GM40 General Purpose Multi-Voltage Commercial Time Switch

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Multi-Voltage General Purpose Time Switch

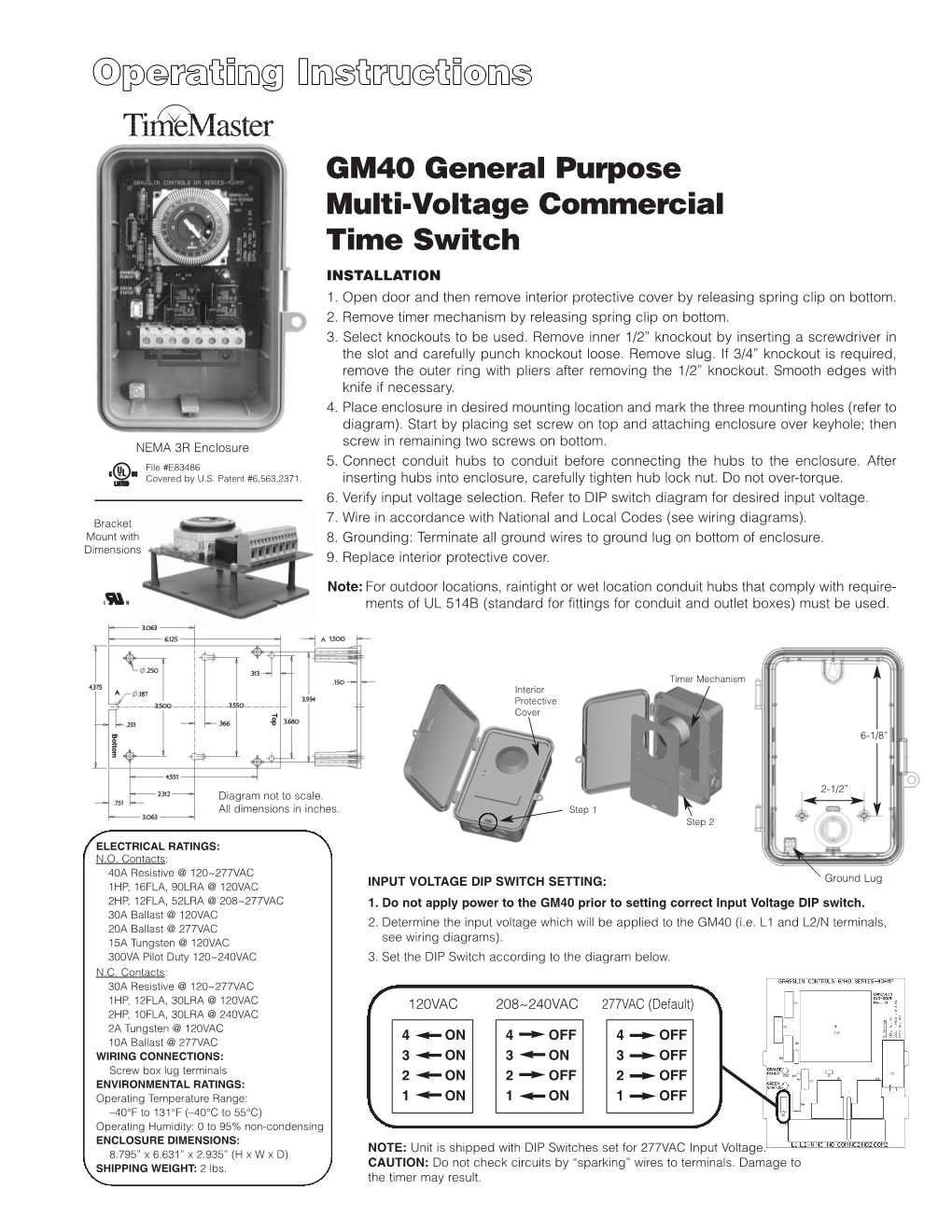

The First and Only... Multi-Voltage General Purpose Time Switch NOW GM40 40 AMPS! Standard Features… All in One Model! • 40 Amp Rating • Multi-Voltage: 120, 208/240, or 277 VAC • SPDT and DPDT ALL-IN-ONE! • NEMA 3R Outdoor Enclosure is Standard • No Tools Required • Power and Status LED Indicators • Real-Time Clock Face • Ground Lug and more…… One Timer is All You Need! GM40 The only electromechanical general purpose time switch with multi-voltage selection, 40 AMP rating, SPDT and DPDT contacts, and an indoor/outdoor NEMA 3R enclosure. All Standard in One Model for One Low Price. NEW Amber and Green Captive Trippers LED Lights Indicate Can’t Be Lost Power and Status NEW Easy Multi-Voltage Field Adjustable DIP Switch for Independently Adjust- 120, 208/240, able Trippers at 15 or 277 VAC Minute Intervals (2 hrs. for 7-day model) Real-Time Clock Face with ON/OFF/AUTO Override Switch NEW NEW New Compact NO TOOLS REQUIRED! VALOX® NEMA 3R Our “GUTS” simply snap Outdoor Enclosure into existing Grasslin or is Standard Intermatic enclosures NEW NEW Large Screw 40 Amp Terminals for Easy Wiring Rated Contacts #8 AWG NEW NEW Moisture Resistant Ground Lug Termination Conformal Coated Board File #E83486 Covered by U.S. Patent #6,563,237 GM40 – 120, 208/240 or 277 Volts – The only one to stock. SPECIFIERS GUIDE ELECTRICAL RATINGS: N.O. Contacts: Furnish and install a GM40 _ Multi-Volt Series 24 hour or (7 day) time switch with 40A Resistive @ 120~277VAC captive trippers and quartz or synchronous drive. -

