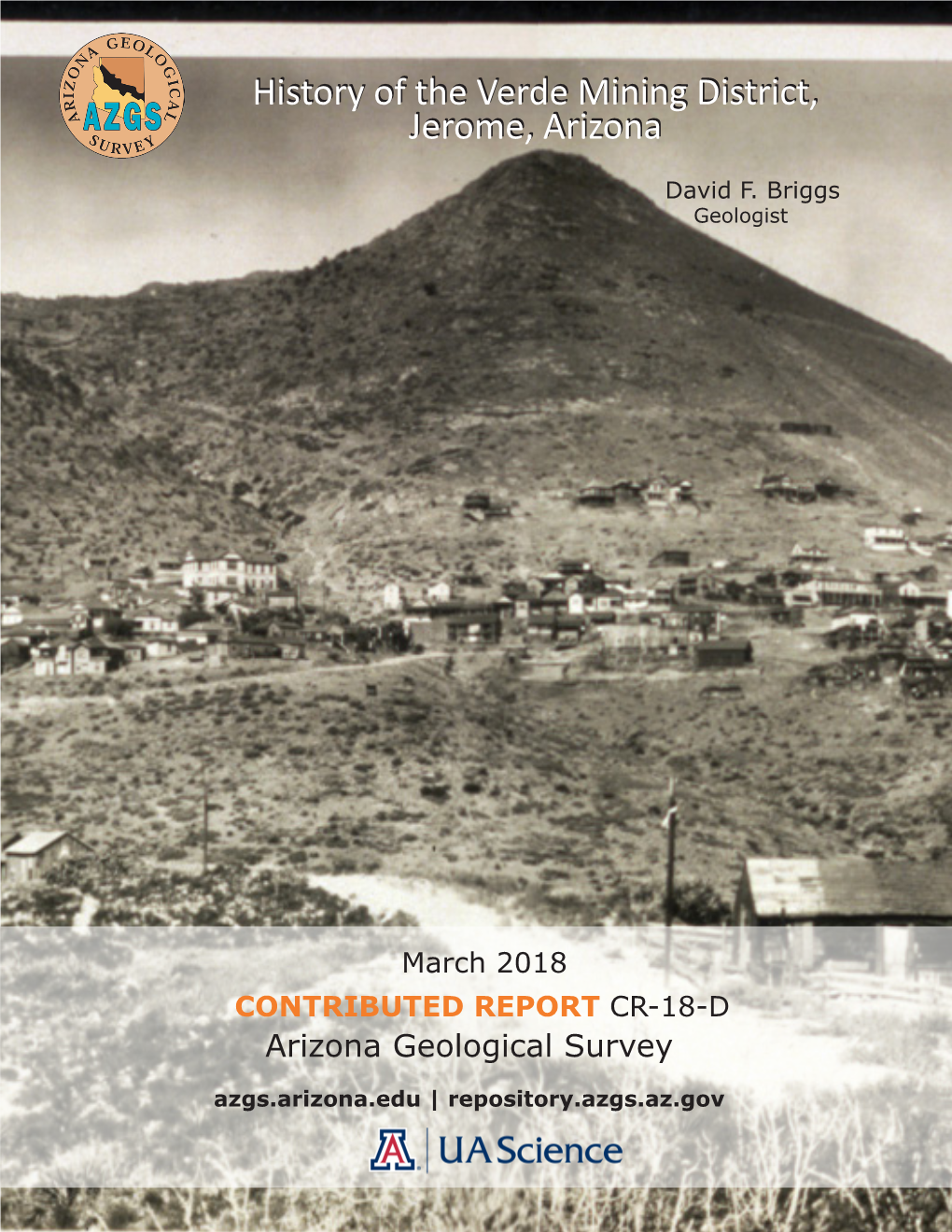

History of the Verde Mining District, Jerome, Arizona

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Lower Gila Region, Arizona

DEPARTMENT OF THE INTERIOR HUBERT WORK, Secretary UNITED STATES GEOLOGICAL SURVEY GEORGE OTIS SMITH, Director Water-Supply Paper 498 THE LOWER GILA REGION, ARIZONA A GEOGBAPHIC, GEOLOGIC, AND HTDBOLOGIC BECONNAISSANCE WITH A GUIDE TO DESEET WATEEING PIACES BY CLYDE P. ROSS WASHINGTON GOVERNMENT PRINTING OFFICE 1923 ADDITIONAL COPIES OF THIS PUBLICATION MAT BE PROCURED FROM THE SUPERINTENDENT OF DOCUMENTS GOVERNMENT PRINTING OFFICE WASHINGTON, D. C. AT 50 CENTS PEE COPY PURCHASER AGREES NOT TO RESELL OR DISTRIBUTE THIS COPT FOR PROFIT. PUB. RES. 57, APPROVED MAT 11, 1822 CONTENTS. I Page. Preface, by O. E. Melnzer_____________ __ xr Introduction_ _ ___ __ _ 1 Location and extent of the region_____._________ _ J. Scope of the report- 1 Plan _________________________________ 1 General chapters _ __ ___ _ '. , 1 ' Route'descriptions and logs ___ __ _ 2 Chapter on watering places _ , 3 Maps_____________,_______,_______._____ 3 Acknowledgments ______________'- __________,______ 4 General features of the region___ _ ______ _ ., _ _ 4 Climate__,_______________________________ 4 History _____'_____________________________,_ 7 Industrial development___ ____ _ _ _ __ _ 12 Mining __________________________________ 12 Agriculture__-_______'.____________________ 13 Stock raising __ 15 Flora _____________________________________ 15 Fauna _________________________ ,_________ 16 Topography . _ ___ _, 17 Geology_____________ _ _ '. ___ 19 Bock formations. _ _ '. __ '_ ----,----- 20 Basal complex___________, _____ 1 L __. 20 Tertiary lavas ___________________ _____ 21 Tertiary sedimentary formations___T_____1___,r 23 Quaternary sedimentary formations _'__ _ r- 24 > Quaternary basalt ______________._________ 27 Structure _______________________ ______ 27 Geologic history _____ _____________ _ _____ 28 Early pre-Cambrian time______________________ . -

The Maricopa County Wildlife Connectivity Assessment: Report on Stakeholder Input January 2012

The Maricopa County Wildlife Connectivity Assessment: Report on Stakeholder Input January 2012 (Photographs: Arizona Game and Fish Department) Arizona Game and Fish Department In partnership with the Arizona Wildlife Linkages Workgroup TABLE OF CONTENTS LIST OF FIGURES ............................................................................................................................ i RECOMMENDED CITATION ........................................................................................................ ii ACKNOWLEDGMENTS ................................................................................................................. ii EXECUTIVE SUMMARY ................................................................................................................ iii DEFINITIONS ................................................................................................................................ iv BACKGROUND ................................................................................................................................ 1 THE MARICOPA COUNTY WILDLIFE CONNECTIVITY ASSESSMENT ................................... 8 HOW TO USE THIS REPORT AND ASSOCIATED GIS DATA ................................................... 10 METHODS ..................................................................................................................................... 12 MASTER LIST OF WILDLIFE LINKAGES AND HABITAT BLOCKSAND BARRIERS ................ 16 REFERENCE MAPS ....................................................................................................................... -

