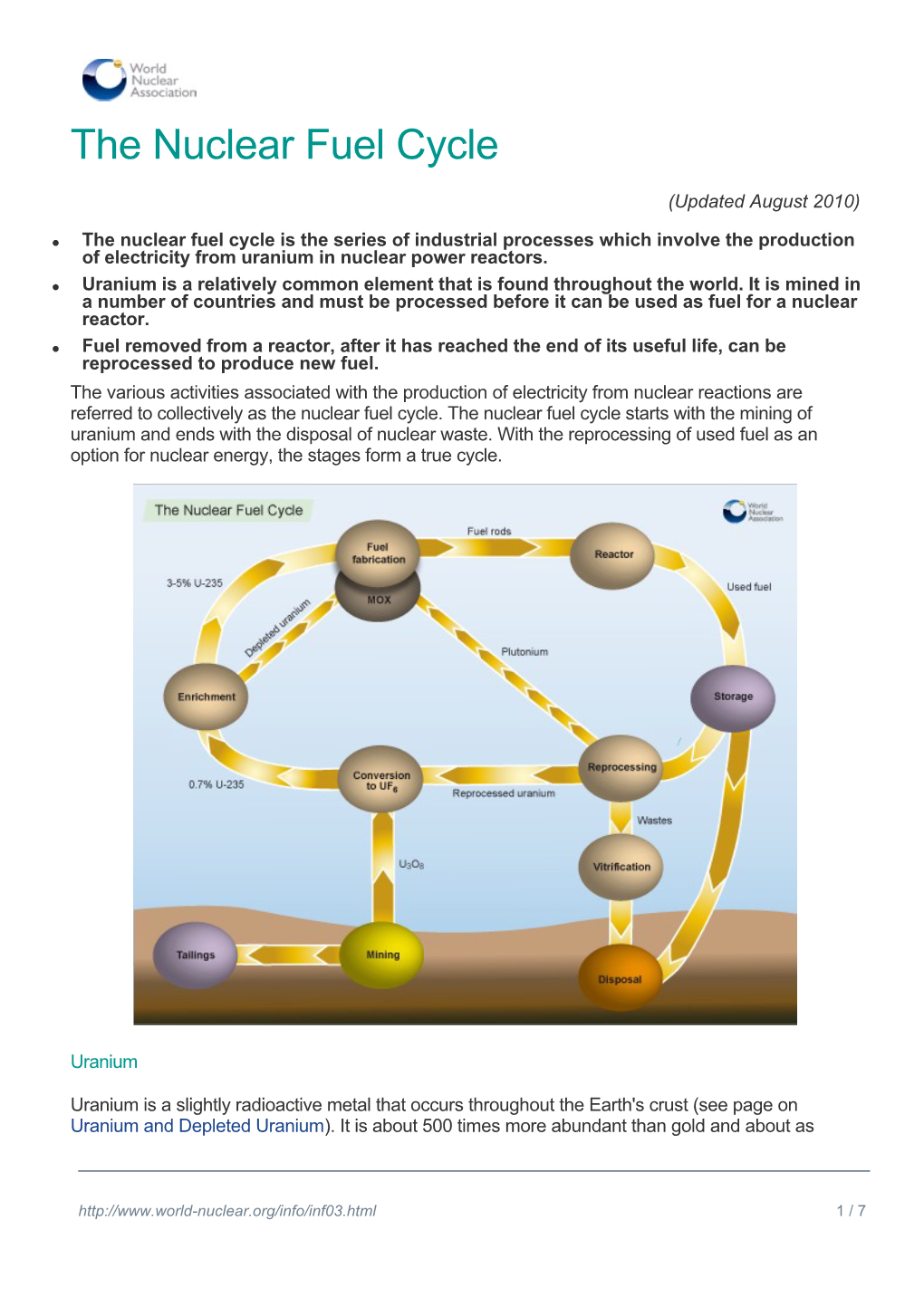

The Nuclear Fuel Cycle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

In Situ Leach (ISL) Mining of Uranium

In Situ Leach (ISL) Mining of Uranium (June 2009) l Most uranium mining in the USA and Kazakhstan is now by in situ leach methods, also known as in situ recovery (ISR). l In USA ISL is seen as the most cost effective and environmentally acceptable method of mining, and Australian experience supports this. l Australia's first ISL uranium mine is Beverley, which started operation late in 2000. The proposal for Honeymoon has government approval and it is expected to be operating in 2008. Conventional mining involves removing mineralised rock (ore) from the ground, breaking it up and treating it to remove the minerals being sought. In situ leaching (ISL), also known as solution mining, or in situ recovery (ISR) in North America, involves leaving the ore where it is in the ground, and recovering the minerals from it by dissolving them and pumping the pregnant solution to the surface where the minerals can be recovered. Consequently there is little surface disturbance and no tailings or waste rock generated. However, the orebody needs to be permeable to the liquids used, and located so that they do not contaminate ground water away from the orebody. Uranium ISL uses the native groundwater in the orebody which is fortified with a complexing agent and in most cases an oxidant. It is then pumped through the underground orebody to recover the minerals in it by leaching. Once the pregnant solution is returned to the surface, the uranium is recovered in much the same way as in any other uranium plant (mill). In Australian ISL mines (Beverley and the soon to be opened Honeymoon Mine) the oxidant used is hydrogen peroxide and the complexing agent sulfuric acid. -

