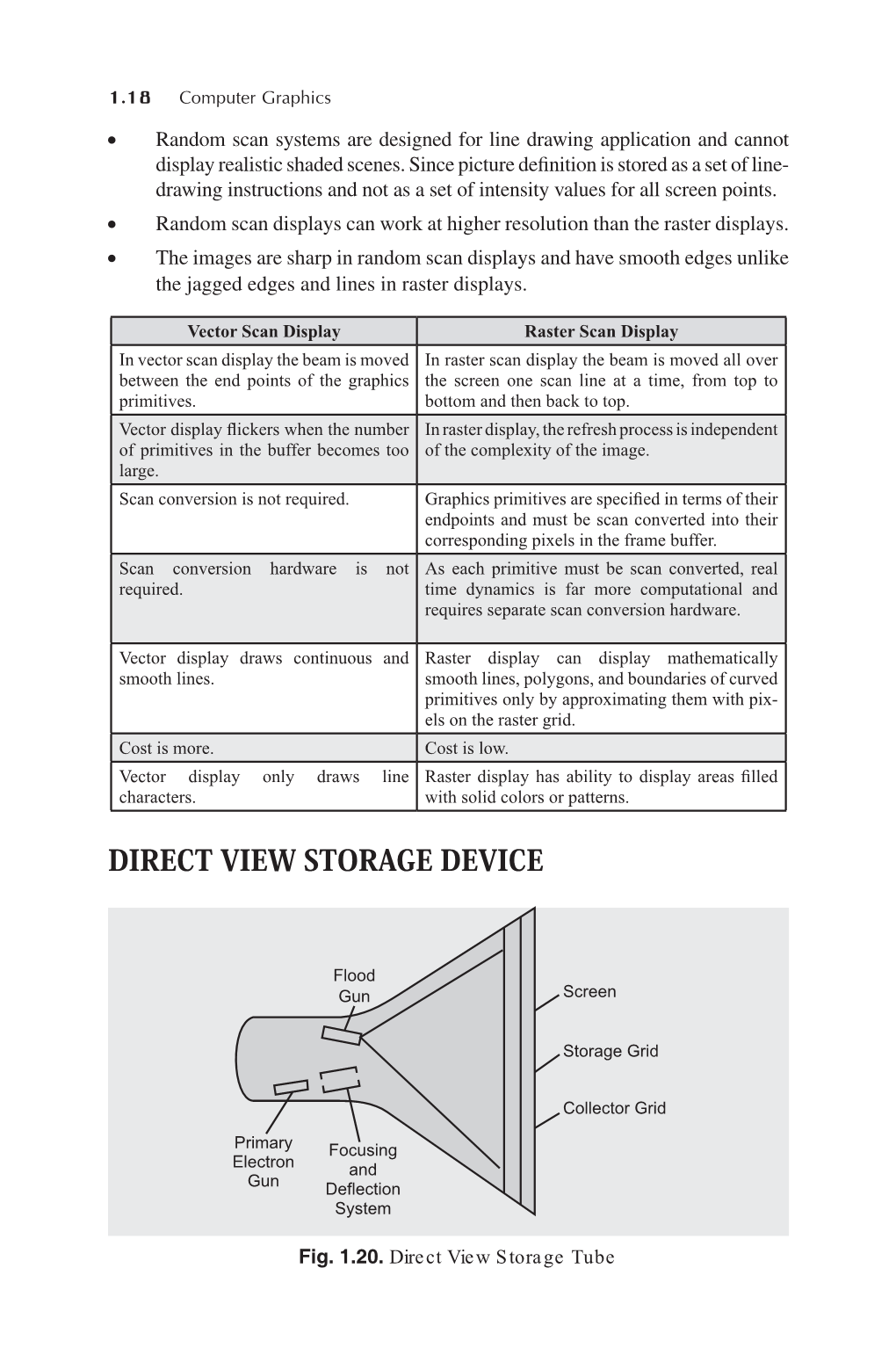

1.18 Computer Graphics Direct View Storage Device

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Off the Grid

IOP PUBLISHING NANOTECHNOLOGY Nanotechnology 24 (2013) 335703 (7pp) doi:10.1088/0957-4484/24/33/335703 Improved accuracy and speed in scanning probe microscopy by image reconstruction from non-gridded position sensor data Dominik Ziegler1, Travis R Meyer2, Rodrigo Farnham3, Christoph Brune4, Andrea L Bertozzi2 and Paul D Ashby1 1 Lawrence Berkeley National Laboratory, Molecular Foundry, 1 Cyclotron Road, 94720 Berkeley, CA, USA 2 Department of Mathematics, University of California Los Angeles, 520 Portola Plaza, Los Angeles, CA 90095-1555, USA 3 Department of Mathematics and Statistics, California State University, Long Beach, 1250 Bellflower Boulevard, Long Beach, CA, 90840-1001, USA 4 Department of Mathematics and Computer Science, University of Munster,¨ Einsteinstrasse 62, D-48149 Munster,¨ Germany E-mail: [email protected] Received 16 March 2013, in final form 3 July 2013 Published 26 July 2013 Online at stacks.iop.org/Nano/24/335703 Abstract Scanning probe microscopy (SPM) has facilitated many scientific discoveries utilizing its strengths of spatial resolution, non-destructive characterization and realistic in situ environments. However, accurate spatial data are required for quantitative applications but this is challenging for SPM especially when imaging at higher frame rates. We present a new operation mode for scanning probe microscopy that uses advanced image processing techniques to render accurate images based on position sensor data. This technique, which we call sensor inpainting, frees the scanner to no longer be at a specific location at a given time. This drastically reduces the engineering effort of position control and enables the use of scan waveforms that are better suited for the high inertia nanopositioners of SPM. -

