Zinc Sulfate

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Toxicological Profile for Zinc

TOXICOLOGICAL PROFILE FOR ZINC U.S. DEPARTMENT OF HEALTH AND HUMAN SERVICES Public Health Service Agency for Toxic Substances and Disease Registry August 2005 ZINC ii DISCLAIMER The use of company or product name(s) is for identification only and does not imply endorsement by the Agency for Toxic Substances and Disease Registry. ZINC iii UPDATE STATEMENT A Toxicological Profile for Zinc, Draft for Public Comment was released in September 2003. This edition supersedes any previously released draft or final profile. Toxicological profiles are revised and republished as necessary. For information regarding the update status of previously released profiles, contact ATSDR at: Agency for Toxic Substances and Disease Registry Division of Toxicology/Toxicology Information Branch 1600 Clifton Road NE Mailstop F-32 Atlanta, Georgia 30333 ZINC vi *Legislative Background The toxicological profiles are developed in response to the Superfund Amendments and Reauthorization Act (SARA) of 1986 (Public law 99-499) which amended the Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA or Superfund). This public law directed ATSDR to prepare toxicological profiles for hazardous substances most commonly found at facilities on the CERCLA National Priorities List and that pose the most significant potential threat to human health, as determined by ATSDR and the EPA. The availability of the revised priority list of 275 hazardous substances was announced in the Federal Register on November 17, 1997 (62 FR 61332). For prior versions of the list of substances, see Federal Register notices dated April 29, 1996 (61 FR 18744); April 17, 1987 (52 FR 12866); October 20, 1988 (53 FR 41280); October 26, 1989 (54 FR 43619); October 17, 1990 (55 FR 42067); October 17, 1991 (56 FR 52166); October 28, 1992 (57 FR 48801); and February 28, 1994 (59 FR 9486). -

Una-Theses-0796.Pdf

THE UNIVERSITY OF MINNES OTA GRADUATE SCHOOL Report of Committee on Examination This is to certify that we the undersigned, as a committee of the Graduate School~ have given finslow Sa~uel Anderson final oral examination for the degree of ··aster of Science We recommend that the degree of Master of Science be conferred upon the candidate. q-~-r: ~ Ci<C 1C /,c,',, (llf( 2;1.-e. ~ •'' , , 'cc 1 ,,,., f I<( < f I .,,• ,, ' ' ,, ' (ff •' ' .. < ' ' ' r' / ', ' ' ,,< ' ' ' .' ' ' ' rll O I flllf •' 'c '', , ,1 •' 14"<11 .,, ' "''!c c•' •'' /,\', ~l2·6M THE UNIVERSITY OF MINNESOTA GRADUATE SCHOOL Report of Cor;,mi ttee on Thesis The undersigned, acting as a Committee of the Graduate School, have read the accompanying thesis submitted by Winslow Sauuel Anderson for the degree of ~ aster of Science. They approve it as a thesis meeting the require ments of the Graduate School of the University of Minnesota, and recommend that it be accepted in partial fulfillment of the requirements for the degree of : ~aster Date~ ~ l'f Y.3 CJ I0- 20 5M ,, ' I : (I I 1 f I I r ~ ( f I : It t t I I Ill I I t I I I ( f I / f ( I II ... AN ATTEMPT TO MAKE TRUE COLORED LITHOPONES A Thesis Submitted to the Graduate Faculty of the University of Minnesota by In partial fulfillment of the requirements for the degree of M'aster of Science June 1923 AN ATTEMPT TO MAKE TRUE COLORED LITHOPONES 32 4472 S-22·8M I ACKNOWLEOOMENT To Dr. c. A. Mann at whose suggestion and under whose direction this investigation was carried out, for his kind encouragement and sympathetic counsel, the author wishes to acknowledge his indebtedness and to offer his sincere thanks. -

