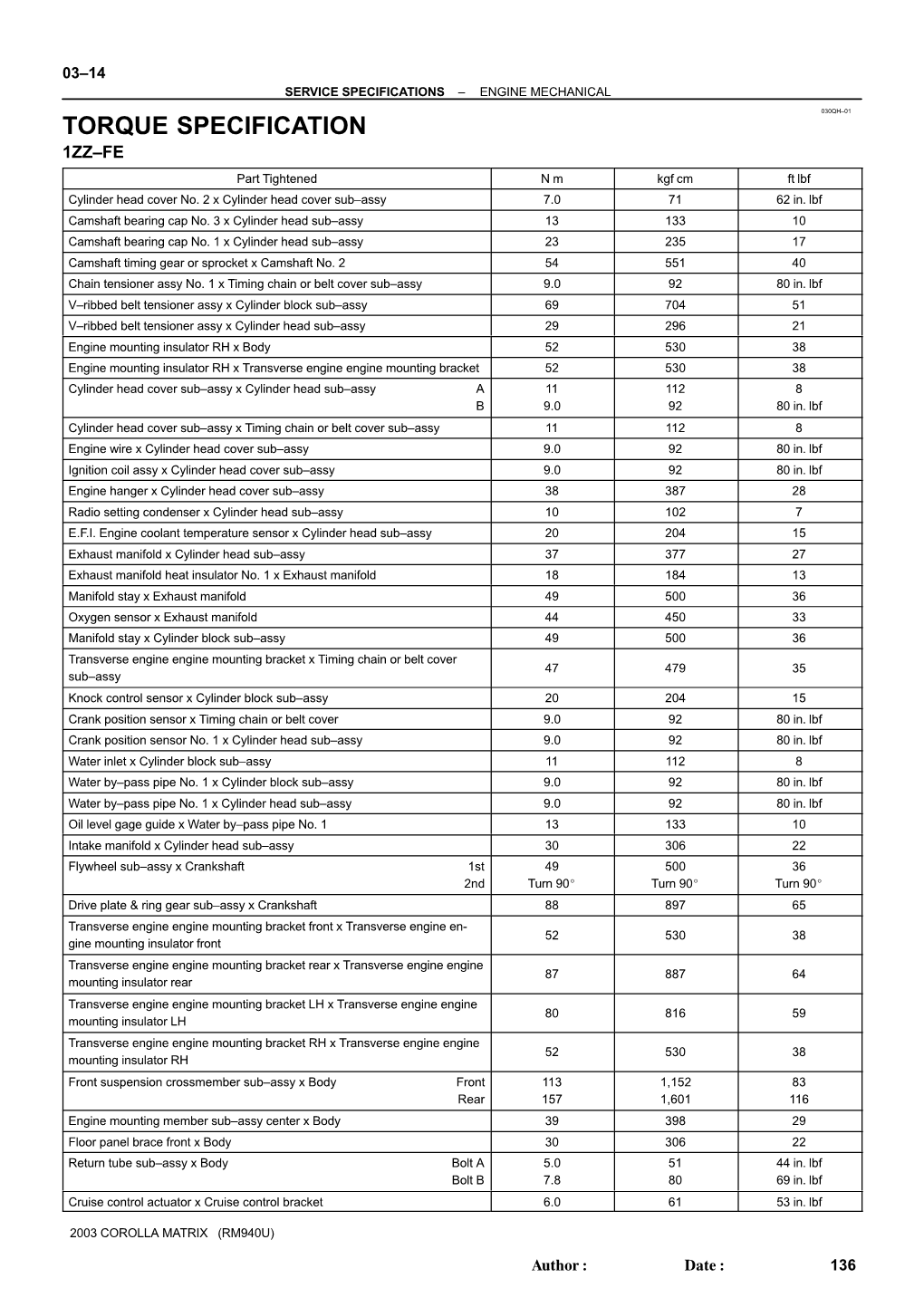

TORQUE SPECIFICATION 1ZZ–FE Part Tightened N⋅M Kgf⋅Cm Ft⋅Lbf Cylinder Head Cover No

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Fiber Optic (Flight Quality) Sensors for Advanced Aircraft Propulsion