Photocontrols & Timers

PMC-CAt-609 PHOTOCONTROLS & TIMERS TO SAVE ENERGY FOR OVER 50 YEARS. PMC-CAT-09-12 Locking Type Photocontrol 12V to 480V Button-Type In Fixture Direct Wire In Photocontrol Photocontrol Pole Mounted Digital Locking Type Push Button Auxillary Power Tap In Wall Timer 6-in-1 Schedules End Sensing Energy Saving Photocontrol /Timer On At Dusk, Off At Your Pre-Set Time Low Voltage Adjustable Photocontrols "Barrel" Type 12 & 24 VAC Photocontrol 24 VDC Easy On/Off Field Setting On Base. Lighting General Purpose Contactor 24 Hour 30 & 60 AMP Time Switch 40 AMP CUSTOMER PHONE SERVICE ALWAYS AVAILABLE 9AM TO 5PM WEEKDAYS EST 201-444-0600 Direct Wire-In Photocontrols (120 - 480 Volts) Heavy-duty Die-cast Enclosure Vandal Proof Lumatrol® “T” Series Lumatrol® “T-30” Wire-In Photo Control - 3000 Watts Cast Aluminum Housing photocontrols - Designed for Designed for those applications which demand more those locations where high vandalism creates high load switching than standard 15 amp. series can maintenance. The heavy-duty cast aluminum housing handle. is 20 times more resistant to high-impact objects (i.e. rocks, bats or small projectiles) than plastic housing. Specifications As the controlling element of the total lighting pack- Housing: Lexan enclosure. age (fixture, lamp ballast) and the least costly compo- Photocell: Broad surface sensing element. nent, it is most important that the control continue to Turn-on: 1 to 3 foot-candles. External light level slide allows function under all adverse conditions. field adjustment between 3 to 10 foot-candles. Specifications Turn-on/ 1:3 Turn-off Ratio: Housing: Vandal proof die cast aluminum housing. -

