and Ingolstadt about • Report: BMW Race Series in New Zealand: Harvey (of course), who will pre- stemming the contest for gear A visitor’s perspective sent his report from the TC. at the TC? The BMW Clubs had just about Not all the visitors to the show • Diary: Key international events for the BMW all the space they could wish saw the good intentions. Club scene and BMW Mobile Tradition for and the vastly reduced BMW budget was available almost in Read more on page 04 Council News 1/08 Editorial / Contents Content Edition 1/08 Dear BMW Club Friends, Page Editorial / Contents To begin this new year, I Greeting from Dr. -

Toyota GR Supra, BMW Z4 Fuel Tank Weld Recall

OMB Control No.: 2127-0004 Part 573 Safety Recall Report 20V-700 Manufacturer Name : BMW of North America, LLC Submission Date : NOV 12, 2020 NHTSA Recall No. : 20V-700 Manufacturer Recall No. : Toyota: 20TB16 Manufacturer Information : Population : Manufacturer Name : BMW of North America, LLC Number of potentially involved : 49 Address : P.O. Box 1227 Estimated percentage with defect : 100 % Westwood NJ 07675-1227 Company phone : 18005257417 Vehicle Information : Vehicle 1 : 2020-2021 BMW Z4 Vehicle Type : LIGHT VEHICLES Body Style : 2-DOOR Power Train : GAS Descriptive Information : Approximately 14 vehicles were assembled with a fuel tank where the weld between the two halves may not have been performed according to specifications. Basis for recall population determination: Vehicle assembly and supplier production records were reviewed to determine the production dates of potentially affected vehicles. Recall component difference to non-recall component: The weld between fuel tank halves may not have been performed according to specifications. Although 100% of the vehicles may not have been welded according to specifications, whether the issue in each case will lead to weld separation and a fuel leak, creating an unreasonable risk to safety, depends on the actual weld condition and the vehicle’s operating conditions. Production Dates : JUN 26, 2019 - JUL 09, 2020 VIN Range 1 : Begin : NR End : NR Not sequential The information contained in this report was submitted pursuant to 49 CFR §573 Part 573 Safety Recall Report 20V-700 Page 2 Vehicle 2 : 2020-2021 Toyota Supra Vehicle Type : LIGHT VEHICLES Body Style : 2-DOOR Power Train : GAS Descriptive Information : Approximately 35 vehicles were assembled with a fuel tank where the weld between the two halves may not have been performed according to specifications. -

Owner's Manual for Contents Vehicle A-Z the Ultimate Driving Machine

Owner's Manual for Contents Vehicle A-Z The Ultimate Driving Machine THE BMW Z4. OWNER'S MANUAL. Online Edition for Part no. 01 40 2 609 184 - 09 11 500 Z4 sDrive28i Owner's Manual for Vehicle Z4 sDrive35i Thank you for choosing a BMW. Z4 sDrive35is The more familiar you are with your vehicle, the better control you will have on the road. We therefore strongly suggest: Read this Owner's Manual before starting off in your new BMW. It contains important information on vehicle operation that will help you make full use of the technical features available in your BMW. The manual also contains information designed to en‐ hance operating reliability and road safety, and to contribute to maintaining the value of your BMW. Supplementary information can be found in the additional bro‐ chures in the onboard literature. We wish you a safe and enjoyable drive. BMW AG Online Edition for Part no. 01 40 2 609 184 - 09 11 500 © 2011 Bayerische Motoren Werke Aktiengesellschaft Munich, Germany Reprinting, including excerpts, only with the written consent of BMW AG, Munich. US English VIII/11, 09 11 500 Printed on environmentally friendly paper, bleached without chlorine, suitable for recycling. Online Edition for Part no. 01 40 2 609 184 - 09 11 500 Contents The fastest way to find information on a partic‐ Mobility ular topic or item is by using the index, refer to 152 Refueling page 208. 154 Fuel 155 Wheels and tires 163 Engine compartment 6 Notes 168 Maintenance At a glance 170 Replacing components 12 Cockpit 176 Breakdown assistance 182 Care Controls 186 Indicator/warning lamps 20 Opening and closing 36 Adjusting Reference 43 Transporting children safely 202 Technical data 45 Driving 208 Everything from A to Z 60 Displays 68 Lamps 73 Safety 81 Driving stability control systems 85 Driving comfort 89 Climate 96 Interior equipment 103 Storage compartments Driving tips 108 Things to remember when driving Entertainment 116 Professional Radio Communication 134 Telephone 145 ConnectedDrive Online Edition for Part no. -