/ .. < / • _7 _ NASA Contractor Report 191195 ? R94AEB175 Fiber Optic (Flight Quality) Sensors For Advanced Aircraft Propulsion Final Report Gary L. Poppel GE Aircraft Engines Cincinnati, Ohio 45215 July 1994 Prepared for: Robert J. Baumbick, Project Manager National Aeronautics and Space Administration 2 I000 Brookpark Road Cleveland, Ohio 44135 Contract NAS3-25805 N94-37401 (NASA-CR-I9II95) FISER OPTIC (FLIGHT QUALITY) SENSORS FOR NationalAeronauticsand ADVANCED AIRCRAFT PROPULSION Fina] Uncl as Space Administration Report, Jan. 1990 - Jun. 1994 (GE) 90 p G3/06 0016023 TABLE OF CONTENTS Section Page 1.0 SUMMARY 2.0 INTRODUCTION 3.0 SENSOR SET DESCRIPTION 3.1 Identification and Requirements 3.2 Engine/System Schematics 3.3 F404 Implementation 3.4 Optical/Electrical Signal Comparison 9 4.0 SENSOR DESIGN, FUNCTIONALITY, & TESTING 9 4.1 TI Temperature Sensor 4.2 T2.5 Temperature Sensor I0 11 4.3 T5 Temperature Sensor 4.4 FVG Position Sensor 12 14 4.5 CVG Position Sensor 4.6 VEN Position Sensor 15 16 4.7 NL Speed Sensor 17 4.8 Nil Speed Sensor 4.9 AB Flame Detector 18 20 5.0 ELECTRO-OPTIC CIRCUITRY 5.1 Litton EOA Circuitry 20 23 5.2 GE Circuitry 24 5.3 Conax T5 Signal Processor 5.4 Ametek AB Flame Detector Assembly 25 26 6.0 ELECTRO-OPTICS UNIT DESIGN, ASSEMBLY, & TESTING 26 6.1 Chassis Design 26 6.2 Assembly Process 6.3 Internal Features 26 27 6.4 Input/Output Interfaces 6.5 Thermal Studies 27 27 6.6 Testing 7.0 CABLE DESIGN & FABRICATION 33 7.1 Identification of Cable Set 33 33 7.2 Optical Sensor Loop Configurations 7.3 GE-Designed Fiber -

MANUAL Kohler 1000 DIESEL Kohler 750 EFI Intimidator 800

2017 OWNER’S MANUAL Kohler 1000 DIESEL Kohler 750 EFI Intimidator 800 UTVRevised 10/18/2017 Owner Memo Name: ____________________________________ Purchasing Date: ____________________________ Type: _____________________________________ Pin Number: _______________________________ Special Notice: _____________________________ Key Number: _______________________________ PAGE 2 OWNER’S MANUAL Table of Contents: Title ........................... Page Number Introduction ......................................................Page 4 Definitions ........................................................Page 4 Safety Labels ...............................................Pages 4-8 ROPS Inspection Guide .............................Pages 9-10 General Safety ..........................................Pages 11-14 Safe Riding Gear .............................................Page 15 Features, Controls and Operation ............Pages 16-33 New Vehicle Break-in ......................................Page 33 Service and Maintenance .........................Pages 34-71 Storing and Maintaining Appearance .......Pages 72-73 Transporting your Intimidator .........................Page 74 Accessories ....................................................Page 74 Specifications ......................................... Pages 75-83 Troubleshooting ...................................... Pages 84-89 Warranties .............................................. Pages 90-99 Service Record .................................... Pages 100-101 Training Certificate ........................................Page -

Sae 2019-01-0249

Downloaded from SAE International by John Kargul, Friday, May 29, 2020 2019-01-0249 Published 02 Apr 2019 Benchmarking a 2018 Toyota Camry 2.5-Liter INTERNATIONAL. Atkinson Cycle Engine with Cooled-EGR John Kargul, Mark Stuhldreher, Daniel Barba, Charles Schenk, Stanislav Bohac, Joseph McDonald, and Paul Dekraker US Environmental Protection Agency Josh Alden Southwest Research Institute Citation: Kargul, J., Stuhldreher, M., Barba, D., Schenk, C. et al., “Benchmarking a 2018 Toyota Camry 2.5-Liter Atkinson Cycle Engine with Cooled-EGR,” SAE Int. J. Advances & Curr. Prac. in Mobility 1(2):601-638, 2019, doi:10.4271/2019-01-0249. This article was presented at WCXTM19, Detroit, MI, April 9-11, 2019. Abstract idle, low, medium, and high load engine operation. Motoring s part of the U.S. Environmental Protection Agency’s torque, wide open throttle (WOT) torque and fuel consumption (EPA’s) continuing assessment of advanced light-duty are measured during transient operation using both EPA Tier Aautomotive technologies in support of regulatory and 2 and Tier 3 test fuels. Te design and performance of this 2018 compliance programs, a 2018 Toyota Camry A25A-FKS 2.5-liter engine is described and compared to Toyota’s published 4-cylinder, 2.5-liter, naturally aspirated, Atkinson Cycle engine data and to EPA’s previous projections of the efciency of an with cooled exhaust gas recirculation (cEGR) was bench- Atkinson Cycle engine with cEGR. The Brake Thermal marked. Te engine was tested on an engine dynamometer Efciency (BTE) map for the Toyota A25A-FKS engine shows with and without its 8-speed automatic transmission, and with a peak efciency near 40 percent, which is the highest value of the engine wiring harness tethered to a complete vehicle parked any publicly available map for a non-hybrid production gasoline outside of the test cell. -

