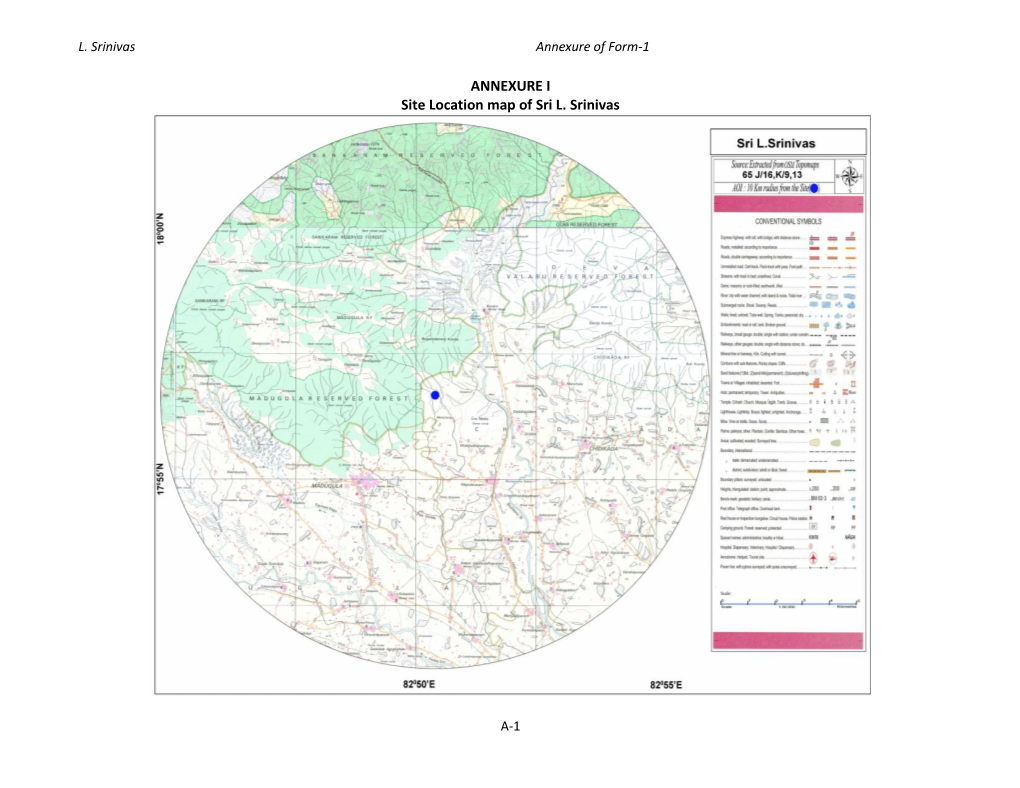

ANNEXURE I Site Location Map of Sri L. Srinivas

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

LHA Recuritment Visakhapatnam Centre Screening Test Adhrapradesh Candidates at Mudasarlova Park Main Gate,Visakhapatnam.Contact No

LHA Recuritment Visakhapatnam centre Screening test Adhrapradesh Candidates at Mudasarlova Park main gate,Visakhapatnam.Contact No. 0891-2733140 Date No. Of Candidates S. Nos. 12/22/2014 1300 0001-1300 12/23/2014 1300 1301-2600 12/24/2014 1299 2601-3899 12/26/2014 1300 3900-5199 12/27/2014 1200 5200-6399 12/28/2014 1200 6400-7599 12/29/2014 1200 7600-8799 12/30/2014 1177 8800-9977 Total 9977 FROM CANDIDATES / EMPLOYMENT OFFICES GUNTUR REGISTRATION NO. CASTE GENDER CANDIDATE NAME FATHER/ S. No. Roll Nos ADDRESS D.O.B HUSBAND NAME PRIORITY & P.H V.VENKATA MUNEESWARA SUREPALLI P.O MALE RAO 1 1 S/O ERESWARA RAO BHATTIPROLU BC-B MANDALAM, GUNTUR 14.01.1985 SHAIK BAHSA D.NO.1-8-48 MALE 2 2 S/O HUSSIAN SANTHA BAZAR BC-B CHILAKURI PETA ,GUNTUR 8/18/1985 K.NAGARAJU D.NO.7-2-12/1 MALE 3 3 S/O VENKATESWARULU GANGANAMMAPETA BC-A TENALI. 4/21/1985 SHAIK AKBAR BASHA D.NO.15-5-1/5 MALE 4 4 S/O MAHABOOB SUBHANI PANASATHOTA BC-E NARASARAO PETA 8/30/1984 S.VENUGOPAL H.NO.2-34 MALE 5 5 S/O S.UMAMAHESWARA RAO PETERU P.O BC-B REPALLI MANDALAM 7/20/1984 B.N.SAIDULU PULIPADU MALE 6 6 S/O PUNNAIAH GURAJALA MANDLAM ,GUNTUR BC-A 6/11/1985 G.RAMESH BABU BHOGASWARA PET MALE 7 7 S/O SIVANJANEYULU BATTIPROLU MANDLAM, GUNTUR BC-A 8/15/1984 K.NAGARAJENDRA KUMAR PAMIDIMARRU POST MALE 8 8 S/O. -

