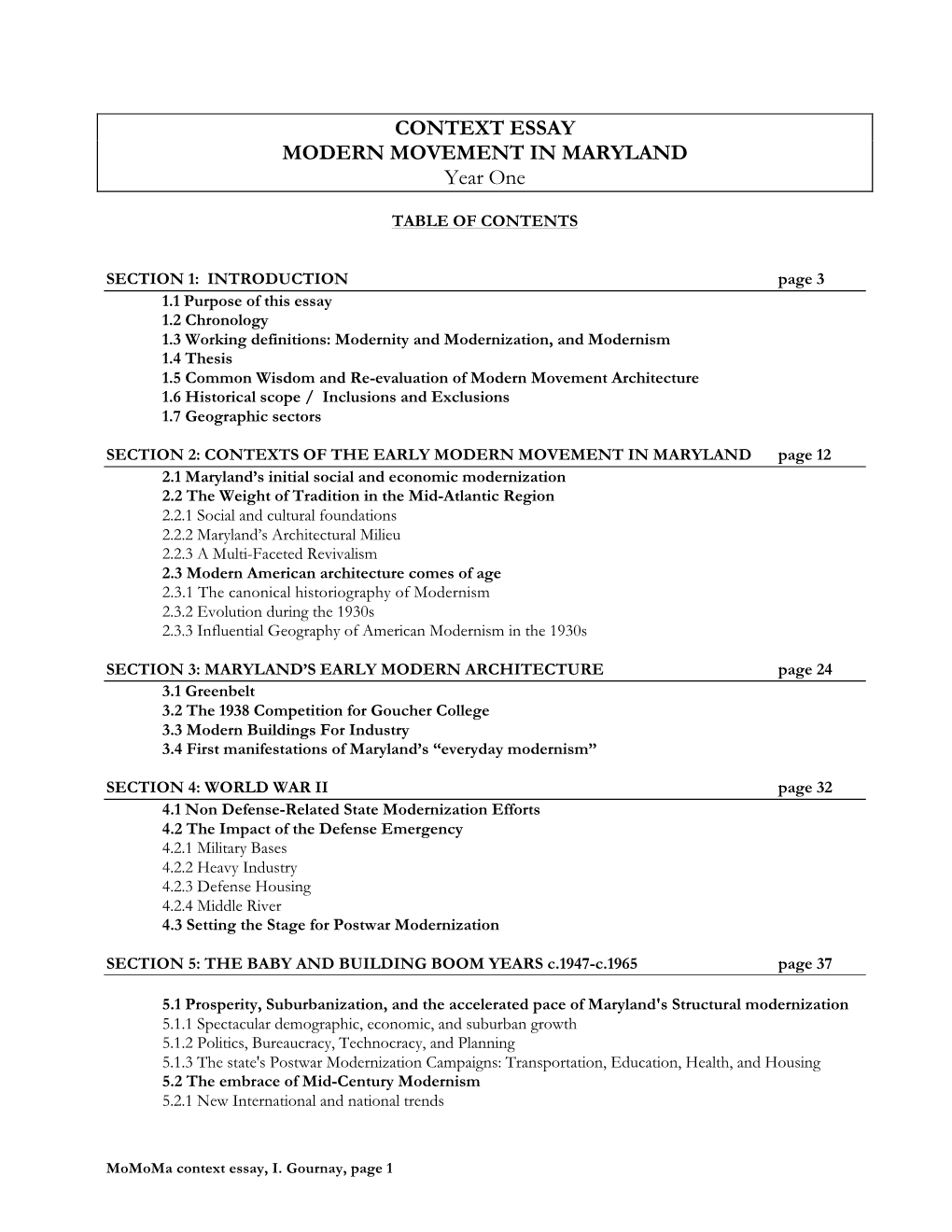

CONTEXT ESSAY MODERN MOVEMENT in MARYLAND Year One

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Mansions of Grosse Pointe

~""__ "'''' __ ''_-iiiJi'''W'' -- 'i If ,I :''j '1 I I , BY HAWKINS FERRY A SU.hurh In Good Taste By Hawkins Ferry Reprinted by Economee Service, In,c. from March, 1956 Issue, Michigan Society of Architects CENTRA~ GR'OSS,EPOINTE PUBLIC UBRAR1 IJDIJRD IN ~;:OOD Tt\STt; BY HAWKINS FERRY THE npllnmg Yllarn of the eighteenth of It:. "elf]! th", ilhores of Lake St Cbir n~JClr ArntJ:,,'::i'Jn t0n~1'1 allraclt'd settlers in the Gl'Om8~' Gretu !i{; r;t \~fid areCI Eorly French farmers bmlt hap~ It III d'!f,~ihngs rtertr the lake both for acces:1 flvt:J11Vfj h~tlSO;g pr(IVtHl to 1:F'~ by cano,) cmd for a convenient water O;H;j "hn[lfll:'lg ;,\lpply TillS resulted in tho hou8e~ boing '.:md l"Jwns th~y together The land of eelen farm sIOnt Cl of l:vlr:q !bf1t j >d'l)' 'ixwnd!!1d from the lake far into the interior enlld by prohlbi!lYC' and m(ll1ilf}IlCll:,;/"' 111 n'lm1W strips, thus having originated C'o~tJ All thli1 er(l tl1'.1t prociuC'<)'d th~, tNm 'ribbon farm." hom,,!s Ul Y'Jl1l,,!llllq rmcl many thif,"'rJl ~'Te It an ()pprr.)p£:-:~t{) h thl' latter part of the nineteenth century mOln'3nt to rellvl11w,1tAthem ',:1$ mmthetl\; th'l mcreational value of the waterfront phenomena. Tf)cognized, and summer cottages took place of farmhouses; but Grosse On@ of the hut lluba\c:mlial ma:nslon~ in P)mte'f!) role as em isolated summer colony Grosse POlllte was thf>' Joseph H. -

An Analysis of the 50-Year Rule, 1966-2010