Characterization of White Pigments E

Palamara et al. Herit Sci (2021) 9:100 https://doi.org/10.1186/s40494-021-00575-4 RESEARCH ARTICLE Open Access Towards building a Cathodoluminescence (CL) database for pigments: characterization of white pigments E. Palamara1,2* , P. P. Das3,4, S. Nicolopoulos4, L. Tormo Cifuentes5, E. Kouloumpi6, A. Terlixi6 and N. Zacharias1 Abstract Paintings and painted surfaces are considered to be extremely complex due to their multitude of materials and thus form the basis for particularly intricate Cultural Heritage studies. The combination of Scanning Electron Microscopy (SEM) with Cathodoluminescence (CL) can serve as a powerful tool for the identifcation of individual pigments. SEM/ CL has the potential of identifying both organic and inorganic pigments and can focus on a micrometer or even nanometer scale. The combination with Energy Dispersive Spectrometry (EDS) allows for robust, cross-checked, ele- mental and mineralogical characterization of pigments. In order to apply SEM/CL in a routine-based way for the iden- tifcation of pigments, it is necessary to have a robust, open-access database of characteristic CL spectra of pigments. A large project has been undertaken to create such a database, focusing primarily at the pigments, both organic and inorganic, which were most commonly used from antiquity until today. In the present paper, the CL characterization of common white pigments is presented. White pigments were selected, due to their signifcance and frequency of use, since they were also present on the ground layers or mixed with other pigments in most of the painting layers. More specifcally, the CL spectra of samples in pure form of calcite, kaolinite, lead white, zinc oxide, barium sulfate, lithopone and titanium white are presented. -

