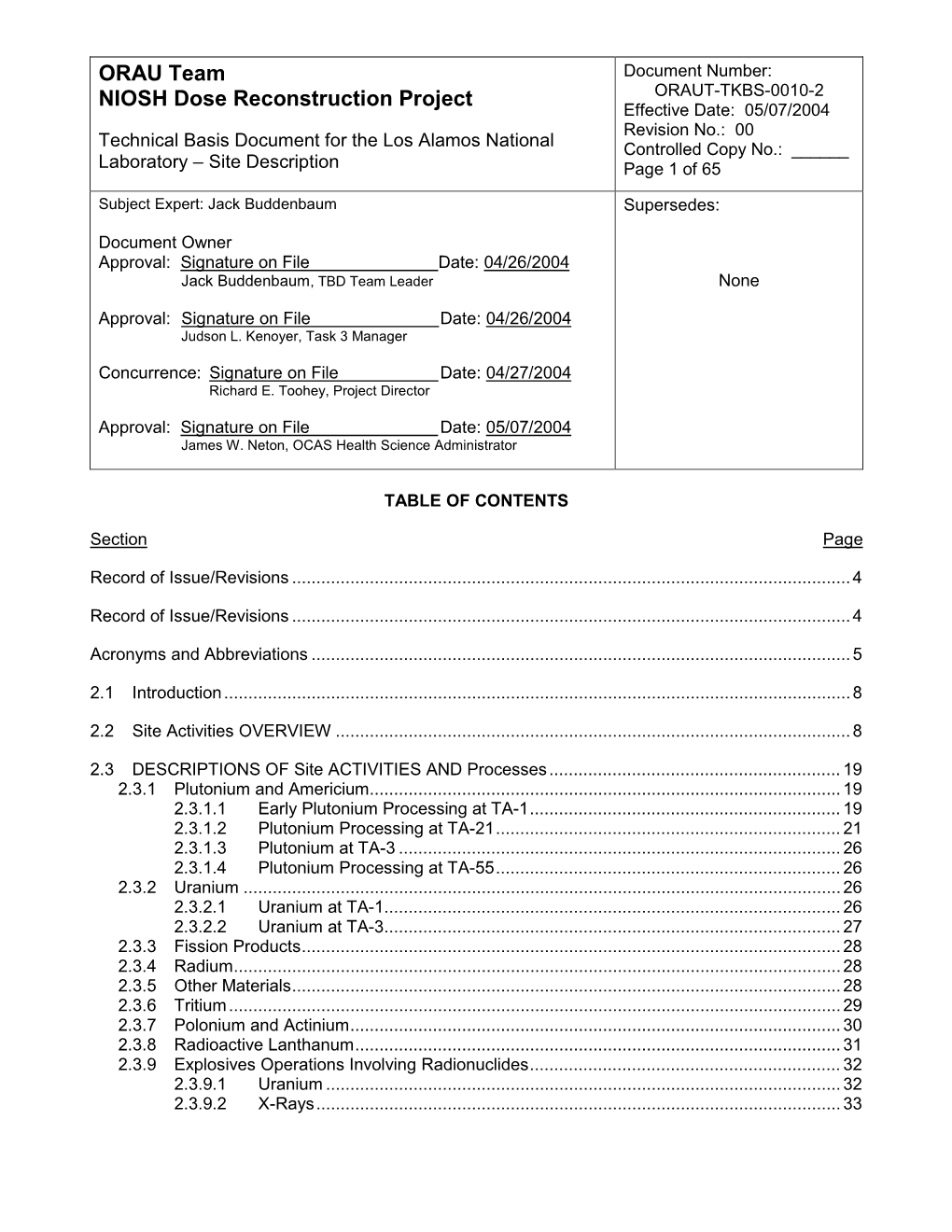

Technical Basis Document for the Los Alamos National Laboratory – Site Description

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Iter: Os Caminhos Da Energia De Fusão E O Brasil (2015)