Graphics Systems

Graphics Systems Dr. S.M. Malaek Assistant: M. Younesi Overview Display Hardware How are images displayed? Overview (Display Devices) Raster Scan Displays Random Scan Displays Color CRT Monirors Direct View Storage Tube Flat panel Displays Three Dimensional Viewing Devices Stereoscopic and Virtual Reality System Overview (Display Devices) The display systems are often referred to as Video Monitor or Video Display Unit (VDU). Display Hardware Video Display Devices The primary output device in a graphics system is a monitor. Video Monitor Cathode Ray Tube (CRT) 1. Electron Guns 2. Electron Beams 3. Focusing Coils 4. Deflection Coils 5. Anode Connection 6. Shadow Mask 7. Phosphor layer 8. Close-up of the phosphor coated inner side of the screen Cathode Ray Tube (CRT) Refresh CRT Light emitted by the Phosphor fades very rapidly. Refresh CRT: One way to keep the phosphor glowing is to redraw the picture repeatedly by quickly directing the electron beam back over the same points. Electron Gun Electron Gun Heat is supplied to the cathode by the filament. Electron Gun The free electrons are then accelerated toward the phosphor coating by a high positive voltage. High Positive Voltage A positively charged metal coating on the inside of the CRT envelope near the phosphor screen. A positively charged metal High Positive Voltage An accelerating anode . Electron Gun Intensity of the electron beam is controlled by setting voltage level on the control grid. Electron Gun A smaller negative voltage on the control grid simply decrease the number of electrons passing through. Focusing System Focusing System The focusing system is needed to force the electron beam to converge into a small spot as it strikes the phosphor. -

What Is Computer Graphics?