Maricopa County Regional Trail System Plan

Maricopa County Regional Trail System Plan Adopted August 16, 2004 Maricopa Trail Maricopa County Trail Commission Maricopa County Department of Transportation Maricopa County Parks and Recreation Maricopa County Planning and Development Flood Control District of Maricopa County We have an obligation to protect open spaces for future generations. Maricopa County Regional Trail System Plan VISION Our vision is to connect the majestic open spaces of the Maricopa County Regional Parks with a nonmotorized trail system. The Maricopa Trail Maricopa County Regional Trail System Plan - page 1 Credits Maricopa County Board of Supervisors Andrew Kunasek, District 3, Chairman Fulton Brock, District 1 Don Stapley, District 2 Max Wilson, District 4 Mary Rose Wilcox, District 5 Maricopa County Trail Commission Supervisor Max Wilson, District 4 Chairman Supervisor Andrew Kunasek, District 3 Parks Commission Members: Citizen Members: Laurel Arndt, Chair Art Wirtz, District 2 Randy Virden, Vice-Chair Jim Burke, District 3 Felipe Zubia, District 5 Stakeholders: Carol Erwin, Bureau of Reclamation (BOR) Fred Pfeifer, Arizona Public Service (APS) James Duncan, Salt River Project (SRP) Teri Raml, Bureau of Land Management (BLM) Ex-officio Members: William Scalzo, Chief Community Services Officer Pictured from left to right Laurel Arndt, Supervisor Andy Kunasek, Fred Pfeifer, Carol Erwin, Arizona’s Official State Historian, Marshall Trimble, and Art Wirtz pose with the commemorative branded trail marker Mike Ellegood, Director, Public Works at the Maricopa Trail -

Geochronology, Geology, and Listric Normal Faulting of the Vulture Mountains, Maricopa County, Arizona

Arizona Geological Society Digest, Volume XII, 1980 89 Geochronology, Geology, and Listric Normal Faulting of the Vulture Mountains, Maricopa County, Arizona by WA. Rehrigi, M. Shafiqullah2, and P.E. Damon2 Abstract Geologic mapping and geochronologic studies in the Vulture Mountains near Wickenburg, Arizona, have led to the recognition of a large, northeast-trending batholith of 68.4-m.y. age that intrudes complex gneissic and granitic rocks of probably Precambrian age. Over- lying the denuded crystalline terrane is a sequence of late Oligocene to Miocene ( .'26 to 16 m.y.) volcanic rocks (vitrophyres, ash-flow tuffs, welded tuffs, breccias, agglomerates, and lava flows) that vary locally. Nearby source areas are suggested. A swarm of north- to north-northwest-trending porphyritic dikes intrudes the volcanics and crystalline basement. Overlying this volcanic sequence in angular unconformity is a thin section of basal conglom- erate and basalt lava flows dated at 13.5 m.y. B.P. The older, tuffaceous sequence is generally calc-alkalic but with a high proportion of rhyolites that are exceptionally rich in potassium and silica. These silicic units are peral- kaline or nearly so, and those with K20/Na2O >3 are ultrapotassic. Initial strontium ratios average 0.7081, whereas an initial ratio for the younger basalt sequence is significantly lower at 0.7054. The silicic volcanics have been severely tilted on multiple, low-angle listric normal faults. The youngest basalt flows are relatively flat lying and postdate this deformation. By geo- logic and radiometric criteria, the transition from tilted silicic volcanics to untilted basalts occurred between about 16 and 14 m.y. -

I:\My Files\Huron\D-TRAFFIC.Wpd

CODIFIED ORDINANCES OF HURON PART THREE - TRAFFIC CODE TITLE ONE - Administration Chap. 301. Definitions. Chap. 303. Enforcement, Impounding and Penalty. Chap. 305. Traffic Control Map and File. TITLE THREE - Streets and Traffic Control Devices Chap. 311. Street Obstructions and Special Uses. Chap. 313. Traffic Control Devices. TITLE FIVE - Vehicles Chap. 331. Operation Generally. Chap. 333. OVI; Willful Misconduct; Speed. Chap. 335. Licensing; Accidents. Chap. 337. Safety and Equipment. Chap. 339. Commercial and Heavy Vehicles. Chap. 341. Commercial Drivers. TITLE SEVEN - Parking Chap. 351. Parking Generally. TITLE NINE - Pedestrians, Bicycles and Motorcycles Chap. 371. Pedestrians. Chap. 373. Bicycles and Motorcycles. Chap. 375. Snowmobiles, Off-Highway Motorcycles and All Purpose Vehicles. Chap. 377. Skateboards. Chap. 379. Golf Carts. TITLE ELEVEN - Watercraft Chap. 381. Watercraft Regulations. Chap. 383. Licensing and Accidents. Chap. 385. Small Boat Mooring Harbor. Chap. 387. Harbor Line. January 2019 Replacement 3 CODIFIED ORDINANCES OF HURON PART THREE - TRAFFIC CODE TITLE ONE - Administration Chap. 301. Definitions. Chap. 303. Enforcement, Impounding and Penalty. Chap. 305. Traffic Control Map and File. CHAPTER 301 Definitions 301.01 Meaning of words and phrases. 301.26 Private road or driveway. 301.02 Agricultural tractor. 301.27 Public safety vehicle. 301.03 Alley. 301.28 Railroad. 301.031 Beacon; hybrid beacon. 301.29 Railroad sign or signal. 301.04 Bicycle; motorized bicycle; 301.30 Railroad train. moped. 301.31 Residence district. 301.05 Bus. 301.32 Right of way. 301.06 Business district. 301.321 Road service vehicle. 301.07 Commercial tractor. 301.33 Roadway. 301.08 Controlled-access highway. 301.34 Safety zone. 301.09 Crosswalk. -