ITER Os caminhos da energia de fusão e o Brasil MINISTÉRIO DAS RELAÇÕES EXTERIORES Ministro de Estado Embaixador Mauro Luiz Iecker Vieira Secretário -Geral Embaixador Sérgio França Danese FUNDAÇÃO ALEXANDRE DE GUSMÃO Presidente Embaixador Sérgio Eduardo Moreira Lima Instituto de Pesquisa de Relações Internacionais Diretor Embaixador José Humberto de Brito Cruz Centro de História e Documentação Diplomática Diretor Embaixador Maurício E. Cortes Costa Conselho Editorial da Fundação Alexandre de Gusmão Presidente Embaixador Sérgio Eduardo Moreira Lima Membros Embaixador Ronaldo Mota Sardenberg Embaixador Jorio Dauster Magalhães e Silva Embaixador Gonçalo de Barros Carvalho e Mello Mourão Embaixador José Humberto de Brito Cruz Embaixador Julio Glinternick Bitelli Ministro Luís Felipe Silvério Fortuna Professor Francisco Fernando Monteoliva Doratioto Professor José Flávio Sombra Saraiva Professor Eiiti Sato A Fundação Alexandre de Gusmão, instituída em 1971, é uma fundação pública vinculada ao Ministério das Relações Exteriores e tem a finalidade de levar à sociedade civil informações sobre a realidade internacional e sobre aspectos da pauta diplomática brasileira. Sua missão é promover a sensibilização da opinião pública nacional para os temas de relações internacionais e para a política externa brasileira. Augusto Pestana ITER Os caminhos da energia de fusão e o Brasil Brasília, 2015 Direitos de publicação reservados à Fundação Alexandre de Gusmão Ministério das Relações Exteriores Esplanada dos Ministérios, Bloco H Anexo II, Térreo 70170 ‑900 Brasília–DF Telefones:(61) 2030 ‑6033/6034 Fax:(61) 2030 ‑9125 Site: www.funag.gov.br E ‑mail: [email protected] Equipe Técnica: Eliane Miranda Paiva Fernanda Antunes Siqueira Gabriela Del Rio de Rezende Luiz Antônio Gusmão André Luiz Ventura Ferreira Projeto Gráfico e Capa: Yanderson Rodrigues Programação Visual e Diagramação: Gráfica e Editora Ideal Impresso no Brasil 2015 P476 Pestana, Augusto. -

LANL Fusion Capabilities

LANL Fusion Capabilities INFUSE workshop Jan 22-23, 2019 1 Managed by Triad National Security, LLC for the U.S. Department of Energy’s NNSA Los Alamos has a long history of fusion research James Tuck, Ivy Mike, 1952 Perhapsatron, 1953 • Today magnetic and inertial fusion work resides in the Physics Division, Theory Division, and X Division (Weapons). There are also related capabilities in detectors, radiation damage, and tritium handling. • Dr. John Kline ( [email protected] ) is the present Fusion Energy Sciences (and Inertial Fusion) program manager, and a point-of-contact. 2 Managed by Triad National Security, LLC for the U.S. Department of Energy’s NNSA 3 Managed by Triad National Security, LLC for the U.S. Department of Energy’s NNSA FRC’s were developed in Russia and Los Alamos FRC’s are high beta plasmas, with many interesting features 4 Managed by Triad National Security, LLC for the U.S. Department of Energy’s NNSA Today FRC plasmas are still being explored 5 Managed by Triad National Security, LLC for the U.S. Department of Energy’s NNSA Magnetized Plasma Team in P-24 Plasma Physics We do experimental plasma work for FES, APRA-E, and NNSA sponsors, with national and international partners, including small businesses. We use our knowledge of plasma diagnostics, pulsed power expertise, and HED plasmas in the areas of fusion energy, weapons support, and basic plasma science. Team Leader: Glen Wurden ([email protected]) Staff: Hsu, Weber, Langendorf, Dunn, Shimada Postdocs: Tom Byvank, Kevin Yates, John Boguski Student: Chris Roper (Summer) 6 Managed by Triad National Security, LLC for the U.S. -