Copyright by Emily Jeanne Koller 2011 The Report Committee for Emily Jeanne Koller Certifies that this is the approved version of the following report: Listed, Obliterated or Status Unknown: An Analysis of the 50-Year Rule, 1966-2010 APPROVED BY SUPERVISING COMMITTEE: Supervisor: Michael Holleran Monica Penick Listed, Obliterated or Status Unknown: An Analysis of the 50-Year Rule, 1966-2010 by Emily Jeanne Koller, B.A.; MA Report Presented to the Faculty of the Graduate School of The University of Texas at Austin in Partial Fulfillment of the Requirements for the Degree of Master of Science in Community and Regional Planning The University of Texas at Austin May 2011 Abstract Listed, Obliterated or Status Unknown: An Analysis of the 50-Year Rule, 1966-2010 Emily Jeanne Koller, MSCRP The University of Texas at Austin, 2011 Supervisor: Michael Holleran The report evolves from previous work in the field that questions the efficacy of the 50-year rule, or criterion consideration G, of the National Register of Historic Places program to register and protect modern and recent past resources. Proponents of the recent past argue that by restricting evaluation of historic architecture to only that which is 50-years or older is leading to widespread endangerment and demolition of buildings and sites with periods of significance from the postwar era. This report studies the use of criterion G in-depth since the inception of the National Register program and attempts to identify and quantify the resources lost through continued adherence to the 50-year rule. The analysis is done in two parts. -