Per-10 Basic Information Relating to Uranium

PER-10 1 BASIC INFORMATION RELATING TO URANIUM-ENRICHMENT CALCULATIONS AND FUEL REQUIREMENTS FOR NUCLEAR POWER REACTORS by K.T. Brown m 3 ATOMIC ENERGY BOARD Pelindaba PRETORIA Republic of South Africa February 1977 :::: : =:::""""""::::::;::: i:::""""""" :::::::::i:::::::::::::::H:::""»"""::::::::::::::::: BASIC INFORMATION RELATING TO URANIUM-ENRICHMENT CALCULATIONS AND FUEL REQUIREMENTS FOR NUCLEAR POWER REACTORS hy K.T. Brown POSTAL ADDRESS: Atomic Energy Board Private Bag X256 PRETORIA 0001 PELINDABA Fi-ln liai v 1977 ISBN U 86Ü6U 654 9 Pago Page SAMEVATTING 2 ABSTRACT 2 3. REACTOR FUEL REQUIREMENTS 5 1. INTRODUCTION 3 3.1 Reactor Types 5 2. URANIUM ENRICHMENT 3 3.1.1 Pressurised-water roactor 5 2.1 Definitions 3 3.1.2 Boiling-water reactor 5 2.1.1 Natural uranium 3 3.1.3 CANDU-PHW 6 2.1.2 Fissile 3 3.1.4 High-temperature gas-cooled reactor 6 2.1.3 Fertile 3 2.1.5 Liquid-metal-cooled fast breeder reactor ... .6 2.1.4 Enrichment 3 3.2 Nuclear Fuel Cycles 6 2.1.5 Product 3 3.3 Typical Fuel Requirements 6 2.1.6 Feed 3 3.3.1 Pressurised-wator reactor 7 2.1.7 Tails, or waste 3 3.3.2 Boiling-water reactor 8 2.1.8 Cascade 3 3.3.3 CANDU-PHW 9 2.1.9 Separative work 4 3.3.4 High-temperature gas-cooled reactor 9 2.1.10 Separative-work unit 4 3.3.5 Liquid-metal-cooled fast breeder reactor ... 10 2.2 Enrichment Parameters 4 3.3.6 Comparative data 10 2.3 Optimum Tails Assay 5 4. -

Understanding Fluid–Rock Interactions and Lixiviant/Oxidant Behaviour for the In-Situ Recovery of Metals from Deep Ore Bodies