Clarkdale Transportation Study 2011 02 17 Final Report I Final Report February 2011

CCllaarrkkddaallee TTrraannssppoorrttaattiioonn SSttuuddyy ADOT MPD Task Assignment 15-10 PGTD 0440 Contract # T08-49-U0001 Final Report Prepared by: Prepared for: ARIZONA DEPARTMENT OF TRANSPORTATION TOWN OF CLARKDALE February 2011 091374034 TABLE OF CONTENTS EXECUTIVE SUMMARY ........................................................................ 1 1 INTRODUCTION ............................................................................ 6 1.1 Study Objectives ......................................................................................... 6 1.2 Study Area .................................................................................................. 8 2 CURRENT AND FUTURE TRANSPORTATION CONDITIONS ..... 10 2.1 Summary of Completed Plans and Studies in the Clarkdale Area ............... 10 2.2 Summary of Stakeholder Interviews .......................................................... 11 2.3 Land Use ................................................................................................... 14 2.3.1 Current Land Use ............................................................................ 14 2.3.2 In-Progress Developments ................................................................... 17 2.3.3 Future Land Use ............................................................................. 17 2.3.4 Demographics and Socioeconomics ........................................................ 21 2.3.5 Housing and Employment Density ........................................................ 21 2.3.6 Current demographics -

Arizona State Rail Plan March 2011

Arizona State Rail Plan March 2011 Arizona Department of Transportation This page intentionally left blank Acknowledgements The State Rail Plan was made possible by the cooperative efforts of the following individuals and organizations who contributed significantly to the successful completion of the project: Rail Technical Advisory Team Cathy Norris, BNSF Railway Chris Watson, Arizona Corporation Commission Bonnie Allin, Tucson Airport Authority Reuben Teran, Arizona Game and Fish Department Zoe Richmond, Union Pacific Railroad David Jacobs, Arizona State Historic Preservation Office Jane Morris, City of Phoenix – Sky Harbor Airport Gordon Taylor, Arizona State Land Department Patrick Loftus, TTX Company Cathy Norris, BNSF Railway Angela Mogel, Bureau of Land Management ADOT Project Team Jack Tomasik, Central Arizona Association of Governments Sara Allred, Project Manager Paul Johnson, City of Yuma Kristen Keener Busby, Sustainability Program Manager Jermaine Hannon, Federal Highway Administration John Halikowski, Director Katai Nakosha, Governor’s Office John McGee, Executive Director for Planning and Policy James Chessum, Greater Yuma Port Authority Mike Normand, Director of Transit Programs Kevin Wallace, Maricopa Association of Governments Shannon Scutari, Esq. Director, Rail & Sustainability Marc Pearsall, Maricopa Association of Governments Services Gabe Thum, Pima Association of Governments Jennifer Toth, Director, Multi-Modal Planning Division Robert Bohannan, RH Bohannan & Associates Robert Travis, State Railroad Liaison Jay -

Southwest Multi-State Rail Planning Study Technical Background Report September 2014