Annexure to Trade Notice No. 01/2017 (General No

Annexure to Trade Notice No. 01/2017 (General No. 1/2017) Dated. 21.06.2017 issued from F.No. V/39/16/2017-CC(VZ)Estt.P.F.I ANNEXURE - I Visakhapatnam Zone : Visakhapatnam Commissionerate and Kakinada Sub-Commissionerate No. of Sl.No. Commissionerate Name Jurisdiction Divisions Divisions This Commissionerate will have the jurisdiction over (i) Visakhapatnam North Visakhapatnam Srikakulam, Vizianagaram, (ii) Visakhapatnam Central 01 4 Commissionerate Visakhapatnam & East Godavari (iii) Visakhapatnam South Districts of Andhra Pradesh (iv) Vizianagaram Division State Kakinada Sub- This Sub-Commissionerate will (i) Kakinada Division Commissionerate have the jurisdiction over East 02 2 (ii) Rajamahendravaram (stationed at Rajamahendravaram) Godavari District of Andhra (Under Visakhapatnam Division Commissionerate) Pradesh State Page 1 of 13 Annexure to Trade Notice No. 01/2017 (General No. 1/2017) Dated. 21.06.2017 issued from F.No. V/39/16/2017-CC(VZ)Estt.P.F.I Sl. GST Division Name Jurisdiction No. of Ranges Ranges No. (i) Bheemunipatnam This Division will have jurisdiction over GVMC (Greater (ii) Madhurawada Visakhapatnam Municipal Corporation) ward Nos. 1 to 19 & (iii) Muvvalavanipalem Bheemunipatnam, Padmanabham & Anandapuram Mandals (iv) Maddilapalem Visakhapatnam (v) Akkayyapalem 01 of Visakhapatnam District. This Division will also have 10 North (vi) Seethammapeta residuary jurisdiction over any other area which is not (vii) Dwarakanagar mentioned or existing in any division under Visakhapatnam (viii) Srinagar District. (ix) Aseelmetta -

Annual Report for 2015

Estd: 26th SEPT 1996Regd No: 1980/2005 SRUJANAVANI be the change… ANNUAL NEWS LETTER April 2015- March 2016 SRUJANAVANI, PLOT No: C-216, SVLN COLONY, VEPAGUNTA (PO), VISAKHAPATNAM, PIN-530047, ANDHRA PRADESH, INDIA (Phone: 9346908717) [email protected] WWW.SRUJANAVANI.ORG INDEX ABOUT US...................................................................................................................................................... 3 MAN MAKING ............................................................................................................................................... 4 VIDYANIDHI ................................................................................................................................................... 5 YUVA KIRAN .................................................................................................................................................. 7 INFRASTRUCTURE DEVELOPMENT .............................................................................................................. 17 Srujanavani Activity Center (SAC) and Teach For Vizag (TFV) ..................................................................... 17 Donation from CESVA ................................................................................................................................. 20 CSR Initiatives .............................................................................................................................................. 21 Renovation of Govt. Schools ...................................................................................................................... -

Salient Architectural Features of Selected Colonial Built Heritage in Visakhapatnam, Andhra Pradesh, India