School of Earth and Planetary Science Department of Applied Geology Understanding Fluid–Rock Interactions and Lixiviant/Oxidant Behaviour for the In-situ Recovery of Metals from Deep Ore Bodies Tania Marcela Hidalgo Rosero This thesis is presented for the degree of Doctor of Philosophy of Curtin University February 2020 1 Declaration __________________________________________________________________________ Declaration To the best of my knowledge and belief, I declare that this work of thesis contains no material published by any other person, except where due acknowledgements have been made. This thesis contains no material which has been accepted for the award of any other degree or diploma in any university. Tania Marcela Hidalgo Rosero Date: 28/01/2020 2 Abstract __________________________________________________________________________ Abstract In-situ recovery (ISR) processing has been recognised as a possible alternative to open- pit mining, especially for low-grade resources. In ISR, the fluid–rock interaction between the target ore and the lixiviant results in valuable- (and gangue-) metal dissolution. This interaction is achieved by the injection and recovery of fluid by means of strategically positioned wells. Although the application of ISR has become more common (ISR remains the preferential processing technique for uranium and has been applied in pilot programs for treating oxide zones in copper deposits), its application to hard-rock refractory and low-grade copper-sulfide deposits is still under development. This research is focused on the possible application of ISR to primary copper sulfides usually found as deep ores. Lixiviant/oxidant selection is an important aspect to consider during planning and operation in the ISR of copper-sulfide ores. -

Uranium Fact Sheet

Fact Sheet Adopted: December 2018 Health Physics Society Specialists in Radiation Safety 1 Uranium What is uranium? Uranium is a naturally occurring metallic element that has been present in the Earth’s crust since formation of the planet. Like many other minerals, uranium was deposited on land by volcanic action, dissolved by rainfall, and in some places, carried into underground formations. In some cases, geochemical conditions resulted in its concentration into “ore bodies.” Uranium is a common element in Earth’s crust (soil, rock) and in seawater and groundwater. Uranium has 92 protons in its nucleus. The isotope2 238U has 146 neutrons, for a total atomic weight of approximately 238, making it the highest atomic weight of any naturally occurring element. It is not the most dense of elements, but its density is almost twice that of lead. Uranium is radioactive and in nature has three primary isotopes with different numbers of neutrons. Natural uranium, 238U, constitutes over 99% of the total mass or weight, with 0.72% 235U, and a very small amount of 234U. An unstable nucleus that emits some form of radiation is defined as radioactive. The emitted radiation is called radioactivity, which in this case is ionizing radiation—meaning it can interact with other atoms to create charged atoms known as ions. Uranium emits alpha particles, which are ejected from the nucleus of the unstable uranium atom. When an atom emits radiation such as alpha or beta particles or photons such as x rays or gamma rays, the material is said to be undergoing radioactive decay (also called radioactive transformation). -

An Advanced Sodium-Cooled Fast Reactor Core Concept Using Uranium-Free Metallic Fuels for Maximizing TRU Burning Rate

sustainability Article An Advanced Sodium-Cooled Fast Reactor Core Concept Using Uranium-Free Metallic Fuels for Maximizing TRU Burning Rate Wuseong You and Ser Gi Hong * Department of Nuclear Engineering, Kyung Hee University, Deogyeong-daero, GiHeung-gu, Yongin, Gyeonggi-do 446-701, Korea; [email protected] * Correspondence: [email protected]; Tel.: +82-31-201-2782 Received: 24 October 2017; Accepted: 28 November 2017; Published: 1 December 2017 Abstract: In this paper, we designed and analyzed advanced sodium-cooled fast reactor cores using uranium-free metallic fuels for maximizing burning rate of transuranics (TRU) nuclides from PWR spent fuels. It is well known that the removal of fertile nuclides such as 238U from fuels in liquid metal cooled fast reactor leads to the degradation of important safety parameters such as the Doppler coefficient, coolant void worth, and delayed neutron fraction. To resolve the degradation of the Doppler coefficient, we considered adding resonant nuclides to the uranium-free metallic fuels. The analysis results showed that the cores using uranium-free fuels loaded with tungsten instead of uranium have a significantly lower burnup reactivity swing and more negative Doppler coefficients than the core using uranium-free fuels without resonant nuclides. In addition, we considered the use of axially central B4C absorber region and moderator rods to further improve safety parameters such as sodium void worth, burnup reactivity swing, and the Doppler coefficient. The results of the analysis showed that the final design core can consume ~353 kg per cycle and satisfies self-controllability under unprotected accidents. The fuel cycle analysis showed that the PWR–SFR coupling fuel cycle option drastically reduces the amount of waste going to repository and the SFR burner can consume the amount of TRUs discharged from 3.72 PWRs generating the same electricity. -