WASH-1097.Pdf

WASH 1097 UC-80 THE USE OF THORIUM IN NUCLEAR POWER REACTORS JUNE 1969 PREPARED BY Brookhaven National Laboratory AND THE Division of Reactor Development and Technology WITH THE ASSISTANCE OF ARGONNE NATIONAL LABORATORY BABCOCK & WILCOX GULF GENERAL ATOMIC OAK RIDGE NATIONAL LABORATORY PACIFIC NORTHWEST LABORATORY For sale by the Superintendent of Documents, U.S. Government Printing Office Washington, D.C. 20402 - Price $1.25 FOREWORD This report on "The Use of Thorium in Nuclear Power Reactors" was prepared under the direction of the Division of Reactor Development and Technology, U.S.A.E.C., as part of an overall assessment of the Civilian Nuclear Power Program initiated in response to a request in 1966 by the Joint Committee on Atomic Energy. It represents the results of the inquiry by the Thorium Systems Task Force whose membership included representatives of Babcock & Wilcox Company, Gulf General Atomic Company, the Argonne National Laboratory, the Brookhaven National Laboratory, the Oak Ridge National Laboratory, the Pacific Northwest Laboratory, and the U.S. Atomic Energy Commission. Publication of this report, which provides information basic to the AEC reactor development program, completes one phase of the evaluation effort outlined in the 1967 Supplement to the 1962 Report to the President on Civilian Nuclear Power, issued in February 1967. The 1967 Supplement outlined changes since 1962 in the technical, economic and resource picture and provided background for further study. Specifically, this report represents the consensus of the task force on the potential use of the thorium cycle and the specific thorium fueled reactor designs which have been proposed. -

Nuclear Power

No.59 z iii "Ill ~ 2 er0 Ill Ill 0 Nuclear Family Pia nning p3 Chernobyl Broadsheet ·, _ I. _ . ~~~~ George Pritchar d speaks CONTENTS COMMENT The important nuclear development since the Nuclear Family Planning 3 last SCRAM Journal was the Government's The CEGB's plans, and the growing opposition, after Sizewell B by go ahead for Sizewell B: the world's first HUGH RICHARDS. reactor order since Chernobyl, and Britain's News 4-6 first since the go ahead was given to Torness Accidents Will Happen 1 and Heysham 2 in 1978. Of great concern is Hinkley Seismic Shocker 8-9 the CEGB's announced intention to build "a A major article on seismic safety of nuclear plants in which JAMES small fanilty• of PWRs, starting with Hinkley GARRETT reveals that Hinkley Point C. At the time of the campaign In the Point sits on a geological fault. south west to close the Hinkley A Magnox Trouble at Trawsfynydd 10-11 station, and .a concerted push in Scotland to A summary of FoE's recent report on increasing radiation levels from prevent the opening of Torness, another Trawsfynydd's by PATRICK GREEN. nuclear announcement is designed to divide Pandora's POX 12 and demoralise the opposition. But, it should The debate over plutonium transport make us more determined. The article on the to and from Dounreay continues by facing page gives us hope: the local PETE MUTTON. authorities on Severnside are joining forces CHERNOBYL BROADSHEET to oppose Hinkley C, and hopefully they will Cock-ups and Cover-ups work closely with local authorities in other "Sacrificed to • • • Nuclear Power" threatened areas - Lothian Region, The Soviet Experience Northumberland, the County Council Coalition "An Agonising Decision• 13 against waste dumping and the Nuclear Free GEORGE PRITCHARD explains why Zones - to formulate a national anti-nuclear he left Greenpeoce and took a job strategy. -

6. Chemical-Nuclear Propulsion MAE 342 2016

2/12/20 Chemical/Nuclear Propulsion Space System Design, MAE 342, Princeton University Robert Stengel • Thermal rockets • Performance parameters • Propellants and propellant storage Copyright 2016 by Robert Stengel. All rights reserved. For educational use only. http://www.princeton.edu/~stengel/MAE342.html 1 1 Chemical (Thermal) Rockets • Liquid/Gas Propellant –Monopropellant • Cold gas • Catalytic decomposition –Bipropellant • Separate oxidizer and fuel • Hypergolic (spontaneous) • Solid Propellant ignition –Mixed oxidizer and fuel • External ignition –External ignition • Storage –Burn to completion – Ambient temperature and pressure • Hybrid Propellant – Cryogenic –Liquid oxidizer, solid fuel – Pressurized tank –Throttlable –Throttlable –Start/stop cycling –Start/stop cycling 2 2 1 2/12/20 Cold Gas Thruster (used with inert gas) Moog Divert/Attitude Thruster and Valve 3 3 Monopropellant Hydrazine Thruster Aerojet Rocketdyne • Catalytic decomposition produces thrust • Reliable • Low performance • Toxic 4 4 2 2/12/20 Bi-Propellant Rocket Motor Thrust / Motor Weight ~ 70:1 5 5 Hypergolic, Storable Liquid- Propellant Thruster Titan 2 • Spontaneous combustion • Reliable • Corrosive, toxic 6 6 3 2/12/20 Pressure-Fed and Turbopump Engine Cycles Pressure-Fed Gas-Generator Rocket Rocket Cycle Cycle, with Nozzle Cooling 7 7 Staged Combustion Engine Cycles Staged Combustion Full-Flow Staged Rocket Cycle Combustion Rocket Cycle 8 8 4 2/12/20 German V-2 Rocket Motor, Fuel Injectors, and Turbopump 9 9 Combustion Chamber Injectors 10 10 5 2/12/20 -

