Anti-Tank Kinetic Energy Projectiles

Total Page:16

File Type:pdf, Size:1020Kb

Load more

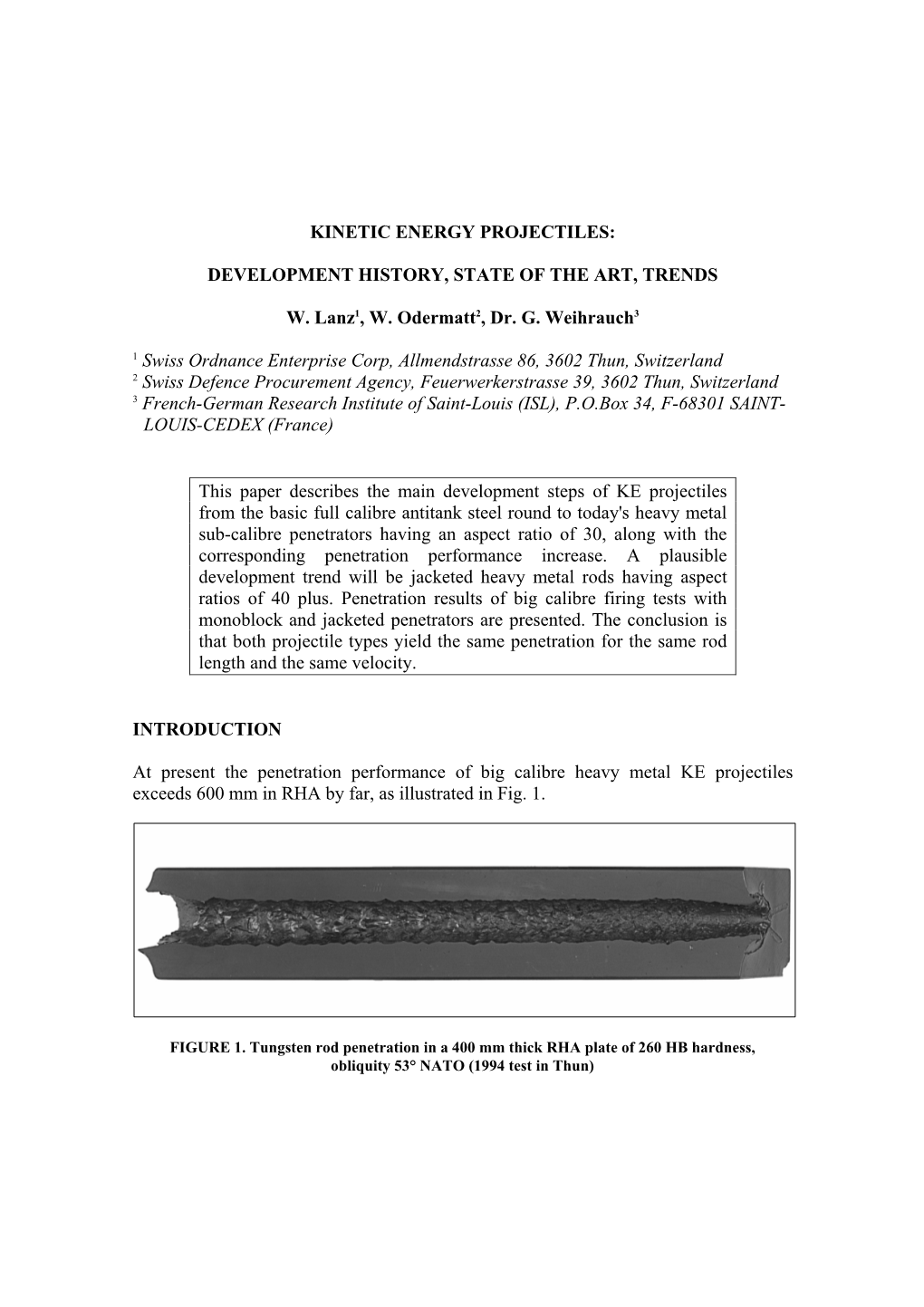

Recommended publications

-

Exo-Atmospheric Intercepts: Bringing New Challenges to Standard Missile

G. A. SULLINS Exo-atmospheric Intercepts: Bringing New Challenges to Standard Missile Gary A. Sullins The Navy Theater Wide System is being designed to provide defense for U.S. forces and our Allies against medium- to long-range tactical ballistic missiles. As part of this system, a new variant of Standard Missile, SM-3, will be introduced to the Fleet. SM-3 will perform a hit-to-kill intercept of the ballistic missile while it is in exo-atmospheric flight (i.e., while outside the Earth’s atmosphere). Exo-atmospheric flight and hit-to-kill intercepts have brought new challenges to the SM Program. These challenges have intro- duced new technologies, which in turn have created the need for new tests to be added to an already robust SM ground test program. This article discusses these new challenges and describes tests geared to verify SM-3 design, with emphasis given to those tests performed at APL. INTRODUCTION The threat of ballistic missile attacks to U.S. forces and the ability of the combat system to engage them and our Allies continues to grow. Currently over 40 by guiding the missile to an intercept. Modifications are nations have the capability to launch ballistic missile being made to the AWS to change the logic consistent attacks. Most of these missiles are not capable of reaching with tracking and engaging ballistic missiles rather than U.S. soil; nevertheless, they do pose a significant threat its traditional Anti-Air Warfare role. to our forces stationed overseas. Many of these nations In addition to modifications to the AWS, the NTW also have the ability to build chemical, biological, or System is developing a new SM variant, SM-3. -