What is Computer Graphics? A set of tools to create, manipulate and interact with pictures. Data (synthetic or natural) is visualized through geometric shapes, colors, textures. Exploits the pattern recognition capabilities of the human visual sys- tem. Graphical User Interfaces (GUI) - means to interact with complex applications Scientific, Engineering, Business and Educational applications. ITCS 4120-5120 1 Introduction What can we do with Computer Graphics? A core technology and infrastructure for drawing programs. Pervasive across scientific, engineering, business and educational applications. ITCS 4120-5120 2 Introduction Applications: 2D/3D Plotting ITCS 4120-5120 3 Introduction Applications:Computer-aided Drafting and Design (CAD) ITCS 4120-5120 4 Introduction Applications:Scientific Data Visualization Bio-Medicine (CAT Scan, MRI, PET), Biology. Biology (molecular structure/models), Bioinformatics (Gene sequences, proteins). Weather Data Environmental Data - pollution data.. ITCS 4120-5120 5 Introduction Applications:Medical Visualization: Visible Human Project From CT From the Physical Data ITCS 4120-5120 6 Introduction Applications:Computer Interfaces ITCS 4120-5120 7 Introduction Applications:Computer/Video Games ITCS 4120-5120 8 Introduction Applications: Entertainment (movies, animation, advertising) ITCS 4120-5120 9 Introduction Virtual and Immersive Environments ITCS 4120-5120 10 Introduction Virtual and Immersive Environments ITCS 4120-5120 11 Introduction What Disciplines does CG draw on? Algorithms Mathematics -

Basics of Video

Basics of Video Yao Wang Polytechnic University, Brooklyn, NY11201 [email protected] Video Basics 1 Outline • Color perception and specification (review on your own) • Video capture and disppy(lay (review on your own ) • Analog raster video • Analog TV systems • Digital video Yao Wang, 2013 Video Basics 2 Analog Video • Video raster • Progressive vs. interlaced raster • Analog TV systems Yao Wang, 2013 Video Basics 3 Raster Scan • Real-world scene is a continuous 3-DsignalD signal (temporal, horizontal, vertical) • Analog video is stored in the raster format – Sampling in time: consecutive sets of frames • To render motion properly, >=30 frame/s is needed – Sampling in vertical direction: a frame is represented by a set of scan lines • Number of lines depends on maximum vertical frequency and viewingg, distance, 525 lines in the NTSC s ystem – Video-raster = 1-D signal consisting of scan lines from successive frames Yao Wang, 2013 Video Basics 4 Progressive and Interlaced Scans Progressive Frame Interlaced Frame Horizontal retrace Field 1 Field 2 Vertical retrace Interlaced scan is developed to provide a trade-off between temporal and vertical resolution, for a given, fixed data rate (number of line/sec). Yao Wang, 2013 Video Basics 5 Waveform and Spectrum of an Interlaced Raster Horizontal retrace Vertical retrace Vertical retrace for first field from first to second field from second to third field Blanking level Black level Ӈ Ӈ Th White level Tl T T ⌬t 2 ⌬ t (a) Խ⌿( f )Խ f 0 fl 2fl 3fl fmax (b) Yao Wang, 2013 Video Basics 6 Color -

Graphics Hardware Cathode Ray Tube (CRT) Color CRT

Graphics Hardware Cathode Ray Tube (CRT) 1 2 3 4 5 6 Monitor (CRT, LCD,…) Graphics accelerator Scan controller Video Memory (frame buffer) 1. Filament (generate heat) Display/Graphics Processor 2. Cathode (emit electrons) CPU/Memory/Disk … 3. Control grid (control intensity) 4. Focus 5. Deflector 6. Phosphor coating Color CRT LED 3 electron guns, 3 color phosphor dots at each pixel Color = (red, green, blue) Black = (0,0,0) White = (1,1,1) Red = 0 to 100% Red = (1,0,0) Green = 0 to 100% Green = (0,1,0) Blue = 0 to 100% Blue = (0,0,1) … 1 LCD Plasma Panels Raster Display graphics How to draw a picture? Digital Display Based on (analog) raster-scan TV technology The screen (and a picture) consists of discrete pixels, and each pixel has one or multiple phosphor dots We have only one electron gun but many pixels in a picture need to be lit simultaneously… 2 Refresh Random Scan Order Refresh – the electron gun needs to come back to Old way: No pixels - The electron gun hit the pixel again before it fades out draws straight lines from location to An appropriate fresh rate depends on the property of location on the screen (vector graphics) phosphor coating Phosphor persistence: the time it takes for the a.k.a. calligraphic display, emitted light to decay to 1/10 of the original intensity Random scan device, vector drawing display Typical refresh rate: 60 – 80 times per second (Hz) Use either display list or (What will happen if refreshing is too slow or too storage tube technology fast?) Raster Scan Order Raster Scan Order What we do now: the electron gun will The electron gun will scan through the scan through the pixels from left to pixels from left to right, top to bottom right, top to bottom (scanline by (scanline by scanline) scanline) Horizontal retrace 3 Raster Scan Order Progressive vs. -