P 01.Qxd 6/30/2005 2:00 PM Page 1

p 01.qxd 6/30/2005 2:00 PM Page 1 June 27, 2005 © 2005 Crain Communications GmbH. All rights reserved. €14.95; or equivalent 20052005 GlobalGlobal MarketMarket DataData BookBook Global Vehicle Production and Sales Regional Vehicle Production and Sales History and Forecast Regional Vehicle Production and Sales by Model Regional Assembly Plant Maps Top 100 Global Suppliers Contents Global vehicle production and sales...............................................4-8 2005 Western Europe production and sales..........................................10-18 North America production and sales..........................................19-29 Global Japan production and sales .............30-37 India production and sales ..............39-40 Korea production and sales .............39-40 China production and sales..............39-40 Market Australia production and sales..........................................39-40 Argentina production and sales.............45 Brazil production and sales ....................45 Data Book Top 100 global suppliers...................46-50 Mary Raetz Anne Wright Curtis Dorota Kowalski, Debi Domby Senior Statistician Global Market Data Book Editor Researchers [email protected] [email protected] [email protected], [email protected] Paul McVeigh, News Editor e-mail: [email protected] Irina Heiligensetzer, Production/Sales Support Tel: (49) 8153 907503 CZECH REPUBLIC: Lyle Frink, Tel: (49) 8153 907521 Fax: (49) 8153 907425 e-mail: [email protected] Tel: (420) 606-486729 e-mail: [email protected] Georgia Bootiman, Production Editor e-mail: [email protected] USA: 1155 Gratiot Avenue, Detroit, MI 48207 Tel: (49) 8153 907511 SPAIN, PORTUGAL: Paulo Soares de Oliveira, Tony Merpi, Group Advertising Director e-mail: [email protected] Tel: (35) 1919-767-459 Larry Schlagheck, US Advertising Director www.automotivenewseurope.com Douglas A. Bolduc, Reporter e-mail: [email protected] Tel: (1) 313 446-6030 Fax: (1) 313 446-8030 Tel: (49) 8153 907504 Keith E. -

U.S. Press Information

A subsidiary of BMW AG BMW U.S. Press Information For Release: EMBARGO: December 13 th 6:00PM EST, 2008 Contact: PREPARED FOR WEB BY AUTOSPIES.COM THE NEW BMW Z4 ROADSTER MODEL HIGHLIGHTS • First BMW Roadster with a retractable hardtop. The new model is the successor to both the BMW Z4 Roadster and the BMW Z4 Coupe. Two- piece electrohydraulically retractable hardtop in lightweight aluminum shell construction. The hardtop opens and closes fully automatically in each case within 20 seconds; the roof elements coming to rest in the roof compartment to give the car a low-slung rear-end design reflecting the traditional proportions of a roadster as well as a large luggage compartment. The high-quality interior lining finished in an extra-light color as well as large windows including the heated glass window at the rear ensure an exclusive ambience and optimized all- round visibility. • Long hood, large wheel arches, long wheelbase and small overhangs. • Head and elbow room as well as the degree of comfort in entering the car have been significantly enhanced over the former model. The low seating position near the rear axle guarantees the driving experience typical of a BMW Roadster. High-quality materials, first-class quality of finish and driver-oriented design of both the instrument panel and the center console guarantee an emotional driving experience in a particularly refined ambience. • Wide range of storage options within the passenger compartment including a spacious crosswise storage compartment behind the seats. • First use of the BMW iDrive control system in the BMW Roadster. In conjunction with the optional navigation system the new generation of BMW iDrive comprises an ergonomically optimized Controller for the selection and control of functions by turning, pressing and tipping the Controller, function buttons on the Controller for direct menu entry, freely programmable favorite buttons for even easier operation, as well as a folding 8.8-inch display with high-resolution graphic presentation and an optimized menu structure. -