Service Specifications Service Data

EG1–77 ENGINE – ENGINE MECHANICAL SERVICE SPECIFICATIONS SERVICE DATA Compression STD pressure Limit Difference between each cylinder Cylinder head Head surface warpage Limit Manifold surface warpage Limit Valve seat Refacing angle Intake Exhaust Contacting angle Contacting width Valve guide Inner diameter Intake bushing Exhaust Outer diameter STD O/S 0.05 Replacing temperature (cylinder head side) Valve Valve overall length STD Intake Exhaust Valve face angle Stem diameter STD Intake Exhaust Stem end refacing Limit Stem oil clearance STD STD Intake Exhaust Limit Intake Exhaust Valve head edge thickness STD Limit Valve spring Free length Installed load at 40.5 mm (1.594 in.) STD Limit Squareness Limit Rocker arm Rocker arm inside diameter and shaft Rocker shaft diameter Shaft to arm oil clearance STD Limit Intake, exhaust Manifold surface warpage manifolds and Limit Intake air intake chamber Exhaust Air intake chamber Chain and Crankshaft sprocket wear Limit sprocket Camshaft sprocket wear Limit EG1–78 ENGINE – ENGINE MECHANICAL Tension and Tensioner head thickness Limit damper No. 1 damper wear Limit No. 2 damper wear Limit Camshaft Thrust clearance STD Limit Journal oil clearance STD Limit Journal diameter STD Circle runout Limit Cam height STD Intake Exhaust Limit Intake Exhaust Cylinder block Cylinder head surface warpage Cylinder bore STD Cylinder bore wear Limit Cylinder block main journal bore STD Piston and Piston diameter STD piston ring Piston to cylinder clearance Ring to ring groove clearance STD Limit Piston ring end gap -

Operator's Manual

OPERATOR'S MANUAL L 3 2 4 0 á L 3 TRACTOR 5 4 0 MODELS L3240áL3540áL3940 á L L4240áL4740áL5040 3 9 L5240áL5740 4 0 á L 4 2 4 0 á L 4 7 4 0 á L 5 0 4 0 á L 5 2 4 0 á L 5 English (Australia) 7 Code No. TD170-1974-2 4 0 PRINTED IN JAPAN ABBREVIATION LIST Abbreviations Definitions 2WD Two Wheel Drive 4WD Four Wheel Drive API American Petroleum Institute ASAE American Society of Agricultural Engineers, USA ASTM American Society for Testing and Materials, USA DIN Deutsches Institut für Normung, GERMANY DT Dual Traction z4WDx fpm Feet Per Minute GST Glide Shift Transmission Hi-Lo High Speed-Low Speed HST Hydrostatic Transmission m/s Meters Per Second PTO Power Take Off RH/LH Right-hand and left-hand sides are determined by facing in the direction of forward travel ROPS Roll-Over Protective Structures rpm Revolutions Per Minute r/s Revolutions Per Second SAE Society of Automotive Engineers, USA SMV Slow Moving Vehicle ABBREVIATION LIST Abbreviations Definitions 2WD Two Wheel Drive 4WD Four Wheel Drive API American Petroleum Institute ASAE American Society of Agricultural Engineers, USA ASTM American Society for Testing and Materials, USA DIN Deutsches Institut für Normung, GERMANY DT Dual Traction z4WDx fpm Feet Per Minute GST Glide Shift Transmission Hi-Lo High Speed-Low Speed HST Hydrostatic Transmission m/s Meters Per Second PTO Power Take Off RH/LH Right-hand and left-hand sides are determined by facing in the direction of forward travel ROPS Roll-Over Protective Structures rpm Revolutions Per Minute r/s Revolutions Per Second SAE Society of Automotive Engineers, USA SMV Slow Moving Vehicle UNIVERSAL SYMBOLS As a guide to the operation of your tractor, various universal symbols have been utilized on the instruments and controls. -