Defining Architectural Design Excellence Columbus Indiana

Defining Architectural Design Excellence Columbus Indiana 1 Searching for Definitions of Architectural Design Excellence in a Measuring World Defining Architectural Design Excellence 2012 AIA Committee on Design Conference Columbus, Indiana | April 12-15, 2012 “Great architecture is...a triple achievement. It is the solving of a concrete problem. It is the free expression of the architect himself. And it is an inspired and intuitive expression of the client.” J. Irwin Miller “Mediocrity is expensive.” J. Irwin Miller “I won’t try to define architectural design excellence, but I can discuss its value and strategy in Columbus, Indiana.” Will Miller Defining Architectural Design Excellence..............................................Columbus, Indiana 2012 AIA Committee on Design The AIA Committee on Design would like to acknowledge the following sponsors for their generous support of the 2012 AIA COD domestic conference in Columbus, Indiana. DIAMOND PARTNER GOLD PARTNER SILVER PARTNER PATRON DUNLAP & Company, Inc. AIA Indianapolis FORCE DESIGN, Inc. Jim Childress & Ann Thompson FORCE CONSTRUCTION Columbus Indiana Company, Inc. Architectural Archives www.columbusarchives.org REPP & MUNDT, Inc. General Contractors Costello Family Fund to Support the AIAS Chapter at Ball State University TAYLOR BROS. Construction Co., Inc. CSO Architects, Inc. www.csoinc.net Pentzer Printing, Inc. INDIANA UNIVERSITY CENTER for ART + DESIGN 3 Table of Contents Remarks from CONFERENCE SCHEDULE SITE VISITS DOWNTOWN FOOD/DINING Mike Mense, FAIA OPTIONAL TOURS/SITES -

Blueprintsvolume XXVII, No

blueprintsVolume XXVII, No. 1–2 NATIONAL BUILDING MUSEUM In Between: The Other Pieces of the Green Puzzle in this issue: HEALTHY Communities, GREEN Communities Word s ,Word s ,Word s Winter & Spring 2008/2009 The Lay of the Landscape Annual Report 2008 in this issue... 2 8 13 18 19 21 23 In Between: The Other Pieces of the Green Puzzle The exhibition Green Community calls attention to important aspects of sustainable design and planning that are sometimes overshadowed by eye-catching works of architecture. The environmental implications of transportation systems, public services, recreational spaces, and other elements of infrastructure must be carefully considered in order to create responsible and livable communities. This issue of Blueprints focuses on the broad environmental imperative from the standpoints of public health, urban and town planning, and landscape architecture. Contents Healthy Communities, ! 2 Green Communities M Cardboard Reinvented Physician Howard Frumkin, of the Centers for Disease Cardboard: one person’s trash is another Control and Prevention, brings his diverse expertise as B an internist, an environmental and occupational health N person’s decorative sculpture, pen and pencil expert, and an epidemiologist to bear on the public health holder, vase, bowl, photo and business card holder, above: Beaverton Round, in suburban Portland, Oregon, was built as part of the metropolitan area’s Transit-Oriented Development Program. implications of community design and planning. p Photo courtesy of the American Planning Association and Portland Metro. stress toy, or whatever you can imagine. Bring out your o Creating Sustainable Landscapes creativity with these durable, versatile, eco-friendly LIQUID h CARDBOARD vases that can be transformed into a myriad from the executive director 8 In an interview, landscape architect Len Hopper discusses s his profession’s inherent commitment to sustainability and of shapes for a variety of uses in your home. -

Anne Arundel County Corridor Growth Management Plan Final Report

FINAL REPORT Anne Arundel County Corridor Growth Management Plan July 20, 2012 LEGEND Baltimore City US 50 MD 2 South MD 2 North Howard County I-97 MD 32 MD 100 4.6-Miles MD 295 MD 3 MD 607-MD 173 14-Miles 2.5-Miles 16-Miles Benfield Blvd. 13-Miles MD176 14-Miles 17-Miles MD170 4.6-Miles MD 713 Ridge Rd. 11-Miles AACOBoundary Anne Arundel County 17-Miles 7-Miles 19-Miles 4-Miles Prince George's County Prepared by: µ 0 1 2 4 Miles a Joint Venture 7055 Samuel Morse Dr., Suite 100 | Columbia, MD 21406 | 410.741.3500 Corridor Growth Management Plan Table of Contents Table of Contents 1 CHAPTER 1: EXECUTIVE SUMMARY ..........................................................................1-1 1.1 OVERVIEW .......................................................................................................... 1-1 1.1.1 Purpose and Scope ................................................................................ 1-2 1.1.2 Project Costs .......................................................................................... 1-2 1.1.3 Alternatives Tested ............................................................................... 1-2 1.1.4 Priorities ................................................................................................ 1-4 1.1.5 Next Steps ............................................................................................. 1-4 1.2 US 50 .................................................................................................................. 1-4 1.3 MD 2 - NORTH ................................................................................................... -