Graphic Images

Graphic Images George Seurat - “pointilist” Un dimanche apres-midi a l’Ile de la Grande Jatte Tile mosaic Output from a computer version of Lite Brite (a toy for children) Needlepoint Vector vs. Raster Display Vector (1960’s, 70’s, 80’s) • vector, stroke, line drawing, … • single phosphor (monochrome) • display list • wireframe Raster (1980’s, 90’s, 00’s) • set of horizontal scan lines (raster) • 1 or 3 (colour) beams • refresh/frame buffer • aliasing • filled polygons • Advantages: – lower cost – filled primitives – refresh independent of complexity • Disadvantages: – scan conversion (more computationally demanding) – aliasing Architecture of a Raster Display • Display controller – receives and interprets sequences of output commands • Refresh buffer – stores the entire image in an array of pixel values (bitmap) • Video controller – entire image is scanned out sequentially by video controller (inexpensive, scan-out logic) Raster Display Scan Pattern ras.ter \’ras-t<e>r\ n (ca. 1934) : a scan pattern (as of the electron beam in a cathode-ray tube) in which an area is scanned from side to side in lines from top to bottom; : a pattern of closely spaced rows of dots that form the image on a cathode-ray tube (as of a television or computer display) From Websters • Number of lines (vertical): 320, 525, 640, 768, 1024 • Resolution along the line (horizontal): 420, … • Frames/second: 25, 30, 60 • Interlaced or not Pixel Based Graphics • Resolution: – number of distinguishable lines per inch that a device can create – Horizontal x Vertical 320x420 -

Graphics Hardware Display Technologies

Graphics Hardware Display Technologies Display (CRT, LCD,…) Front projection Graphics accelerator BkBack pro jtijection Scan controller Video Memory (frame buffer) Direct view Display/Graphics Processor Backlit CPU/Memory/Disk … Display Technologies Trade-offs CRT LED Cost, Weight, Size LCD Power consumption Plasma Panels Spatial & Color resolution DLP Peak brightness, Black, contrast OLED Etc. Etc. 1 Cathode Ray Tube (CRT) 1 2 3 4 5 6 1. Filament (generate heat) 2. Cathode (emit electrons) 3. Control grid (control intensity) 4. Focus 5. Deflector 6. Phosphor coating - Direct view Color CRT LED - backlight source 3 electron guns, 3 color phosphor dots at each pixel Color = (red, green, blue) Black = (0,0,0) White = (1,1,1) Red = 0 to 100% Red = (1,0,0) Green = 0 to 100% Green = (0,1,0) Blue = 0 to 100% Blue = (0,0,1) … 2 LCD: backlit Plasma Panels: emit light; soon extinct? DLP: http://www.dlp.com/includes/video_demo.aspx Trade-offs For digital projection Peak brightness Black level Digital Micromirror Device Contrast Rear projection Screen brightness FtFront pro jtijection Motion artifaces Direct view Aging Backlit Maximum resolution Thickness Weight Power consumption http://www.displaymate.com/ShootOut_Comparison.htm 3 Random Scan Order Vector graphics Display list Old way: No pixels - The electron gun Move (100,200) Draw(200,200) draws straight lines from location to Draw(200,100) location on the screen (vector graphics) Draw(100,100) a.k.a. calligraphic display, Random scan device, vector drawing display Use -

Hsync, Vsync Signals • Blanking Signal! • Horizontal and Vertical Counts (Hcount, Vcount)