Zinc Sulphate Heptahydrate

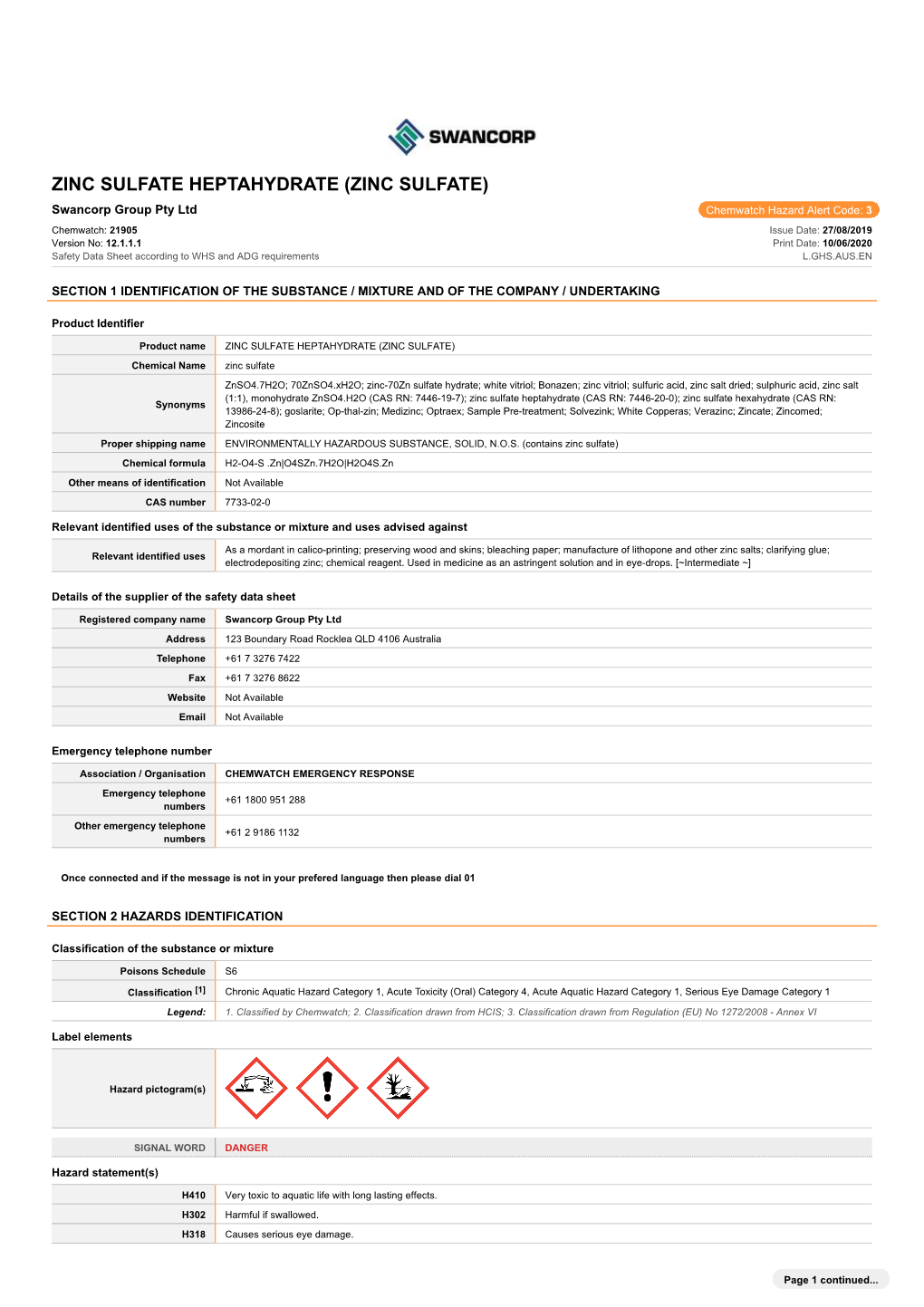

ZINC SULPHATE HEPTAHYDRATE Swancorp Chemwatch Hazard Alert Code: 3 Chemwatch: 21905 Issue Date: 22/10/2015 Version No: 11.1.1.1 Print Date: 22/10/2015 Safety Data Sheet according to WHS and ADG requirements Initial Date: Not Available S.GHS.AUS.EN SECTION 1 IDENTIFICATION OF THE SUBSTANCE / MIXTURE AND OF THE COMPANY / UNDERTAKING Product Identifier Product name ZINC SULPHATE HEPTAHYDRATE Chemical Name zinc sulfate ZnSO4.7H2O, "white vitriol", Bonazen, "zinc vitriol", "sulfuric acid, zinc salt dried", "sulphuric acid, zinc salt (1:1), monohydrate ZnSO4.H2O", Synonyms Op-thal-zin, Medizinc, Optraex, Solvezink, "White Copperas", Verazinc, Zincate, Zincomed, Zincosite Proper shipping name ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S. (contains zinc sulfate) Chemical formula H2-O4-S .Zn|O4SZn.7H2O|H2O4S.Zn Other means of Not Available identification CAS number 7446-20-0 Relevant identified uses of the substance or mixture and uses advised against As a mordant in calico-printing; preserving wood and skins; bleaching paper; manufacture of lithopone and other zinc salts; clarifying glue; Relevant identified uses electrodepositing zinc; chemical reagent. Used in medicine as an astringent solution and in eye-drops. Details of the supplier of the safety data sheet Registered company Swancorp name Address 123 Boundary Road Rocklea 4106 QLD Australia Telephone +61 7 3276 7422 Fax +61 7 3276 8622 Website Not Available Email Not Available Emergency telephone number Association / Not Available Organisation Emergency telephone 1800 039 008 (24hrs, Australia), +800 2436 2255 (24hrs, NZ) numbers Other emergency Not Available telephone numbers SECTION 2 HAZARDS IDENTIFICATION Classification of the substance or mixture HAZARDOUS CHEMICAL. -