Download This

NPS Form 10-900 OMB No. 10024-0018 (Oct. 1990) r~ _ B-1382 United States Department of the Interior National Park Service National Register of Historic Places Registration Form This form is for use in nominating or requesting determinations for individual properties and districts. See instructions in How to Completelhe National Register of Historic Places Registration Form (National Register Bulletin 16A). Complete each item by marking "x" in the appropriate box or by entering the information requested. If any item does not apply to the property being documented, enter "N/A" for "not applicable." For functions, architectural classification, materials, and areas of significance, enter only categories and subcategories from the instructions. Place additional entries and narrative items on continuation sheets (NPS Form 10-900a). Use a typewriter, word processor, or computer, to complete all items. 1. Name of Property I historic name Highfield House____________________________________________ other names B-1382___________________________________________________ 2. Location street & number 4000 North Charles Street ____________________ LJ not for publication city or town Baltimore___________________________________________________ D vicinity state Maryland code MD county Baltimore City code 510 zip code 21218 3. State/Federal Agency Certification As the designated authority under the National Historic Preservation Act of 1966, as amended, I hereby certify that this ^ nomination D request for determination of eligibility meets the documentation standards for registering properties in the National Register of Historic Places and meets the procedural and professional requirements set forth in 36 CFR Part 60. In my opinion, the property E] meets D does not meet the National Register criteria. I recommend that this property be considered significant D nationally D statewide ^ locally. -

Saarinen Family Papers Ca. 1880-1989 5 Linear Ft

ARCHIVES Saarinen Family Papers ca. 1880-1989 5 linear ft. Acquisition Number: 1990-08 Acquisition: Gift of Robert S. and Ronald S. Swanson, 1989-1990. In 1988, Matthew Ginal donated copies of materials on Kleinhans to the Archives and these were incorporated into this collection. Access: Access to the collection is unrestricted Copyright: Copyright to this collection is held by the Cranbrook Educational Community, except for some of the Kleinhans materials (see specific folders). Preferred Citation: Saarinen Family Papers, Cranbrook Archives, Bloomfield Hills, Michigan. Photographs: In Photograph Special File and Scrapbooks (Series VI) Audio/Video: 16 mm films are in Series VI, Box 10 Index: The correspondence series is indexed (see end of finding aid) Processing: Betsy Wagner; James Luzenski, 1991; Ryan Wieber, 1998 PROVENANCE Between December 1989 and September 1990, Ronald Saarinen Swanson and Robert Saarinen Swanson donated five lots of Saarinen and Swanson family papers to the Cranbrook Archives. The brothers’ gift included a core grouping of archival materials relating to Eliel, Loja, and Eero Saarinen that had been held by Loja Saarinen until her death and later by Pipsan Saarinen Swanson. This grouping of material constitutes the majority of the Saarinen Family papers. Materials relating to Pipsan Saarinen Swanson and her husband, J. Robert S. Swanson, were organized into the Swanson Family papers (1990-1). Other non-aligned Archives holdings pertaining to the Saarinens and Swansons were subsequently added to both collections. The inventories of the Swansons’ gift have been kept and can be consulted. Not all of the Saarinen Family papers were donated to Cranbrook. After Eliel’s death, Loja Saarinen donated a cache of his honorary degrees and awards, drawings, and photographs to the Museum of Finnish Architecture in Helsinki. -