The Glib/GTK+ Development Platform

The GLib/GTK+ Development Platform A Getting Started Guide Version 0.8 Sébastien Wilmet March 29, 2019 Contents 1 Introduction 3 1.1 License . 3 1.2 Financial Support . 3 1.3 Todo List for this Book and a Quick 2019 Update . 4 1.4 What is GLib and GTK+? . 4 1.5 The GNOME Desktop . 5 1.6 Prerequisites . 6 1.7 Why and When Using the C Language? . 7 1.7.1 Separate the Backend from the Frontend . 7 1.7.2 Other Aspects to Keep in Mind . 8 1.8 Learning Path . 9 1.9 The Development Environment . 10 1.10 Acknowledgments . 10 I GLib, the Core Library 11 2 GLib, the Core Library 12 2.1 Basics . 13 2.1.1 Type Definitions . 13 2.1.2 Frequently Used Macros . 13 2.1.3 Debugging Macros . 14 2.1.4 Memory . 16 2.1.5 String Handling . 18 2.2 Data Structures . 20 2.2.1 Lists . 20 2.2.2 Trees . 24 2.2.3 Hash Tables . 29 2.3 The Main Event Loop . 31 2.4 Other Features . 33 II Object-Oriented Programming in C 35 3 Semi-Object-Oriented Programming in C 37 3.1 Header Example . 37 3.1.1 Project Namespace . 37 3.1.2 Class Namespace . 39 3.1.3 Lowercase, Uppercase or CamelCase? . 39 3.1.4 Include Guard . 39 3.1.5 C++ Support . 39 1 3.1.6 #include . 39 3.1.7 Type Definition . 40 3.1.8 Object Constructor . 40 3.1.9 Object Destructor . -

Relative Fission Product Yield Determination in the Usgs

RELATIVE FISSION PRODUCT YIELD DETERMINATION IN THE USGS TRIGA MARK I REACTOR by Michael A. Koehl © Copyright by Michael A. Koehl, 2016 All Rights Reserved A thesis submitted to the Faculty and the Board of Trustees of the Colorado School of Mines in partial fulfillment of the requirements for the degree of Doctor of Philosophy (Nuclear Engineering). Golden, Colorado Date: ____________________ Signed: ________________________ Michael A. Koehl Signed: ________________________ Dr. Jenifer C. Braley Thesis Advisor Golden, Colorado Date: ____________________ Signed: ________________________ Dr. Mark P. Jensen Professor and Director Nuclear Science and Engineering Program ii ABSTRACT Fission product yield data sets are one of the most important and fundamental compilations of basic information in the nuclear industry. This data has a wide range of applications which include nuclear fuel burnup and nonproliferation safeguards. Relative fission yields constitute a major fraction of the reported yield data and reduce the number of required absolute measurements. Radiochemical separations of fission products reduce interferences, facilitate the measurement of low level radionuclides, and are instrumental in the analysis of low-yielding symmetrical fission products. It is especially useful in the measurement of the valley nuclides and those on the extreme wings of the mass yield curve, including lanthanides, where absolute yields have high errors. This overall project was conducted in three stages: characterization of the neutron flux in irradiation positions within the U.S. Geological Survey TRIGA Mark I Reactor (GSTR), determining the mass attenuation coefficients of precipitates used in radiochemical separations, and measuring the relative fission products in the GSTR. Using the Westcott convention, the Westcott flux, ; modified spectral index, ; neutron temperature, ; and gold-based cadmium ratiosφ were determined for various sampling√⁄ positions in the USGS TRIGA Mark I reactor. -

Eighth World Conference on Nondestructive Testing Huitieme Conference Moiudiale Sur Les Essais Non Destructifs