Summer 2020 Cruizin Newz

Cruizin’Cruizin’ NewzNewz The Official Magazine of the Z Series Car Club of America SUMMER 2020 President’s Message! - Jon Moorhead www.zscca.org ZSCCA Board of Directors & Staff Jon Moorhead • President Salida, CO Be Like Ella [email protected] • 719-221-1891 I spent 36 years in education. One of the Glenn Kraft • Vice President days that caused me the most anxiety was Canton, GA [email protected] • 678 770-0364 “Observation Day”. That’s when the school Robert Van Zandt • Secretary administrator is scheduled to come into my Yorktown, VA classroom for a walk-through for the formal [email protected] observation which transfers to my perfor- Chuck Krblich • Treasurer mance review for rehire. Prior to the visita- Fort Lauderdale, FL tion, I have planned for every contingency, [email protected] • 954.295.0277 prepped the lesson, prepped the kids, antici- Jim Dunn • Membership Liaison [email protected] pated every question and have rehearsed Seattle, WA multiple answers to all of them. Materials Please take a moment and enjoy what “are hung from the chimney with care.” We Chris Wootten she came up with…search YouTube for Strategic Relationships Ambassador are READY!!! “Ella Fitzgerald - Mack the Knife - Ella Easton, MD [email protected] in Berlin”. (https://www.youtube.com/ Then Murphy’s Law strikes – anything that watch?v=qs3oCqdkNuc) Reenie Paley Marshall can possibly go wrong will. Or the corollary Special Projects Manager – things that work in theory never work in Midlothian, VA Did the critics pan her performance? Did [email protected] practice, things that work in practice never the audience boo her off the stage? Did she work during the game. -

Bmw Z4 Roadster. Bmw Bmw Z4 Roadster

BMW Z4 Roadster The Ultimate BMW Z4 bmw.ca Driving Experience.® ROADSTER. BMW EfficientDynamics Less emissions. More driving pleasure. DECEMBER 2014 BMW Z4 ROADSTER. BMW Z4 OUTRUN THE ORDINARY. A stunning example of BMW design, the Z4 Roadster evokes the 507 roadster of the Fifties. Every sculptural line and detail functions together to reduce wind resistance and improve performance. In only 19 seconds, its retractable hardtop, available in a choice of contrasting colours, will take you from the hushed comfort of an enclosed cabin to the wide-open sky. Shown: Z4 sDrive35is in Valencia Orange Metallic paint; Exclusive Hyper Orange Package interior. BMW Z4 ROADSTER. TECHNICAL DATA PACKAGES Packages may vary by model; not all packages shown. For details, please visit your BMW Retailer or bmw.ca. Z4 Roadster Z4 sDrive28i Z4 sDrive35i Z4 sDrive35is BMW Individual Hardtop with Contrasting Paintwork Cylinders/displacement cm3 4/1,997 6/2,979 6/2,979 Glacier Silver Metallic Hardtop Jet Black Hardtop Output hp @ rpm 241 @ 5,000-6,500 300 @ 5,800 335 @ 5,900 8-Speed Sport Automatic Transmission (Only available on 28i) Torque lb-ft @ rpm 258 @ 1,250-4,800 300 @ 1,400-5,000 332 @ 1,500 Sport Leather Steering Wheel with Shift Paddles Sport Automatic Transmission 0–100 km/h s 5.8 (5.7) [5.3] [5.0] Fuel Consumption* Ivory White Burnt Sienna Package Exclusive Hyper Orange Package City L/100 km 10.7 (10.7) [13.7] [13.7] Fineline Brown Wood Trim Metal Weave Trim Highway L/100 km 6.8 (7.1) [10.0] [10.0] Ivory White Nappa Leather Design Pure Traction Combined L/100 km 8.9 (9.1) [12.1] [12.1] Design Pure Fusion Black/Orange Extended Alcantara/Leather Interior Figures in ( ) refer to vehicles with automatic transmission. -