Lecture 5 Video with the FPGA Lab 2 Part 1 due today/tomorrow*! Lab 2 Part 2 due this upcoming Tuesday! Pset 4 is out today due upcoming Tuesday! Lab 3 is Out! (on video) 9/19/19 6.111 Fall 2019 8 Displays are for Eyes • Human color perception comes from three types of cone cells in the center of the eye. Each type generally has an abundance of one photoreceptive protein (which causes electrical stimulation): • S cones with protein from OPN2 gene • M cones with protein from OPN1MW gene • L cones with protein from OPN1LW gene • A human eye therefore has three independent inputs regarding visual EM radiation • Called ”trichromatic” 9/18/19 6.111 Fall 2019 9 Color Space • Human trichromatic vision is comprised of three inputs, therefore the most general way to describe these inputs is in a 3-dimensional space • Because the L, M, and S cones “roughly” line up with Red, Green, and Blue, respectively a RGB space is often the most natural to us • There are others, though One form of RGB space (not the only way to display it) https://engineering.purdue.edu/~abe305/HTMLS/rgbspace.htm 9/18/19 6.111 Fall 2019 10 Worst Case Scenario • If a person has all color receptors working… • because of noise limitations in our naturally- evolved encoding scheme that communicates from the cone cells up to the brain… • we can perceive about 7-10 million unique colors depending on your research source… • How many bits do we need to encode all possible colors for this worst case? • log$ 10_000_000 = 23.25 bits • Round up to 24 9/18/19 6.111 Fall 2019 11 Image or Frame • An image/frame can be thought of as a 2-dimensional array of 3-tuples: • 2 spatial dimensions • 3 color dimensions • Each color tuple is a “pixel” 9/19/19 6.111 Fall 2019 12 Video (just draw a bunch of frames quickly) • Rely on the poor RC time constants of our eye’s to ”fake” motion. -

Video Products.Pdf

Overview ePVGA 510 Features The PVGA series of video test instruments • Composite RGB video generation • NTSC video/S-video generation from Advanced Testing Technologies, Inc. • Component video generation (YPbPr) provide a comprehensive solution set for • Raster video generation video generating and acquisition • Polar raster video generation requirements in a UUT test environment. • Mixed video (stroke over composite/raster) The first generation PVGA garnered • Stroke video generation multinational acceptance and is • Digital video (parallel digital/flat panel, DVI, SD-HDI (VESA and HD formats)) generation successfully supporting the B-1B, F-15, C-17, • Full EDID processing functionality Eurofighter, T-50, and other diverse military • Integrated software tool environment with powerful features including platforms. The experience derived with GUI-based ePVGA operation, automatic C-code or macro generation, these applications has been integrated into stand-alone test sequencer, expanded video imaging testing capabilities the next generation, the ePVGA. The with oscilloscope-like waveform viewing, and electronic template comparison ePVGA supports dual channel RGB • Supports RS170, RS343, RS330, STANAG 3350A, STANAG 3350C standards • Automatic run time alignment of all analog parameters with remote sense composite video generation, stroke video capabilities generation, mixed video generation, NTSC • Sophisticated control structure provides the ability to simulate dynamic video/S-video generation, component and interactive displays video (YPbPr) -

A Cab Coefgh U.S

||||||||||||||| USOO51 19082A United States Patent (19) 11 Patent Number: 5,119,082 Lumelsky et al. 45) Date of Patent: Jun. 2, 1992 54) COLOR TELEVISION WINDOW EXPANSION AND OVERSCAN OTHER PUBLICATIONS CORRECTION FOR HIGH-RESOLUTION "Digital Image Processing", by Gregory A. Baxes, pp. RASTER GRAPHICS DISPLAYS 160-161, 1984. Philips Co. SIGNETICS; Digital Video Signal Proces 75 Inventors: Leon Lunnelsky, Stanford, Conn.; sing-Part One. Sung Min Choi, White Plains; Alan Primary Examiner-Alvin E. Oberley W. Peevers, Peekskill, both of N.Y. Assistant Examiner-Amare Mengistu Attorney, Agent, or Firm-Roy R. Schlemmer; Jack M. (73) Assignee: International Business Machines Arnold Corporation, Arnonk, N.Y. 57) ABSTRACT A video pixel presentation rate expansion circuit is pro (21) Appl. No.: 415,012 vided for use with a high-resolution display system. The overall display system includes a high-resolution moni tor, a computer for providing control signals, including 22 Fied: Sep. 29, 1989 a high-resolution frame buffer for storing computer graphics and TV video images and reading out said (51) Int. Cl. ......................... G09G 1/06; H04N 9/74; video data at a rate controlled by said control signals H04N 7/0 and providing said data with a high-resolution monitor 52) U.S. C. .................................... 340/731; 340/703; for display. The expansion circuit of the present inven 340/814; 358/22; 358/140 tion comprises means responsive to an expansion pat 58 Field of Search ....................... 340/717, 814, 731; tern generated by the computer for changing the time 358/22, 140 base of the video pixel data read out of said frame buffer. -