International Journal of Engineering Research and Development e-ISSN: 2278-067X, p-ISSN: 2278-800X, www.ijerd.com Volume 4, Issue 2 (October 2012), PP. 24-34 Salient Architectural features of Selected Colonial Built Heritage in Visakhapatnam, Andhra Pradesh, India Viswanadha Kumar G.1, Vazeer M.2, Kishore D.V.3 1Department of Architecture, Andhra University College of Engineering, Visakhapatnam, India 2Department of Civil Engineering, Andhra University College of Engineering, Visakhapatnam, India 3School of Planning and Architecture, Jawaharlal Nehru Architecture and Fine Arts University, Hyderabad, India Abstract:- Colonization of Visakhapatnam by the British during 1801-1947AD had left impeccable signs of urban planning and local architecture that are excellent cum exemplary visual evidences of the glorious past. The British employed local techniques coupled with their native practices to build several structures that stand now as proud heritage. Salient architectural characteristics of fifteen randomly selected Colonial built heritage were brought out in this communication. These Colonial buildings were recognized to fall into three broad architectural categories, namely, British Colonial style of 1801-1850, Indo-Saracenic style of 1875-1917 and British Colonial style of 1890-1947. Keywords:- Architecture, Built heritage, Colonial, Visakhapatnam, India I. INTRODUCTION Andhra Pradesh is the 4th largest (275,069 Km²) state in India and possesses half a dozen gateways of international trade with Visakhapatnam (17°41′18.16″N 83°13′07.53″E) as one among them. This port city included under Visakhapatnam Metropolitan Region is situated midway between Kolkata and Chennai on the east coast of India along Bay of Bengal. The city was under Madras Presidency during the British Colonial period that spanned from 1801 to 1947 AD. -

GENERAL POPULATION TABLES ANDHRA PRADESH (Tables A-1 to A-4)

CENSUS OF INDIA 2001 GENERAL POPULATION TABLES ANDHRA PRADESH (Tables A-1 to A-4) {.~ ~ ~~ ~8 a" ~ PEOPLE OR IENTED OFFICE OF THE DIRECTOR OF CENSUS OPERATIONS, ANDHRA PRADESH Data Product Number 28-026-2001-Cen Book (E) (ii) Contents Pages 1. PREFACE v 2. ACKNOWLEDGEMENTS vi 3. FIGURES AT A GLANCE vii-viii 4. MAP RELATING TO ADMINISTRATIVE DIVISIONS ix 5. SECTION I : General Note 3-11 Census Concepts and Definitions 11-16 6. SECTION II: TABLE A-I: NUMBER OF VILLAGES, TOWNS, HOUSEHOLDS, POPULATION AND AREA 1. Fly Leaf 20-25 Statements 26-36 2. Diagram regarding Area and percentage to total Area 37 3. Map relating to Rural and Urban Population by Sex 2001 38 • 4. Map relating to Sex Ratio - 2001 39 5. Diagram regarding Area, India and States 2001 40 6. Diagram regarding Population - India and States - 200 1 41 7. Diagram regarding Population - Andhra Pradesh and Districts 200 1 42 8. Map relating to Density of PopUlation, 2001 43 9. Table A-I 45-142 Annexure - I 142-143 Annexure - II 144--146 10. Appendix and Annexure 147-150 7. TABLE A-2 : DECADAL VARIATION IN POPULATION SINCE 1901 1. Fly Leaf 153 Statements 153-158 2. Diagrams relating to Growth of Population 1901-2001 India and Andhra Pradesh 159-160 3. Table A-2 161-166 4. Appendix 167 (iii) Pages 8. TABLE A-3 : VILLAGES BY POPULATION SIZE CLASS 1. Fly Leaf 171 Statements 171-173 2. Table A-3 174-275 3. Appendix 276-302 9. TABLE A-4 : TOWNS AND URBAN AGGLOMERATIONS CLASSIFIED BY POPULATION SIZE CLASS IN 2001 WITH VARIATION SINCE 1901 1. -