AR3066II March 12, 1991 Project No: 400754

March 12, 1991 Project No: 400754 y' •' . ,- \ '...I •" March 12, 1991 Mr. Randy Sturgeon Enforcement Project Manager U.S. Environmental Protection Agency Region IJH 841 Chestnut Street Philadelphia, Pennsylvania 19107 Dear Mr. Sturgeon: SUBJECT: Du Pont Newport Site, Newport, Delaware Supplemental Phase DI RI Tasks Introduction This letter serves as a response to the EPA's August 9, 1990, letter and the EPA's subsequent request of January 8, 1991, to address the need for further evaluation of the pigment-colored sediments observed at the northern riverbank along a portion of the Ciba-Geigy Newport Plant area and concerns for off-site historical are emissions. Furthermore, this letter is submitted in lieu of a Final Work Plan-Volume II, which is no longer deemed necessary for this project. Du Pont Environmental Remediaton Services • Page 1 AR3066II March 12, 1991 Project No: 400754 As agreed to during Du Font's and the EPA 's January 8, 1991, meeting, Du Pont has conducted a comprehensive literature search regarding the toxicity of the pigments associated with the historical operations at the Newport Site. In addition, Du Pont and Woodward-Clyde Consultants (WCC) have reviewed the historical aerial photographs of the city of Newport to evaluate the feasibility of off-site soil sampling. Each of these areas of concern are addressed separately below. Pigment Colored Riverbank Sediments Our review of the history of the riverbank operations suggests that during the 1950's, pigment products awaiting transport were stored in drums on pallets over gravel along the riverbank. This form of outdoor storage was conducted in accordance with standard practices of the time and is still an acceptable industry practice today. -

Download the Tapco Bulk Material Density Table

BULK material DENSITY table Material Loose Bulk Material Loose Bulk Description Density #/Ft. Description Density #/Ft. Alfalfa Meal 14-22 Bark, Wood, Refuse 10-20 Alfalfa Pellets 41-43 Barley, Fine, Ground 24-38 Alfalfa Seed 10-15 Barley, Malted 31 Almonds, Broken 28-30 Barley, Meal 28 Almonds, Whole Shelled 28-30 Barley, Scoured 41 Alum, Fine 45-50 Barley, Whole 36-48 Alum, Lumpy 50-60 Basalt 80-105 Alumina Fines 35 Bauxite, Dry, Ground 68 Alumina 50-65 Bauxite, Crushed, -3” 75-85 Alumina, Sized or Briquette 65 Bauxite, Mine Run 66-90 Aluminum Chips, Oily 7-15 Beans, Castor, Whole Shelled 36 Aluminum Chips, Dry 7-15 Beans, Castor, Meal 35-40 Aluminum Hydrate 13-20 Beans, Navy, Dry 48 Aluminum Ore (See Bauxite) - Beans, Navy, Steeped 60 Aluminum Oxide 60-120 Beets, Whole 48 Aluminum Silicate (Andalusite) 49 Bentonite, Crude 35-40 Aluminum Chloride, Crystalline 45-52 Benzene Hexachloride 56 Aluminum Nitrate 45-62 Bicarbonate of Soda (See Baking Soda) - Aluminum Sulfate 45-58 Blood, Dried 35-45 Ammonium Chloride 45-52 Blood, Ground 30 Ammonium Nitrate 45 Bones, Whole 35-50 Ammonium Sulfate, Granular 45-58 Bones, Crushed 35-50 Arsenate of Lead (See Lead Arsenate) - Bones, Ground 50 Arsenic, Pulverized 30 Bonemeal 50-60 Arsenic Oxide (Arsenolite) 100-120 Bone Ash (Tricalcium Phosphate) 40-50 Asbestos, Rock (Ore) 81 Borate of Lime 60 Asbestos, Shred 20-40 Borax 2”-3” Lump 60-70 Ash, Black Ground 105 Borax 1-1/2”-2” Lump 55-60 Ashes, Coal, Dry -l/2” 35-45 Borax Screening -1/2” 55-60 Ashes, Coal, Dry 3” & under 35-40 Borax, Fine 45-55 Ashes, -