Ballistic Missile Defense Technology: Weapons, Power, Communications, and Space Transportation CONTENTS Page Introduction

Chapter 5 Ballistic Missile Defense Technology: Weapons, Power, Communications, and Space Transportation CONTENTS Page Introduction . ......................105 5-6b. Boost and Post-Boost Kill Weapons . ..................,......105 Effectiveness (500 single-RV Kinetic-Energy Weapons (KEW) ....106 ICBMs atone site) . ...........117 Directed-Energy Weapons . .........123 5-7. Boost and Post-Boost Kill Power and Power Conditioning . ......142 Effectiveness (200 “medium- Space Power Requirements . ........142 bum-booster” ICBMs at one site). .............118 Space Power Generation Technology .143 5-8. Schematic of an Electromagnetic Power Conditioning . .. ..........145 Launcher (EML) or “Railgun” ..119 Communication Technology . .........146 5-9. Lightweight Homing Projectile. .l2l 60-GHz Communication Links .. ....147 5-10. Illustration of the Relationships Laser Communication Links . .......148 Between Laser Parameters and Space Transportation . ..............148 Power Density Projected on a Space Transportation Target . .............125 Requirements. ................149 5-11. FEL Waveforms . .............125 Space Transportation Alternatives ...149 5-12. Schematic of a Neutral Particle Space Transportation Cost Beam Weapon.. .............129 Reduction . ................153 5-13a. Annual Space Launch Capacity .152 Conclusions . ....................153 5-13b. Space Transportation . .........152 Weapon Technology Conclusions ....153 Space Power Conclusions. .........155 Tables Space Communications Conclusion. ..l55 Table No. Page Space Transportation -