Ecm Operation Manual

ECM OPERATION MANUAL FOR USE WITH MODELS: OL11-105FDBE OL16-125FDBE OL11-105RDBE OL16-125RDBE : IF YOU DO NOT FOLLOW THE SAFETY PRECAUTIONS BELOW AND IN THIS MANUAL, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER. (REFERRED TO IN THESE INSTRUCTIONS AS A QUALIFIED HEATING CONTRACTOR). PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION, INITIAL FIRING, AND BEFORE PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS MUST BE LEFT WITH THE HOMEOWNER AND SHOULD BE RETAINED FOR FUTURE REFERENCE BY QUALIFIED SERVICE PERSONNEL. THERMO PRODUCTS, LLC. BOX 237 DENTON, NC 27239 PHONE: 800-476-4328 MADE IN USA MO-507 ECN 5577-MA 190924 All installations and services must be performed by qualified service personnel. INDEX SECTION BEGINNING PAG I. BLOWER CONTROL INFORMATION 1 A. TERMINAL DEFINITIONS & FIELD WIRING 1 B. WIRING & SWITCHES 2 C. INPUTS 4 D. OUTPUTS 4 E. OPERATING MODES 5 F. CFM TABLES 7 G. ECM SPECIFIC REPLACEMENT PARTS 8 III. ECM TROUBLESHOOTING 8 A. DIAGNOSTIC FEATURES 8 B. GENERAL GUIDELINES TO TROUBLESHOOTING GE ECM 9 C. TROUBLESHOOTING CHARTS 12 i i All installations and services must be performed by qualified service personnel. I. BLOWER CONTROLLER INFORMATION A. TERMINAL DEFINITIONS & FIELD WIRING Burner Harness Connector P1 Pin 1 – Limit switch connection. Pin 2 – 120 VAC Line connection. Pin 3 – Burner pilot contact. Pin 4&5 – 120 VAC Neutral connection. -

Exterior Lighting Control Guidance

Table of Contents 1 Welcome ............................................................................................................ 1 2 Why Control Lighting? ........................................................................................ 2 3 Control Strategies ............................................................................................... 3 4 Strategy Decisions ............................................................................................. 4 5 Strategies by Application .................................................................................... 5 6 Controls and Light Sources ................................................................................ 7 7 Energy Code Compliance................................................................................... 9 8 Lighting Control Devices..................................................................................... 12 9 Control Wiring..................................................................................................... 14 10 Control Zoning .................................................................................................... 16 11 Commissioning ................................................................................................... 18 12 Light Reduction Control using Occupancy Sensors ........................................... 21 CLTC Research .................................................................................................. 22 U.S. Department of Energy Research ............................................................... -

EN Universal Timer Module

MO144 Operators Guide EN Universal Timer Module MO144 | Operators Guide | Notices EN | 2 Copyright Notice Notice of Liability Unless otherwise indicated, this publication is the While every precaution has been taken in the copyright of Bosch Security Systems, Inc. (“Bosch”). preparation of this document, neither Bosch Security All rights are reserved. Systems, Inc. nor any of its official representatives You may download a single copy of this publication. shall have any liability to any person or entity with By downloading the publication you agree that you respect to any liability, loss or damage caused or will: (i) only use the publication for your own alleged to be caused directly or indirectly by the reference; (ii) not commercially exploit or charge any information contained in this book. person for the use of the publication; and (iii) not Bosch Security Systems, Inc. reserves the right to modify the publication in any way without the prior make changes to features and specifications at any written permission of Bosch. time without prior notification in the interest of Except as specified above or where authorised by the ongoing product development and improvement. Copyright Act 1968 (Cth), no part of this publication may be reproduced, transmitted, modified or stored, in any form or by any means, without the prior written permission of Bosch. Bosch Security Systems, Inc. | 3/08 | F01U000819-02 MO144 | Operators Guide | 1. Introduction EN | 3 1. Introduction Table 2: Operating Mode Switch Settings The programmable MO144 Universal Timer Module is designed to be one of the most adaptable timing units available. The universal timer module has eight Mode Mode Type 1 2 3 unique modes of operation and a flexible relay 1 One Shot Off Off Off output making the unit suitable for security 2 One Shot – Retriggerable On Off Off applications as well as for any other situation where 3 Strobe Reset Off On Off accurate time delays are required. -