Safety Data Sheet Zinc Sulphate Heptahydrate

February 2017 Revision 5 Page 1 of 11 SAFETY DATA SHEET ZINC SULPHATE HEPTAHYDRATE Section 1 - CHEMICAL PRODUCT AND COMPANY IDENTIFICATION SYNONYMS: zinc sulphate heptahydrate; Zinc sulfate; Sulfuric acid, zinc salt (1:1), heptahydrate; Zinc vitriol (heptahydrate); White vitriol (heptahydrate); Verazinc; zinc sulfate heptahydrate; zinc sulphate heptahydrate PROPER SHIPPING NAME: ENVIRONMENTALLY HAZARDOUS SUBSTANCE, SOLID, N.O.S Zinc Sulphate Heptahydrate CAS NUMBER: 7446-20-0 UN NUMBER: 3077 ACID PRODUCT USE: As a mordant in calico-printing; preserving wood and skins; bleaching paper; manufacture of lithopone and other zinc salts; clarifying glue; electrodepositing zinc; chemical reagent; dietary supplement; animal feeds. SUPPLIER: Interchem Agencies Limited 7 Gladstone Road Northcote AUCKLAND 0627 NEW ZEALAND Telephone: +64 9 418 0097 Fax: +64 9 418 4008 24 H Emergency Contact: 0800 243 622 International Emergency Number: +64 4 917 9888 Section 2 - HAZARDS IDENTIFICATION STATEMENT OF HAZARDOUS NATURE Hazardous Substance according to the criteria of the New Zealand Hazardous Substances and New Organisms legislation. Dangerous Good. EPA Approval number: HSR003701 HAZARD LABELLING DANGER See Section 14 for UN labelling. 24 HOUR EMERGENCY CONTACT TELEPHONE 0800 CHEMCALL 0800 243 622 Zinc Sulphate Heptahydrate - February 2017 Revision 5 Page 2 of 11 HAZARD CLASSIFICATION AND STATEMENTS HSNO GHS EQUIVALENT 6.1D (oral) Acute toxicity: Oral - Category 4 6.9B (oral) Specific Target Organ Systemic Toxicity (Repeated exposure) Category 2 8.3A Serious eye damage - Category 1 9.1A Aquatic toxicity (Acute) - Category 1 9.3C Harmful to terrestrial vertebrates Harmful if swallowed. May cause damage to organs through prolonged or repeated exposure orally. Causes serious eye damage. -

Multianalytical Study of Historical Luminescent Lithopone for The

Multianalytical Study of Historical Luminescent Lithopone for the Detection of Impurities and Trace Metal Ions † ‡ † ‡ ∥ ‡ § Sara Bellei,*, , Austin Nevin, Anna Cesaratto, , Valentina Capogrosso, HervéVezin, ⊥ ‡ ‡ Caroline Tokarski, Gianluca Valentini, and Daniela Comelli † Istituto di Fotonica e Nanotecnologie - Consiglio Nazionale delle Ricerche (CNR-IFN), Piazza Leonardo da Vinci 32, Milano, 20133 Italy ‡ Dipartimento di Fisica, Politecnico di Milano, Piazza Leonardo da Vinci 32, Milano, 20133 Italy § Laboratoire de Spectrochimie Infrarouge et Raman (LASIR), UMR CNRS 8516, Universitéde Lille 1 Sciences et Technologies, 59655 Villeneuve d’Ascq Cedex, France ⊥ Miniaturisation pour la Synthese,̀ l’Analyse & la Proteomiqué (MSAP), USR CNRS 3290, Universitéde Lille 1 Sciences et Technologies, 59655 Villeneuve d’Ascq Cedex, France Received: February 10, 2015 Accepted: May 15, 2015 ithopone is a modern inorganic white pigment composed for identification of the pigment has been proposed with the aid of a coprecipitate of zinc sulfide (ZnS) and barium sulfate of different molecular spectroscopy techniques, such as fiber- L fl (BaSO4). It was manufactured on a commercial scale starting in optic re ectance spectroscopy (FORS) in the UV-vis-NIR and 1874 and sold under different names (Griffith white, Charlton micro-Raman analyses.4 Few studies have dealt with the White, Orr’s Zinc White). It found its application first in the photoluminescence (PL) properties of lithopone: in 2012, cheaper grades of polish varnishes, floor paints, and paints for Comelli et al.5 published results of PL attributed to Zn-based interiors as a substitute of lead white. Despite the cheapness of whites in a painting by Vincent Van Gogh “Les bretonnes et le its manufacturing processes and good property as pigment, pardon de Pont Aven” (Milan, Galleria di Arte Moderna). -