Fast-Spectrum Reactors Technology Assessment

Clean Power Quadrennial Technology Review 2015 Chapter 4: Advancing Clean Electric Power Technologies Technology Assessments Advanced Plant Technologies Biopower Clean Power Carbon Dioxide Capture and Storage Value- Added Options Carbon Dioxide Capture for Natural Gas and Industrial Applications Carbon Dioxide Capture Technologies Carbon Dioxide Storage Technologies Crosscutting Technologies in Carbon Dioxide Capture and Storage Fast-spectrum Reactors Geothermal Power High Temperature Reactors Hybrid Nuclear-Renewable Energy Systems Hydropower Light Water Reactors Marine and Hydrokinetic Power Nuclear Fuel Cycles Solar Power Stationary Fuel Cells U.S. DEPARTMENT OF Supercritical Carbon Dioxide Brayton Cycle ENERGY Wind Power Clean Power Quadrennial Technology Review 2015 Fast-spectrum Reactors Chapter 4: Technology Assessments Background and Current Status From the initial conception of nuclear energy, it was recognized that full realization of the energy content of uranium would require the development of fast reactors with associated nuclear fuel cycles.1 Thus, fast reactor technology was a key focus in early nuclear programs in the United States and abroad, with the first usable nuclear electricity generated by a fast reactor—Experimental Breeder Reactor I (EBR-I)—in 1951. Test and/or demonstration reactors were built and operated in the United States, France, Japan, United Kingdom, Russia, India, Germany, and China—totaling about 20 reactors with 400 operating years to date. These previous reactors and current projects are summarized in Table 4.H.1.2 Currently operating test reactors include BOR-60 (Russia), Fast Breeder Test Reactor (FBTR) (India), and China Experimental Fast Reactor (CEFR) (China). The Russian BN-600 demonstration reactor has been operating as a power reactor since 1980. -

Advanced Nuclear Power and Fuel Cycle Technologies: Outlook and Policy Options

Order Code RL34579 Advanced Nuclear Power and Fuel Cycle Technologies: Outlook and Policy Options July 11, 2008 Mark Holt Specialist in Energy Policy Resources, Science, and Industry Division Advanced Nuclear Power and Fuel Cycle Technologies: Outlook and Policy Options Summary Current U.S. nuclear energy policy focuses on the near-term construction of improved versions of existing nuclear power plants. All of today’s U.S. nuclear plants are light water reactors (LWRs), which are cooled by ordinary water. Under current policy, the highly radioactive spent nuclear fuel from LWRs is to be permanently disposed of in a deep underground repository. The Bush Administration is also promoting an aggressive U.S. effort to move beyond LWR technology into advanced reactors and fuel cycles. Specifically, the Global Nuclear Energy Partnership (GNEP), under the Department of Energy (DOE) is developing advanced reprocessing (or recycling) technologies to extract plutonium and uranium from spent nuclear fuel, as well as an advanced reactor that could fully destroy long-lived radioactive isotopes. DOE’s Generation IV Nuclear Energy Systems Initiative is developing other advanced reactor technologies that could be safer than LWRs and produce high-temperature heat to make hydrogen. DOE’s advanced nuclear technology programs date back to the early years of the Atomic Energy Commission in the 1940s and 1950s. In particular, it was widely believed that breeder reactors — designed to produce maximum amounts of plutonium from natural uranium — would be necessary for providing sufficient fuel for a large commercial nuclear power industry. Early research was also conducted on a wide variety of other power reactor concepts, some of which are still under active consideration. -