Design and Optimization of an Electromagnetic Railgun

Michigan Technological University Digital Commons @ Michigan Tech Dissertations, Master's Theses and Master's Reports 2018 DESIGN AND OPTIMIZATION OF AN ELECTROMAGNETIC RAILGUN Nihar S. Brahmbhatt Michigan Technological University, [email protected] Copyright 2018 Nihar S. Brahmbhatt Recommended Citation Brahmbhatt, Nihar S., "DESIGN AND OPTIMIZATION OF AN ELECTROMAGNETIC RAILGUN", Open Access Master's Report, Michigan Technological University, 2018. https://doi.org/10.37099/mtu.dc.etdr/651 Follow this and additional works at: https://digitalcommons.mtu.edu/etdr Part of the Controls and Control Theory Commons DESIGN AND OPTIMIZATION OF AN ELECTROMAGNETIC RAIL GUN By Nihar S. Brahmbhatt A REPORT Submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE In Electrical Engineering MICHIGAN TECHNOLOGICAL UNIVERSITY 2018 © 2018 Nihar S. Brahmbhatt This report has been approved in partial fulfillment of the requirements for the Degree of MASTER OF SCIENCE in Electrical Engineering. Department of Electrical and Computer Engineering Report Advisor: Dr. Wayne W. Weaver Committee Member: Dr. John Pakkala Committee Member: Dr. Sumit Paudyal Department Chair: Dr. Daniel R. Fuhrmann Table of Contents Abstract ........................................................................................................................... 7 Acknowledgments........................................................................................................... 8 List of Figures ................................................................................................................ -

House Bill No. 944

FIRST REGULAR SESSION HOUSE COMMITTEE SUBSTITUTE FOR HOUSE BILL NO. 944 101ST GENERAL ASSEMBLY 1836H.02C DANA RADEMAN MILLER, Chief Clerk AN ACT To repeal section 571.030, RSMo, and to enact in lieu thereof one new section relating to unlawful use of weapons, with penalty provisions. Be it enacted by the General Assembly of the state of Missouri, as follows: Section A. Section 571.030, RSMo, is repealed and one new section enacted in lieu 2 thereof, to be known as section 571.030, to read as follows: 571.030. 1. A person commits the offense of unlawful use of weapons, except as 2 otherwise provided by sections 571.101 to 571.121, if he or she knowingly: 3 (1) Carries concealed upon or about his or her person a knife, a firearm, a blackjack or 4 any other weapon readily capable of lethal use into any area where firearms are restricted under 5 section 571.107; [or] 6 (2) Sets a spring gun; [or] 7 (3) Discharges or shoots a firearm into a dwelling house, a railroad train, boat, aircraft, 8 or motor vehicle as defined in section 302.010, or any building or structure used for the 9 assembling of people; [or] 10 (4) Exhibits, in the presence of one or more persons, any weapon readily capable of 11 lethal use in an angry or threatening manner; [or] 12 (5) Has a firearm or projectile weapon readily capable of lethal use on his or her person, 13 while he or she is intoxicated, and handles or otherwise uses such firearm or projectile weapon 14 in either a negligent or unlawful manner or discharges such firearm or projectile weapon unless 15 acting in self-defense; [or] 16 (6) Discharges a firearm within one hundred yards of any occupied schoolhouse, 17 courthouse, or church building; [or] EXPLANATION — Matter enclosed in bold-faced brackets [thus] in the above bill is not enacted and is intended to be omitted from the law. -

Ballistic Aiming System Manual

BALLISTICS AIMING SYSTEM Table of Contents Boone and Crockett™ Big Game Reticle ......................... Page 1 Varmint Hunter’s™ Reticle .................................... Page 11 LR Duplex® Reticle .......................................... Page 22 LRV Duplex® Reticle ......................................... Page 29 SAbot Ballistics Reticle (SA.B.R.®) ............................. Page 34 Ballistic FireDot® Reticle ..................................... Page 44 Multi-FireDot™ Reticle....................................... Page 51 Pig-Plex Ballistic Reticle...................................... Page 59 TMOA™ Reticles ............................................ Page 64 Various language translations of the BAS Manual can be found at www.leupold.com. La traduction en français du manuel BAS se trouve à www.leupold.com. La traducción al español del manual BAS se encuentra en www.leupold.com. Das BAS-Handbuch in deutscher Sprache finden Sie unter www.leupold.com. La traduzione in italiano del manuale BAS è pubblicata sul sito seguente: www.leupold.com. 1 The Leupold Ballistics Aiming System®– Boone and Crockett™ Big Game Reticle The goal of every hunter is a successful hunt with a clean harvest. It was with this in mind that Leupold® created the Leupold Ballistics Aiming System®. Because we so strongly agree with the Boone and Crockett Club’s legacy of wildlife conservation and ethical fair chase hunting, we have designated one of the system’s reticles as the Boone and Crockett™ Big Game reticle. The Boone and Crockett Big Game reticle gives the hunter very useful tools intended to bring about successful hunts with clean and efficient harvests. Through the use of these straightforward and easy-to-follow instructions, it is sincerely hoped that all hunters will find their skills improved and their hunts more successful. Boone and Crockett Club® is a registered trademark of the Boone and Crockett Club, and is used with their expressed written permission. -