Preview Product

Your Source for Automation & Control Components TM Certified System ISO 9001 QMI-SAI Global MAINS OR BACKUP LOW BATTERY OR BATTERY AUX REPLACEMENT MIN MAX OUT BATTERY DIAGNOSIS CHARGING LEVEL All in one PRODUCT PREVIEW NEW Products Push-in Technology Terminal Blocks Highlight & Features • No tool required for easy connection • Direct connection of solid wires and flexible wires with ferrules • Thinnest 3.5 mm wide terminal block in the industry • Can be opened quickly and easily and closed safely • Sizes up to 15.7 x 19.7 x 8.9 in Hinged Door • Good operability of components Enclosure • No restrictions for the assembly of internal fittings TECTI RO ON P IP67 KU363N DC Motor Disconnects Switches • KU363N DIN Rail Mountable Multi Function - 60A/48V DC (3 Pole in series) Wire Prep & • PV 132 RT Ferrule Crimper - 32A/48 V DC (1 Pole) • Automatically Loads Ferrule - Door mounting kit available • Crimps Ferrules from - Switching mechanism speed 20 AWG to 14AWG PV 132 RT is independent from the operator • Built in Lead Wire Stripper / Cutter 2 908.806.9400 - www.altechcorp.com Sensor & Actuator Cables & Connectors M8 & M12 • Molded Female Cable Assemblies • Field Wired Connectors • Panel Feed- Through Connectors Position switches Safety Rope Pull IN73 and MN78 Switch SRO • Especially suitable for switching low currents • Choose from metal or thermoplastic • Sophisticated combination of metal and/or enclosures and actuators plastic components • Emergency stop button available • Modular design with numerous actuators to upon request choose from • Max. rope length of 30 m Altech UL 489 with Dual Terminals A B C A Box terminal for solid conductors or flexible conductors with or without cable lug. -

Installation & Operation

Operating and Instruction Manual Manual No. MS717660 August 2003 MODEL S-5000 STATIONARY COMPOSITE VACUUM SAMPLER Manning Environmental, Inc. 1968 S. Austin Ave. Suite 101 Georgetown, Texas 78626 USA Office: (512) 863-9337 Fax: (512) 863-4472 E-Mail: [email protected] OPERATION AND MAINTENANCE of MANNING ENVIRONMENTAL, INC. MODEL S-5000 STATIONARY COMPOSITE STAMPLER Manual Part Number 717660 August 2003 Manning Environmental, Inc. 1968 South Austin Avenue Suite 101 Georgetown, Texas 78626-7808 Telephone: 512-863-9337 Fax: 512-863-4472 Copyright 2003, by Manning Environmental, Inc. All rights reserved. This work is protected by Copyright and other laws. Copying any aspect of this work is strictly prohibited. Warning! Dangerous electrical voltages are present in this equipment. Turn equipment off and disconnect power prior to servicing. Only qualified personnel should make electrical connections to the equipment Caution The pinch solenoid assemblies located underneath the measuring chambers close with great force. Do not place your fingers, tools or other items in their path while power is turned on. Caution Some fluids that are sampled may pose a health risk. Observe proper protective procedures when handling sample containers or any other parts of the equipment that has come in contact with the fluid. Caution The electronics enclosure and refrigerator are heavy. Observe caution when moving the equipment. i Manning Environmental Limited Factory Warranty Manning Environmental, Inc., warrants this product to the original purchaser against any defects that are due to faulty workmanship or material for a period of one year (365 days) from the date of shipment. During the warranty period Manning Environmental, Inc. -

Time Switches – 24 Hour Dial 24 Hr. W/Skipper, Optional Carryover

Time Switches – 24 Hour Dial T100 Series – Designed for industrial, commercial and residential applications. Highest HP ratings in the industry for loads up to 40 amps, providing direct 24 hr. control of most loads. Provides 1 to 12 “ON/OFF” operations each day with minimum ON/OFF times of 1 hour. All models equipped with one “ON” and one “OFF” tripper. Applications • Indoor/Outdoor Lighting • Post Lanterns • Signs • Pool Heaters • Filters • Hydrochlorinators • Air Conditioning • Blowers • Electric Fences • Pumps • Heating/Ventilating Systems • Music and Signal Systems • Fans • Poultry Foggers • Conveyers Specifications Case – Drawn steel 7-3/4" (19.7 cm) H, 5" (12.7 cm) W, 3" (7.6 cm) D in gray finish. Spring hasp, with hole for lock, holds permanently attached, side hinged door closed. Three mounting holes on back plus handy box mounting holes. Knockouts – Combination 1/2"–3/4" nominal knockouts, one on back and each side of case and two on bottom. Optional Enclosures – See Time Switch Cases page for optional enclosures. Special Voltages and Cycles – See Time Switch Motors page for available motors. Switch Rating – Each Pole; 40 Amp Resistive, 120-480 VAC; 40 Amp Tungsten, inductive or 1000 VA pilot duty, 120-277 VAC; 2 HP (24 FLA) 120 VAC; 5 HP (28 FLA) 240 VAC single phase; 7-1/2 HP (28 FLA) 208 VAC three phase; 10 HP (28 FLA) 240 VAC three phase. Model # Model # Clock Motor AMPS Model # w/See-Thru Cover Plastic Case Switch Volts 60 Hz (per pole) HP Rating T101 T101PCD82 T101P SPST 125 40 2 T102 –– T102P SPST 208-277 40 5 T103 T103PCD82 T103P DPST 125 40 2 T104 T104PCD82 T104P DPST 208-277 40 5 T101B* –– –– SPST 125 40 2 T105 –– –– 1NO / 1NC** 125 40 2 T106R† –– –– 1NO / 1NC** 208-277 40 5 * Separate clock motor terminals for switching circuits not on line voltage ** Can be wired as SPDT † Only available in NEMA 3R case For additional trippers (1 ON / 1 OFF per pack), order No. -