Southwest Multi-State Rail Planning Study Technical Background Report September 2014 Table of Contents Chapter 1. Introduction .......................................................................................................................................... 7 1.1 Overview .................................................................................................................................................... 7 1.2 What is a Multi-State Rail Plan? ................................................................................................................ 7 1.3 Why the Southwest?.................................................................................................................................. 8 1.4 Geographic Scope of Study ........................................................................................................................ 9 1.5 Study Stakeholders .................................................................................................................................. 10 1.6 Guiding Principles for Southwest Multi-State Rail Network Planning ..................................................... 11 Chapter 2. Planning Context ................................................................................................................................. 12 2.1 Overview of the Study Area ..................................................................................................................... 12 2.2 Population and Travel Demand .............................................................................................................. -

Dragline Maintenance Engineering

University of Southern Queensland Faculty of Engineering and Surveying Dragline Maintenance Engineering A dissertation submitted by Bruce Thomas Jones in fulfilment of the requirements of Courses ENG4111 and 4112 Research Project towards the degree of Bachelor of Engineering (Mechanical) Submitted November, 2007 1 ABSTRACT This research project ‘Dragline Maintenance Engineering’ explores the maintenance strategies for large walking draglines over the past 30 years in the Australian coal industry. Many draglines built since the 1970’s are still original in configuration and utilize original component technology. ie electrical drives, gear configurations. However, there have been many innovative enhancements, configuration changes and upgrading of components The objective is to critically analyze the maintenance strategies, and to determine whether these strategies are still supportive of optimizing the availability and reliability of the draglines. The maintenance strategies associated with dragline maintenance vary, dependent on fleet size and mine conditions; they are aligned with the Risk Based Model. The effectiveness of the maintenance strategy implemented with dragline maintenance is highly dependent on the initial effort demonstrated at the commencement of planning for the mining operation. Mine size, productivity requirements, machinery configuration and economic factors drive the maintenance strategies associated with Dragline Maintenance Engineering. 2 University of Southern Queensland Faculty of Engineering and Surveying ENG4111 -

<Pea~ Cvistrict ~Iries Chistorical C-Societycltd

<pea~ CVistrict ~iries CHistorical C-SocietyCLtd. NEWSLETTER No 96 OCTOBER 2000 SUMMARY OF DATES FOR YOUR DIARY 22 October U/ground meet - Rochdale Page 2 19 November Ecton Mines Page 3 25 November AGM and Anual Dinner Page 1 22-23 September 2000 NAMHO Field Meet Pagell TO ALL MEMBERS MrN Potter+ ~otice is hereby given that the Twenty Sixth Annual Mr J R Thorpe*(Acting Hon secretary) General Meeting of the Peak District Mines Historical Those whose names are marked (*) are retiring as Society Ltd will be held at 6.00pm on Saturday required by the Articles of Association and are eligible for 25 November 2000 at the Peak District Mining Museum, re-election. Those whose names are marked (+) are Grand Pavilion, Matlock Bath, Derbyshire. retiring and are not eligible for re-election. The Agenda will be distributed at the start of the Fully paid up members of the Society, who are aged meeting. 18 years and over, are invited to nominate Members of the By Order Society (who themselves are fully paid up and who have J Thorpe consented to the nomination) for the vacant positions on Hon Secretary the Committee. Nominations are required for the position of: THE COMPANIES ACT 1985 As required under Article 24 of the Articles of Chairman Association of the Company, the following Directors will Deputy Chairman retire at the Annual General Meeting: Hon Secretary 1. The Hon Secretary (acting) Hon Treasurer 2. The Chairman Hon Recorder 3. The Deputy Chairman Hon Editor 4. The Hon Treasurer Two Ordinary Members 5. The Hon Editor 6. -