Sw24/Sw28 St35/St45

Operator's Manual Compact loaders SW24/SW28 ST35/ST45 Machine type S04-01/S04-02/S04-03/S04-04 Edition 1.7 Order no 5200022252 Language us 5200022252 Dokumentationen Documentations Language Order no. Documentations Language Order no. Operator's Manual [us] 5200022252 SW24 [de en fr] 1000323666 ST35 [de en fr] 1000323692 SW24 [it es en] 1000323669 ST35 [it es en] 1000323693 Spare parts list Spare parts list SW28 [de en fr] 1000323670 ST45 [de en fr] 1000323865 SW28 [it es en] 1000323691 ST45 [it es en] 1000323870 Legend Original Operator‘s Manual x Translation of original Operator‘s – Manual Edition 1.7 Date 05/2016 Document 5200022252_1_7 Copyright © 2015 Wacker Neuson Baumaschinen GmbH, Hörsching Printed in Austria. All rights reserved, in particular the globally applicable copyright, right of reproduction and right of distribution. No part of this publication may be reproduced, translated or used in any form or by any means – graphic, electronic or mechanical including photocopying, recording, taping or information storage or retrieval systems – without prior permission in writing from the manufacturer. No reproduction or translation of this publication, in whole or part, without the written consent of Wacker Neuson Linz GmbH. Violations of legal regulations, in particular of the copyright protection, will be subject to civil and criminal prosecution. Wacker Neuson Linz GmbH keep abreast of the latest technical developments and constantly improve their products. For this reason, we may from time to time need to make changes to diagrams and descriptions in this documentation which do not reflect products which have already been delivered and which will not be implemented on these machines. -

Combustion Chamber Design Effect on the Rotary Engine Performance - a Review

Boughou Smail et al / International Journal of Automotive Engineering Vol.11, No.4(2020) Review article 20204578 Combustion Chamber Design Effect on The Rotary Engine Performance - A Review Boughou Smail 1) AKM Mohiuddin 2) 1) International University of Rabat UIR, Renewable Energies and Advanced Materials Laboratory LERMA, Technopolis Rabat-Shore, Morocco (E-mail [email protected]) 2) International Islamic University of Malaysia IIUM, Faculty of Engineering P.O. Box 10, 50728 Kuala Lumpur, Malaysia (E-mail [email protected] ) Received on March 5 ,2020 ABSTRACT: Comparatively, this review is meant to focus on possible developments studies of the rotary engine design. The controversial engine produces a direct rotational motion. Felix Wankel derived the triangular rotor shape from complex geometry of the Reuleaux triangle. The Wankel engine simulation and prediction of its performance is still limited. The current work reviews rotary engine’s flow field inside the combustion chamber with different commercial software used. It studies different parameters effect on the performance of the engine, such as the effect of the recess sizes and the shape-factor. It is found that the engine chambers design is one of the aspects of improvement opportunities. KEY WORDS: Rotary engine; Design geometry, Shape factor; Combustion simulation. [A1] The rotary engine recently got interests for possible 1. Introduction reliability as range extenders for electric vehicles. The rotary engine is reliable to be applied for the design architecture of UAV powertrains 12,13. The small-scale reliability to unmanned aerial Although the controversial rotary engine was adopted and vehicles UAVs. Such as for aviation of RQ-7A Shadow 200 and developed by many manufacturers, it is seen that multiple Sikorsky Cypher are run with a rotary engine. -