Complex Projectile Technology and Homo Sapiens Dispersal Into Western Eurasia

Complex Projectile Technology and Homo sapiens Dispersal into Western Eurasia JOHN J. SHEA Department of Anthropology and Turkana Basin Institute, Stony Brook University, Stony Brook, NY 11794-4364, USA; [email protected] MATTHEW L. SISK Interdepartmental Doctoral Program in Anthropological Science, Stony Brook University, Stony Brook, NY 11794-4364, USA; [email protected] ABSTRACT This paper proposes that complex projectile weaponry was a key strategic innovation driving Late Pleistocene human dispersal into western Eurasia after 50 Ka. It argues that complex projectile weapons of the kind used by ethnographic hunter-gatherers, such as the bow and arrow, and spearthrower and dart, enabled Homo sapiens to overcome obstacles that constrained previous human dispersal from Africa to temperate western Eurasia. In the East Mediterranean Levant, the only permanent land bridge between Africa and Eurasia, stone and bone projectile armatures like those used in the complex weapon systems of recent humans appear abruptly ca 45–35 Ka in early Upper Paleolithic contexts associated with Homo sapiens fossils. Such artifacts are absent from Middle Paleolithic contexts associated with Homo sapiens and Neandertals. Hypotheses concerning the indigenous vs. exogenous origins of complex projectile weaponry in the Levant are reviewed. Current evidence favors the hypothesis that complex projectile technology developed as an aid to ecological niche broadening strategies among African popu- lations between 50–100 Ka. It most likely spread to western Eurasia along with dispersing Homo sapiens popula- tions. Neandertals did not routinely deploy projectile weapons as subsistence aids. This puzzling gap in their otherwise impressive record for survival in some of the harshest environments ever occupied by primates may reflect energetic constraints and time-budgeting factors associated with complex technology. -

The Strategic Defense Initiative and the Militarization of Space: Scientific Responsibility and Citizen Resistance

Penn State International Law Review Volume 9 Article 2 Number 2 Dickinson Journal of International Law 1991 The trS ategic Defense Initiative and the Militarization of Space: Scientific Responsibility and Citizen Resistance Matthew Lippman Follow this and additional works at: http://elibrary.law.psu.edu/psilr Part of the International Law Commons, and the Military, War, and Peace Commons Recommended Citation Lippman, Matthew (1991) "The trS ategic Defense Initiative and the Militarization of Space: Scientific Responsibility and Citizen Resistance," Penn State International Law Review: Vol. 9: No. 2, Article 2. Available at: http://elibrary.law.psu.edu/psilr/vol9/iss2/2 This Article is brought to you for free and open access by Penn State Law eLibrary. It has been accepted for inclusion in Penn State International Law Review by an authorized administrator of Penn State Law eLibrary. For more information, please contact [email protected]. The Strategic Defense Initiative and the Militarization of Space: Scientific Responsibility and Citizen Resistance Matthew Lippman* I. Introduction The moderating of international tensions between the superpow- ers, the slowing of the nuclear arms race and the promise of a peace dividend have all contributed to a lessened popular concern over is- sues of national defense.1 The diversion of attention from war and peace has resulted in little scholarly attention being paid to the omi- nous potential growth in third-generation high-technology weapons. 2 These automated weapons systems are being designed primarily to operate in outer space where, despite claims to the contrary, they will be used to enhance the United States'ability to launch a first strike nuclear attack.3 The technological and strategic foundation of this revolution in weaponry is the Strategic Defense Initiative (SDI). -