The Nuclear Fuel Cycle

THE COLLECTION > From the uranium mine> toI wNTasRtOeD dUisCpToIsOaN l 1 > The atom 2 > Radioactivity 3 > Radiation and man 4 > Energy 5 > Nuclear energy: fusion and fission 6 > How a nuclear reactor works 7 > The nuclear fuel cycle 7 > The nuclear fuel cycle FROM RESEARCH 8 > Microelectronics 9 > The laser: a concentrate of light TO INDUSTRY 10 > Medical imaging 11 > Nuclear astrophysics 12 > Hydrogen 7 >>TThhee nnuucclleeaarr ffuueell ccyyccllee UPSTREAM THE REACTOR: PREPARING THE FUEL IN THE REACTOR: FUEL CONSUMPTION DOWNSTREAM THE REACTOR: REPROCESSING NUCLEAR WASTE NUCLEAR WASTE © Commissariat à l’’Énergie Atomique et aux Energies Alternatives, 2005 Communication Division Bâtiment Siège - 91191 Gif-sur-Yvette cedex www.cea.fr ISSN 1637-5408. From the uranium mine to waste disposal 7 > The nuclear fuel cycle From the uranium mine to waste disposal 7 > The nuclear fuel cycle 2 > CONTENTS > INTRODUCTION 3 Uranium ore is extracted from open-pit mines – such as the McClear mines in Canada seen here – or underground workings. a m e g o C © “The nuclear fuel cycle includes an erray UPSTREAM THE REACTOR: of industrial operations, from uranium PREPARING THE FUEL 4 e mining to the disposal of radioactive l Extracting uranium from the ore 5 waste.” c Concentrating and refining uranium 6 y Enriching uranium 6 c Enrichment methods 8 l introduction uel is a material that can be burnt to pro - IN THE REACTOR: FUEL CONSUMPTION 9 Fvide heat. The most familiar fuels are wood, e Preparing fuel assemblies 10 coal, natural gas and oil. By analogy, the ura - e g a nium used in nuclear power plants is called Per unit or mass (e.g. -

1 Introduction

1 Introduction WHO commissions reviews and undertakes health risk assessments associated with exposure to potentially hazardous physical, chemical and biological agents in the home, work place and environment. This monograph on the chemical and radiological hazards associated with exposure to depleted uranium is one such assessment. The purpose of this monograph is to provide generic information on any risks to health from depleted uranium from all avenues of exposure to the body and from any activity where human exposure could likely occur. Such activities include those involved with fabrication and use of DU products in industrial, commercial and military settings. While this monograph is primarily on DU, reference is also made to the health effects and behaviour of uranium, since uranium acts on body organs and tissues in the same way as DU and the results and conclusions from uranium studies are considered to be broadly applicable to DU. However, in the case of effects due to ionizing radiation, DU is less radioactive than uranium. This review is structured as broadly indicated in Figure 1.1, with individual chapters focussing on the identification of environmental and man-made sources of uranium and DU, exposure pathways and scenarios, likely chemical and radiological hazards and where data is available commenting on exposure-response relationships. HAZARD IDENTIFICATION PROPERTIES PHYSICAL CHEMICAL BIOLOGICAL DOSE RESPONSE RISK EVALUATION CHARACTERISATION BACKGROUND EXPOSURE LEVELS EXPOSURE ASSESSMENT Figure 1.1 Schematic diagram, depicting areas covered by this monograph. It is expected that the monograph could be used as a reference for health risk assessments in any application where DU is used and human exposure or contact could result. -