Gas Turbines in Simple Cycle and Combined Cycle Applications

GAS TURBINES IN SIMPLE CYCLE & COMBINED CYCLE APPLICATIONS* Gas Turbines in Simple Cycle Mode Introduction The gas turbine is the most versatile item of turbomachinery today. It can be used in several different modes in critical industries such as power generation, oil and gas, process plants, aviation, as well domestic and smaller related industries. A gas turbine essentially brings together air that it compresses in its compressor module, and fuel, that are then ignited. Resulting gases are expanded through a turbine. That turbine’s shaft continues to rotate and drive the compressor which is on the same shaft, and operation continues. A separate starter unit is used to provide the first rotor motion, until the turbine’s rotation is up to design speed and can keep the entire unit running. The compressor module, combustor module and turbine module connected by one or more shafts are collectively called the gas generator. The figures below (Figures 1 and 2) illustrate a typical gas generator in cutaway and schematic format. Fig. 1. Rolls Royce RB211 Dry Low Emissions Gas Generator (Source: Process Plant Machinery, 2nd edition, Bloch & Soares, C. pub: Butterworth Heinemann, 1998) * Condensed extracts from selected chapters of “Gas Turbines: A Handbook of Land, Sea and Air Applications” by Claire Soares, publisher Butterworth Heinemann, BH, (for release information see www.bh.com) Other references include Claire Soares’ other books for BH and McGraw Hill (see www.books.mcgraw-hill.com) and course notes from her courses on gas turbine systems. For any use of this material that involves profit or commercial use (including work by nonprofit organizations), prior written release will be required from the writer and publisher in question. -

Engines for Biogas

Engines for biogas Klaus von Mitzlaff A Publication of the Deutsches Zentrum für Entwicklungstechnologien GATE , a Division of the Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH - 1988 Copyright Deutsches Zentrum für Entwicklungstechnologien - GATE Deutsches Zentrum für Entwicklungstechnologien - GATE - stands for German Appropriate Technology Exchange. It was founded in 1978 as a special division of the Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH. GATE is a centre for the dissemination and promotion of appropriate technologies for developing countries. GATE defines "Appropriate technologies" as those which are suitable and acceptable in the light of economic social and cultural criteria. They should contribute to socio-economic development whilst ensuring optimal utilization of resources and minimal detriment to the environment. Depending on the case at hand a traditional, intermediate or highly-developed can be the "appropriate" one. GATE focusses its work on three key areas: - Dissemination of Appropriate Technologies: Collecting, processing and disseminating information on technologies appropriate to the needs of the developing countries; ascertaining the technological requirements of Third World countries; support in the form of personnel material and equipment to promote the development and adaptation of technologies for developing countries. - Research and Development: Conducting and/or promoting research and development work in appropriate technologies. - Environmental Protection: The growing -

Torque Specification (Echo)

SS-10 SERVICE SPECIFICATIONS - ENGINE MECHANICAL SS175-01 TORQUE SPECIFICATION Part tightened N·m kgf·cm ft·lbf Plug x Timing chain cover 15 150 11 Chain vibration damper x Cylinder block 9.0 92 80 in .·lbf Chain tensioner 9.0 92 80 in .·lbf Timing chain cover Bolt A 11 112 8 Bolt B 24 245 18 Bolt C 11 112 8 Bolt D 24 245 18 Bolt E 11 112 8 Nut F 24 245 18 Nut G 11 112 8 RH engine mounting bracket x Timing chain cover 55 561 41 Crankshaft position sensor x Timing chain cover Bolt A 7.5 76 66 in .·lbf Bolt B 11 112 8 Oil control valve 8.0 82 71 in .·lbf Crankshaft pulley x Crankshaft 128 1,300 94 Cylinder head cover x Cylinder 10 100 7 RH engine mounting insulator Bolt A 45 459 33 Bolt B 52 530 38 Nut 52 530 38 Cylinder head x Cylinder block 1st 29.4 300 22 2nd Turn 90° Turn 90° Turn 90° 3rd Turn 90° Turn 90° Turn 90° Water bypass pipe x Cylinder head 9.0 92 80 in .·lbf No. 1 camshaft bearing cap x Cylinder head 23 235 17 No. 2 camshaft bearing cap x Cylinder head 12.7 130 10 Camshaft timing sprocket x Camshaft 64 650 47 Valve timing controller assembly x Camshaft 64 650 47 Intake manifold x Cylinder head 30 300 22 Exhaust manifold x Cylinder head 27 275 20 Upper heat insulator x Exhaust manifold 8.0 82 71 in .·lbf Exhaust manifold stay x Cylinder block 37 377 27 Front exhaust pipe x Exhaust manifold 62 630 46 Water filler x Cylinder head 7.5 76 66 in .·lbf Engine hanger x Cylinder head 38 388 28 LH engine mounting 49 500 36 Rear engine mounting bracket 49 500 36 Front exhaust pipe x Tailpipe Bolt A 62 630 46 Bolt B 32 330 24 Clutch release cylinder x Transaxle 12 120 9 Clutch release cylinder bracket x Transaxle 4.9 50 43 in.·lbf A/C compressor x Engine 25 250 18 Air cleaner case 7.5 76 66 in.·lbf Air cleaner inlet assembly 7.5 76 66 in.·lbf Connecting rod cap x Connecting rod 1st 15 150 11 2nd Turn 90° Turn 90° Turn 90° 2002 ECHO (RM884U) Author: Date: 136 SS-1 1 SERVICE SPECIFICATIONS - ENGINE MECHANICAL Bearing cap x Cylinder block 1st 22 220 16 2nd Turn 90° Turn 90° Turn 90° Oil pan No. -