EXECUTIVE COUNCIL MEMBERS Acharya Nagarjuna University

EXECUTIVE COUNCIL MEMBERS Acharya Nagarjuna University Prof. A. Rajendra Prasad Vice-Chancellor Acharya Nagarjuna University Prof. K.R.S. Sambasiva Rao Dr. Shaheda Akthar Rector Dept. of Computer Science, Acharya Nagarjuna University Govt. Degree College for Women, Guntur Sri Aditya Nath Das, I.A.S., Special Chief Secretary to Govt Sri T.S.S. Sing Education (HE) Department Principal A.P. Secretariat, Velagapudi ABM Degree College, Amaravathi Ongole Sri G.S. Panda Das I.A.S., Special Commissioner of Technical Sri P.V. Krishna Reddy Education & Collegiate Education, MD & Director, Megha Engineering Govt. of Andhra Pradesh & Infrastructure Ltd. ANR Towers, Jammichettu Street Hyderabad Prasadampadu, Vijayawada Sri Muddada Ravichandra, I.A.S., Sri GVSL Kantha Rao Special Chief Secretary to Govern- Managing Director ment (FAC) Virat Crane Industries Finance Department Guntur A.P. Secretariat, Hyderabad Velagapudi Prof. M. Koteswara Rao Dr. K. Basava Punnaiah Dean CDC, Dept. of Economics, Chairman, Acharya Nagarjuna University Nagarjuna Educational Society, Srinivasanagar Colony, Guntur Prof. Kodela Venkat Rao Dr. P. Hymavathi University Librarian Bharati Nursing Home, Acharya Nagarjuna University Sundaraiah Bavan Road, Near New Bus stand, Ongole CONTENTS Message from the Vice-Chancellor, Rector & Registrar, II Message from the OSD, OSD-II & Principal III Driving Force IV Our University Emblem 01 About the University & College 01 Infrastructure 02 Pharmacy Faculty 03-04 B Pharmacy Students Profile - 2017 05-08 B Pharmacy Students Profile - 2018 -

Full Length Research Article DEVELOPMENT RESEARCH

Available online at http://www.journalijdr.com International Journal of DEVELOPMENT RESEARCH ISSN: 2230-9926 International Journal of Development Research Vol. 06, Issue, 08, pp.9235-9240, August, 2016 Full Length Research Article SOCIO ECONOMIC CULTURE AND QUALITY LIFE OF TRIBAL PEOPLE IN ITDA PADERU AREA OF VISAKHAPATNAM DISTRICT *Dr. Radhika, B. School of Distance Education, Andhra University, Visakhapatnam-530 003 ARTICLE INFO ABSTRACT Article History: India has 461 tribal groups with a population of 677.68 (8.08%) lakhs, account for about Received 25th May, 2016 onefourth of the world tribal population (1991 census). The state Andhra Pradesh consists of 33 Received in revised form tribal groups with a population of 4.2 (6.31%) million. A large chunk of tribal population in the 19th June, 2016 state is mainly concentrated in the nine scheduled districts like Srikakulam, Vizianagaram, Accepted 16th July, 2016 Visakhapatnam, West Godavari, East Godavari, Warangal, Khammam, Adilabad and Kurnool. st Published online 31 August, 2016 The district Visakhapatnam has a tribal population of 3,54,127, which forms 13.4%, out of the total population. The major tribal groups found in the district are Bagata, Kotiya, Kondadora, Key Words: Nookadora, Konda Kammara, Konda Kapu, Gadaba, Mali, Porja, Mannedora, Khond and Valmiki. Among these tribes, Khond, Porja and Gadaba are considered to be the most primitive Indebtedness, tribes. Majority of the tribal population in the district stand below the poverty line and facing the Illiteracy, problems like indebtedness, illiteracy, malnutrition and exploitation. The interior tribal’s still live Malnutrition and Exploitation. relatively in isolation. Objective: The main objective of this paper is aimed to discuss the socio economic culture and quality life of tribal people in ITDA paderu area of visakhapatnam district, their socio-economic and cultural background. -

Irrigation Profile Visakhapatnam

10/31/2018 District Irrigation Profiles IRRIGATION PROFILE OF VISAKHAPATNAM DISTRICT *Click here for Ayacut Map INTRODUCTION The District has a population of 42.88 lakhs (census 2011). The plains division is watered and drained by Sarada, Varaha and Thandava Rivers and rivulets Meghadrigedda and Gambheeramgedda. Irrigation Circle, Visakhapatnam, is in charge of maintenance of Minor and Medium irrigation sources under Sarada, Varaha, Sarpa, Thandava and Gosthani Rivers in 31 Mandals expect agency area in Visakhapatnam District. The boundaries of this district are Bay of Bengal in the East, East Godavari district in the South, Orissa State in the West and North directions. The population of district is 42.88 Lakhs as per the 2011 Census. Rivers: Sharada, Varaha, Thandava, Machkand, Champavathi and Gostnani. Geographic coordinates of district- Latitude -18° 7' N Longitude - 83° 25' N and Altitude-73m Major Places: Visakhapatnam, Anakapalli, Bheemunipatnam and Narsipatnam. Forest occupies 42% of the district area. Forest yields quality Timber and Bamboo useful in Paper Industry. State Forest Department planted Cashew nut trees and Eucalyptus trees throughout the district. Coffee Estates are picking up their produce each year of progress. Titanium's ores, Magnalyte and Bauxite ores, quality Clays, Mica, and Graphite are the minerals found in this soil. Visakhapatnam is also oftenly called as the Metropolitan City of Andhra Pradesh has developed a lot since last decade. Major Industries are setup in the district especially in the Head quarters because of the Seaport. India's First Shipping Yard - Hindustan Shipyard, Visakhapatnam Steel Plant, producing quality steel are the major industries found. Visakhapatnam Port - which is called as the Natural Harbor because of the Natural formation of the mountain peaks of the shape of Dolphin Nose emerging from the sea, making this Port an unique one. -