./ 1ÍOIS_ UJ._ EIGHTH WORLD CONFERENCE ON NONDESTRUCTIVE TESTING HUITIEME CONFERENCE MOIUDIALE SUR LES ESSAIS NON DESTRUCTIFS A NONDESTRUCTIVE EXAMINATION PROGRAM FOR UNCLAD CARBON-COMPOSITE REACTOR FUEL ELEMENTS UN PROGRAMME D'KSSAIS NON DESTRUCTIFS POUR LES ELEMENTS COMBUSTIBLES DE REACTEUR NON GAINÊS EN COMPOSITE DU CARBONE FULLBRIGHT H. J. LOS ALAMOS, NEW MEXICO LOS ALAMOS SCIENTIFIC LABORATORY U. S. A. SUMMARY- ^ non<lestructive testing program for the examination of (U,Zr)C—C reactor fuel elements is described. RESUME :O n décrit un programme d'essais non destructifs pour examiner les elements combustibles de réacteur en (U.Zr)C-C. I. INTRODUCTION The Los Alamos Scientific Laboratory has been active for the past twenty years in the development and testing of graphitic-based high temperature reactor fuel elements. The initial involvement was in the field of nuclear propulsion systems. Project Rover began as a program to develop a nuclear-powered, hydrogen-propelled rocket engine. The target exhaust temperature of the propellant was about 2775 K. The fuel element for such an engine would have to maintain its integrity and strength at higher temperatures and would have to resist currosion by the hot hydrogen gas, which is very reactive. These constraints limited the choice of materials to a very few. Carbon melts above about 3800 K, has excellent high-tenperature strength, and is not a strong neutron absorber. It is very reactive to high temperature hydrogen. The basic fuel element foi the Rover Program became uranium-loaded graphite. The enriched uranium fuel was incorporated into the graphite matrix as uranium oxide, later as py- rolytic-carbon coated uranium dicarbide inicrospheres, and, aosf recently, as a solid solution of uranium carbide and zirconium carbide. -

Hydrogen Peroxide Material Compatibility Chart from ISM and IS

ver 09-Jul-2020 Hydrogen Peroxide Material Compatibility Chart All wetted surfaces should be made of materials that are compatible with hydrogen peroxide. The wetted area or surface of a part, component, vessel or piping is a surface which is in permanent contact with or is permanently exposed to the process fluid (liquid or gas). Less than 8% concentration H2O2 is considered a non-hazardous substance. Typically encountered versions are baking soda-peroxide toothpaste (0.5%), contact lens sterilizer (2%), over-the-counter drug store Hydrogen Peroxide (3%), liquid detergent non-chlorine bleach (5%) and hair bleach (7.5%). At 8% to 28% H2O2 is rated as a Class 1 Oxidizer. At these concentrations H2O2 is usually encountered as a swimming pool chemical used for pool shock treatments. In the range of 28.1% to 52% concentrations, H2O2 is rated as a Class 2 Oxidizer, a Corrosive and a Class 1 Unstable (reactive) substance. At these concentrations, H2O2 is considered industrial strength grade. Concentrations from 52.1% to 91% are rated as Class 3 Oxidizers, Corrosive and Class 3 Unstable (reactive) substances. H2O2 at these concentrations are used for specialty chemical processes. At concentrations above 70%, H2O2 is usually designated as high-test peroxide (HTP). Concentrations of H2O2 greater than 91% are currently used as rocket propellant. At these concentrations, H2O2 is rated as a Class 4 Oxidizer, Corrosive and a Class 3 Unstable (reactive) substance. Compatibility Compatibility Compatibility Compatibility Material 10% H2O2 30% H2O2 50% -