Best Viewed in Landscape Mode

The Ultimate Driving Machine Best viewed in THE Z4 landscape mode THE BMW Z4. RETURN BY CLICKING SELECT A TOPIC BELOW TO EXPLORE: FEATURED MODEL. BMW Z4 M40i: M TwinPower Turbo six-cylinder in-line petrol engine, 340hp (250kW), 19" M light alloy Double-spoke style 799 M wheels, Jet Black, San Francisco Red metallic paint, M Sport seats upholstered in Ivory White Vernasca leather with decorative stitching, Aluminium Mesh effect interior trim, instrument panel in Sensatec, High-gloss Shadowline exterior trim with extended contents. Content correct at time of publishing (as of April 2020). Prices and technical data subject to change. The models shown on these pages may feature optional equipment. Standard equipment may also vary depending on engine variant. For further details, please contact your local BMW Retailer. “ IT’S NOW A CAR WITH FINE BODY CONTROL AND A CHASSIS THAT COMBINES TRADEMARK BMW REAR-DRIVE HANDLING POISE WITH LOTS OF LATERAL GRIP AND TRACTION. THE CAR’S HANDLING IS ACCURATE AND COMPOSED, IT HAS USEFULLY GOOD HIGH-SPEED STABILITY AND IT’S PLENTY OF FUN TO DRIVE.” Autocar Read the full review “ THE Z4’S CHASSIS RELAXES NICELY INTO COMMUTING OR LONG-HAUL WORK. AND WHILE YOU’RE AT IT, THE DRIVER AIDS AND HEADLAMPS ARE ALL YOU’D EXPECT FROM MODERN GERMAN PREMIUM.” Top Gear Read the full review M40i. STANDARD EQUIPMENT, INCLUDES: In addition / replacement to Sport models █ 19" M light alloy Double-spoke style 800 M █ M aerodynamics bodystyling wheels, Bicolour Cerium Grey █ M Leather steering wheel █ Adaptive M suspension █ M Sport braking system █ BMW TwinPower Turbo six-cylinder petrol engine █ Lumbar support, driver and █ Exterior trim, High-gloss Shadowline front passenger █ Instrument panel in Sensatec █ Seat adjustment – front, electric █ Interior trim, Aluminium Tetragon with driver memory Standard equipment Optional equipment The BMW Z4 M40i model is shown above in San Francisco Red metallic paint. -

Europe Swings Toward Suvs, Minivans Fragmenting Market Sedans and Station Wagons – Fell Automakers Did Slightly Better Than Cent

AN.040209.18&19.qxd 06.02.2004 13:25 Uhr Page 18 ◆ 18 AUTOMOTIVE NEWS EUROPE FEBRUARY 9, 2004 ◆ MARKET ANALYSIS BY SEGMENT Europe swings toward SUVs, minivans Fragmenting market sedans and station wagons – fell automakers did slightly better than cent. The only new product in an cent because of declining sales for 656,000 units or 5.5 percent. mass-market automakers. Volume otherwise aging arena, the Fiat the Honda HR-V and Mitsubishi favors the non-typical But automakers boosted sales of brands lost close to 2 percent of vol- Panda, was on sale for only four Pajero Pinin. over familiar sedans unconventional vehicles – coupes, ume last year, compared to 0.9 per- months of the year. In terms of brands leading the roadsters, minivans, sport-utility cent for luxury marques. European buyers seem to pro- most segments, Renault is the win- LUCA CIFERRI vehicles exotic cars and multi- Traditional European-brand gressively walk away from large ner with four. Its Twingo leads the spaces such as the Citroen Berlingo automakers dominate the tradi- sedans, down 20.3 percent for the minicar segment, but Renault also AUTOMOTIVE NEWS EUROPE – by 16.8 percent last year to nearly tional car, minivan and premium volume makers and off 11.1 percent leads three other segments that it 3 million units. segments, but Asian brands control in the upper-premium segment. created: compact minivan, Scenic; TURIN – Automakers sold 428,000 These non-traditional vehicle cat- virtually all the top spots in small, large minivan, Espace; and multi- more specialty vehicles last year in egories, some of which barely compact and large SUV segments. -