Visakhapatnam

2019 DISTRICT DEVELOPMENT PLAN - VISAKHAPATNAM The city of Destiny Final Report January 2019 Submitted to: Office of Economic Advisor Department of Industrial Policy and Promotion Ministry of Commerce and Industries Government of India INDIAN INSTITUTE OF MANAGEMENT LUCKNOW Phone: 0522-6696001 Table of Contents Executive Summary iii Chapter 1 2 Overview 2 1.1 Introduction 2 1.2 Objectives 2 1.3 Scope of the study 3 Chapter 2 7 Baseline Profile of Visakhapatnam District 7 2.1 Introduction 7 2.2 Location and Geography 7 2.3 Climatic conditions 10 2.4 Demographic Details 10 2.5 Working Population 10 2.6 Administrative Profile 12 2.7 Economic Profile of the District 12 Chapter 3 15 Sectoral Analysis of Visakhapatnam District 15 3.1 Primary Sector: 15 3.2 Secondary Sector 20 3.3 Tertiary Sector 21 3.4 Overall analysis of all sector using BCG Matrix 22 3.5 Short listing of Key Sectors for GDP Growth 27 Chapter 4 29 Detailed Analysis of Selected Sectors 29 Chapter 5 50 Recommendations 50 1. List of Tables 64 2. List of Figures 65 3. List of Abbreviations 66 Bibliography 67 Appendix 69 i | P a g e ii | P a g e Executive Summary Visakhapatnam is one of the fastest growing districts and fourth cleanest city in the country. Population density is 384 persons per square km and population growth was 11.89% during 2001 and 2011. GDVA was growing at an impressive rate of 10.62 during last three years. Visakhapatnam is popularly known as “The jewel of the east coast” and has a coastal line of 132 kms. -

Environmental Assessment Report

ENVIRONMENTAL ASSESSMENT REPORT CONSULTANCY SERVICES FOR PREPARATION OF MASTER PLAN, DETAILED DESIGN AND SUPERVISION OF WORKS FOR THE RESTORATION AND REDEVELOPMENT OF 380 ACRE KAILASAGIRI HILL TOP PARK AT VISAKHAPATNAM CONSULTANCY SERVICES FOR PREPARATION OF MASTER PLAN, DETAILED DESIGN AND SUPERVISION OF WORKS FOR THE RESTORATION AND REDEVELOPMENT OF 380 ACRE KAILASAGIRI HILL TOP PARK AT VISAKHAPATNAM IDENTIFICATION TABLE Client/Project owner VISAKHAPATNAM URBAN DEVELOPMENT AUTHORITY, ANDHRA PRADESH CONSULTANCY SERVICES FOR PREPARATION OF MASTER PLAN, DETAILED DESIGN AND SUPERVISION OF WORKS FOR THE RESTORATION Project AND REDEVELOPMENT OF 380 ACRE KAILASAGIRI HILL TOP PARK AT VISAKHAPATNAM Type of document ENVIRONMENTAL ASSESSMENT REPORT Confidentiality YES Language ENGLISH Number of pages 77 DISCLAIMER All rights reserved. The report and maps have been prepared as part of the, Consultancy Services For Preparation Of Master Plan, Detailed Design And Supervision Of Works For The Restoration And Redevelopment Of 380 Acre Kailasagiri Hill Top Park At Visakhapatnam, Andhra Pradesh No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior written permission of Visakhapatnam Urban Development Authority, Andhra Pradesh. The designations employed and the presentation of the material in the report, maps or any part of the document prepared for the Consultancy Services For Preparation Of Master Plan, Detailed Design And Supervision Of Works For The Restoration And Redevelopment Of 380 Acre Kailasagiri Hill Top Park At Visakhapatnam, do not imply the expression of any opinion whatsoever on part of Vishakhapatnam Urban Development Authority, Andhra Pradesh. -