Sell-1559, Leaching

CONTACT INFORMATION Mining Records Curator Arizona Geological Survey 416 W. Congress St., Suite 100 Tucson, Arizona 85701 520-770-3500 http://www.azgs.az.gov [email protected] The following file is part of the James Doyle Sell Mining Collection ACCESS STATEMENT These digitized collections are accessible for purposes of education and research. We have indicated what we know about copyright and rights of privacy, publicity, or trademark. Due to the nature of archival collections, we are not always able to identify this information. We are eager to hear from any rights owners, so that we may obtain accurate information. Upon request, we will remove material from public view while we address a rights issue. CONSTRAINTS STATEMENT The Arizona Geological Survey does not claim to control all rights for all materials in its collection. These rights include, but are not limited to: copyright, privacy rights, and cultural protection rights. The User hereby assumes all responsibility for obtaining any rights to use the material in excess of “fair use.” The Survey makes no intellectual property claims to the products created by individual authors in the manuscript collections, except when the author deeded those rights to the Survey or when those authors were employed by the State of Arizona and created intellectual products as a function of their official duties. The Survey does maintain property rights to the physical and digital representations of the works. QUALITY STATEMENT The Arizona Geological Survey is not responsible for the accuracy of the records, information, or opinions that may be contained in the files. The Survey collects, catalogs, and archives data on mineral properties regardless of its views of the veracity or accuracy of those data. -

Long Term Sustainability of Nuclear Power in India - Prospects and Challenges

Page | 45 5 LONG TERM SUSTAINABILITY OF NUCLEAR POWER IN INDIA - PROSPECTS AND CHALLENGES Vipin Shukla, Vivek J. Pandya and C. Ganguly ABSTRACT: Nuclear power is emerging as a viable for at least 12 additional indigenous PHWR 700 carbon – free option for India to meet the ever- reactors. The target is to have ~ 45,000 MWe nuclear increasing demand of base – load electricity at an power by 2030. Since the last six years, India has affordable price, in a safe, secured and sustainable also been importing natural uranium oreconcentrate manner. Since the 1970s, India had been pursuing (UOC) and finished natural UO2 pellets tofuel the a self-reliant indigenous nuclear power program ten PHWR 220 units at Rawathbhata, Kakrapara and linking the fuel cycles of Pressurized Heavy Water Narora. India has also been importing enriched UO2 Reactor (PHWR), Fast Breeder Reactor (FBRs) and fuel for the two BWRs at Tarapur and the two VVERs thorium-based self-sustaining breeder in stage 1, 2 at Kudankulunm. The present paper summarizes the and 3 respectively, for efficient utilization of modest on-going and the expanding nuclear power program low grade (0.03-0.06 % U3O8) uranium reserves but in India highlighting the challenges of availability of vast thorium resources. Natural uranium fueled uranium and plutonium for manufacturing nuclear PHWR is the backbone of the program. India has fuels. achieved industrial maturity in PHWR and the related uranium fuel cycle technology. Presently, 21 reactors are in operation, including 16 units of PHWR 220 MWe, 2 units of PHWR 540 MWe, 2 units of Boiling Water Reactor (BWR) 160 MWe and a (Water KEYWORDS Water Energy Reactor) VVER 1000 MWe. -

Highly Enriched Uranium: Striking a Balance

OFFICIAL USE ONLY - DRAFT GLOSSARY OF TERMS APPENDIX F GLOSSARY OF TERMS Accountability: That part of the safeguards and security program that encompasses the measurement and inventory verification systems, records, and reports to account for nuclear materials. Assay: Measurement that establishes the total quantity of the isotope of an element and the total quantity of that element. Atom: The basic component of all matter. Atoms are the smallest part of an element that have all of the chemical properties of that element. Atoms consist of a nucleus of protons and neutrons surrounded by electrons. Atomic energy: All forms of energy released in the course of nuclear fission or nuclear transformation. Atomic weapon: Any device utilizing atomic energy, exclusive of the means for transportation or propelling the device (where such means is a separable and divisible part of the device), the principal purpose of which is for use as, or for development of, a weapon, a weapon prototype, or a weapon test device. Blending: The intentional mixing of two different assays of the same material in order to achieve a desired third assay. Book inventory: The quantity of nuclear material present at a given time as reflected by accounting records. Burnup: A measure of consumption of fissionable material in reactor fuel. Burnup can be expressed as (a) the percentage of fissionable atoms that have undergone fission or capture, or (b) the amount of energy produced per unit weight of fuel in the reactor. Chain reaction: A self-sustaining series of nuclear fission reactions. Neutrons produced by fission cause more fission. Chain reactions are essential to the functioning of nuclear reactors and weapons.