Time Switches (Digital/Analogue), Sun Relays & Accessories

Time Switches (digital/analogue), Sun Relays & Accessories Product Information July 2012 © 2012 Eaton Corporation. All rights reserved. New Products Dense Overview EATON Art.# EATON type designation Description Sun relay with integrated time switch 167377 SRCD1CO and external light sensor (2 - 2000 lx) Analogue sun relay with external light sensor 167378 SRSD1COW (2 - 2000 lx) Analogue sun relay with external light sensor 167375 SRSD1NO (2 - 100 lx) Analogue sun relay with integrated light sensor 167376 SRSW1NO for wall mounting (2-2000 lx) 167384 TSADCF DCF Antenna 167385 TSAGPSKIT Set: GPS antenna & power supply 167387 TSAMEM Memory key for OBELISK Software 167386 TSAMEMKIT PC Set: Interface, Software & memory key Digital time switch with week program 167379 TSDW1CO 1 channel Astronomical time switch with week program 167381 TSDW1COA 1 channel Digital time switch with week program 167382 TSDW1CODG 1 channel (connectable with external antenna) Digital time switch with week program 167383 TSDW1COMIN 1 channel, 1 module slim Digital time switch with week program 167380 TSDW2CO 2 channels Analogue time switch day program 167390 TSQD1CO 1 channel, quartz operated Analogue time switch with day program 167388 TSQD1NO 1 channel, quartz operated Analogue time switch week program 167392 TSQW1CO 1 channel, quartz operated Analogue time switch day program 167391 TSSD1CO 1 channel, grid freq. synchronized Analogue time switch with day program 167389 TSSD1NO 1 channel, grid freq. synchronized © 2012 Eaton Corporation. All rights reserved. 2 Type Key Explanation Sun Relay • SR S D 1NO • SR S W 1NO • SR C D 1CO • SR S D 1CO W SR …. Sun Relay S/C … Stand alone/Clock controlled D/W … DIN rail mounted/wall mounted 1CO/1NO … 1 change over/1normally open W … wide lux area (2…5000 lux) © 2012 Eaton Corporation. -

Timers/Time Switches/Counters/Hour Meters T Imers/Time Switches/Counters/Hour Meters ’06–’07

’06–’07 Timers/Time Switches/Counters/Hour Meters T imers/Time Switches/Counters/Hour Meters ’06–’07 Switches/Counters/Hour imers/Time These materials are printed on ECF pulp. These materials are printed with earth-friendly vegetable-based (soybean oil) ink. Ltd. Matsushita Electric Works, Please contact .......... Matsushita Electric Works, Ltd. Automation Controls Business Unit Head Office: 1048, Kadoma, Kadoma-shi, Osaka 571-8686, Japan Telephone: +81-6-6908-1050 Facsimile: +81-6-6908-5781 http://www.nais-e.com/ Timers/Time Switches/Counters/Hour Meters All Rights Reserved © 2006 COPYRIGHT Matsushita Electric Works, Ltd. ARCT1B274E ’06.10 ARCT1B274E 200610-3YT Specifications are subject to change without notice. Printed in Japan. Matsushita Electric Works, Ltd. T ABLE OF CONTENTS Page Page TIMERS COUNTERS TIMERS CHART...........................................................2 COUNTERS SELECTOR CHART..............................93 TIMERS SELECTOR CHART.......................................3 TYPICAL COUNTER APPLICATIONS.......................94 ON-DELAY TIMER BASIC CIRCUIT............................7 COUNTER-RELATED TERMINOLOGY.....................95 TIMER-RELATED TERMINOLOGY .............................8 PRECAUTIONS IN USING THE COUNTER..............96 PRECAUTIONS IN USING THE TIMERS ..................10 LC2H Counters ...........................................................98 PM4S Timers ..............................................................13 LC2H Preset Counters..............................................106 PM4H-A/S/M -