Heritage Sites in Visakhapatnam City: Typologies, Architectural Styles and Status

European Scientific Journal October 2013 edition vol.9, No.30 ISSN: 1857 – 7881 (Print) e - ISSN 1857- 7431 HERITAGE SITES IN VISAKHAPATNAM CITY: TYPOLOGIES, ARCHITECTURAL STYLES AND STATUS Viswanadha Kumar Giduthuri, M. Arch. Associate Professor, Department of Architecture, Andhra University College of Engineering (A), Visakhapatnam, India Abstract Heritage on mother earth was recognized as one of the important fields of human endeavor. Many nations around the world have been pursuing the subject for the benefit of present and future generations. In the process, several first order cities around the world have geared up to meet the requirement. However, second order cities in many nations, especially in developing countries like India did not yet raise to the occasion. Therefore, a comprehensive study on heritage and its preservation was taken up in Visakhapatnam, India and the present communication dealing with heritage sites in Visakhapatnam Metropolitan Region forms a part of it. During this attempt, a total of 44 cultural heritage sites were identified from the city and their architectural styles, typologies and status analyzed. Keywords: Heritage sites, Historic affiliation, Heritage typologies, Architectural styles Introduction Heritage, both of tangible and intangible nature on mother earth was recognised as one of the important fields of human endeavor for over eight decades now (Larkham, 2010). World over, it is customary to distinguish archaeological possessions from heritage subjects based on age as the fundamental criterion. The thumb rule for delineating the two groups varies from country to country and in India, the criterion is set at 100 years. That means all assets having equal or more than 100 years of existence in India fall into archaeological arena and the ones less than 100 years into heritage spectrum (Anonymous, 2011). -

Ground Water Brochure Visakhapatnam District, Andhra Pradesh

For Official Use Only CENTRAL GROUND WATER BOARD MINISTRY OF WATER RESOURCES GOVERNMENT OF INDIA GROUND WATER BROCHURE VISAKHAPATNAM DISTRICT, ANDHRA PRADESH SOUTHERN REGION HYDERABAD September 2013 CENTRAL GROUND WATER BOARD MINISTRY OF WATER RESOURCES GOVERNMENT OF INDIA GROUND WATER BROCHURE VISAKHAPATNAM DISTRICT, ANDHRA PRADESH (AAP-2012-13) BY G. BHASKARA RAO SCIENTIST-D SOUTHERN REGION BHUJAL BHAWAN, GSI Post, Bandlaguda NH.IV, FARIDABAD - Hyderabad-500068 121001 Andhra Pradesh HARYANA, INDIA Tel: 040-24225201 Tel: 0129-2418518 Gram: Antarjal Gram: Bhumijal GROUND WATER BROCHURE VISAKHAPATNAM DISTRICT, ANDHRA PRADESH CONTENTS Sl. No. CHAPTER District at a Glance 1 Introduction 2 Rainfall & Climate 3 Geomorphology & Soil Types 4 Ground Water Scenario 5 Ground Water Management Strategy 6 Ground Water Related Issues and Problems 7 Awareness and Training Activity 8 Areas Notified by CGWA/ SGWA 9 Recommendations Acknowledgements TABLES I Mandal Wise Ground Water Resources of Visakhapatnam District (As on March 2009) II General range of Important Chemical Constituents FIGURES 1 Administrative Divisions 2 Hydrogeology 3 Depth To Water Level - Pre Monsoon (May, 2012) 4 Depth To Water Level - Post Monsoon (November, 2012) 5 Ground Water Yield Potential VISAKHAPATNAM DISTRICT AT A GLANCE 1. GENERAL INFORMATION Geographical Areas : 11,342.84 sq. km Administrative Divisions District HQ : Visakhapatnam Mandals : 43 Towns : 10 Villages : 3,108 Population : 42,88,113 (2011 census) Average Annual Rainfall : 1,116 mm Annual rainfall (2012) : 1,218 mm 2. GEOMORPHOLOGY Major Physiographic Units : Structural hills, pediplains, alluvial plains and coastal plains Major Drainage : Machkund, Tandava, Varaha, Sarada & Gosthani 3. LAND USE (ha.) Forest Area : 4,41,166 Net Area Sown : 3,00,371 Cultivable waste : 10,366 4.