Methods of Trench Excavation Is Ap

^ f Tit'--" '4 "It"-' •^^ ^ .^t' -4- -i- f ^ ^ -k f f <«: ^-fv 4- r * UNIVERSITY OF ILLINOIS A * # 4 + J, i LIBRARY > 4 V 4 + + Class Book Volume 4- -f M rl()-20M L t -4 4- - 4- f f-- ^- -f- f > t -•f * f f ^ + + ^ •f ^ 4 - ' + ^ ^ r -4^ / - - ^ s^::.. ;-,^.;-,,=ii^ r 4 r* ^ f -f 4 \^Jtf- f ^- f -f- -f- 4- -f. ^ ^ ^ti':v-^. ^ f "J*" f -f- t ,„- 1^ .,..-"f- r 4 Digitized by the Internet Archive in 2013 I http://archive.org/details/methodsoftrencheOOpopp METHODS ()J^^ TRENCH EXCAVATION BY Hknry John Popperfuss THESIS FOR THE DKQREE OF BAf'HRT.OR OF SCIENCE IN CIVIL ENGINEERING COLLEGE OF ENGINEERING UNIVKKSITV OF ITjLr]\OIS ' P K S EN T K D J L X E , 1 $1 1 O ^ UNIVERSITY OP ILLINOIS COLLEGE OT^ ENGINEERING. J\me 1, 1910 This is to certify that the thesis of HENRY JOHN POPPERFUSS entitled Methods of Trench Excavation is ap- proved by me as meeting this part of the requirements for the degree of Bachelor of Science in Civil Engineer ing. Approved: Professor of Civil Engineering* lost 66 lUTRODUCTIOH (A) ' SXGAVATIfiG BY HAED (a) nationality of worlonen (b) Method of doing v/ork (c) Cost (B) LEVIGES ?0R EZCAVATIjJG BY POWER fa) Trenching Iklachines (1) Parsons (2) Buokoyo (3) Chicago (b) Ditching Llachines (1) Austin (c) Steam Shovel (d) Orange Peel or Clam Shell Buckets (C) DEVICES FOR TRiUTSPORTIi^G BY POV/ER fa) Straddle Trestle (1) Carson (2) Potter (b) Overhead Cableway (c) Derrick COHCLUSIOUS 1. niTRODUCTIOH The cost of earthwork forms a consideraljle item in the construction of small canals, drainage and irrigation ditches, sewers, and the distributing systems of wator works. -

February 12, 2020 Page 2 72Nd Gold Rush Days February 14-16, 2020

Layout and Design: Juan C. Jiménez / The Wickenburg Sun Sponsored by: Presented in Part by: & Pard’ners A Special Supplement to February 12, 2020 Page 2 72nd Gold Rush Days February 14-16, 2020 “Design with a Twist”© A Unique and Eclectic Home Interior Boutique Downtown Store: 164 N. Tegner Street 928-232-2340 Hours: Monday-Saturday 9-5, Sunday 10-4 Design Center: 1120 N. Tegner Street 928-232-0282 Hours: Tuesday-Saturday 9-5, Sunday 10-4 SHOP HISTORIC DOWNTOWN WICKENBURG SERAPE BLEU Final Logo — Full Color FASHION + GIFTS Experience the amazing style and service at Serape Bleu, a new boutique located in Historic Downtown Wickenburg. Shop our favorite brands like Double D Ranch, Free People, Tasha Polizzi, Lucchese, Flying Monkey, and Johnny Was. 144 N. TEGNER STREET • WICKENBURG, AZ 928.232.2600 • SERAPEBLEU.COM • OPEN DAILY MON-SAT 10 AM - 5 PM • SUN 11 AM - 4 PM February 14-16, 2020 72nd Gold Rush Days Page 3 Visitors to Vulture City are thrown back in time as they explore original buildings and countless artifacts of this once booming town! Seasonal Guided Tours • Celebrity Ghost Hunts Weddings, Social and Corporate Events Vulturecitytours.com JUST 12 MILES SOUTH OF WICKENBURG ON VULTURE MINE RD. Page 4 72nd Gold Rush Days February 14-16, 2020 HOWDY! Welcome to Wickenburg! A western-style “Out Wickenburg Way” welcome to all of our visitors this weekend! Additionally it is important to remember our members, We hope whether you’re a returning Gold Rush Days fan volunteers and sponsors, whose contributions, volunteerism, or a first-timer that you enjoy our 72nd Annual Gold Rush and partnerships share in the success of this signature heri- Days celebration.