Artillery Through the Ages, by Albert Manucy 1

Artillery Through the Ages, by Albert Manucy 1 Artillery Through the Ages, by Albert Manucy The Project Gutenberg EBook of Artillery Through the Ages, by Albert Manucy This eBook is for the use of anyone anywhere at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org Title: Artillery Through the Ages A Short Illustrated History of Cannon, Emphasizing Types Used in America Author: Albert Manucy Release Date: January 30, 2007 [EBook #20483] Language: English Artillery Through the Ages, by Albert Manucy 2 Character set encoding: ISO-8859-1 *** START OF THIS PROJECT GUTENBERG EBOOK ARTILLERY THROUGH THE AGES *** Produced by Juliet Sutherland, Christine P. Travers and the Online Distributed Proofreading Team at http://www.pgdp.net ARTILLERY THROUGH THE AGES A Short Illustrated History of Cannon, Emphasizing Types Used in America UNITED STATES DEPARTMENT OF THE INTERIOR Fred A. Seaton, Secretary NATIONAL PARK SERVICE Conrad L. Wirth, Director For sale by the Superintendent of Documents U. S. Government Printing Office Washington 25, D. C. -- Price 35 cents (Cover) FRENCH 12-POUNDER FIELD GUN (1700-1750) ARTILLERY THROUGH THE AGES A Short Illustrated History of Cannon, Emphasizing Types Used in America Artillery Through the Ages, by Albert Manucy 3 by ALBERT MANUCY Historian Southeastern National Monuments Drawings by Author Technical Review by Harold L. Peterson National Park Service Interpretive Series History No. 3 UNITED STATES GOVERNMENT PRINTING OFFICE WASHINGTON: 1949 (Reprint 1956) Many of the types of cannon described in this booklet may be seen in areas of the National Park System throughout the country. -

In Bore Behaviour of Large Calibre Armour Piercing Fin Stabilised Discarding Sabot Projectiles

IN BORE BEHAVIOUR OF LARGE CALIBRE ARMOUR PIERCING FIN STABILISED DISCARDING SABOT PROJECTILES. Copyright by DYNAmore N.Eches, N.Paugain, C. Doffémont; Giat Industries, Division des systèmes d’armes et de munitions. 7 route de Guerry, 18023 Bourges Cedex; France Tel : +33 2 48 21 91 85 - Fax : +33 2 48 21 91 42. Introduction The efficiency of large calibre armour piercing fin stabilised discarding sabot projectiles (APFDS) is primarily linked to their terminal ballistics performances. But other parameters, such as its accuracy and its yaw at the impact have also a large influence on the performance. These two parameters magnitude, as well as the survivability of the projectile during the launch phase are greatly affected by the interaction between the projectile and the gun, also known as the “balloting”. Nowadays, the accurate description of the rod free flight has been made possible thanks to Computational Fluid Dynamics calculations, allowing to predict the flight quality or the retardation, and back calculation of initial disturbances of an unexpectedly odd shot. But this situation is not true for the early moments of the firing sequence, i.e. the projectile in- bore travel and the sabot separation. For the latter, a long way to go remains. But, in the field of projectiles in-bore behaviour, a lot of works have been performed, using different numerical methods, which allowed scientists to make significant progress. This paper describes some of the works performed in the Giat Industries Weapon and Ammunition Systems Division (DSAM), whose purpose was to understand how the interactions between the weapon and the projectile could affect its mechanical behaviour and its muzzle exit conditions. -