Analysis of Displays Attributes for Use in Avionics Head up Displays

International Journal of Computer Applications (0975 – 8887) Volume 122 – No.3, July 2015 Analysis of Displays Attributes for use in Avionics Head up Displays Pooja Verma Vinod Karar Vandana Niranjan Surender Singh Saini Department of ECE Department of ODS Department of ECE Department of ODS IGDTUW, Delhi CSIR-CSIO, Chandigarh IGDTUW, Delhi CSIR-CSIO, Chandigarh ABSTRACT These devices are used for backlighting the LCD panels and Modern avionics provide a comprehensive human-machine also used in the LED based navigational, landing and taxi interaction. The modern electronic displays are the key lighting system of aircrafts. However, they are not suitable for components of any glass cockpit based aircraft employing the direct application as a display device in a cockpit display [1], state of art avionics and are being increasingly used due to [3]. two main reasons: firstly, the continuous advancements and The liquid crystal display (LCD) is a non-emissive display improvements in the electronic display technologies, and technology based on the principle of dynamic scattering of second being the progressive changes in the onboard data light. Mostly used structure of LCD is twisted nematic. They distributing and processing methods in both military and civil can result in high contrast ratio coupled with lesser aircraft. In this article we have discussed several electronic operational voltage requirement and reduced power display devices and relevant technologies for avionics display consumption. However, this technology suffers from the use especially with reference to the head-up displays. These disadvantage such as poor intrinsic viewing angle, display technologies have been analysed with reference to the backlighting requirements, temperature and sunlight avionics display requirements and vital parameters like size, dependent performance, etc. -

Understanding Digital Terres Trial Broadcasting

Understanding Digital Terrestrial Broadcasting Understanding Digital Terrestrial Broadcasting Seamus OLeary Artech House Boston London www.artechhouse.com Library of Congress Cataloging-in-Publication Data OLeary, Seamus. Understanding digital terrestrial broadcasting / Seamus OLeary. p. cm. (Artech House digital audio and video library) Includes bibliographical references and index. ISBN 1-58053-063-X (alk. paper) 1. Digital communications. 2. Television broadcasting. 3. Digital audio broadcasting. I. Title. II. Series. TK5103.7.O49 2000 621.384dc21 00-040624 CIP British Library Cataloguing in Publication Data OLeary, Seamus Understanding digital terrestrial broadcasting. (Artech House digital audio and video library) 1. Digital television 2. Digital audio broadcasting I. Title 621.388 ISBN1-58053-462-7 Cover and text design by Darrell Judd © 2000 ARTECH HOUSE, INC. 685 Canton Street Norwood, MA 02062 All rights reserved. Printed and bound in the United States of America. No part of this book may be reproduced or utilized in any form or by any means, electronic or mechani- cal, including photocopying, recording, or by any information storage and retrieval system, without permission in writing from the publisher. All terms mentioned in this book that are known to be trademarks or service marks have been appropriately capitalized. Artech House cannot attest to the accuracy of this information. Use of a term in this book should not be regarded as affecting the validity of any trademark or service mark. International Standard Book Number: 1-58053-063-X Library of Congress Catalog Card Number: 00-040624 10987654321 This book is dedicated to the memory of Una and Denis McLoughlin, Go raibh leaba i measc na naoimh agaibh i gcónaí.