Jihadists and Nuclear Weapons

VERSION: Charles P. Blair, “Jihadists and Nuclear Weapons,” in Gary Ackerman and Jeremy Tamsett, eds., Jihadists and Weapons of Mass Destruction: A Growing Threat (New York: Taylor and Francis, 2009), pp. 193-238. c h a p t e r 8 Jihadists and Nuclear Weapons Charles P. Blair CONTENTS Introduction 193 Improvised Nuclear Devices (INDs) 195 Fissile Materials 198 Weapons-Grade Uranium and Plutonium 199 Likely IND Construction 203 External Procurement of Intact Nuclear Weapons 204 State Acquisition of an Intact Nuclear Weapon 204 Nuclear Black Market 212 Incidents of Jihadist Interest in Nuclear Weapons and Weapons-Grade Nuclear Materials 213 Al-Qa‘ida 213 Russia’s Chechen-Led Jihadists 214 Nuclear-Related Threats and Attacks in India and Pakistan 215 Overall Likelihood of Jihadists Obtaining Nuclear Capability 215 Notes 216 Appendix: Toward a Nuclear Weapon: Principles of Nuclear Energy 232 Discovery of Radioactive Materials 232 Divisibility of the Atom 232 Atomic Nucleus 233 Discovery of Neutrons: A Pathway to the Nucleus 233 Fission 234 Chain Reactions 235 Notes 236 INTRODUCTION On December 1, 2001, CIA Director George Tenet made a hastily planned, clandestine trip to Pakistan. Tenet arrived in Islamabad deeply shaken by the news that less than three months earlier—just weeks before the attacks of September 11, 2001—al-Qa‘ida and Taliban leaders had met with two former Pakistani nuclear weapon scientists in a joint quest to acquire nuclear weapons. Captured documents the scientists abandoned as 193 AU6964.indb 193 12/16/08 5:44:39 PM 194 Charles P. Blair they fled Kabul from advancing anti-Taliban forces were evidence, in the minds of top U.S. -

Ceramic Carbides: the Tough Guys of the Materials World

Ceramic Carbides: The Tough Guys of the Materials World by Paul Everitt and Ian Doggett, Technical Specialists, Goodfellow Ceramic and Glass Division c/o Goodfellow Corporation, Coraopolis, Pa. Silicon carbide (SiC) and boron carbide (B4C) are among the world’s hardest known materials and are used in a variety of demanding industrial applications, from blasting-equipment nozzles to space-based mirrors. But there is more to these “tough guys” of the materials world than hardness alone—these two ceramic carbides have a profile of properties that are valued in a wide range of applications and are worthy of consideration for new research and product design projects. Silicon Carbide Use of this high-density, high-strength material has evolved from mainly high-temperature applications to a host of engineering applications. Silicon carbide is characterized by: • High thermal conductivity • Low thermal expansion coefficient • Outstanding thermal shock resistance • Extreme hardness FIGURE 1: • Semiconductor properties Typical properties of silicon carbide • A refractive index greater than diamond (hot-pressed sheet) Chemical Resistance Although many people are familiar with the Acids, concentrated Good Acids, dilute Good general attributes of this advanced ceramic Alkalis Good-Poor (see Figure 1), an important and frequently Halogens Good-Poor overlooked consideration is that the properties Metals Fair of silicon carbide can be altered by varying the Electrical Properties final compaction method. These alterations can Dielectric constant 40 provide knowledgeable engineers with small Volume resistivity at 25°C (Ohm-cm) 103-105 adjustments in performance that can potentially make a significant difference in the functionality Mechanical Properties of a finished component. -

Nicholas Christofilos and the Astron Project in America's Fusion Program

Elisheva Coleman May 4, 2004 Spring Junior Paper Advisor: Professor Mahoney Greek Fire: Nicholas Christofilos and the Astron Project in America’s Fusion Program This paper represents my own work in accordance with University regulations The author thanks the Program in Plasma Science and Technology and the Princeton Plasma Physics Laboratory for their support. Introduction The second largest building on the Lawrence Livermore National Laboratory’s campus today stands essentially abandoned, used as a warehouse for odds and ends. Concrete, starkly rectangular and nondescript, Building 431 was home for over a decade to the Astron machine, the testing device for a controlled fusion reactor scheme devised by a virtually unknown engineer-turned-physicist named Nicholas C. Christofilos. Building 431 was originally constructed in the late 1940s before the Lawrence laboratory even existed, for the Materials Testing Accelerator (MTA), the first experiment performed at the Livermore site.1 By the time the MTA was retired in 1955, the Livermore lab had grown up around it, a huge, nationally funded institution devoted to four projects: magnetic fusion, diagnostic weapon experiments, the design of thermonuclear weapons, and a basic physics program.2 When the MTA shut down, its building was turned over to the lab’s controlled fusion department. A number of fusion experiments were conducted within its walls, but from the early sixties onward Astron predominated, and in 1968 a major extension was added to the building to accommodate a revamped and enlarged Astron accelerator. As did much material within the national lab infrastructure, the building continued to be recycled. After Astron’s termination in 1973 the extension housed the Experimental Test Accelerator (ETA), a prototype for a huge linear induction accelerator, the type of accelerator first developed for Astron.