Less Emissions. More Driving Pleasure. Technology Day 2009

Technology Day 2009. BMW EfficientDynamics. Aerodynamics development in the context of design. BMW EfficientDynamics. Less emissions. More driving pleasure. Technology Day 2009. BMW EfficientDynamics. Aerodynamics development in the context of design. Aerodynamics. BMW 328. 1936 1940 1950 Aerodynamics. BMW 328 Mille Miglia. 1940 1950 Aerodynamics. Aerodynamic development from the thirties. 1940 1950 Aerodynamics. Aerodynamic development in the seventies. 1972 1980 1990 Aerodynamics. Wind tunnel in Aschheim near Munich: Planning and construction. 1979 1990 Aerodynamics. Wind tunnel in Aschheim near Munich: The beginnings. 1980 1990 Aerodynamics. Wind tunnel in Aschheim near Munich: The beginnings. 1980 1990 Aerodynamics. Wind tunnel in Aschheim near Munich: Understanding grows. 1986 1990 2000 Aerodynamics. Wind tunnel in Aschheim near Munich: New proportions. 1990 2000 Aerodynamics. Wind tunnel in Aschheim near Munich: Motor sport. 2000 2003 2009 Aerodynamics. Wind tunnel in Aschheim near Munich: Top figures. 2006 2009 Aerodynamics. Wind tunnel in Aschheim near Munich: World champion. 2006 2009 Aerodynamics. Teamwork Design and Aerodynamics. Development Design Data model Data model Development Aerodynamics Decision 1st month 2nd month 3rd month Decision 2006 2009 Aerodynamics. Wind tunnel in Aschheim near Munich: Joy. 2008 Technology Day 2009. BMW EfficientDynamics. Design. Design. BMW 315/1. 1934 - 1936 Elegantly curved roadster line. BMW double kidney grille. In-line 6-cylinder engine. Design. BMW 328 Mille Miglia Roadster. 1936 - 1940 (Racing version) Winner at the Mille Miglia 1940. Aluminium lightweight design body. Design. BMW 507, BMW Z1, BMW Z3 and BMW Z8. 1956 - 1959 1988 BMW 507. BMW Z1. 1995 - 2003 2000 - 2003 BMW Z3. BMW Z8. Design. The first BMW Z4 Roadster. -

BMW to Showcase Iperformance Family of Plug-In Hybrid Electric Vehicles at the 2016 Los Angeles Auto Show’S Automobility LA

FROM: BMW of North America CONTACTS: Phil DiIanni: 201-571-5660; [email protected] BMW of North America Brady Littlefield: 212-843-9220; [email protected] Rubenstein Communications Request for Coverage BMW to Showcase iPerformance Family of Plug-In Hybrid Electric Vehicles at the 2016 Los Angeles Auto Show’s Automobility LA. Featured BMW Vehicles Include: BMW 740e xDrive, BMW 330e and BMW X5 xDrive40e. Additional Highlights include BMW M760i xDrive, BMW ALPINA B7 xDrive and BMW i8, as well as Updated Models Throughout the 2017 BMW model lineup. ReachNow to Announce Expansion and Launch of Several New Mobility Services at a Press Conference on November 15th at 9:50 a.m. The BMW-Designed Paralympic Racing Wheelchair Piloted by Members of Team USA to a Collective Seven Medals at the 2016 Paralympic Games in Rio will also be on display. BMW will showcase its iPerformance family of plug-in hybrid electric vehicles at the 2016 Los Angeles Auto Show, taking place at the Los Angeles Convention Center (located at 1201 South Figueroa Street). English-, German- and Spanish-speaking BMW representatives will be available for interviews on Wednesday, November 16 and Thursday, November 17 at the BMW Stand. BMW iPerformance, BMW’s plug-in hybrid models, apply eDrive technology from BMW i (BMW’s brand that emphasizes sustainability in visionary vehicle concepts and technologies) to the BMW core brand via the technical expertise regarding electric motors, battery cells, and electronic control systems. BMW iPerformance vehicles that will be displayed throughout the Los Angeles Auto Show include the BMW 740e xDrive, BMW 330e, and BMW X5 xDrive40e.