The Development of the Single Sleeve Valve Two-Stroke Engine Over the Last 110 Years

energies Review The Silent Path: The Development of the Single Sleeve Valve Two-Stroke Engine over the Last 110 Years Robert Head * and James Turner Mechanical Engineering, Faculty of Engineering and Design, University of Bath, Bath BA2 7AY, UK; [email protected] * Correspondence: [email protected]; Tel.: +44-0789-561-7437 Abstract: At the beginning of the 20th century the operational issues of the Otto engine had not been fully resolved. The work presented here seeks to chronicle the development of one of the alternative design pathways, namely the replacement for the gas exchange mechanism of the more conventional poppet valve arrangement with that of a sleeve valve. There have been several successful engines built with these devices, which have a number of attractive features superior to poppet valves. This review moves from the initial work of Charles Knight, Peter Burt, and James McCollum, in the first decade of the 20th century, through the work of others to develop a two-stroke version of the sleeve- valve engine, which climaxed in the construction of one of the most powerful piston aeroengines ever built, the Rolls-Royce Crecy. After that period of high activity in the 1940s, there have been limited further developments. The patent efforts changed over time from design of two-stroke sleeve-drive mechanisms through to cylinder head cooling and improvements in the control of the thermal expansion of the relative components to improve durability. These documents provide a foundation for a design of an internal combustion engine with potentially high thermal efficiency. Keywords: two-stroke; sleeve valves; patents Citation: Head, R.; Turner, J. -

Compact, Lightweight, High Efficiency Rotary Engine for Generator, Apu, and Range-Extended Electric Vehicles

2018 NDIA GROUND VEHICLE SYSTEMS ENGINEERING AND TECHNOLOGY SYMPOSIUM POWER & MOBILITY (P&M) TECHNICAL SESSION AUGUST 7-9, 2018 - NOVI, MICHIGAN COMPACT, LIGHTWEIGHT, HIGH EFFICIENCY ROTARY ENGINE FOR GENERATOR, APU, AND RANGE-EXTENDED ELECTRIC VEHICLES Alexander Shkolnik, PhD, Nikolay Shkolnik, PhD Jeff Scarcella, Mark Nickerson Alexander Kopache, Kyle Becker Michael Bergin, PhD, Adam Spitulnik Rodrigo Equiluz, Ryan Fagan Saad Ahmed, Sean Donnelly, Tiago Costa LiquidPiston, Inc. Bloomfield, CT ABSTRACT Today automotive gasoline combustion engine’s are relatively inefficient. Diesel engines are more efficient, but are large and heavy, and are typically not used for hybrid electric applications. This paper presents an optimized thermodynamic cycle dubbed the High Efficiency Hybrid Cycle, with 75% thermodynamic efficiency potential, as well as a new rotary ‘X’ type engine architecture that embodies this cycle efficiently and compactly, while addressing the challenges of prior Wankel-type rotary engines, including sealing, lubrication, durability, and emissions. Preliminary results of development of a Compression Ignited 30 kW X engine targeting 45% (peak) brake thermal efficiency are presented. This engine aims to fit in a 10” box, with a weight of less than 40 lb, and could efficiently charge a battery to extend the range of an electric vehicle. INTRODUCTION in Figure 1, and will describe the development Today’s Diesel / heavy-fueled engines, while status of the X4, a .8L Compression Ignition relatively efficient, are large and heavy, with a power-to-weight ratio of approximately .1-.2 hp/lb (see, e.g., [12]). This paper presents a new type of rotary Diesel combustion engine architecture (the “X Engine”), which is based on an optimized thermodynamic cycle: the High Efficiency Hybrid Cycle (HEHC).