Artillery Ammunition from the 1781 Siege of Star Fort

University of South Carolina Scholar Commons Archaeology and Anthropology, South Carolina Faculty & Staff Publications Institute of 9-2020 Artillery Ammunition from the 1781 Siege of Star Fort James B. Legg Follow this and additional works at: https://scholarcommons.sc.edu/sciaa_staffpub Part of the Archaeological Anthropology Commons, and the Military History Commons Research Artillery Ammunition from the 1781 Siege of Star Fort By James B. Legg th Regular readers of Legacy, will recall that daily feature of the siege. By June 18 , the The 6-pounder was the standard field in 2018 and 2019, SCIAA Director Steve Americans were entrenched immediately caliber used by both British and American Smith conducted USC “Maymester” north of the ditch of Star Fort, but a large artillery during the Revolution. Historical archaeological field schools in and around relief force of British regular troops was sources indicate that the Americans used Star Fort, a component of the 1781 British on its way to break the siege. Greene at least four, 6-pounder field guns in defenses of Ninety Six, South Carolina, at decided to risk a direct assault on Star Fort the siege of Star Fort, while the British Ninety Six National Historic Site (Figures before giving up the siege, but the attack had only two or three 3-pounders, and 1 and 2). The work included formal met with a bloody repulse. Greene broke possibly some very light-caliber swivel excavation units, and an array of metal off the siege and withdrew the following guns. Nevertheless, we found both detector sample areas. Among our findings day, but the British then decided that the American and British 6-pounder shot in was a significant assemblage related to the post of Ninety Six was too exposed to be Star Fort. -

Projectile Motion

PROJECTILE MOTION Objectives • Distinguish between a vector PROJECTILE MOTION quantity and a scalar quantity. 5 (5.1) • Explain how to find the Projectile motion can be resultant of two perpendicular THE BIG vectors. (5.2) described by the horizontal and • Describe how the components IDEA .......... vertical components of motion. of a vector affect each other. (5.3) • Describe the components of n the previous chapter, we studied simple straight-line projectile motion. (5.4) motion—linear motion. We distinguished between motion • Describe the downward motion with constant velocity, such as a bowling ball rolling of a horizontally launched I projectile. (5.5) horizontally, and accelerated motion, such as an object • Describe how far below an falling vertically under the influence of gravity. Now we imaginary straight-line path a extend these ideas to nonlinear motion—motion along projectile falls. (5.6) a curved path. Throw a baseball and the path it follows is a curve. This curve is a combination of constant- velocity horizontal motion and accelerated vertical discover! motion. We’ll see that the velocity of a thrown ball at any instant has two independent “components” of MATERIALS cardboard, tape, motion—what happens horizontally is not affected soda straws, pencil, ruler, two marbles by what happens vertically. EXPECTED OUTCOME Marble 2 will hit Marble 1. ANALYZE AND CONCLUDE 1. Yes; the speed of Marble 2 discover! 2. Same 3. Gravity accelerates both How Should You Aim to Hit a Falling 4. At the same time, marbles equally. Target? release Marble 1 and launch TEACHING TIP Known to many 1. -

Assessing Israel's Iron Dome Missile Defense System

Research memo Assessing Israel’s Iron Dome Missile Defense System By Jacob Nagel and Jonathan Schanzer November 13, 2019 The Israeli Iron Dome missile defense system continues to make headlines as it knocks Hamas and Palestinian Islamic Jihad rockets out of the sky. The system is the crucial lower tier of Israel’s layered missile defense system, which guards Israel’s skies from threats near and far. The David’s Sling system covers middle-layer threats, and the Arrow system defends against long-range projectiles. Iron Dome has earned great praise across professional, political, military, and civilian circles. The U.S. Army recently acquired two Iron Dome batteries as an interim solution to existing vulnerabilities, and may acquire more for the long term. The U.S. Marine Corps has also expressed interest and recently conducted several successful tests in the United States. Even among Israel’s foes, Iron Dome is widely recognized as a remarkable military innovation. But over time, certain potential disadvantages also have become a topic for debate. For one, Iron Dome’s efficacy in shooting down projectiles may encourage Israel’s enemies to increase their rocket launches to achieve their aims. And by granting time and space to Israeli officials to consider a proportional or surgical strike, Iron Dome can have the unintended consequence of potentially prolonging a conflict. In other words, the system raises the threshold for Israeli political leaders and military brass to launch a decisive operation, even as the volume of rocket provocations increases. There is also a psychological warfare element. Israel’s enemies can repeatedly broadcast photos of their cadres firing rockets with relatively little response from the Israeli side.