Kimmel in the C M Nity

THE SIDNEY KIMMEL COMPREHENSIVE CANCER CENTE R AT JOHNS HOPKINS KIMMEL IN THE C MNITY PILLARS OF PROGRESS Closing the Gap in Cancer Disparities MUCH PROGRESS HAS been made in Maryland toward eliminating cancer disparities, and I am very proud of the role the Johns Hopkins Kimmel Cancer Center has played in this progress. Overcoming cultural and institutional barriers and increasing minority participation in clinical trials is a priority at the Kimmel Cancer Center. Programs like our Center to Reduce Cancer Disparities, Office of Community Cancer Research, the Maryland Cigarette Restitution Fund at Johns Hopkins, and Day at the Market are helping us obtain this goal. Historical Trends (1975-2012) The challenge before Maryland is greater than Mortality, Maryland most states. Thirty percent of Maryland’s citizens are All Cancer Sites, Both Sexes, All Ages Deaths per 100,000 resident population African-American, compared to a national average 350 of 13 percent. We view our state’s demographics as 300 black (includes hispanics) an opportunity to advance the understanding of 250 factors that cause disparities, unravel the science White (includes hispanics) 200 that may also play a contributory role, and become the model for the rest of the country. Our experts are 150 setting the standards for removing barriers and 100 hispanic (any race) improving cancer care for African-Americans and 50 other minorities in Maryland and around the world. 0 1975 1980 1985 1990 1995 2000 2005 2010 Although disparities still exist in Maryland, we year of Death continue to close that gap. Overall cancer death rates have declined in our state, and we have narrowed the gap in cancer death disparities between African -American and white Marylanders by more than 60 percent since 2001, far exceeding national progress. -

Adopted Grosse Pointe Estate Historic District Preliminary Study

PRELIMINARY HISTORIC DISTRICT STUDY COMMITTEE REPORT GROSSE POINTE ESTATE HISTORIC DISTRICT GROSSE POINTE, MICHIGAN Adopted FEBRUARY 15, 2021 CHARGE OF THE HISTORIC DISTRICT STUDY COMMITTEE The historic district study committee was appointed by the Grosse Pointe City Council on December 14, 2020, pursuant to PA 169 of 1970 as amended. The study committee was charged with conducting an inventory, research, and preparation of a preliminary historic district study committee report for the following areas of the city: o Lakeland Ave from Maumee to Lake St. Clair o University Place from Maumee to Jefferson o Washington Road from Maumee to Jefferson o Lincoln Road from Maumee to Jefferson o Entirety of Rathbone Place o Entirety of Woodland Place o The lakefront homes and property immediately adjacent to the lakefront homes on Donovan Place, Wellington Place, Stratford Place, and Elmsleigh Place Upon completion of the report the study committee is charged with holding a public hearing and making a recommendation to city council as to whether a historic district ordinance should be adopted, and a local historic district designated. A list of study committee members and their qualifications follows. STUDY COMMITTEE MEMBERS George Bailey represents the Grosse Pointe Historical Society on the committee. He is an architect and has projects in historic districts in Detroit; Columbus, OH; and Savannah, GA. He is a history aficionado and serves on the Grosse Pointe Woods Historic Commission and Planning Commission. Kay Burt-Willson is the secretary of the Rivard Park Home Owners Association and the Vice President of Education for the Grosse Pointe Historical Society. -