Lighting Controls

LIGHTING CONTROLS HUMIDITY CONTROLS LIGHTING Kele Provides System and Zone Controls, with a Wide Variety of Peripheral Sensors and Switches. DLM Series | p. 615 AF16 Series | p. 664 LX-24 | p. 624 WSD Series | p. 637 CI-24 | p. 626 ET Series | p. 674 LIGHTING CONTROLS Products manufactured MODEL/SERIES PAGE in the United States Emergency Lighting Control ELCU-100 — WattStopper Emergency Lighting Control . 666 Products that are ELCU-200 — Emergency UL924 Bypass/ Shunt Relays . 668 new to the catalog ESR Series — Functional Devices UL924 Emergency Bypass / Shunt Relays . 670 Light Sensors MK7-B Series — PLC-Multipoint Celestial Self-Contained Ambient Light Sensors, Voltage Based . 643 PSR-1, PSR-1-T — Kele Photo-Sensitive Resistor . 645 K, LC Series — Photo Switches . 647 EM Series — Photo Switches . 649 MAS Series — PLC-Multipoint Self-Contained Ambient Light Sensors, Current Based . 650 Lighting Contactors and Relays HDR — Relay 5 Wire with Override and Connector . 660 RR-7, RR-9 — GE Lighting Relays . 661 2R7CDD, 2R9CDD — ILC Lighting Relays . 663 AF16 Series — ABB Lighting Contactors . 664 LIGHTING CONTROLS LS7K Series — AEG Lighting Contactors . 665 LMCP Series | p. 613 Lighting Panels and Control Products RP Basic Series — BlueRidge Relay Panels . 609 ZC Basic Series — BlueRidge Lighting Zone Controller . 611 LMCP Series — WattStopper Lighting Integrator Panels with Digital Lighting Management (DLM) Support . 613 DLM Series Digital Lighting Management — Digital Lighting Controls . 615 LC8 Series — WattStopper Modular Contractor Panel . .. 618 CX Series Commercial Lighting Control Panels — Standalone Programmable Lighting Control Panel . 620 ILC Apprentice II — Programmable Lighting Control Panel . 622 PIL-1 — Kele Pulse Initiator . 658 LDIM2 — Kele Fluorescent Dimming Control Module . -

Make Your House Smarter +

xComfort Make your house smarter + + + + + + + What is xComfort? Functions and solutions Who can use xComfort? xComfort is a wireless control system for all the The xComfort system can be used for anything electrical equipment in your home, which gives from updating existing installations or extending the house smarter functions, greater security and and improving them, all the way up to setting up increased comfort. completely new installations. You can start small, with simple and practical functions, and expand The advantages: the system later as the need or desire arises. Do • less power consumption you need to install an extra light switch in the hall, • flexible design tailored to your style or at both the top and bottom of the stairs? These are basic tasks that xComfort is used for • controls your lights and heating every day, with absolutely no mess or visible • increased security cables. Since installing xComfort usually involves • wireless control making changes to electrical systems, it does need • no unsightly cables to be installed by a qualified electrician. For advice • remote control via smartphone or web and assistance, consult your local Eaton sales engineer or local xComfort installer. 2 Control your house from the other side of the world Installing an xComfort system with a Smart Home forget to do it yourself. Simply having a master switch Controller will give you full remote access of anything by the entrance can let you switch off all the lights in the electrical within the home or controlled environment, house with a single press of a button, and upon return from anywhere in the world.