Cadmium Red Medium, Cadmium Yellow Medium REVISED: 11/10/2015

SAFETY DATA SHEET: Gamblin Dry Pigment: Cadmium Red Medium, Cadmium Yellow Medium REVISED: 11/10/2015 SAFETY DATA SHEET SECTION 1: PRODUCT AND COMPANY IDENTIFICATION PRODUCT Product Name: Gamblin Dry Pigment: Cadmium Red Medium, Cadmium Yellow Medium Product Description: Dry pigment Intended Use: Fine art painting and decorative coatings COMPANY Company Name: Gamblin Artists Colors Company Address: 323 SE Division Pl. Portland, OR 97202 USA Company Phone: 503-235-1945 Emergency Phone: Local Emergency Room SECTION 2: HAZARDS IDENTIFICATION GHS HAZARD CLASSIFICATION: NOT CLASSIFIED GHS LABEL ELEMENTS: SIGNAL WORD: NO SIGNAL WORD LABEL CODES / PICTOGRAMS: NO PICTOGRAMS HAZARD STATEMENTS: NONE UNDER GHS CLASSIFICATION PRECAUTIONARY STATEMENTS PREVENTION: NONE ASSIGNED UNDER GHS RESPONSE: NONE ASSIGNED UNDER GHS STORAGE: NONE ASSIGNED UNDER GHS DISPOSAL: NONE ASSIGNED UNDER GHS SUPPLEMENTAL INFORMATION NOTE: CADMIUM PIGMENTS ARE MUCH LESS HAZARDOUS THAN OTHER CADMIUM COMPOUNDS AS THEY ARE EXTREMELY INSOLUBLE. THIS GREATLY REDUCES THE RISK OF ABSORPTION OF CADMIUM INTO THE BODY AND ALSO GREATLY REDUCES THEIR ENVIRONMENTAL HAZARD. AS SUCH, THE PRODUCER HAS NOT CLASSIFIED THEIR CADMIUM PIGMENTS AS HAZARDOUS UNDER THE GHS SYSTEM FOR THE US OR UNDER EU REACH STANDARDS. THE CATEGORY 1 SAFETY DATA SHEET: Gamblin Dry Pigment: Cadmium Red Medium, Cadmium Yellow Medium REVISED: 11/10/2015 “CADMIUM AND CADMIUM COMPOUNDS” IS REGULATED UNDER VARIOUS U.S. LAWS (SARA 313, CERCLA, RCRA, OSHA CADMIUM STANDARD AT 29 CFR 1910.1027, CALIFORNIA PROPOSITION 65, VARIOUS STATE LISTS, ETC.) AS INDICATED ON THIS SAFETY DATA SHEET. PER THE OSHA CADMIUM STANDARD - DO NOT EAT, DRINK, SMOKE, CHEW TOBACCO OR GUM, OR APPLY COSMETICS IN REGULATED AREAS, CARRY THE PRODUCTS ASSOCIATED WITH THESE ACTIVITIES INTO REGULATED AREAS, OR STORE SUCH PRODUCTS IN THOSE AREAS. -

Risk Management Scope for Zinc and Soluble Zinc Compounds Under The

Risk Management Scope for Zinc and Soluble Zinc Compounds under the Zinc and its Compounds grouping Environment and Climate Change Canada Health Canada June 2019 Summary of proposed risk management This document outlines the risk management options under consideration for zinc and soluble zinc compounds , which have been proposed to be harmful to the environment. In particular, the Government of Canada is considering reducing anthropogenic releases of zinc to water from the following sectors or activities: 1. Metal mining: by applying the updated zinc effluent limits (amended in 2018) in the Metal and Diamond Mining Effluent Regulations (MDMER), and reviewing information received from regulated mines in response to environmental effects monitoring requirements under these regulations to determine if additional regulatory or non- regulatory risk management is appropriate. 2. Base metals smelting and refining: by addressing facilities that are subject to the MDMER through the action proposed above for metal mining. Base metals smelting and refining facilities that are not subject to the MDMER are not proposed for risk management action. Interested stakeholders are invited to provide the following information to help in refining ECCC’s risk analysis: Dissolved or total concentrations of zinc in effluents, receiving environments, and reference areas for surface waters. Measurements of dissolved organic carbon (DOC), pH, and hardness related to these dissolved concentrations of zinc. This information should be provided on or before August 28, 2019, to the contact identified in Section 8 of this document. Under phase 3 of the Chemicals Management Plan (CMP3), ECCC and HC are conducting assessments of a variety of metals that may also identify metal mines and base metals smelting and refining facilities as sources of risk. -