National Register of Historic Places Registration Form

B-4480 NPS Form 10-900 OMB No. 10024-0018 (Oct. 1990) United States Department of the Interior National Park Service National Register of Historic Places Registration Form This form is for use in nominating or requesting determinations for individual properties and districts. See instructions in How to Complete the National Register of Historic Places Registration Form (National Register Bulletin 16A). Complete each item by marking V in the appropriate box or by entering the information requested. If any item does not apply to the property being documented, enter "N/A" for "not applicable." For functions, architectural classification, materials, and areas of significance, enter only categories and subcategories from the instructions. Place additional entries and narrative items on continuation sheets (NPS Form 10-900a). Use a typewriter, word process, or computer, to complete all items. 1. Name of Property historic name One Charles Center other names B-4480 2. Location street & number 100 North Charles Street Q not for publication city or town Baltimore • vicinity state Maryland code MP County Independent city code 510 zip code 21201 3. State/Federal Agency Certification As the designated authority under the National Historic Preservation Act of 1966, as amended, I hereby certify that this G3 nomination • request for determination of eligibility meets the documentation standards for registering properties in the National Register of Historic Places and meets the procedural and professional requirements set forth in 36 CFR Part 60. In my opinion, the property C3 meets • does not meet the National Register criteria. I recommend that this property be considered significant D nationally • statewide K locally. -

Lustron Corporation Steel Houses Peter Lobner, 15 June 2020 The

Lustron Corporation steel houses Peter Lobner, 15 June 2020 The Lustron Corporation was formed in 1947 by Carl Strandlund, in collaboration with Chicago Vitreous Enamel Corporation, to mass- produce steel-constructed housing after World War II (WW II). The name “Lustron” refers to the factory-applied, lustrous, permanent porcelain enamel finish on all steel components. Lustron received an initial $15,500,000 loan from the Reconstruction Finance Corporation (RFC) to mass-produce steel pre-fabricated houses in a former Curtiss-Wright aircraft factory in Columbus, OH, with more than 1,000,000 square feet of manufacturing floor space. After WW II, steel was a rationed material controlled by the Department of Commerce. There was only a limited allocation for “non-essential” use, such as manufacturing pre-fabricated homes, and Lustron received a large share of that allocation. The only 2-bedroom Lustron “Esquire” prototype model. It was built in Hinsdale, IL. Source: http://instanthouse.blogspot.com 1 Lustron homes were FHA approved and financed. The customer could choose from three production models, Winchester, Newport and Meadowbrook, which could be ordered with 2- or 3-bedroom floor plans. The Winchester could be ordered in “Standard” or “Deluxe” finish. Representative Lustron floor plans. Source: Screenshot from video, “The History of the Lustron House,” Raleigh Historic Development Commission All houses came standard with porcelain enamel-coated steel exterior panels available in four colors: surf blue, maize yellow, desert tan, and dove gray. The houses also had an enamel-coated steel shingle roof, enamel-coated steel interior wall panels most often in a standard light grey color, metal ceiling tiles, interior pocket doors, metal cabinets, and service and storage areas. -

National Register of Historic Places Registration Form

NPS Form 10-900 OMB No. 1024-0018 United States Department of the Interior National Park Service National Register of Historic Places Registration Form This form is for use in nominating or requesting determinations for individual properties and districts. See instructions in National Register Bulletin, How to Complete the National Register of Historic Places Registration Form. If any item does not apply to the property being documented, enter "N/A" for "not applicable." For functions, architectural classification, materials, and areas of significance, enter only categories and subcategories from the instructions. 1. Name of Property Historic name: Checker Cab Taxi Garage and Office Building Other names/site number: Detroit Cab Company Garage Name of related multiple property listing: N/A (Enter "N/A" if property is not part of a multiple property listing _____________________________________________________________________ 2. Location Street & number: 2128 Trumbull Avenue City or town: Detroit State: Michigan County: Wayne Not For Publication: Vicinity: _______________________________________________________________________ 3. State/Federal Agency Certification As the designated authority under the National Historic Preservation Act, as amended, I hereby certify that this X nomination ___ request for determination of eligibility meets the documentation standards for registering properties in the National Register of Historic Places and meets the procedural and professional requirements set forth in 36 CFR Part 60. In my opinion, the property X meets ___ does not meet the National Register Criteria. I recommend that this property be considered significant at the following level(s) of significance: ___national ___statewide X local Applicable National Register Criteria: X A ___B _X__C ___D Signature of certifying official/Title: Date Michigan State Historic Preservation Office State or Federal agency/bureau or Tribal Government In my opinion, the property meets does not meet the National Register criteria.