Cadmium Yellow Medium Product Code: PS-CA0020 Department: Cadmium Dry Pigments C.A.S.: 8048-07-5, 7727-43-7

Material Safety Data Sheet Cadmium yellow medium Product Code: PS-CA0020 Department: cadmium dry pigments C.A.S.: 8048-07-5, 7727-43-7 Section: 1 Identification Product name: Cadmium pigment company: KAMA pigments 7442 St-hubert montréal Québec, H2R 2N3 phone : 514 272 2173 fax : 514 948 5253 email : [email protected] us d.o.t. / un name: not regulated for transport recommended uses: pigment for use in plastics, artists’ colors, paints; coloring material for use in ceramics and glass. not for use in tattoo inks, cosmetics any medical related applications emergency telephone no.: usa – chemtrec: 1-800-424-9300 outside usa: +1 703-527-3887 Section: 2 Hazard Identification ghs hazard classification: not classified ghs label elements: signal word: no signal word label codes / pictograms: no pictograms hazard statements: none under ghs classification precautionary statements : prevention : none assigned under ghs response : none assigned under ghs storage : none assigned under ghs disposal : none assigned under ghs other hazards / u.s. - hazards not otherwise classified / un ghs - other hazards which do not result in classification: see 29 cfr 1910.1027 for the osha cadmium standard. note – cadmium pigments are much less hazardous than other cadmium compounds as they are extremely insoluble. this greatly reduces the risk of absortion of cadmium into the body and also greatly reduces their environmental hazard. as such, the producer - james m. brown ltd. – has not classified their cadmium pigments as hazardous under the ghs system for the us or under eu reach standards. the category “cadmium and cadmium compounds” is regulated under various u.s. -

SDS Should Be Provided

Zinc Sulphate Heptahydrate ALPHA CHEMICALS PTY LTD Chemwatch Hazard Alert Code: 3 Chemwatch: 33-6647 Issue Date: 01/11/2019 Version No: 3.1.1.1 Print Date: 19/01/2021 Safety Data Sheet according to WHS and ADG requirements S.GHS.AUS.EN SECTION 1 Identification of the substance / mixture and of the company / undertaking Product Identifier Product name Zinc Sulphate Heptahydrate Chemical Name Not Applicable ZnSO4.7H2O; 70ZnSO4.xH2O; zinc-70Zn sulfate hydrate; white vitriol; Bonazen; zinc vitriol; sulfuric acid, zinc salt dried; sulphuric acid, zinc salt Synonyms (1:1), monohydrate ZnSO4.H2O; zinc sulfate heptahydrate (CAS RN: 7446-20-0); zinc sulfate hexahydrate (CAS RN: 13986-24-8); goslarite; Op-thal-zin; Medizinc; Optraex; Sample Pre-treatment; Solvezink; White Copperas; Verazinc; Zincate; Zincomed; Zincosite; zinc sulfate Chemical formula Not Applicable Other means of identification Not Available Relevant identified uses of the substance or mixture and uses advised against As a mordant in calico-printing; preserving wood and skins; bleaching paper; manufacture of lithopone and other zinc salts; clarifying glue; Relevant identified uses electrodepositing zinc; chemical reagent. Used in medicine as an astringent solution and in eye-drops. [~Intermediate ~] Details of the supplier of the safety data sheet Registered company name ALPHA CHEMICALS PTY LTD Address 4 ALLEN PLACE WETHERILL PARK NSW 2099 Australia Telephone 61 (0)2 9982 4622 Fax Not Available Website ~ Email [email protected] Emergency telephone number Association / Organisation ALPHA CHEMICALS PTY LTD Emergency telephone 61 (0)418 237 771 numbers Other emergency telephone Not Available numbers SECTION 2 Hazards identification Classification of the substance or mixture HAZARDOUS CHEMICAL.